Phase control relays: operating principle, types, marking + how to adjust and connect

The result of the technical situation, when the stator windings of the motor consume more current than the set parametric values, is excess heat. This factor causes a decrease in the quality of motor insulation. Equipment fails.

The reaction time of thermal overload relays is usually not enough to provide effective protection against excess heat generated by high current. In such cases, only the phase monitoring relay is seen as an effective protective device.

The content of the article:

General Instrument Information

The functionality of electrical appliances of this type is much wider than just protection against overheating and short circuit.

In practice, the effective properties of the relay for selecting overloaded phases have been noted, which ultimately provide comprehensive protection.

Thanks to phase monitoring devices, the following benefits are achieved:

- extended engine life;

- reducing costly repairs or replacing a motor;

- reduced downtime due to engine defects;

- reduced risk of electric shock.

In addition, the device provides reliable protection against fire and short-circuit of the motor windings.

Typical safety relays

There are two main types of protective devices intended for use as part of three-phase systems - current measurement and voltage relays.

Pros of using devices

The advantageous side of current protective relays in relation to voltage monitoring relay obvious. This type of instrument operates independently of the influence of EMF (electromotive force), which invariably accompanies a phase failure during engine overloads.

In addition, devices operating on the principle of measuring current are able to determine the abnormal behavior of the motor. Monitoring is possible either on the line side in the branch circuit or on the load side where the relay is installed.

Devices that control the process by the principle of measuring voltage are limited to detecting abnormal operating conditions only on the side of the line where the device is connected.

However, voltage sensitive devices also have an important advantage. It lies in the ability of devices of this type to detect an abnormal condition that is independent of the state of the engine.

For example, a relay type that is sensitive to changes in current detects an abnormal phase state only directly during engine operation. But the voltage measuring device provides protection immediately before starting the motor.

Also among the advantages of voltage measuring devices are simple installation and lower price.

This type of protection device:

- does not need additional current transformers;

- applied regardless of system load.

And for its operation it is only required to connect the voltage.

Phase Failure Detection

A phase failure is quite possible due to the failure of a fuse in one of the parts of the power distribution system. A mechanical failure of the switching equipment or a break in one of the power lines also provokes a phase failure.

A single-phase three-phase motor draws the required current from the remaining two lines. Attempting to start it in single-phase mode will block the rotor and the engine will not start.

The reaction time per thermal overload unit may be too long to provide effective protection against excessive heat. If it is not installed to protect against it thermal relay, then when a failure occurs due to overheating that appears in the motor windings.

Protection of a three-phase motor from the phase failure factor is difficult because an underloaded three-phase motor operating on one of the three phases generates a voltage called regenerated (reverse emf).

It is formed inside a tattered winding and is almost equal to the value of the lost input voltage. Therefore, voltage measurement relays that control only its value in such situations do not provide complete protection against the phase failure factor.

A higher degree of protection can be obtained using a device that can detect phase angle displacement, usually accompanying phase failure. Under normal conditions, the three-phase voltage is 120 degrees in phase relative to each other. Failure will cause the angle to shift from normal to 120 degrees.

Phase reverse detection

Phase reversal can occur:

- Maintenance is being carried out on motor equipment.

- The electricity distribution system has been amended.

- When power recovery leads to a different phase sequence that was before the power outage.

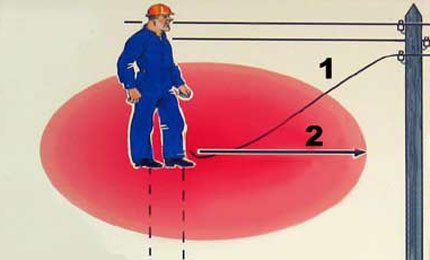

The detection of a phase reversal is important if a reverse engine can damage the driven mechanism or, even worse, cause physical harm to maintenance personnel.

The rules of operation of electric networks require the use of protection against possible phase reversal on all equipment, including vehicles for transporting personnel (escalators, elevators, etc.).

Voltage imbalance detection

An imbalance is usually manifested if the incoming line voltage supplied by the electricity company has different levels. An imbalance can occur when single-phase loads of lighting, electrical outputs, single-phase motors and other equipment are connected in separate phases and are not distributed in a balanced manner.

In any of these cases, a current imbalance forms in the system, which reduces efficiency and shortens the life of the motor.

An unbalanced or insufficient voltage applied to a three-phase motor leads to an imbalance in the current in the stator windings, which is equal to a multiple value of the unbalance of interphase voltages. This moment, in turn, is accompanied by an increase in heating, which is the main reason for the rapid destruction of the motor insulation.

Based on all the technical and technological factors described, it becomes obvious the importance of using this type of relay and not only for cases of operation of electric motors, but also for generators, transformers and other electrical equipment.

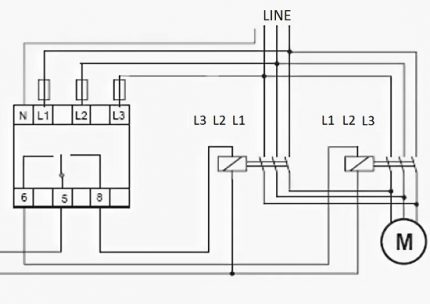

How to connect a control device?

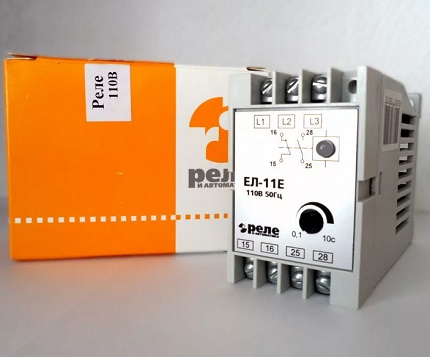

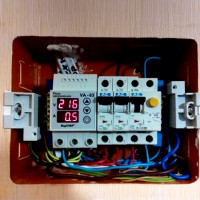

The design of the relays, which control the phases, with all the wide range of products available, have a unified housing.

Product structural elements

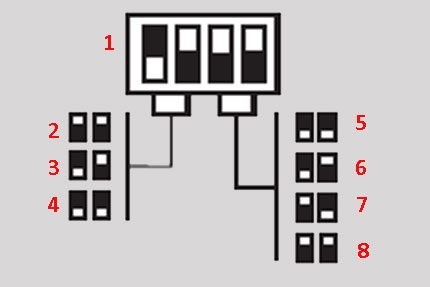

Terminal blocks for connecting electrical conductors, as a rule, are displayed on the front of the case, which is convenient for installation work.

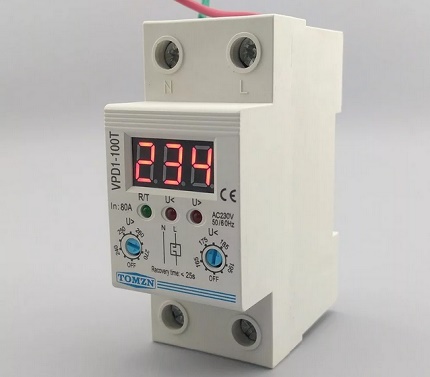

The device itself is made for installation on a DIN rail or simply on a flat plane. The terminal strip interface is usually a standard reliable clamp designed for mounting copper (aluminum) conductors with a cross-section up to 2.5 mm2.

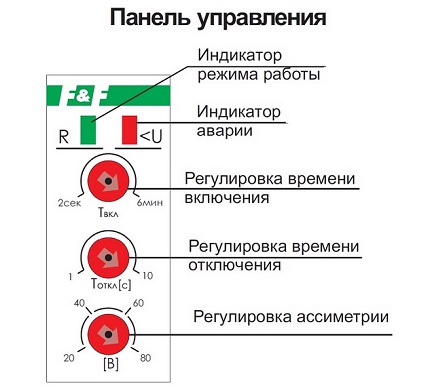

The front panel of the device contains the regulator / regulators of adjustment, and also light control indication. The latter shows the presence / absence of supply voltage, as well as the state of the actuator.

Three-phase voltage is connected at the operating terminals of the device, indicated by the corresponding technical symbols (L1, L2, L3). The installation of a neutral conductor on such devices is usually not provided, but this moment is specifically determined by the execution of the relay - the type of model.

To connect to control circuits, a second interface group is used, usually consisting of at least 6 working terminals. One pair of the contact group of the relay commutes the coil circuit of the magnetic starter, and through the second, the control circuit of the electrical equipment.

Everything is quite simple. However, each individual relay model may have its own connection features. Therefore, applying the device in practice, one should always be guided by the accompanying documentation.

Fixture setup steps

Again, depending on the version, the design of the product can be equipped with different circuit options for setting and adjusting. There are simple models that provide constructive output to the control panel of one or two potentiometers. And there are devices with advanced settings.

Among such advanced tuning elements, block microswitches are often found located directly on a printed circuit board under the device’s body or in a special openable niche. By setting each of them in one position or another, the required configuration is created.

The setting usually boils down to setting the protection values by rotating the potentiometers or by positioning the microswitches. For example, to monitor the state of contacts, the sensitivity level of the voltage difference (ΔU) is usually set to 0.5 V.

If it is necessary to control the power supply lines of the load, the voltage difference sensitivity regulator (ΔU) is adjusted to such a boundary position where the transition point from the working signal to the emergency one with a small tolerance towards the nominal value is noted.

As a rule, all the nuances of the instrument settings are clearly described by the accompanying documentation.

Marking the phase control device

Classical instruments are simply labeled. An alphanumeric sequence is applied on the front or side panel of the case, or the designation is indicated in the passport.

So, a Russian-made device for connecting without a neutral wire is marked:

EL-13M-15 AC400V

where: EL-13M-15 - the name of the series, AC400V - permissible AC voltage.

Samples of imported products are marked slightly different.

For example, a PAHA series relay is abbreviated as follows:

PAHA B400 A A 3 C

The decoding is approximately the following:

- PAHA is the name of the series.

- B400 - standard voltage 400 V or connected from a transformer.

- A - adjustment by potentiometers and microswitches.

- A (E) - type of housing for mounting on a DIN rail or in a special connector.

- 3 - case size of 35 mm.

- C is the end of the code marking.

On some models, another value may be added before paragraph 2. For example, "400-1" or "400-2", and the sequence of the others does not change.

This is how phase control devices are marked, endowed with an additional power interface for an external source. In the first case, the supply voltage is 10-100 V, in the second 100-1000 V.

With the principle of operation, design features and the purpose of the load switch will introduce next article, which we highly recommend reading.

Conclusions and useful video on the topic

The video is dedicated to describing and reviewing a single product from EKF. However, almost all manufactured phase monitoring devices operate on the same principle:

With all the variety of devices on the market, it is difficult to determine any marking standard. If foreign manufacturers label according to one canon, then domestic ones according to others. Nevertheless, it is always possible to refer to reference data if an exact interpretation of the characteristics is required.

Do you want to share your own experience in the selection and installation of a voltage relay designed for phase monitoring? Do you have useful information that is useful to site visitors? Please write comments in the block below, post pictures on the topic, ask questions.

Thermal relay: operating principle, types, connection diagram + adjustment and marking

Thermal relay: operating principle, types, connection diagram + adjustment and marking  Voltage control relays: operating principle, circuit, connection nuances

Voltage control relays: operating principle, circuit, connection nuances  Intermediate relay: how it works, labeling and types, nuances of adjustment and connection

Intermediate relay: how it works, labeling and types, nuances of adjustment and connection  Electromagnetic relay: device, marking, types + subtleties of connection and adjustment

Electromagnetic relay: device, marking, types + subtleties of connection and adjustment  Thermal relay for an electric motor: operating principle, device, how to choose

Thermal relay for an electric motor: operating principle, device, how to choose  Pulse relay for lighting control: how it works, types, labeling and connection

Pulse relay for lighting control: how it works, types, labeling and connection  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements