Which wire to use for wiring in the house: recommendations for selection

It is impossible to build a home electrical network without an electric cable. However, for the arrangement of housing it is not enough to install it correctly; you still need to correctly select the appropriate type. And for this you need to know what characteristics affect the choice. Do you agree?

We will tell you what types of products the modern market offers and which wire to use for wiring in the house. We will introduce you to the demanded nomenclature and help to understand the labeling of products for laying power lines. Let’s indicate what customers and independent electricians should be guided by.

The information presented for acquaintance with the purpose of optimizing perception was supplemented with diagrams, photo selections, video recommendations.

The content of the article:

What are electric cables made of?

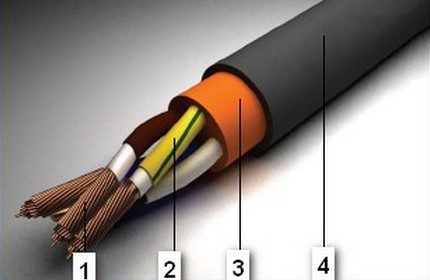

The main elements of any electric cable are the cores - elements for the passage of electric current, isolated from each other by an inner sheath and enclosed in a common sheath.

They are designated by abbreviation TPG.

The cores for the transmission of electrical energy are of two types:

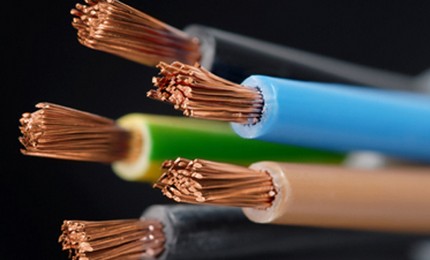

- single wire solid;

- multiwireconsisting of a large number of thin threads.

Some mistakenly believe that single-wire cores and single-core cables are the same concept. In fact, single-core products can have only one core, which, in turn, can be made single or multi-wire.

The basis for the manufacture of conductive conductors may be copper or aluminum. If we compare these metals, then aluminum, although it is cheaper, but loses in that it has a lower level of electrical conductivity.

This means that with an equal cross section, the copper conductor is able to pass more current. The only "minus" of copper is the fact that when it can not be directly connected with other metals. Those. To connect with aluminum, an adapter is required that eliminates the formation of a galvanic pair.

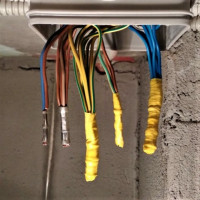

If the connection is made by twisting, then this place will quickly oxidize, which will lead to rupture of contacts, as a result of which the trunk can be closed. Ideally, for all lines in the apartment, you should choose the same type of wire.

Cables for electrical signals are equipped with a common protective sheath.

The insulating layer can be made of:

- rubber;

- polyethylene;

- PVC compound.

Each of these materials is characterized by high insulating characteristics. Due to this, they can be used in networks of various voltage classes within 500 watts.

Any cable used for home apartment wiringhas at least two insulating layers: the first protects the inner cores assembled into a bundle, the second encircles only one core.

Varieties of electrical wires

There are several classifications that wizards are guided by when choosing cable for house wiring.

The first sign that cables are shared is number of cores. The operational parameters of single and multicore products are detailed in the table below.

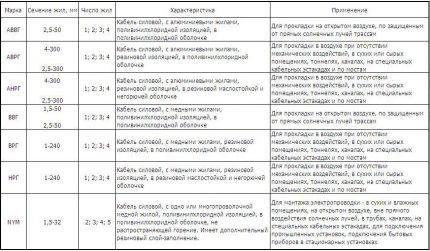

Below are four of the most popular types of cables used in arranging in-house wiring.

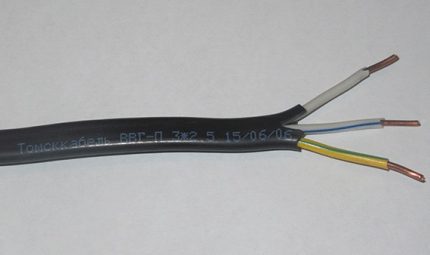

View # 1 - VVG cable

When arranging an intra-apartment wiring, which provides junction box installationapply VVG cable. It is used to transmit electric current at an operating voltage within 1000 V. The number of cores in such products can range from one to five.

The indisputable advantages of VVG products include a wide temperature operating range. It can be safely used at temperatures from -50 ° C to +50 ° C. The wire is famous for its high tensile strength and ability to withstand moisture up to 98%.

A product of this type can have one of three designations:

- «P"- indicates a flat type of section;

- «s"- means that between the insulation TPG and the outer braid is a rubber compound or PVC harnesses;

- «ng"- indicates that insulation does not spread combustion.

In any cables of the VVG type, with the exception of those that have the designation “z,” the space between the outer sheath and the insulating layer of the cores is not filled.

For domestic use, cable cross-section from 1.5 mm2, when arranging a private house, the product is 6 mm2. The value of the bending radius of the product is determined by multiplying the smaller cross-section by 10.

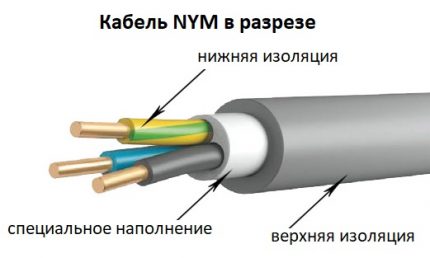

View # 2 - NYM Cable

NYM - Another high-quality power cable designed for conducting power and lighting networks with voltage up to 660V. Stranded conductive wires of the product are made of copper.

The number of NYM cable conductors can range from one to five. The minimum cross-sectional parameters of products on sale is 1.5 mm2maximum - 16 mm2.

The value of the bending radius corresponds to four diameters of the cross section.

The cable has double insulation:

- the outer shell is made of polyvinyl chloride;

- The inner braid is made of non-combustible PVC.

The inner space between the insulating layers is filled with a filler, which is coated rubber. This solution increases the strength of the product and makes it more resistant to high temperatures.

Therefore, NYM cable is one of moisture and heat resistant products. Its working temperature limits are from -40 ° C to +70 ° C.

The only drawback of NYM cable is its vulnerability to UV rays. For this reason, when used in an open area where direct rays fall, it is recommended to cover it.

If we compare NYM cable with VVG analogue, the first is more preferable in terms of operational parameters.But with a limited budget, you can always save by using the NYM cable only to connect room and apartment panels to the floor panels, and lay the VVG cable in the areas.

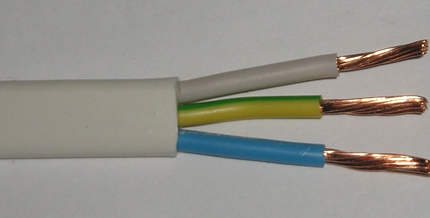

View # 3 - PUNP wire

Often they use a budget analog for posting - PUNP flat wire. It is a two- or three-core product with a cross section of 1.5-6 mm2. Each core of a flat wire is made of copper and is single-wire.

The cable also has double insulation:

- the outer shell is made of PVC plastic;

- inner braid made of polyvinyl chloride.

In terms of quality, such a wire is far from the best option. In addition, as practice shows, the insulation of the wire is very vulnerable to temperature fluctuations and quickly collapses when heated.

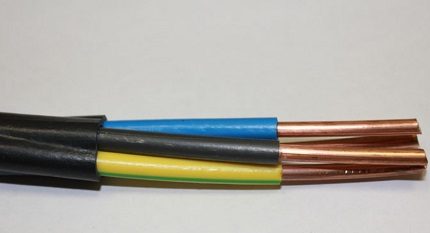

View # 4 - armored cable VBBSHV

When arranging a lighting system adjacent to the house, the armored power unit is the best fit VBBSHV cable. It is designed to operate under conditions of variable rated voltage, the range of which varies from 660 to 1000 V.

It is convenient to lay a moisture-proof product in the ground, in reinforced concrete pipes and in the corrugation in the open air, provided that additional protection against direct light rays is created.

Conductors made of copper. The number of threads can vary from one to five, each of which can consist of one or more wires.

The cross section of VBBSHV products ranges from 1.5 mm2 up to 240 mm2. Polyvinyl chloride is used as the inner insulation and outer shell.

Competent selection criteria

The key to the smooth operation of the home highway of the electrical system is the quality of components. Therefore, at the stage of their acquisition, one of the key tasks is to choose a cable of proper quality.

To navigate when choosing the right cable, you need to carefully study the product labeling. On the cable should be indicated: brand, name of the manufacturer and compliance with GOST or technical specifications. The cross-sectional size and brand of cable should be repeated at equal intervals along the entire length of the outer braid of the product.

The marking of any power cable is represented by numbers and three letters.

The first digit of the numerical designation determines the number of cores, the second digit is the cross-sectional area of each of them, the third is the calculated voltage of the network. The remaining numbers indicate the flexibility class of the cord. The first letter defines the type of material involved in creating the upper braid of insulation.

The second letter indicates the type of wire:

- «TO"- control;

- «P"- flat;

- «M"- mounting;

- «W" or "At"- installation;

- «Mg»- assembly room with flexible conductor.

The third letter of the marking defines the material applicable for the inner insulation of the cores.

Variants of its designation and decoding:

- «P"- the insulation is made of polyethylene;

- «AT" or "BP"- the braid is made of rubber;

- «Pv"- applied vulcanizing polyethylene;

- «Ps"- used self-extinguishing polyethylene;

- «WITH"- the outer braid is made of lead;

Rubber insulation can be protected with a nitrite sheath "N"Or polyvinyl chloride"AT».

The following letter indicates the type of cable: "NG"- non-combustible and fireproof,"B"- armored,"LS"- does not emit smoke during melting. Products with an armored shell are used where there is a possibility of mechanical damage.

The presence in the marking of the letter "E”Reports that filler is present between the cores. Letter combination "Coolant"Shows that it is a single-wire core.

How to calculate the cross section of the wire?

Cross-sectional areas of conductors are standardized. Their values are selected with orientation on the strength of the current, the material of manufacture of the cores and the laying conditions. Indeed, when the cable is operated at the limit of its capabilities, the conductors will heat up several tens of degrees.

And if several such cables will be laid in one tray, then with the mutual heating of the products, the value of the permissible current will decrease to 30%.

The calculation is done according to this formula P / V.

Where:

- R - power of devices, the parameters of which are indicated in the technical documentation;

- V - network voltage of 220 V.

Sectional area is measured in square millimeters. So, one “square” of aluminum wire is able to pass from 4 to 6 amperes through itself. In a copper analog, this parameter reaches a mark of 10 amperes.

For example, for an electric appliance with a power of 4 kilowatts, according to this formula, the current strength becomes equal to 18.18 A = 4000 W / 200V. To power such a device, it is required to lay wiring with copper threads with a cross section of 1.8 mm2.

As a safety net, it is better to multiply the obtained value by 1.5. Therefore, the most ideal option for powering such a powerful device is a copper wire with a cross section of 2 mm2. If we consider the option of installing an aluminum analogue, you will need a cord whose thickness is 2.5 times more.

Simplify the task by wire cross section calculation The table below will help.

An important point! When designing hidden wiring, the data from the table must be multiplied by a factor of 0.8.

When open, it is capable of mounting in the same private house, in any case, for reliability, it is better to use a wire with a cross section of 4 mm or more2 and higher, preferring products with high mechanical strength.

According to the indicators of the cross-sectional plane, the installation cable for entering the house should be one step higher than that which is necessary for servicing the most installed electrical appliances.

To save money, such a wire can be used only for entering into the house and connecting to the terminal strip, and through the machines to draw lines of the desired section.

According to the requirements of the PUE PUE 7.1.34, each line should be calculated separately with orientation to a specific load. However, there are options acceptable for all residential facilities with standard cross-sectional values:

You will learn about which cable to use for the wiring device in a wooden house from another popular article our site.

Conclusions and useful video on the topic

Before choosing and practical use of wires, it is better to once again recall the theory by watching useful videos.

Video # 1. How to choose the right wire:

Video # 2. Wizard's advice, which wire is better for home:

The price range of power cables on sale is quite wide. But in this matter it is not worth saving. A lower price may indicate that low quality materials were used in the manufacture of the cable product or the wire has a cross section less than the declared.

When purchasing products from Chinese manufacturers, be prepared for the fact that in the desire to save instead of copper conductors, many of them use copper-plated aluminum wires. Outwardly, they practically do not differ from copper counterparts, but differ only in performance characteristics.

Do you have any useful recommendations that you want to inform website visitors and us? Having questions while reading the information? Please write comments in the block below the text of the article.

What cable to use for wiring in the apartment: a review of the wires and choosing the best option

What cable to use for wiring in the apartment: a review of the wires and choosing the best option  Wire cross section for home wiring: how to correctly calculate

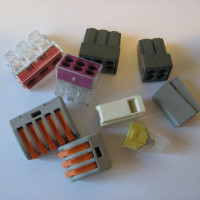

Wire cross section for home wiring: how to correctly calculate  How to connect wires without soldering: the best ways and their features + installation recommendations

How to connect wires without soldering: the best ways and their features + installation recommendations  Electrician in a wooden house: diagrams + installation instructions

Electrician in a wooden house: diagrams + installation instructions  Wiring in a wooden house: design rules + step-by-step installation

Wiring in a wooden house: design rules + step-by-step installation  Self-locking terminal blocks: types and scope + recommendations for customers

Self-locking terminal blocks: types and scope + recommendations for customers  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Changing or installing new wiring in the apartment, I always recommend using a multi-wire stranded copper cable. This is the key to the durability and safety of electrical wiring. Be sure to calculate the power of electrical appliances and use a cable of suitable cross section with one and a half power margin. This will prevent cable overheating and premature aging of the insulation.

Good afternoon, Valery.

The capacities of refrigerators, washing machines, and other household electrical appliances are indicated on the nameplates, in the passports - no one counts them. Calculate the load of group lines, laying the prospect of development (PUE reserve does not stipulate).

Regarding the 1.5-fold supply - I doubt that the amount of apartment capacity can so increase. Suppose, nevertheless, something very powerful is acquired - then you can forward an additional line from the apartment panel.

There are many recommendations, but the main one is the rejection of aluminum in favor of copper. Naturally, such a replacement wiring will require a major overhaul. But it is impossible to connect copper wires with aluminum directly. This must be done through adapter pads. These options are resorted to when you need to connect the replaced copper wiring in the apartment with aluminum wires that are laid in the rest of the house.

Electrical appliances used in everyday life have a rated capacity. The total capacity of the house and individual rooms is used to calculate the network, try not to consider the simultaneity factor. 50% put for future electricity consumers. The permissible current load is 10A / sq. Mm to prevent overheating of the wires. And I also wanted to say: try not to use stranded wires and cables (only in carrying), their connection in the terminal blocks weakens with time, which can not be said for single-core ones.

Good afternoon, Alexander.

Your call to try not to take into account the simultaneity coefficient is contrary to SP 256.1325800.2016. There, clause 4.1 obliges designers to take into account many regulatory documents that operate with a simultaneity factor. Clause 12.6 of this joint venture states: the cross-section of the supply conductors is determined by the sum of the currents of the connected equipment - the simultaneity factor is taken into account.

You advise a 50 percent margin for the future. Following your recommendation will significantly increase the cost of electricity to the apartment. Even a 20 percent supply is provided by the typical design of a power transformer, and for rural projects, networks can have a 30 percent supply capacity.

The only thing that can be advised is to install an introductory shield with reserve places for future connections.

We took it cheaper, called PugVV, it is a little thin, but it will do for a garden house. I looked at these in the store, their prices just bite.

Due to this, they can be used in networks of various voltage classes within 500 watts. Do you even edit the text

Thanks for the signal. The bug has been fixed. Indeed, they missed the author’s slip.