Pressure gauges for measuring gas pressure: types, design features and operation of meters

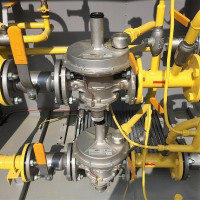

Often there is a need to measure the pressure created by the gas. For example, in cylinders, in gas pipelines, in various containers and vessels. To control and monitor indicators, pressure gauges are used to measure gas pressure. These devices serve in various spheres of life, from medicine to heavy industry.

In order for the purchase of the device to be not in vain, and the purchased pressure gauge meets the requirements of production processes, it is worth familiarizing yourself with the classification. We will introduce you to the varieties of gas pressure meters. We will tell about their design features and principles of action.

The content of the article:

Classification by type of measured pressure

Devices that serve to obtain data on the parameters of gas pressure in gas holders, transportation lines, in gas bottles and other tanks are classified according to several criteria. They differ in their structure and principle of operation.

Devices that measure pressure are divided into classes by:

- type of measured pressure;

- appointment;

- principle of action;

- accuracy class.

By the type of measured pressure, devices designed to determine accurate indicators are divided into manometers, vacuum gauges, gravimeters, pressure gauges, barometers and others.

Depending on the degree of protection from the influence of the external environment, the following devices are produced:

- standard;

- protected from dust;

- waterproof

- protected from aggressive environments;

- explosion proof.

One product can combine several types of protection.

A pressure gauge is a small-sized device with which a pressure or pressure difference is measured. The principle of operation of this instrument is dependent on its internal structure. Within the same class, they are still divided into groups depending on the accuracy class.

In order to measure the absolute pressure, the indicators of which are counted from absolute zero (vacuum), absolute pressure gauges are used. Overpressure is determined by gauge overpressure. In the general case, all varieties of such devices are called in one word: "pressure gauge".

Most types of pressure gauges are designed to measure overpressure. Their peculiarity is that they show pressure representing the difference between absolute and atmospheric.

Vacuum gauges are devices showing the value of the pressure of a rarefied gas. Using manovacuometers, measure the excess pressure and the pressure of the rarefied gas. Information is displayed on a single scale.

Using head gauges, overpressure parameters are determined with values up to 40 kPa. Tractometers, on the contrary, allow measuring sparseness up to - 40 kPa. The pressure gauges measure rarefaction and overpressure in the range from - 20 to + 20 kPa.

Differential pressure gauges can determine the pressure difference at two arbitrary points to be studied. A micromanometer is a differential pressure gauge that allows you to measure the pressure difference within 40 kPa.

Functional classification

Gas manometers, depending on the reading mechanism, are divided into:

- Deformation;

- Electric;

- Cargo piston;

- Liquid.

Each type has its own characteristics.

Deformation view of pressure gauges

The principle and basis for the operation of deformation class devices is that pressure acts on the sensitive element of the device, which is deformed. The pressure level is determined by the degree of deformation.

The sensing elements in the tubular spring devices are tubular springs. These products are round bent tubes with a transverse oval cross-section. Gas has an effect on the inner surface of the tube. During this action, the tube deforms and changes its shape, approaching a rounded one.

One end of the tube is sealed and able to move. The second is open and locked by the holders. When the spring tube is bent, the ring also acts, which then unbends the spring. The sealed end of the spring moves in accordance with the pressure force. This movement is transmitted to the measuring scale.

When measuring pressures up to 40 bar, circular springs are used. At higher pressures, helical or spiral springs are used that are in the same plane. The error in the readings when measuring pressure by this method is from 1 to 4%.

Diaphragm and bellows sensitive elements allow you to effectively measure small values of excess and vacuum pressure.

The bellows are manufactured according to the principle of a plumbing bellows hose. It is a thin-walled metal tube made of movable transverse rings. Depending on the material and manufacturing parameters, the bellows may be more or less rigid.

Sensitive membrane elements have the greatest variety. The accuracy class of such devices does not exceed 1.5. In such devices a protective system is provided. In case of overload, the membrane abuts against a special protective device.

Membrane boxes are often installed in instruments that measure pressure and pressure. Head gauges, draft gauges and weight gauges with membrane boxes are produced with accuracy classes of 1.5; 2.5 and a measurement limit of up to 25 kPa.

Flat membranes have a slight displacement of the working point, so they are most often used to convert pressure to force. They are unstable, but they are well calculated.

Corrugated membranes along with similar boxes are used to improve static performance. The former move better, but are difficult to calculate. The latter are used much more often due to their reduced stiffness.

To measure small pressure values, devices with flaccid membranes are used.

Devices need protection from exposure to high temperature, as it negatively affects the elasticity and sensitivity of the main working elements.

Mechanical Pressure Gauges

Many tube spring pressure gauges are actually direct conversion devices. This means that the pressure is converted into a displacement of the sensing element and the mechanical device in contact with it.

Under the influence of pressure, the free end of the spring moves, the leash acts on the gear sector, the gear rotates and the arrows show.

Spring-loaded pressure gauges are produced with a measuring range from 0.1 to 103 MPa and have different accuracy classes. Model models are produced with accuracy classes of 0.15; 0.25; 0.4. Measuring instruments of the working category of increased accuracy - 1 and 0.6. General technical workers - with accuracy classes 1.5; 2.5; 4.

Contact Pressure Gauges

Structurally, it is a refinement of the indicating pressure gauge. The essence of the work is that when the arrow reaches the threshold pressure value, the network closes.

The electrical circuit closes and an alarm is triggered when the indicating arrow reaches one of the arrows with contacts. The accuracy class of such pressure gauges is 1.5. The measuring range corresponds to the standard values.

To provide an alarm or for the purpose of positional regulation, a pressure switch with the marking of RD is used. They measure pressures in the range from 12 to 1600 kPa. The relay is set to the upper and lower activation limits according to the testimony of the control device, and it has an breaking capacity of 10 watts.

Recording Pressure Gauge Models

The industry produces pressure gauges with an integrated indicator reading system, which captures the values on a disk chart so that you can then track the dynamics of the indicators. One revolution can take place in 8, 12, 24 hours. The movement is due to the electric motor or clockwork.

The work of the manometric recorder is based on the transmission of a signal by a tubular spring of large diameter, which has a pulling force. It transmits movement from the sensor to the display system. Devices marked with MTS record overpressure.

Such devices require control by the operator and have accuracy classes of 1; 1.5; 2.5.

Bellows-type sensing elements are used in self-recording differential pressure gauges, which can additionally be equipped with an alarm device and a pneumatic transducer. Such devices measure pressure in the range from 6.3 kPa to 0.16 MPa and have accuracy classes 1; 1,5.

Piston type pressure gauges

Such pressure gauges are often used as a reference when calibrating other measuring instruments. Their measurement range is very wide. Depending on the design of the device, it can begin with serious rarefaction values, and end with a redundancy of up to 2500 MPa. The accuracy class reaches maximum values up to 0.0015.

The principle of operation is to keep the cylinder in the piston in a specific state while calibration weights act on the one hand and the measured pressure on the other. Depending on the weight of the goods, the magnitude of the created pressure is judged.

The main working element of the device is a measuring column. Depending on the quality of its production, the accuracy and purity of the compounds, the magnitude of the error also changes.

Functionally, the deadweight tester consists of a device for creating pressure, a measuring system and weights. The device is equipped with a rotary mechanism to increase and decrease pressure, as well as a pressure relief valve.

Widely used pressure gauges with a loose piston. There is a gap between the piston and the cylinder. The container under the piston is filled with oil, which flows under pressure into the gap and lubricates the friction surfaces.

Electric gas meter

Such pressure gauges are used to convert direct or indirect gas pressure into an electrical parameter. The most common pressure gauges of this type are: strain gauge, capacitive and resistance devices. Pressure is measured in the range from 100 Pa to 1000 MPa. Devices are manufactured with accuracy classes from 0.1 to 2.5.

The work of pressure gauges acting on the basis of the strain-resisting effect consists in changing the value of the conductor resistance due to deformation. Measure pressure in the range of 60 to 108 Pa with a minimum error.

The flange mount of the sensor and the special design of the device allows reading pressure data in particularly aggressive environments with temperatures up to 300 ° C. They are used to measure pressure in systems with fast processes.

A manganin wire, the resistance of which is easily measured by a balanced bridge, acts as a sensitive element in such a device.

The operation of capacitive pressure gauges is based on the effect of pressure on the membrane, which is a movable electrode. When the membrane moves, a change in the capacitance of the transducer follows. Characterized by significant temperature errors.

In capacitive pressure gauges, the deflection of the membrane is determined by the electrical circuit. Such devices are used in systems with rapid pressure drops.

Liquid measuring instruments

The determination of pressure by these devices occurs by balancing the determined pressure with the pressure formed by the liquid column. In this way, you can measure a slight overpressure, atmospheric pressure, the level of vacuum, the pressure difference.

This group is represented by U-shaped pressure gauges, which consist of communicating vessels, and pressure is determined by fluid levels; compensation micromanometers; cup manometers in which a reservoir is used instead of the second tube; float, bell and ring differential pressure gauges.

In liquid measuring instruments, the working fluid is an analogue of a sensitive element.

Diffmanometers are usually equipped with signaling devices, flow meters, regulators and recording devices. Measurement range 10 to 105 Pa Depending on the liquids filling the device, the measurement limit changes.

Functional Division

According to the purpose, the following types of pressure gauges used to measure gas pressure are distinguished:

- general technical;

- reference;

- special.

Consider the features of each type.

General-purpose pressure gauges

This type of pressure gauges is produced in order to measure the values of vacuum and gauge pressure for general technical purposes. Various device modifications allow their use in a wide variety of environments. They are used to measure pressure in production directly during technological processes.

Such pressure gauges can measure the pressure of gaseous media that are non-aggressive with respect to copper alloys at operating temperatures up to 150 ° C. Typically, the body of the product is made of steel, and the details of the mechanism are made of brass alloy.

General-technical pressure gauges for low or high pressure gas are produced resistant to vibrations with a frequency in the range from 10 to 55 Hz, as well as a displacement amplitude of a maximum of 0.15 millimeters. They have several accuracy classes from 1 to 2.5.

General-purpose gas manometers with an electronic board on which the data of the measurements are displayed are gaining popularity. They are often equipped with converters, which automates technological processes. Pressure values are displayed on the electronic dial.

Special Pressure Gauges Group

Such devices are manufactured for a specific type of gas and the environment it creates. For systems with high pressure, manometers for high pressure gas are manufactured. Some gases are aggressive with respect to certain alloys, therefore stable materials are required to work with them.

Special pressure gauges are painted in paints of various colors depending on the type of gas.

Propane pressure gauges are painted red, have a steel body and the characteristics of general technical pressure gauges. The operating pressure of such devices is from 0 to 0.6 MPa. This is the standard propane pressure. Operation in the temperature range from - 50 to + 60 ° C is possible. Working environment temperature up to + 150 ° С. Often included with balloon gearboxes.

Ammonia pressure meters in cylinders and other tanks are painted yellow. Multi-stage compression units are equipped with a temperature scale. Pressure gauge components are made of materials that are resistant to ammonia vapors.

Acetylene manometer is painted white. It is made as a manometer of security systems from non-fat materials. It is used to measure overpressure in various distribution and generating acetylene systems.The body is made of steel, the internal components are made of brass alloy. The range of permissible temperatures is from - 40 to + 70 ° C.

The hydrogen pressure gauge turns dark green. The pressure gauge for other flammable gases is painted red. The measuring device for non-combustible mixtures is painted black. The oxygen gauge is painted blue.

Reference devices for measuring pressure

This type of pressure gauge is designed to check, calibrate and adjust other instruments in order to ensure the highest possible measurement accuracy. Such devices are characterized by a higher accuracy class in comparison with general technical ones. Working standards are divided into three categories.

Check gauges used to verify the accuracy of the readings of the measuring devices at the installation site are also called high-precision gauges. Measuring range from 0-0.6 to 0-1600 bar for gaseous media.

Pressure gauges for conventional and composite gas cylinders must undergo a verification procedure at least once a year, unless otherwise specified in the documents for the device. Verification is carried out by accredited metrological organizations with the status of legal entities. After verification, a certificate is issued and a mark is put.

The gears in the reference pressure gauges are processed with an increased frequency of gearing. They are characterized by minimal friction in the switch mechanism, as well as high sensitivity of the internal elements.

Exemplary pressure gauges, with an accuracy class of 0.4, have a scale of 250 units, with an accuracy class of 0.15 or 0.25, have a scale of 400 units with a division price of 1 unit. Operation of the device is possible at different temperatures, depending on the filler body. The ideal operating temperature is 20 ° C.

Introduces the specifics of refueling gas cylinders next article. It is worth reading to all owners of suburban property that is not connected to a centralized gas supply.

Conclusions and useful video on the topic

The principle of operation of the spring manometer:

Characteristics and applications of the pressure gauge:

Manometers are produced to solve various problems. The most popular are the general technical types used in small industries by various companies when working with gas equipment and systems. Contact manometers are devices that signal a critical value has been reached.

For calibration and adjustment of pressure gauges, reference pressure gauges are used. Special pressure gauges are produced to measure the pressure of a particular gaseous medium. Among them are very popular propane pressure gauges, which are often installed complete with a gearbox on gas cylinders.

Do you want to share useful information on the topic of the article, ask a question or post a photo? Please leave comments in the form below the block. Share useful information and recommendations that may be useful to site visitors.

Pressure reducer for gas tank: operating principle, design features and replacement instruction

Pressure reducer for gas tank: operating principle, design features and replacement instruction  Gas pressure relief valve: types of devices + selection guidelines

Gas pressure relief valve: types of devices + selection guidelines  Why the gas cylinder gearbox buzzes: what to do if the gas pressure regulator is noisy

Why the gas cylinder gearbox buzzes: what to do if the gas pressure regulator is noisy  Gas filters: types, device, purpose and features of the choice of filter for gas

Gas filters: types, device, purpose and features of the choice of filter for gas  Warranty period for gas meters: service life and features of replacing gas meters

Warranty period for gas meters: service life and features of replacing gas meters  Smart gas meters: how smart flow meters are arranged and work + installation features of new meters

Smart gas meters: how smart flow meters are arranged and work + installation features of new meters  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements