DIY gas stove connection: how to install a gas stove in an apartment step by step

The installation or replacement of a gas stove can be entrusted to professionals. But only for this you will have to pay separately and wait for the arrival of the master. Some do the connection of a gas stove with their own hands - the work is not particularly difficult, but requires strict adherence to a number of requirements.

We offer familiarization instructions with a description of the stages of work, how to connect the unit to a gas distribution pipe and safety standards. This article is informative in nature, and does not call for independent action, since all manipulations with gas are very dangerous.

The content of the article:

- Installation of gas stoves: regulatory requirements

- Choosing a place for kitchen equipment

- Preparation of tools and parts

- The way to connect the stove to the system

- Types of gaskets for gas systems

- Step-by-step process for connecting a gas stove

- Safety Rules and Tips

- Conclusions and useful video on the topic

Installation of gas stoves: regulatory requirements

According to the current legislation, gas systems are considered to be a zone of increased danger and intervention in their functionality is allowed only to employees of regional and local gas services, distribution companies or firms that have an official license to carry out such a plan.

Among the activities requiring the participation of a representative of the gas service include: initial equipment connection, reconnection, scheduled and unscheduled repairs, gas meter installation, replacement of parts, etc.

Even if the owners did all the work in person, starting the gas to the burner is allowed only after the specialist inspects all the connection nodes for possible leaks and officially gives the go-ahead for the activation of the equipment and its further correct operation.

The owners will be able to carry out the subsequent replacement of the stove with another model on their own, but the gas company will still have to inform about this.

Gas units prepared for installation must be registered with the appropriate service. Its employees come to the client every six months and conduct a scheduled inspection of the equipment for compliance with all standards and rules for safe operation.

For unauthorized connection to the network or gas pipe transfer a fine is provided.

However, if after connecting the owner did not use the stove, and first invited the master to examine the correctness and quality of the compounds, no punishment will follow. The unit will be inspected, registered as a new gas flow point, and it can be used in normal mode.

Choosing a place for kitchen equipment

Before connecting the home gas stove to the central communications, a suitable place is chosen for it. It is advisable that the floor on the installation site be absolutely even, otherwise the hob is skewed and the dishes will not be able to cook evenly.

The bulk of modern units are equipped with adjusting legs, which make it possible to level the equipment even on the floor with noticeable defects and height differences.

If the model does not have adjustments, they simply place thick cardboard, a piece of chipboard or a wooden plank under the edges of the lower part, aligning the hob in this way with respect to the floor level.

All connecting nodes must be freely accessible so that in the event of a leak or any other malfunction, the problems can be fixed as quickly as possible.

They do not push the plate tightly against the wall, but, on the contrary, leave a small gap behind. Its size is usually indicated in the accompanying instructions by the manufacturer, and professionals recommend that this data is always strictly adhered to.

Preparation of tools and parts

For the correct connection of the gas stove, the following tools and parts are used:

- flexible hose the required length - universal - about 1.5 m, or individual rubber - from 1 m or more;

- ball valve made of nickel-plated brass, designed to operate in systems supplying subscribers with natural and liquefied petroleum gas of low and medium pressure;

- keys - gas and adjustable wrenches;

- gasket - usually sold complete with a stove;

- screwdrivers different types;

- sealing tape or a thread - for example, FUM tape or Loktail 55 thread;

- soap solution medium concentration and a brush to check the correctness and accuracy of the connection for leaks.

As soon as all the necessary components are at hand, proceed directly to work.

The way to connect the stove to the system

For independent connection of the gas stove to the communication nodes use special hoses with special physical characteristics.

Upon purchase, these parts are checked for strength and flexibility, and they also look at the quality certificate to understand whether the proposed product meets the requirements for gas equipment elements.

In some special cases, the plate is connected using a metal connecting pipe, however, this method is used extremely rarely, since it is labor intensive and has a number of inconveniences.

Types of modern gas hoses

A hose for connecting a gas stove is not purchased at the market or outlet, but only at specialized stores or company points of sale of installation equipment.

Sellers, in addition to the product itself, provide the customer with information about the technical specifications and issue a check, according to which in case of a malfunction, the product can be replaced.

Red and blue shades mark water hoses. They have much lower strength and burn out in gas systems 15-30 days after installation.

Today, 3 types of gas hoses are most popular on the market of related equipment. Between them there are distinctive features, thanks to which the owner has the opportunity to choose the most successful option for himself personally.

Combine products with parameters such as flexibility and strength. Due to this, the stove connected to the system can be moved without fear of breaking or somehow damaging the gas pipeline and provoking a leak.

Rubber hose Belongs to the category of the most popular connecting elements. It has a high level of strength, demonstrates excellent flexibility and costs quite reasonable money.

It is made from vulcanized rubber reinforced with textile thread. It functions perfectly in the temperature range from -35 ° C to + 50 ° C and can easily withstand severe operational load for a long time.

If the unit has a 3/8 'thread, then for a correct connection to the system, you will need to use a special adapter. Almost always, it comes complete with a stove. In case of absence, the item is purchased at a hardware store

Metal braided rubber hose is an improved version of the above described option. The metal casing provides even greater product strength and virtually eliminates the occurrence of leakage.

The product is offered on the market in the widest assortment and has various lengths. This allows the use of this type of hose in any kitchen facilities and even where the stove is used with maximum intensity.

Bellows hose - This is a flexible piece of metal-plastic corrugated tube with excellent physical characteristics. It is produced using modern technologies, it is resistant to intense pressure and its drops, stretches well and has a surface protective shell of high strength.

Bellows are reproached with only a rather high price compared to similar products made from cheaper materials.

However, despite this, representatives of gas distribution companies strongly advise the owners to connect the stoves through the bellows hose in order to increase the level of safety during the operation of home gas units.

For more information on the classification of gas hoses and their selection, see this article.

Basic hose requirements

The connecting hose used to connect the stove to the central gas system must meet certain requirements ^

- limited length - no more than 1.5 meters;

- evenness - the surface of the part without extensions or narrowed sections;

- lack of bends, knots and twists;

- durability - the service life can be obtained from the seller or from the quality certificates confirming the compliance of the hose with the standards generally accepted for gas equipment;

- no cracks, incisions, rust and other visible damage.

Another important point to consider is that the hose must under no circumstances touch hard, sharp corners and materials subject to burning.

It is better if it will be freely located behind the plate, not adhering to any surface. Then the owners will be able to easily control his condition and will not miss the moment when required hose replacement.

Pipe connection

Connecting the stove to a centralized system using a metal pipe is a very reliable, but already outdated method. Today it is rarely used due to the complexity and the need in some cases to use specific professional equipment.

The main disadvantage of connecting with pipes is that in the future the stove can not be moved away for cleaning or moved to another place without resorting to disconnecting from the central communications.

Types of gaskets for gas systems

So that the connection points of the stove to the gas distribution system do not leak and ensure the tightness of all communications for years, use special sealants, for example, Loktayt 55 thread or FUM tape.

Employees of gas services do not recommend connecting elements from other materials. Their performance is too weak for such an impressive daily load.

Thread Loktayt 55 - A practical, modern material designed specifically for reliable fixation of connecting sections in communication networks of varying degrees of complexity.

It is a sealing fiber made of high-strength multifilament yarns, supplied in plastic containers and has various lengths (from 12 to 160 m, depending on the packaging).

To create a tight connection, I manually wind the thread on the threaded section of the pipe fittings. It is instantly fixed in place and no longer changes its position.

The second reliable sealing element is FUM tapemade of PTFE 4D.

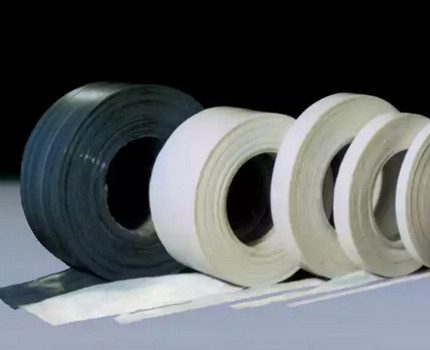

There are three types of FUM tapes on the market:

- Brand 1 equipped with additional lubricant based on petroleum jelly. It is used in industrial systems and communication networks with caustic, aggressive environments.

- Brand 2 It has no lubrication and is best manifested in complexes operating on various oxidizing agents.

- Brand 3 produced using edge fragments of the first two types and is suitable for both industrial and domestic purposes.

It is a thin thread laid in a film.

The FUM tape allows for a strong connection of the pipe elements, which for many years will provide the system with complete tightness. The warranty shelf life of the tape in the container is 13 years.

Step-by-step process for connecting a gas stove

Before connecting a gas stove in a house or apartment, they find the most convenient place for it. Then remove the original packaging, screw the adjusting legs to the bottom of the unit and place the module in the selected area.

Between the equipment and the wall leave a gap corresponding to the dimensions indicated in the accompanying instructions for household appliances.

A building level is laid near one of the sides, and then, with the help of the adjusting legs, the slab is exposed as evenly as possible. First, carefully twist the legs on one side, and then on the other.

After all these measures, the unit takes a hard position, does not swing and does not roll either to the right or to the left.

Next, connect the equipment with a flexible hose. To do this, from the outside, a layer of a special sealant is carefully wound on the thread of the hose fitting (Loktayt 55 thread or FUM tape, designed to fix individual sections in communication systems).

This will ensure further reliability and complete tightness of the complex.

The hose fitting with gasket is screwed into the gas valve at the lower end, and the second open edge of the hose is screwed into the outlet thread of the gas stove.

When household appliances are connected for the first time, they turn to a specialized service and invite a professional craftsman with the appropriate knowledge and the right to activate the equipment.

In the presence of a gas service officer, all docking places are treated with a medium concentration soap emulsion, the tap is opened and the system is tested for possible leaks. If the gasman does not detect any problems, they begin to use the stove in standard mode.

Safety Rules and Tips

Self-installation of a gas stove is carried out in strict accordance with safety rules governing actions in contact with gas networks.

Norms required:

- The flexible hose connecting the unit to the gas supply system is placed in plain sight in an easily accessible place and in no case is it blocked. This item should always be available for inspection or planned replacement.

- A gas hose is made in strict accordance with generally accepted regulatory documents, not exceeding the permitted size per inch.

- The connecting sleeve itself is not painted, since the paint damages the surface and contributes to its premature cracking. If the appearance of the sleeve is not too aesthetic, it is masked under self-adhesive paper.

- Directly connect the hose only to the supply valve and gas stove. The adapter is used only in case of non-standard threaded connection of one of the outputs.

- Prior to the installation of the stove, the gas is shut off, turning the stop valve on the pipe from the supply riser to the stop, and notify everyone in the room about the work in progress.

- During installation, only special tools, consumables, and components used for work with gas valves are used.

- All pipes opened during connection are plugged immediately. For lowering, a thick wet rag is used as a plug. Water, absorbed into the fabric, gives the material a high level of gas impermeability.

- To temporarily close the feed pipe with 1/2 ″ thread, take a cork from the wine bottle. It is cut along the narrowed edge in the shape of a cone, treated with sandpaper and tightly “screwed” into the pipe hole. If the part is stuck, remove using a corkscrew.

At the end of the work, the docked areas are coated with a soap solution of medium concentration, a gas shut-off valve is opened and the system is tested for leaks.

If the soapy liquid begins to bubble, the gas is again shut off and the joint area is brought to complete tightness.

When the hissing is heard during the test run or the smell of gas is felt, the valve is immediately closed, windows, doors are opened and the emergency gas service team is called.

Sometimes when connecting or moving the plate, it may be necessary gas tap replacement. This work is carried out only by representatives of the gas service with a preliminary shutdown of gas throughout the riser.

Conclusions and useful video on the topic

A detailed description of the process of installing a gas stove in an apartment with your own hands. Useful tips and curious nuances of the process. Recommendations for using the tool.

How to easily and quickly connect a gas stove in a residential building, which hoses and other related items to choose. Information on the cost of work.

Overview of bellows hoses for gas fired stoves. Pros and cons of details and expert opinion on whether to use them.

The basic rules for connecting a gas stove in an apartment or a private house are not complicated. If you carefully study the installation instructions, use a suitable tool and observe safety measures, the process will go smoothly and will not take much time.

When there is no self-confidence, it is better to contact the gas distribution company at the place of residence and invite professional craftsmen to the house. They will quickly install and do everything in strict accordance with the regulations and generally accepted standards.

All interested in the issue of connecting a gas stove or oven are invited to leave comments and ask questions. The contact form is located in the lower block.

How to sheathe a gas stove: options and instructions for decorating the wall near the gas stove + security measures

How to sheathe a gas stove: options and instructions for decorating the wall near the gas stove + security measures  How to transfer a gas pipe in an apartment: transfer rules and location tips

How to transfer a gas pipe in an apartment: transfer rules and location tips  Gas hob connection: safe connection instruction

Gas hob connection: safe connection instruction  Do-it-yourself gas hose replacement: installation rules

Do-it-yourself gas hose replacement: installation rules  What to do when water gets into the gas pipe: a review of options for resolving the problem and possible consequences

What to do when water gets into the gas pipe: a review of options for resolving the problem and possible consequences  How to insulate a gas pipe on the street from condensation: an overview of the best materials and installation instructions

How to insulate a gas pipe on the street from condensation: an overview of the best materials and installation instructions  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I think that any adequate man will be able to install the stove himself, without the help of the company, the main thing is to have the necessary tool. Do not take a rubber hose for connection, they crack and pass gas. You need at least a metal braid, or the best option is a bellows hose, although the price will be more expensive, but it's worth it. By the way, hardly anyone will give a FUM tape a guarantee of 13 years, now it is almost all Chinese, there they guarantee a couple of years from the force.

I think, after all, not everyone. For example, I did not even try to connect the stove myself. They don’t joke with gas! Trying to connect, having no experience, just from the pictures and instructions from the Internet is rather reckless, in my opinion. The services of a professional craftsman are not so expensive to take such a risk. And not every house has the right tool.

Hello. Install - please. Though drag it all over the apartment.But ПП№410 prohibits unauthorized connection to networks, up to the threat of disconnection from gas supply. According to Art. 7.19 Administrative Code of the Russian Federation you will be fined for unauthorized connection. And they will easily find out ... right during maintenance, when your stove turns out to be unregistered - “according to PP No. 549, they did not indicate a change in the composition of the gas-using equipment”.

Some say that they say you can install, you can not put into operation. But the connection already implies joining the gas pipeline.

Yes, you need to gain experience with a wrench to unscrew and tighten the two nuts. This is not a joke to you. But expensive or not, everyone has their own opinion on the amount of cash. If for Alexander 2.5 - 3 tr. inexpensive, it’s wonderful, but the rich have their own quirks. Moscow prices.

Gas workers are not punctual; they allow themselves unreasonable snobbery when communicating with consumers. I don’t want to turn to such “specialists” and pay them my money.

Tell me please. I want to change the stove to the gas hob built into the countertop. And as far as I know, there is no lid like on a regular plate in the photo. And my hose goes directly behind the stove. Is it possible to install the VP in this way next to the hose, is this not dangerous?

I do not see any problems, at least those that could not be solved quickly and simply. So, in fact, you do not have any questions regarding the installation of the hob, everything is quite easy here.

Regarding the protection provided by the glass cover, you can mount exactly the same. Only it will not be mounted on the hob, but with the help of special mounts on the wall. For this, special fastenings and anchors are provided. I think this is the optimal solution, it is many times more practical and easier than transferring the hose or changing it to a metal pipe.

The rubber hose can be replaced with a flexible metal hose, then the need for a protective glass disappears. But from the photo it is impossible to determine the distance from the hob to the wall, as well as the possibility of such a connection. Therefore, mounting glass on the wall is the simplest and most practical solution.

Hello. As far as I know, the heating temperature of the hose in no part of it should exceed the room temperature by more than 30 degrees.