Overview of the septic tank “Leader”: device, principle of operation, advantages and disadvantages

When installing an autonomous sewage system, local treatment facilities are used that collect and process domestic wastewater. If you are interested in acquiring a fully equipped factory system, pay attention to the domestic septic tank "Leader", which works on the principle of four-stage cleaning.

The article we presented describes the principle of operation of the plant, which produces a deep degree of treatment of domestic wastewater. We introduce the most popular models of this brand. Independent home masters with us will find installation manuals and useful operating tips.

The content of the article:

- Description of the design of VOCs from “Leader”

- The principle of operation of the autonomous system

- How to choose the right model?

- Advantages and disadvantages of constructions of the brand "Leader"

- Installation and Maintenance Recommendations

- Actual cost of septic tanks and service prices

- Conclusions and useful video on the topic

Description of the design of VOCs from “Leader”

A compact but roomy design is a container, the inside of which is divided into several compartments. The volume of the inner chambers, respectively, and the dimensions of the tank as a whole depend on the amount of incoming waste.

The material of manufacture is low-pressure polyethylene, characterized by wear resistance and resistance to high and low temperatures. The walls of the polymer are still good in that they withstand the pressure of the soil, do not rust and do not become moldy.

Upon purchase of one of the Leader models for arrangement independent sewage You will receive the following kit:

- housing;

- Japanese-made compressor (HIBLOW);

- two types of crushed stone for filling: calcareous and granite;

- set of polymer ruffs;

- instruction and warranty card.

There are two options for VOC “Leader”: both consist of several functional compartments for various purposes. The first modification is intended for a gravity drainage method.

The second variety is called "Leader n", as it is additionally equipped with a drainage pump.

Inside, the design is divided into 6 technological tanks, each of which has its own purpose:

- 1 - septic tank receiving sewage; primary fermentation and separation of waste occurs in it;

- 2 - bioreactor with artificial algae, facilitating the oxidation of substances by anaerobes;

- 3 - aerotank of the 1st stage, in which the decay of waste continues, but with the help of aerobes;

- 4 - secondary sump separating clarified wastewater and activated sludge;

- 5 - aeration tank of the 2nd stage, in which further oxidation and neutralization of phosphates occurs;

- 6 - tertiary sedimentation tank for separation of sediment.

The first sedimentation tank is not equipped with equipment, the rest install additional parts and fill up the filler. Artificial algae is loaded into the bioreactor and the deep purification chamber.

Aerotanks are supplied with perforated aerators and loads, granite and limestone. In the sumps, in addition to the first, airlifts for pumping sludge are installed.

In the last chamber of the Leader n models, there is a drainage pump, with the help of which the cleaned sewage is pumped as intended - into an absorbing well, into a pond or a gutter.

The principle of operation of the autonomous system

Biological treatment is a multi-stage process that is carried out by microorganisms, aerobes and anaerobes. In order to process more efficiently, at the first stage, in the sump, there is a mechanical separation of particles.

Solid insoluble elements fall to the bottom in the form of sediment, fat floats to the surface, as a result, the liquid partially clarifies. Fermentation of sewage begins here.

In the next compartment - the bioreactor - fermentation takes an active phase. The chamber is filled with artificial algae, which are products from a ruff-type polymer fishing line.

Anaerobes, for which vital activity does not require oxygen, form colonies on algae. By processing incoming wastewater, they facilitate the oxidation process.

The third chamber is intended for further clarification of the liquid. Oxygen entering the compartment through perforated polymer tubes, and aerobic bacteria that multiply on a porous charge (gravel backfill) in the form of activated sludge, continue to oxidize and process organics.

Further, the effluents are separated: the clarified water flows further to the next purification stage, and the excess sludge is removed using an airlift.

The next chamber, an aerobic bioreactor with polymer loading, performs the purification of already partially clarified effluents. At the same time, neutralization of phosphates occurs - for this, limestone crushed stone is created at the bottom of the compartment, creating an alkaline environment.

The precipitate formed during the cleaning process is also removed by airlift. From the last chamber, the purified liquid is discharged out, by gravity or by force (pump).

As solid sludge accumulates in the sump, scavengers are called up, other technological work can be carried out on their own.

How to choose the right model?

When choosing a bioremediation station, it is necessary to take into account many factors, from the possibility of connecting to power supply to the technical characteristics of the device (capacity, volume, etc.). In order not to be mistaken, it is better to consult with a consultant - a specialist from the manufacturing company who will recommend a suitable model.

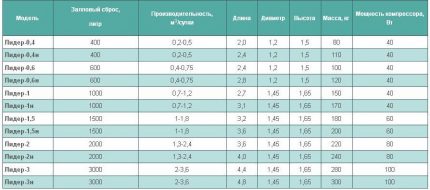

Overview of the VOC Leader lineup

Knowing the technical characteristics of the septic tank and the number of people constantly living in the house, you can choose a suitable installation for performance. The dimensions of the device directly depend on the performance: the higher it is, the larger the dimensions. With increasing productivity, the weight also increases, but the mass of models with a pump is always greater than without it.

In total, there are 28 models. When marking them, the presence of a pump and the volume of volley discharge were taken into account. For example, if a salvo discharge is 600 l, the model is called “Leader-0.6”, a similar device equipped with a pump is “Leader-0.6n”.

The most compact versions are Leader-0.4 and Leader-0.4n. They are designed for a volley discharge of 400 l and have a capacity of 0.2 to 0.5 m3/day. Given that there is approximately 200 l / day per person, the smallest model is suitable for houses with 1-2 permanent residents.

The most voluminous model of household devices, that is, intended for private use, is “Leader-3” (“Leader-3n”). Judging by the performance (from 2 to 3.6 m3/ day), it is able to serve a group of people from 10-15 people.

Power is tied to performance compressorsupplying air to the aerators. For models "Leader-0.4 ... 1" a compressor with a power of 40 W is designed, modifications of 1.5 - 60 W, etc.

The diameter and height of the case have slight differences in size, the main difference concerns the length. This should be taken into account when arranging the foundation pit.

More powerful modifications are provided for hotels, hotels, sports bases - up to the Leader-25 model (Leader-25n).

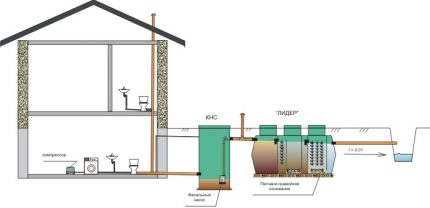

Connection and drainage schemes

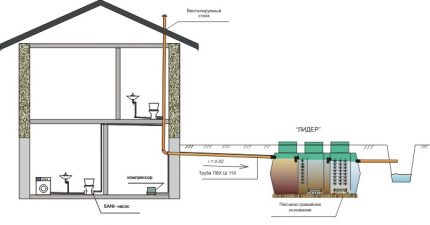

When choosing a scheme for discharging treated water, one of the main factors is the presence of a reservoir for the disposal of recycled waste water. The role of such a reservoir can play a ditch, drainage ditch, pond.

If there is the possibility of laying pipes at an angle (0.02 m / m), it is rational to apply a gravity-fed method in which drains without the help of additional equipment enter the septic tank and from the septic tank into the ditch.

However, two more conditions must be met:

- the pond should be near the VOC;

- the sewer pipe must exit the building at least 0.3 m from the ground surface.

A gravity-free method of moving wastewater is used without connecting additional electrical equipment, therefore, it is economical.

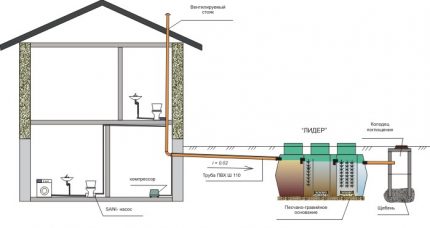

The following drainage scheme differs from the first only in the final discharge point: instead of a ditch or pond, absorbing well.

It may be required if:

- the ditch (ditch, pond) is absent or far away;

- suburban area located in the conservation area;

- neighbors do not give consent;

- there are other reasons why an open discharge is not desirable.

The absorbing well will function correctly in sandy soils with high filtering ability.

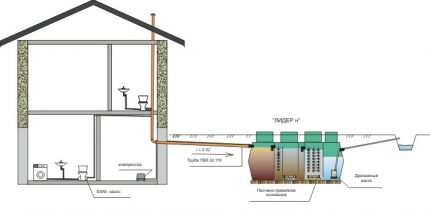

If the reservoir intended for draining the effluent is too small (its bottom is above the drain pipe) or is located at a far distance, it is rational to use a pump drainage scheme. In the last camera set drainage pump, which provides forced fluid movement.

The connection problem can be encountered if the sewage system is present in the basement or basement, and there is no possibility of gravity drainage, that is, the pipe leaves the house too low in the ground (below half a meter from the surface).

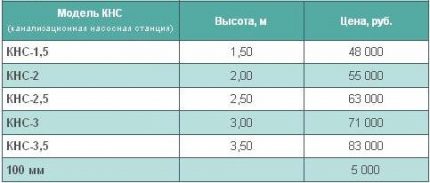

In this case, it is necessary to equip the so-called sewerage pumping station in front of the septic tank - a separate well equipped fecal pump. SPS is purchased separately.

Installation connection and drainage require a professional approach, therefore, consulting or monitoring a representative of a company that has carried out installation supervision will not hurt.

Advantages and disadvantages of constructions of the brand "Leader"

One of the advantages that Leader brand devices have is the location of the structure relative to a residential building. Due to the absence of an unpleasant odor and the quiet operation of the equipment, the septic tank can be placed at the minimum allowable distance of 5 m (SNiP).

Other norms should be taken into account, for example, to the nearest well - 25-30 m with disconnected sandy (gravel, gravel) soils, 45-50 m in the presence of cohesive, i.e. clay rocks (loam, sandy loam).

Residents of cottages, who have been using septic tanks for several years, note such advantages as:

- high efficiency of sewage treatment - several processing chambers are able to clean the liquid by 95%;

- the ability to work without biologically active additives, which are recommended to be added to septic tanks by specialists of some companies;

- stable operation even with regular long interruptions in the supply of wastewater, during which conservation is not required

- easy tolerance of power outages - in case of force majeure circumstances, the system is able to work in normal mode for 2 weeks, without changing the properties of purified water;

- the possibility of using one of the drainage schemes with orientation to the type of reservoir or the presence of a facility for discharge of purified liquid;

- compactness of the structure, which allows economically distributing the free territory of the site;

- the ability to install in clay soil or on a site with high groundwater without a specially provided concrete base (the presence of a stable concrete slab at the bottom of the pit is one of the conditions for the installation of septic tanks from competitors).

The manufacturer recommends choosing a structure so that the useful volume of the device is about 3 times more than the daily amount of sewage. Many consider this a drawback, in fact, this ratio helps to easily withstand volley discharges and clean the liquid by at least 95%.

Another plus can be found by buying the Leader cleaning system directly from the manufacturer. Without extra charges, the cost of equipment, which belongs to the middle price segment, is much lower.

One of the minuses is the poor functioning of the installation at low temperatures and the need for additional insulation, however, this problem applies to any VOCs.

Some users report a bad smell, but it is most likely due to improper installation or untimely removal of sludge or sludge. According to reviews, it can be judged that the advantages of the septic tank Leader prevail over its shortcomings.

Installation and Maintenance Recommendations

It is better to dig a pit for installation aside from roads in order to protect the septic tank from accidental collision. The case is a single tank, so even a small breakdown or leakage can lead to a complete replacement of the device.

In addition to the basic rules for installing a septic tank in a pit, you need to know a few more engineering nuances:

- for external sewage it is necessary to use polymer pipes with Ø 100-110 mm;

- the slope of the supply pipe is 0.02 m per meter of length;

- the slope of the discharge pipe is 0.05 m per meter of length (should not be too long);

- the foundation pit is filled with sand or sand and gravel and carefully compacted (concreting or installation of a concrete slab is not necessary);

- the liquid inside the housing must reach the level of weirs;

- insulated hatches intended for maintenance must be kept closed.

A few notes relate to compressor installation. It must be in the winter in a heated room (basement, utility room), for ease of maintenance - near the outlet of the sewer. For the operation of the device, a power point is required.

When sediment extraction is in progress, the compressor should be shut off.

During the operation of the septic tank, ensure that the performance matches the nominal value. If it exceeds the declared performance by 20%, you should consider replacing the installation with a more powerful one. When using a biological station, it is necessary to review the range of detergents and cleaning products: they should not include petroleum products or chlorine.

The owner of a septic tank "Leader" can produce the main part of the service independently. Once every three years it will be necessary to replenish the lime filling in 2 aerotanks, and the walls of the hull and weirs will have to be cleaned with the same frequency.

Every year, polymer rinsing should be washed, and excess activated sludge should be pumped to the first compartment (receiving chamber) using airlifts. Sludge is removed as it accumulates, approximately every 3-6 months. Once a year, the removal of accumulated sludge will require the help of sewage collectors.

If the seasonal operation of the Leader brand sewage treatment plant is planned, it will be necessary to preserve for the winter. What it consists of, you will learn from our recommended article.

Actual cost of septic tanks and service prices

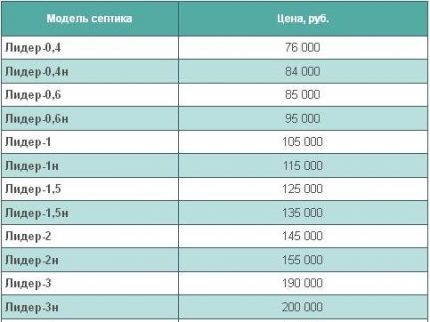

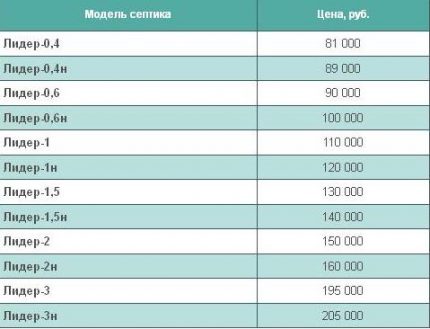

The price of the kit, which includes the case and the necessary equipment, differs when buying in different regions. For example, in February 2017, Leader-0.4 in Moscow costs 76 thousand rubles, the same model in St. Petersburg for 5 thousand rubles. more expensive - 81 thousand rubles. The cost of modification with a pump is even higher.

Price list with Moscow prices:

For comparison, prices in St. Petersburg:

CNS cost:

To save money, it is better to purchase from an authorized dealer, and not from an intermediary.

In addition to buying a septic tank, you can use the services of consultants. For example, a consultation at the facility with drawing up a connection diagram and estimates will cost 1 thousand rubles. (on weekends - 2 thousand rubles).

You can also order installation of the station - this will be about 30% of the purchase price (without excavation - 20%). Annual service package - 12 thousand rubles.

Conclusions and useful video on the topic

A few video sketches will give you an idea of how the biological treatment plant looks and functions.

Video # 1: How the installation works:

Video # 2. A clip giving an idea of the quality of sewage treatment:

Video # 3. Quality control of cleaning in the cold winter period:

As you can see, the Leader septic tank has decent technical characteristics for effective use in stand-alone conditions. To ensure that the quality of the effluents meets the declared parameters, we recommend that you operate the installation in accordance with the instructions.

Tell us about your experience in the construction of an independent sewage system with a Leader brand sewage treatment plant or similar installation. It is possible that you have information that will be useful to visitors to the site. Please write comments, ask questions and post photos in the block form below.

Overview of the cedar septic tank: device, principle of operation, advantages and disadvantages

Overview of the cedar septic tank: device, principle of operation, advantages and disadvantages  Overview of the Eco-Grand septic tank: device, principle of operation, advantages and disadvantages of the system

Overview of the Eco-Grand septic tank: device, principle of operation, advantages and disadvantages of the system  Overview of the Tver septic tank: device, principle of operation, advantages and disadvantages

Overview of the Tver septic tank: device, principle of operation, advantages and disadvantages  Overview of the Rostock septic tank: device, lineup, advantages and disadvantages

Overview of the Rostock septic tank: device, lineup, advantages and disadvantages  Overview of the septic tank “Eurobion Yubas”: device, advantages and disadvantages, comparison with competitors

Overview of the septic tank “Eurobion Yubas”: device, advantages and disadvantages, comparison with competitors  Overview septic tank for giving “Topas”: principle of operation, device, advantages and disadvantages

Overview septic tank for giving “Topas”: principle of operation, device, advantages and disadvantages  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Excellent not whimsical treatment plant, no dirt, no smell. I pump it out once a year.

Suitable for Siberia? Need to be insulated additionally? Or is it better to take another model for our edges?

It depends on how deep you will be in the septic tank. If you plan to go deep by 1.5-2 meters, then additional insulation of the septic tank is not needed. If the septic tank is very close to the surface, then the optimal solution would be to insulate it with penoplex. I believe that penoplex is the best insulation in this case, based on the characteristics and ease of installation.

In winter, it is necessary to move the compressor from the septic tank to a warm room so that the system works without interruptions. Also, do not forget to insulate the pipes leading to the septic tank, in this case it is better to use polystyrene, there are special heaters for the shape of the pipes.