How to build a drain pit of brick: options and methods of arrangement

Are you planning to build a drainage system in a suburban area by equipping a pit? Agree that a cottage or a house of permanent residence with all amenities will be much more comfortable. But you do not know how a brick drain pit is constructed and what consumables are required for this?

We will help you cope with the task - the article discusses the popular varieties of a cellar made of bricks. And also the step-by-step process of constructing such a sewer, starting with choosing a place for the pit and calculating its dimensions.

The material is equipped with visual photographs. Also selected videos with useful tips on self-construction of a brick tank for wastewater. The advantages and features of its operation and periodic maintenance are considered.

The content of the article:

The principle of operation of the drain pit

A drain or cesspool is one of the oldest options for sewage collection and primary processing of sewage on the ground. It can be built without even having any construction experience.

Moreover, often such a device is created on the site at the very beginning of construction work to provide builders with a minimum set of amenities.

Technically, the drain pit is the simplest septic tank or accumulator of human waste. To this tank, located underground, a sewer pipe leading from the house is brought.

The pipes of a separate toilet, bathhouse and other premises available on the site are also brought to it.

One common cesspool on the site is not the only option for organizing such a system. If desired, you can make a separate small container for each room.

Such a solution may be convenient, for example, if the bath is located at a considerable distance from the rest of the buildings.

Waste is gradually accumulated and partially disposed of depending on the type of construction. As the pit is filled with drains, it is necessary to clean it to prevent overfilling of the structure.

Modern tools allow for the disposal of waste with a fairly high degree of efficiency. We recommend that you familiarize yourself with the best methods for cleaning cesspools.

Varieties of cesspools

From a brick, you can build a cesspool of any type:

- tight;

- with permeable walls;

- without bottom;

- divided into several sections.

Each structure has certain characteristics. For instance, sealed pit used in areas with high groundwater levels. This design prevents the likelihood of environmental pollution by effluents.

Permeable drain pitsintended for the processing and disposal of gray effluents are arranged with a meter sand and gravel filter in the bottom area.

With insufficient capacity of the underlying rocks, they are equipped with small holes in the walls through which the liquid part of the waste is utilized.

In the so-called pits without bottom the lower part is not concreted. The walls of such structures are erected on a concrete base with a clearance in which a sand-gravel filter is laid directly on the ground.

Liquid runoff will slowly seep through this natural filter, and then fall into the underlying subterranean formations, where they undergo their final treatment. Using a brick allows you to create a sealed drain hole, as well as its permeable version. Most often, such structures are made with a rectangular base, this is the simplest scheme.

Divided into several sections. A large pit can be divided by partitions into two or three sections, which are connected by overflows.

Such a device, like a septic septic tank, allows you to repeatedly separate the bulk of solid and liquid waste and increase the degree of their processing using bacteria.

Features of a brick structure

The use of bricks for the construction of the walls of a cesspool has several advantages. This material perfectly retains impurities and is durable. Using masonry, you can create a structure of any size and configuration.

When using concrete rings, you have to adapt to their typical sizes. Pouring monolithic concrete is no less time-consuming process than bricklaying.

For a cesspool, it is not necessary to use high-class material, bricks that were previously used earlier will do.

Masonry work requires certain skills, this is a real building art.It is best to master such operations precisely on the construction of sewer structures, since all flaws will be hidden underground in the future.

And yet you should not do the masonry very casually. An uneven brick wall may collapse over time.

A brick drive has one useful property - it is stable at almost any level of groundwater, it is well resistant to soil swelling during freezing in the winter.

Such a drain hole can be arranged both on light sandy soils and on heavy clay soils.

Useful recommendations for the construction of a brick pit are given in the following photo selection.

Example of constructing a shower pit and toilet

As an illustrative example, consider an example of the construction of a brick pit for receiving drains from a country shower and toilet. This decision is justified by its small size and lack of ability to arrange objects separately.

The pit will be located directly under the toilet, and a ladder will be led out of the shower into it.

The main work is done. Now you need to pour concrete into the formwork and put the vital hygiene objects:

The shower frame is better sheathed with waterproof material, for example, cellular or monolithic polycarbonate, plexiglass. For flashing the toilet, any chipboard or fiberboard, board, and similar materials are suitable.

The intricacies of building a brick pit

Before starting work, you need to determine the size of the future cesspool, and also find a suitable place for the construction.

Stage # 1 - preliminary calculations

The simplest calculation option is according to the average standard. The number of people permanently living in the house is multiplied by the norm of 0.5 cubic meters. meters.

After that, it is necessary to calculate the parameters of the cesspool depending on its configuration. Capacity is usually made in the form of a cube or cylinder. The first option is preferable, since it is easier to lay a container with straight walls with a brick.

The depth of the pit should be no more than three meters, but practice shows that to service sewers with a depth of less than two meters or less. The volume of the pit now needs to be divided by the selected height. The resulting figure will be the base area.

It remains to choose the length and width for the container with a rectangular base. If you decide to dig a cylindrical hole, you will have to use the circle area formula:

S = πr2

Where:

- S - area of the structure;

- π - the number "pi" equal to 3.14;

- r - radius of the structure.

The resulting area should be divided by 3.14, i.e. by the number pi. From the result, which is the square of the radius of the circle, you need to extract the root, having received the radius of the base of this cylinder.

Before marking, all parameters must be increased by the size of the brickwork and concrete foundation. This role is usually played by a concrete slab 30-40 cm thick.

A concrete screed should have approximately the same dimensions. The thickness of the brickwork for sewer structures should be 25 cm on the outer contour, and 12-13 cm is enough for the internal walls.

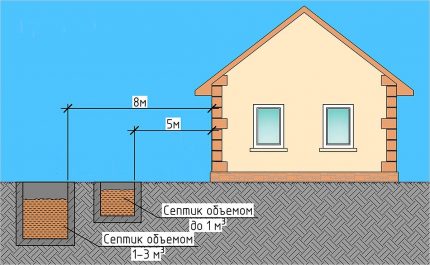

When choosing the parameters of the tank, it should be remembered that its filling by more than two-thirds is undesirable, therefore, the depth of the pit under the cesspool should be increased to the required size. When choosing a place for construction, a number of sanitary standards should be taken into account.

For example, the distance from the sewage store to the apartment building should be at least five meters, to the fence - at least two meters, to the source of drinking water - at least 25 meters, etc.

In addition, in areas with a heterogeneous relief, sewer devices should be located lower than the source of water. Finally, it should be possible to drive up for special construction equipment.

The machine does not have to be in close proximity to the cesspool, but the distance between them should not exceed a limit of four meters.

Stage # 2 - earthworks

After the marking is completed, you can start digging the pit. It is easiest to order the services of an excavator, but if you need a small capacity and have a desire to save, you can handle it manually.

The technology of work is very simple: they dig the earth with a bayonet shovel, and as the foundation pit deepens, they select it with a bucket on a rope. A ladder will come in handy to get out of the pit, as well as the usual construction level to control the quality of work.

The walls of the pit are usually made vertical, but a slight slope is attached to the bottom so that the contents of the tank accumulate in the corner above which the service hatch will be located.

In the future, this moment will facilitate the pumping of waste from the tank.On light soils, walls may need protection against shedding, for example, using temporary wooden structures.

Stage # 3 - installation of concrete foundation

If the bottom of the pit is supposed to be sealed, then either a concrete slab should be laid down, or concrete work should be performed. In the first case, everything is simple: they select a reinforced concrete structure of suitable sizes and install it below.

If it is decided to concrete the bottom, then first lay down a sand cushion about 15 cm thick. Sand should be leveled and compacted, observing the previously made slope.

Then, a reinforcing mesh is laid at the bottom and a cement-sand screed is poured. After this, you need to wait until the concrete base hardens.

It takes about four weeks for it to completely dry, but when constructing a cesspool, work usually continues as early as seven days after the foundation is poured.

If it is planned to construct a cesspool without a bottom, only the space over which the walls will be erected should be poured with concrete screed.

Open ground is left in the center, onto which a sand and gravel filter is subsequently laid. To properly fill the concrete base in this case, you will need to build a wooden formwork.

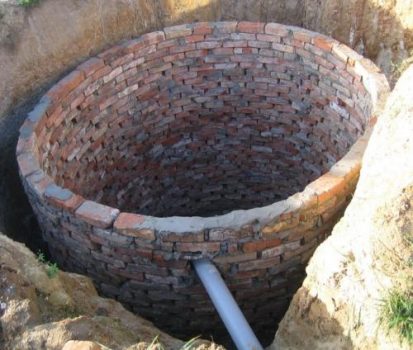

Stage # 4 - bricking

For a cesspool, it is recommended to use a strong red ceramic brick, but white silicate is also considered quite suitable.

To prepare the masonry mortar, you will need the following ingredients:

- cement M400 brands - 1 part;

- building sand - 3 parts;

- water - 0.8 parts;

- slaked lime or clay - 0.5 parts.

Sand and cement need to be sieved so that there are no solid inclusions, this will make the solution homogeneous and bring it to the consistency of liquid sour cream.

First, a clay castle is made on the base, the first row of bricks is laid on it. The masonry is immediately leveled with a level. The thickness of the clay castle will be heterogeneous, since the bottom is made with a slope.

First, lighthouse bricks are put in the corners, their position is carefully leveled. Next, the masonry is performed by rope beacons, which are pulled for each row.

Experienced craftsmen can do the laying of three rows at once or use a special rail-order. It is recommended for beginners to first check literally every brick laid.

Using a plumb line, they control the quality of the masonry vertically so that the wall is even.

Depending on the thickness of the wall, a brick masonry scheme is chosen. If it is necessary to make a wall 25 cm thick, then the brickwork is done “in one brick”, and if 12 cm - “in half a brick”. The length of the brick corresponds to the width of the wall.

Of course, a permeable cesspool does not. Usually it is placed “in a half-brick”, while gaps are made between the individual bricks so that liquid drains can exit through these holes.

In any case, you should adhere to the rule: vertical seams between bricks in adjacent rows should not coincide. Masonry is performed as follows: a small amount of solution is applied to the surface of the base with a trowel.

They lay and press a brick on top, gently tapping it with a trowel so that it takes the right position.

Then the excess solution is picked up with a trowel. There is another technology: the solution is applied to a separate brick, then it is installed in place.

Here are some useful masonry tips:

- The dimensions of the joint filled between the bricks should be about 6-8 mm.

- The seam everywhere should be the same size everywhere, this will improve the quality of work.

- The brick should be laid out along the walls in small portions to reduce the time of work (you do not have to bring each brick from a common pile).

- Before laying, the bricks are poured with water, this improves the adhesion of the surface to the solution.

- Every fifth row is recommended to be laid using a special reinforcing mesh.

Of course, a sewer pipe must be brought to the cesspool. The entry point should be carefully treated with a solution so that there are no leaks.

The pipe must be properly insulated, laid below the level of soil freezing with the necessary slope. We recommend to look at the detailed information on material for insulation of the sewer pipe in this article.

After the masonry work is completed, the walls need to be plastered.

Stage # 5 - waterproofing and ceiling

A layer of waterproofing material, for example, bitumen mastic, is placed on the plaster. These measures will help extend the life of your sewer device.

When applying waterproofing materials, you must strictly follow the instructions. For example, a mastic requires a dry base.

Now you can set the upper overlap. To do this, it is best to purchase a ready-made concrete slab with a hole and a cover - sewer manhole.

As an alternative, you can consider a concrete structure of your own manufacture or overlapping of wood. The latter option does not differ in strength; every few years, such an overlap will have to be replaced.

If you decide to make the floor of concrete yourself, you should start to do it simultaneously with the base and using a similar technology. Pouring is performed in wooden formwork.

The parameters of the upper floor must exceed the size of the hole that it will close by at least 30 cm.

First, a layer of the solution is poured a few centimeters, then the reinforcement is installed and the main layer is poured. This item should dry for four weeks. In the upper ceiling, you need to make another hole - ventilation.

The sewer device needs proper ventilation, as over time, waste water begins to emit methane, which is a dangerous gas.

To organize natural ventilation using a plastic pipe with a diameter of about 100 mm. The pipe is covered with a protective device from above, its lower part also does not hurt to equip the grill.

After installing the ceiling, a waterproofing layer should be applied over the structure, roofing material and even a thick plastic film will do.

A soil-plant layer is usually laid on top to ennoble the site and protect the cesspool from freezing in winter.

Features of the operation of the device

The main care for the cesspool is to empty and clean it in a timely manner. Substantial assistance in the processing and disposal of waste can be special bacteriadesigned for cesspools.

Such preparations are usually provided with detailed instructions and are very easy to use. They must either simply be poured / poured into the sewer, or pre-mixed with a certain amount of water.

Such microorganisms are able to process effluents, decomposing them into safe components. At the same time, the smell characteristic of sewer devices also disappears.

But at the same time, it should be remembered that contact with certain types of household chemicals is harmful for bacteria, so you will have to check the composition of the washing and cleaning products that are available in the house.

After the cesspool has been cleaned, it does not hurt to inspect it and check the integrity of the brick walls. If necessary, perform minor repairs of the structure: replace damaged bricks with whole ones, restore damaged waterproofing, etc.

In addition to bricks, concrete rings, tires, a barrel and so on can serve as a material for the manufacture of a cesspool.

Detailed guidelines for the manufacture of racks from various types of materials can be found in the following articles posted on our website:

- Barrel pit: step-by-step master-class on arrangement

- How to construct a cesspool of concrete rings: schemes + step-by-step guide

- How to build a cesspool of tires: step-by-step technology of self-construction

- Plastic cesspool: how to choose a container and properly equip a plastic pit

Conclusions and useful video on the topic

The process of laying bricks when creating a permeable cesspool is presented here:

This video describes the process of creating a cesspool on a site with high groundwater:

Brick cesspool - a reliable and convenient construction. To make such a device is not easy, but all efforts will pay off, because if the technology is followed, such a device can last for many years.

Do you use a do-it-yourself brick pit as a sewer? Or are you planning a construction of a cesspool? Maybe you still have questions after reading this material? Ask them in the comments to our article - we will try to clarify the difficult points.

How a cesspool is constructed without a bottom: schemes and arrangement rules

How a cesspool is constructed without a bottom: schemes and arrangement rules  How a cesspool is constructed in a private house: a review of structures + rules for their arrangement

How a cesspool is constructed in a private house: a review of structures + rules for their arrangement  How to construct a cesspool of concrete rings: schemes + step-by-step guide

How to construct a cesspool of concrete rings: schemes + step-by-step guide  Do-it-yourself pit in a private house: how to dig and equip yourself

Do-it-yourself pit in a private house: how to dig and equip yourself  DIY drain pit from tires: step-by-step instructions for arranging

DIY drain pit from tires: step-by-step instructions for arranging  Do-it-yourself cesspool: analysis of popular options for arranging

Do-it-yourself cesspool: analysis of popular options for arranging  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Now I am engaged in the construction of a cesspool just of brick. And already regretted his choice, it would be better to make a shaft of concrete rings, it would be faster. I’ve been driving the pit for two months now, I can’t finish it. I reassure myself only that the sewer well with brick walls will last longer. The brickwork is ready, it remains only to connect the pipe, plaster and block. I will try to finish in two weeks.

Himself made a drain well. If you really make it out of brick, then do it yourself. I myself am a mason, and therefore I laid the masonry myself. I left the brick from disassembling the old garage (still Sovdepovsky). I’m talking about this: it will be a little expensive if you hire someone from the side to lay out. And the brick is not cheap. I would advise you to dig a hole to put the inner formwork and everything in concrete. This is for me the best option. Even from ready-made concrete rings, you can quickly build. And so on the site everything is specifically painted.