How to connect wires without soldering: the best ways and their features + installation recommendations

Home electrical network is a complex system of wiring products and devices connected by electric current conductors. In electrical panels, junction boxes and device cases, wires are connected.

We will consider how to connect wires without soldering using special clamps and terminals so that the switching is as reliable as possible and meets the safety requirements. Why give 4 detailed instructions with the best ways to connect wires.

We will also supplement our material with useful installation tips from experienced electricians.

The content of the article:

Briefly about possible switching options

Electricians use various methods of connecting conductors - from the simplest isolated twisting to crimping with special sleeves.

Some procedures require additional supplies and special tools, others are performed manually.

The question of choosing the most reliable connection methods became relevant when the load on the home network increased - a lot of powerful devices appeared, respectively, the requirements for the use of conductors and electrical installations were tightened.

Factors affecting the choice of method:

- total cross section of conductors;

- type and method of cable insulation;

- material of which the wires are made;

- purpose of the switching node;

- external connection conditions;

- degree of mobility of the compound, etc.

The on-site installer determines how he will make the switch, taking into account the above factors. Much depends on his skills in using a special tool (soldering iron, welding machinecrimping pliers) and materials at hand.

However, professionals always have an installation kit with them and use the methods recommended by the GOST and PUE standards.

Today you can come across a variety of wire connection options:

According to PUE 2.1.21, simple twisting should in principle not be used for switching. Only welding, soldering, crimping and various types of clamping devices.

To carry out soldering or welding, special equipment is not always at hand, especially if the job is performed by an amateur. Therefore, it is advisable to consider methods that are both reliable and affordable.

Safe and effective connections

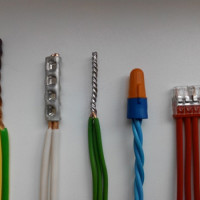

Consider 4 options for connecting conductors suitable for home installation: spring terminal blocks, terminal blocks, PPE caps and crimping with sleeves.

To perform the work, consumables are required - terminals, clamps, sleeves, selected depending on the type and cross-section of the conductors. We recommend that you purchase products only from trusted manufacturers, and not cheap Chinese substitutes.

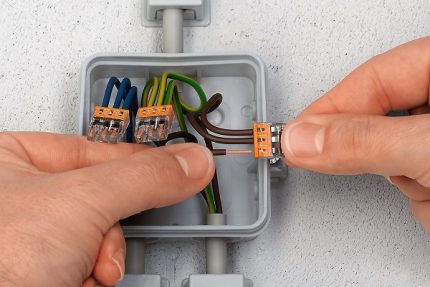

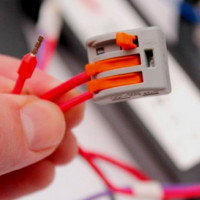

Method # 1 - WAGO terminal block switching

The main advantage of terminal switching is 100% connection reliability. Thanks to the development of the company Wago screwless connections have received international standard status.

Now other manufacturers are engaged in the production of spring clips. They are used in high-speed cars, airplanes, mobile chains - that is, where special responsibility is required.

To install the terminal block, you do not need to specially prepare. Experienced installers who value quality have also been using only self-locking terminals for a long time.

We offer step-by-step instructions for connecting 2 conductors with a clamp of the 222 series, whose representatives are successfully used to connect branches of various types of wires:

After the correct execution of the actions, spontaneous opening of the terminal is impossible. The advantage of such a connection is the ability to disconnect. To open the conductors, you must first click on the movable mechanism, and then remove the corresponding conductor.

Terminal Connection Benefits:

- connection of single and multicore conductors made of copper or aluminum, as well as mixed connections;

- high quality connection;

- during installation, the wires are not damaged;

- the design provides for the removal of circuit parameters without disconnection;

- neatness and order in the places of work - distribution boxes, panels, wiring devices.

This method saves time - it only takes a few seconds. However, it requires accuracy. If the ends are not fully inserted, overheating may occur and the terminal block body will melt.

The main disadvantage is the high cost, especially branded products. For example, a set of 20 three-wire universal Vago terminal blocks costs about 500 rubles.

More information on Vago terminals in the following video:

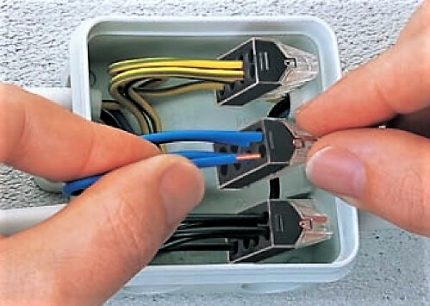

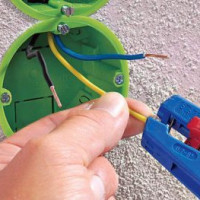

Method # 2 - using terminal blocks

Inexpensive plastic products have a clamping mechanism with which the conductors are fixed and connected inside the case. Each single or stranded wire is removed from insulation, inserted into a separate socket and secured by tightening the screw.

Using stripping strippers allows even a novice to cope with this task without much difficulty.

Wires can be wound in two ways - on one side and on both sides, towards each other. This method is often used for desoldering in junction boxes, so manufacturers began to produce switch boxes with built-in pads.

Advantages of connecting with pads:

- profitability;

- quick installation;

- aluminum / copper compound;

- high quality.

The main disadvantage is that with one pair of blocks you can connect only 2 occasions. Experienced installers do not recommend using the block method for connecting stranded or aluminum wires, since a screw connection can destroy a more fragile material.

And one more minus - a large number of low-quality pads.

For a better understanding of this method of switching wires, we recommend that you look at what the terminal boxes are good or bad for:

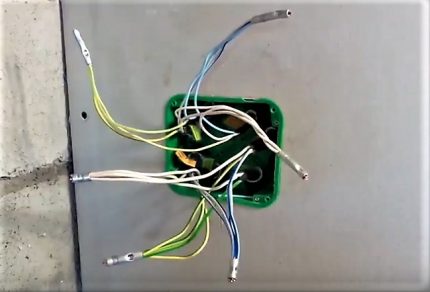

Method # 3 - use of PPE caps

For the manufacture of spring clamps, caps use non-combustible plastic. The body material is an insulator suitable for mechanical and fire parameters.

To install the cap, it is necessary to prepare the cores, insert them inside, and then with an effort to make twisting movements. To protect the exposed parts of the cores from oxidation, the inside of the cap is treated with paste.

The caps are compact, have a simple device, so they are often used for desoldering. One distribution box includes up to a dozen products.

A practical example of the use of PPE for desoldering in a distribution box:

After the work on connecting the cores is completed, carefully place the caps in a circle and close the distributor box cover. At any time, you can unscrew the spring elements and reconnect or repair.

Advantages of PPE:

- low cost;

- material - non-combustible polymer;

- high speed and ease of installation;

- variety of coloring.

The last item may come in handy when using old, unlabeled wiring. You can determine the purpose of the cores with the help of caps, picking them by color. In more detail about color marking of wires we spoke in this article.

The main disadvantage is that the connection is considered unreliable. The spring force is not enough to ensure a strong connection, which is why additional twisting is performed.

Before use, it is recommended to check the quality of the products.

And further - PPE is not intended for switching aluminum / copper wires.

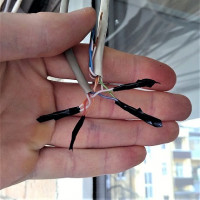

Method # 4 - crimping conductors with sleeves

This method is chosen by installers who really care about the quality of the connection. Crimping with a special tool guarantees an increase in contact area and minimal resistance.

If you cut the crimped sleeve in half, then you can see that all the wires almost merged into one monolith.

Cores can be started both on the one hand, and on both. In any case, their total cross-section should not be larger than the diameter of the sleeve.

In practice, more often choose a larger sleeve, and the free space inside it is “clogged” with pieces of wiring. The denser the sleeve is filled, the better the connection.

Step-by-step crimping instructions:

If there is a shortage of space in the box and compactness comes to the first place, before crimping, the sleeve is cut in half and crimped only once. But this should be considered as an exception.

This method is considered inexpensive - each sleeve (copper) costs 8-9 rubles, and ticks can be rented.

The benefits of crimping:

- excellent connection quality;

- profitability;

- high speed of work.

The disadvantage is that the connection is one-piece, and if necessary, you will have to completely replace the switching blocks. If there is a supply of wires in the box, the old sleeve is cut off and a new one is installed.

The downside is that without a special tool, it will not be possible to perform high-quality crimping.

Tips from experienced installers

There are many controversial issues both in connection methods and in the application of individual mounting products. But a number of rules apply to absolutely all masters who are involved in electrical installation.

For instance, It is strictly forbidden to twist aluminum conductors with copper. The process of rapid oxidation leads to the destruction of switching and the emergence of a dangerous point, which at any time can spark or flare up.

Some more important rules:

If the conductor is coated with an oxide film, it must be carefully removed with either contact paste or fine sandpaper. The diameters of sleeves, tips, caps, it is better to choose the size.

Single conductors in screw terminals are loose. Therefore, it is recommended to bend the stripped end in half or make an arbitrary loop out of it.

At the end of work, be sure to check the reliability of the connections - slightly twitch the wires. It happens that the switching is unsuccessful, and the core simply slides out of the terminal block.

If the volume of the distribution box allows, for example, the shields contain many wires and devices, then leave the cable with a margin. Sometimes switching is required and an extra length comes in handy if the connections are one-piece or burnt.

We also have other articles on the site on connectors of conductors, methods of connecting wires of different sections and recommendations for choosing the best connector:

- Methods of connecting electrical wires: types of connections + technical nuances

- Terminals for connecting wires: which terminal blocks are better and how to work with them

- Wire connectors: the best types of connectors + what to look at when choosing a connector

Conclusions and useful video on the topic:

Comparative analysis of various switching methods:

As you can see, equipping the electrical wiring, you can completely do without soldering and welding.

There are enough modern devices on the market to ensure the switching of conductors using safe and effective technologies. The choice of the method depends on personal preferences and material capabilities..

Choose a safe way to connect electrical wires without soldering, but you still have questions that we did not touch on in our article? Feel free to ask your questions to our experts in the comments section.

If you have extensive experience in performing electrical work, in particular, connecting conductors without the use of soldering and welding tools, please leave useful recommendations for beginners and additions to our material below under the article.

How to connect a twisted pair cable to each other: methods + instructions for building up a twisted wire

How to connect a twisted pair cable to each other: methods + instructions for building up a twisted wire  Methods of connecting electrical wires: types of connections + technical nuances

Methods of connecting electrical wires: types of connections + technical nuances  Wire connectors: the best types of connectors + what to look at when choosing a connector

Wire connectors: the best types of connectors + what to look at when choosing a connector  Electrician in a wooden house: diagrams + installation instructions

Electrician in a wooden house: diagrams + installation instructions  Stripping wires from insulation: methods and specifics of removing insulation from cables and wires

Stripping wires from insulation: methods and specifics of removing insulation from cables and wires  Cable for the Internet: varieties, device + what to look for when buying wire for the Internet

Cable for the Internet: varieties, device + what to look for when buying wire for the Internet  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

There are ways to connect the wires without soldering, but the main thing is that it is not a simple twist. It is impossible to create a reliable connection through twisting, over time it will certainly begin to overheat, or even sparkle. How many ignitions and fires have already been and still will be due to the disregard for the wiring. Very carefully and responsibly you need to relate to this topic.

There is professional experience in electrical work. Based on it, of course, I choose sleeves.Just the ends of the wire you need to leave with a margin, that is, about 20 cm. The sleeves are crimped easily with pliers, the main thing is that it be filled. In second place in terms of reliability are clamping blocks. But it is difficult to make a lighting layout with many beams and a large number of core blocks.

Good afternoon, Vladimir.

The connection of cables and wires with crimping sleeves is a whole science. Having worked for a long time in the electric power industry, I met with many technologies that take into account all kinds of factors that regulate the tool used.

I saw manual, mechanical, hydraulic pincers, I saw how pressure testing by an explosion works. In the latter case, special matrices, punches are used. The crimping part of the ticks, I note, also has an intricate configuration. The only thing I did not see was crimping with pliers. This connection will not pass the tests - read the "Rules for the technical operation of electrical installations of consumers" section "p.p3.0.1".

You can replenish your experience as an electrician with special literature. Among them is the “Instruction for the Connection of Insulated Conductors of Wires and Cables” under the number “I 1.09-10”.

For wire stocks and other wisdom of their preparation for connection, you can read GOST 23469.3-79 "Cable connecting copper sleeves, fixed by crimping."

Professional electricians have this expression: a hot joint is always cold (note: high-quality), and a cold joint is always hot.

The most reliable method of connection is welding. Sleeves in second place, everything else is only for open access.