DIY bio-fireplace burner: instructions and manufacturing tips

The ecological type of fireplace, unlike gas and wood burning equipment of this category, can be operated in multi-storey buildings. For his organization does not need to get permission from the administration. No need to build a chimney and a warehouse for storing fuel. And if the hearth is interestingly decorated, a do-it-yourself burner is made for a bio-fireplace, the cost of arranging it will also be significantly reduced. Is it true?

You will find all about how to make a spectacular eco-fireplace with a fail-safe fuel cell in our article. Using the proposed information and valuable advice, you can make a stunning piece of furniture with your own hands that does not pose the slightest threat during the burning period.

Our article describes in detail the process of the independent manufacture of three types of burners for the installation of biofireplaces. Interesting decoration options are given, recommendations are given for the safe use of spectacular homemade products. The material presented is supplemented by photo illustrations and a video guide.

The content of the article:

The principle of operation and the device biofireplace

Biofireplace (ecofireplace) - a variant of the hearth, which is heated by liquid biological fuel. When burning such substances, smoke and soot are not emitted, so a chimney is not needed for the operation of such a device.

At the same time, the room where the biofireplace is located must be ventilated periodically, since oxygen is consumed during any combustion.

In more detail, we examined the principle of operation of a fireplace on biofuel in the next article.

Classification by installation method

Such heating devices differ not so much in their design as in the dimensions and placement in the apartment. According to the mentioned criteria, three types of eco-fires can be distinguished.

Variety # 1 - Board

Tabletops are small products that have a variety of shapes and designs. For fire safety in such structures provides a dense screen of refractory glass, hiding the flame.

Variety # 2 - Wall Mounted

Wall-mounted devices, the dimensions of which can reach up to 1 meter in length, are usually made of metal and glass. Such models are not only decorative, but also functional. They heat the room, especially if several burners are installed in the hearth.

Variety # 3 - Floor

Large-sized eco-fireplaces are installed on the floor, often in niches or corners of the room. There are floor models, supplemented by supporting legs that allow you to adjust the height of the structure, or wheels, thanks to which the device can be moved around the house.

Like wall biofireplaces, floor options combine a decorative role with a functional one, filling the room with warmth.

Advantages and disadvantages of bio fireplaces

Like any device, such centers have strengths and weaknesses.

Regardless of the model, all eco-fireplaces have the following advantages:

- Device simplicity. For the equipment of the hearth does not require laying ventilation ducts, chimney devices, coordination with neighbors.

- Mobility. Biofireplaces are usually fairly lightweight fixtures. Many options are specially designed for their movement indoors.

- Ease of operation. Using such devices is extremely simple. It is only important to procure on time biofuel and refuel the fireplace.

- Safety. When burning, soot, carbon monoxide, smoke and other harmful substances are not released, in addition, many models have a dense screen that prevents open fire.

- Humidification. When burning bioethanol, carbon dioxide and water vapor are formed, which improve the indoor microclimate.

At the same time, a number of problems associated with the work of eco-fireplaces should be noted.

Among the negative factors include:

- Low heat dissipation. When burning biofuels, a small amount of heat is released.

- The high cost of bioethanol. Liquid biofuel is more expensive than traditional fuel options.

- Need for ventilation. Since when the fire burns, the oxygen level in the room where the eco-fireplace is located is reduced, it is advisable to arrange additional ventilation in it or take care of the frequent ventilation of the room.

The negative sides of biological foci can be neglected, especially when it comes to decorative devices.

Basic structural elements

With all the variety of ecofireplace models, their design consists of similar elements, namely:

- Heating block. The main component of the bio-site where the fuel is located. There are two options for such a device: a burner and a tank, which we will talk about similarly below.

- Enclosures. This part defines the design of the product.Depending on the project, the case can be open or closed, take the form of various geometric shapes, be styled as a shelf, candelabrum, coffee table.

- Decorative components. To decorate eco-fireplaces, decor is often used made of heat-resistant materials: stones, metal, refractory ceramics.

All these parts can be done independently by constructing do-it-yourself bio fireplace.

Two types of devices for heating can be used in biofireplaces: a fuel tank and a burner.

Fuel tank, the volume of which is from 60 ml to 5 liters, is usually used in factory models of biofireplaces.

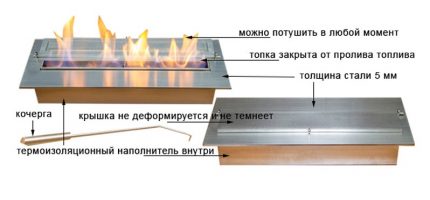

As a rule, tanks are made of durable metal, most often stainless steel. It is very important that the walls and bottom of the device are of sufficient thickness: this guarantees safety and a long service life.

Fuel tanks have significant advantages:

- Their design guarantees absolute tightness of the container, so that dust and foreign bodies do not get inside.

- When using such models in the room, the smell of bioethanol is completely absent, since liquid fuel and its vapors are trapped in the tank.

- The design of the fuel tanks provides special devices for regulating the intensity of the fire. This is especially important if the fireplace is built into the wall or its surface is decorated with accessories made of materials that do not have special fire resistance.

- Such devices also provide the ability to quickly and easily extinguish the fire. To do this, just turn the lever with which the biofuel supply is blocked.

The disadvantage of such models is the rather high price.

A simpler option for the heating unit is eco-fireplace burner. Externally, such a device looks extremely simple: it is a reservoir designed for pouring bioethanol, which can have a different shape.

The use of such devices is not as convenient as a fuel boiler. The burners also do not have a mechanism for regulating the intensity of fire, as well as the ability to quickly extinguish a flaming flame

For extinguishing, there are special devices that need to be bought additionally, in addition, when they are used in the room, a sharp smell is felt.

At the same time, biofire burners have their own advantages. Such devices have a low price, and a simple design allows you to make them yourself. In addition, in one hearth, several such devices can be installed at once, which will significantly increase heat transfer.

Features of the manufacture of the burner

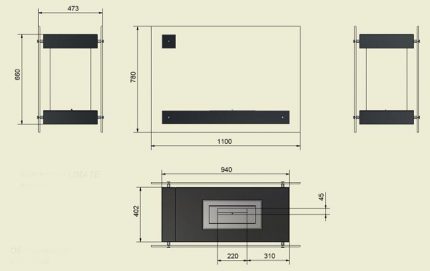

Before starting work on creating an ecofireplace, it is important to decide on the model of the hearth: whether it will be a large device installed on the floor, a hanging version near the wall, or a compact device that can be put on the table. The size of the burner directly depends on this.

Having decided, try to sketch out a biofireplace project, on its basis to prepare drawings of the design, as well as the heating element. Since the principle of operation of various models usually coincides, design and functionality come to the fore.

It is important to pay great attention to the quality of the materials used, since the safety of the source, as well as the period of its use, depends on this. A heating block made of durable billets will work properly and without failures.

Although biofuels for fireplaces are often packaged in plastic bottles, this does not mean that the burner can be made of plastic: such a device should be completely made of metal.

The most durable and reliable devices are made of stainless steel, since such a material combines high chemical and thermal stability. It is also possible to use ordinary structural steel, although its quality indicators are slightly lower.

For the manufacture of the fuel block, it is important to use blanks with thick walls. Thin parts will become deformed during heating, which can lead to depressurization of the joints and fuel leakage, as a result of which a fire can start.

The size and parameters of the fuel tank depend not only on the dimensions of the model, but also on the design features. If the fuel tank does not involve the use of an absorbent, the capacity can be made low. In this case, it is desirable to make sure that only a small surface part of the combustible material is involved in the combustion

Burners for a biofireplace can also be equipped with a protective shield made of glass. For this purpose it is better to take refractory material. If it is not at hand, you can use ordinary glass, for example, taking it from A4 photo frames. In this case, a greater distance from the burner should be provided so that the material does not burst from overheating.

To ensure that the flame is evenly distributed in all directions, it is recommended to cover the fuel tank with a metal mesh on top. A similar detail will also serve as the basis for strengthening decorative elements.

To ignite a homemade burner, a wick is used, which can be made from shoe lace. One end is placed in a tank filled with biofuel, the second is brought out and set on fire. A particularly spectacular appearance is the eco-fireplace, the external wick of which is hidden between the decorative elements.

The distance from the burner to the glass screen should be approximately 15 cm, the same distance should be observed between several heating elements, if they are installed in the same bio-fireplace.

One burner is designed for an area of 16 square meters: this norm should be taken into account when planning the design of the hearth with several heating devices.

As soon as the biofireplace burner is assembled, it is necessary to visually evaluate the structure, compare it with the drawing, and also make sure that there is no deformation. If defects are detected, the device should be disassembled and the parts carefully adjusted again.

Burner options for biofireplaces

There are many schemes for the manufacture of fuel blocks on their own, we offer several simple options.

# 1: The simplest fuel cell model

For the simplest version of a burner for a biofireplace, a conventional stainless steel tank with walls of at least 2 mm thick is used.

The depth of such a reservoir should be approximately 3-5 cm, and its length and width should depend on the parameters of the biofireplace. The appearance of the tank does not matter, since this part is not visible, however, you should only take a sturdy, solid construction.

It is poured into the tank high-quality biofuels and the wick is lowered, which is displayed on the outer surface, for example, through a net thrown over a fire. When saturated with fuel, when ignited, the cord will burn, giving a bright light.

# 2: Two-chamber burner with perforation (cuts)

A similar design option is commonly used in factory models. It allows you to reduce the surface area of the combustion, and, consequently, reduce fuel consumption.

First of all, you need to take a bath or other container made of stainless steel, the dimensions and requirements of which coincide with the previous version.

Then you need to cut a plate of the same thickness as the walls of the tank, with a length equal to the length of its internal space.

The width of this element is calculated by the formula:

W = Wв - 1.5 + 2xHв

Where: W - the width of the inner tank in cm, and HB - its depth (also in cm).

Plates bend at an angle of 90about from the side of the long edges, so as to make legs whose height is equal to the depth of the bath (HB). Similarly, we get a U-shaped element, the length of which corresponds to the length of the bath, and the width is 1.5 centimeters less.

In one of the legs of the U-shaped part, we drill holes or cut it so that it resembles a comb. The element is installed on the legs in the bath so that between the surface with holes (cuts) and the tank wall there is a gap of 1.5 cm.

After that, the tank can be filled with fuel and ignite it. In this case, the flame will form only on a narrow open strip 1.5 cm wide, while the fuel in most of the tank, covered with a U-shaped element, will not burn due to the lack of access to air.

At the same time, fuel will constantly flow into the “working” compartment thanks to the slots or openings provided in the plate.

To immediately extinguish the fire, it is also recommended to additionally cut out a steel plate, which will cover the combustion zone.

How to make an inclined tank level? In order for fuel to burn without residue, it is advisable to give the bottom of the model described above a slight slope directed towards the “working” volume.

This is easy enough to do. To do this, pour a certain amount of gypsum mixture into the tank, then tilt it in the right direction and wait for the solution to solidify.

In this case, the “leg” of the U-shaped part, on which there is no perforation, it is advisable to shorten it a bit so that the structure remains strictly horizontal, despite the existing slope of the bottom.

It is also possible to make a fuel tank having a double bottom. To do this, the already made burner is placed in a larger tank, while the edges of the upper element should overlap the walls of the lower one.

# 3: The simplest device with a filler

The reservoir of the working compartment (U-shaped part) can also be filled with absorbent (filler), which is most often used mineral wool.

Instead of basalt fibers, it is better to prefer an acrylic-based material for the following reasons:

- This type of glass wool is characterized by the highest hygroscopicity indicator, which means that it absorbs liquid best.

- The fibrous filler has excellent vapor permeability, therefore, alcohol vapors will circulate freely between the fibers.

- Soft white cotton wool burns for a long time, giving a bright even flame.

- In the manufacture of this type of mineral wool, formaldehyde is not used, which guarantees the ecological purity of the absorbent.

If you were not able to find cotton wool made on the basis of acrylic, other types of similar products are suitable, preferably softer materials.

Saturating bioethanol, the absorbent will gradually give off fuel, prolonging the burning time of the biofireplace.

The lightest version of the glass wool burner is available to everyone. In this case, a small metal container, for example, a mug or a tin can, is required. An absorbent is placed in the tank so that it fills the entire volume (it does not need to be densified), after which the filler is well impregnated with bioethanol or other liquid fuel.

From above, the container is covered with a suitable-sized metal mesh or a lid with perforated holes, after which the fuel is ignited.

Fuel device decoration

The fireplace burner can be decorated with additional elements. This will not only ennoble the design, but also help mask the wick.

Among the most popular jewelry are:

- Ceramic logs, the size of which should coincide with the dimensions of the outbreak. Such elements will imitate a bonfire.

- Different types of natural and artificial stones, which can be of the same or different sizes, transparent or colored, smooth or with a textured surface. Pebbles can be laid out not only on the grill, but also beyond.

- Stylized Entourage Items: poker, tongs, tools for ignition and extinguishing. Here you can put fuel in a decorative package.

Also, decorative cladding made of heat-resistant ceramics and clay, earthenware figures, which can be placed on the fireplace cover or next to it, are also good.

It is advisable to use removable decor components, which will periodically change the appearance of the device.

Conclusions and useful video on the topic

We offer you instructions for the independent manufacture of a burner for a biofireplace:

Own production of a biofireplace, of which the heating element is an integral part:

As you can see, the design of the burner is quite easy, and it is accessible to everyone. Placing it in a suitable building, you will receive a wonderful bio fireplace, which will bring cosiness and originality to the interior of the room.

Thinking about making a fireplace for biofuels with your own hands? Maybe you have some original decorating ideas and want to share them with other users? Or want to clarify the technical aspects of the bio-fireplace assembly process? Or maybe you have already made a stylish fireplace and want to demonstrate it to beginners? Write your recommendations, add a photo under this article.

How to make a hydrogen generator for your home with your own hands: practical tips for manufacturing and installing

How to make a hydrogen generator for your home with your own hands: practical tips for manufacturing and installing  How to make a bio fireplace with your own hands: device, diagrams and step-by-step assembly instructions

How to make a bio fireplace with your own hands: device, diagrams and step-by-step assembly instructions  Biofuel for the fireplace: types of biofuel, its properties + how to choose and how to do it yourself

Biofuel for the fireplace: types of biofuel, its properties + how to choose and how to do it yourself  How to choose fuel for a biofireplace: a comparative overview of the types of fuel + analysis of popular brands

How to choose fuel for a biofireplace: a comparative overview of the types of fuel + analysis of popular brands  How to make biofuel with your own hands from manure at home

How to make biofuel with your own hands from manure at home  Fireplaces on biofuel: device, types and principle of action of bio-fireplaces

Fireplaces on biofuel: device, types and principle of action of bio-fireplaces  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

A very beautiful and extremely unusual decoration of any interior, but how safe are such fireplaces, especially if the owners gape and forget to turn it off for example at night? Is it possible that the flame can be transferred to surrounding surfaces from the windif a window is opened in the room where it is installed? And can it, in principle, cause a serious fire?

A biofireplace is the same fire as usual. And he has the same dangers. Yes, with a strong gust of wind, a small biofireplace, especially artisanal assembly, may tip over. Therefore, you need to buy / make bio fireplaces with a reliable base and keep them away from books and other flammable things.

In principle, the article describes the main shortcomings of bio-amines, but since you are worried about such important questions that concern security, I will try to answer them.

First of all, biofireplaces more serve as an aesthetic or design solution to create an entourage or atmosphere in the room. Leaving these fireplaces unattended is unsafe, especially at night! The biofuel that is used in these fireplaces is safe, but drafts or wind gusts that can occur in the house can spread fire to nearby areas.

Accordingly, it is not recommended to install such biofireplaces near windows - usually a protective structure is built around that prevents leaks. However, to leave unattended in working condition is still highly recommended!

For the house, I think this is a great thing, especially for a suburban. Personally, we did not bother and purchased a fireplace in the store. In general, it is not so difficult to make it, it looks beautiful and does not require much. Design is one of the most important steps in home improvement, you need to do everything aesthetically and, most importantly, reliably. The principle is simple, but it is important to add fuel from time to time.