Do-it-yourself pit in a private house: how to dig and equip yourself

In small towns there is no common sewage system. At the same time, the need for safe collection of sewage in a suburban area plays an important role. Do you agree? A well-equipped drain pit in a private house will perfectly cope with the responsibilities of receiving and partially disposing of sewage.

But is it able to provide comfort and epidemiological safety to households? How to make sure that the pit does not cause trouble? These issues should be carefully considered before deciding on the device of such a system.

We will also discuss solutions to the problem of wastewater in a suburban area and talk about how to independently build a cesspool and what is needed for this. The article contains expert advice, photo and video materials that help to better understand the arrangement of a sewer point on the site.

The content of the article:

Features of local sewage

The operation of a suburban household is associated with the generation of wastewater. Each homeowner is faced with the task of not so much accumulating domestic wastewater as cleaning it. Moreover, a solution common in rural areas - digging an old barrel or tank under the sewer cesspool - is ineffective.

If the daily volume of effluents exceeds one cubic meter (1000 l), then the disadvantages "Barrel" septic tanks unpleasant odors will soon manifest themselves. Or worse, intestinal infections among households. Finally, a self-organized drain pit from a worn barrel is illegal in some situations.

Russian regulations require private homeowners to comply with measures to protect groundwater from pollution by domestic wastewater.

Law “On the Sanitary and Epidemiological Well-Being of the Population” (No. 52-FZ of March 30, 1999) and “Hygienic requirements for the protection of groundwater from pollution (SP 2.1.5.1059-01) charge homeowners with a solution to the sewage problem.

In turn, "Sanitary rules for the maintenance of the territory of populated areas" (SanPiN 42-128-4690-88), "Planning and development of horticultural (suburban) associations of citizens, structures and buildings" (SNiP 30-02-97), as well as Sewerage.

External networks and structures (SP 32.13330.2012) standardize the conditions for the organization and operation of the "pit" sewage system:

- distance from home to the drain pit - from 8 m;

- distance from the well (spring capture) - from 50 m;

- distance from neighboring households (fences) - from 2 m;

- deepening the capacity of the cesspool is carried out to the level of groundwater, but not more than 3 m;

- cleaning is done upon completion, but at least once a year.

Please note - the condition for the distance from the sources of drinking water is valid regardless of where these sources are located.

Those. whoever the closest well is - yours, neighborly or public - cesspool it is permissible to arrange strictly 30 meters from it. Otherwise, there will be expenses for fines, reconstruction of a cesspool to a two-three-chamber septic tank and restoration of the ecological balance in the soil layers.

Cesspool capacity

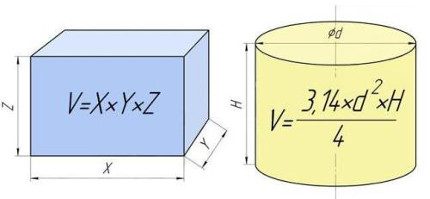

Homeowners need to decide in advance (before choosing the type of cesspool) how to make a drain pit sufficient in volume. Its required capacity is calculated by the formula:

V = ndays• Xpeople• Vday / person

Wherein:

- V - estimated volume of the cesspool, m3;

- Ndays - the number of days the pit accumulated (before pumping out);

- Xpeople - the number of permanent household members;

- Vday / person - daily consumption of water by one household, l.

For example, for a private household with a permanent residence of 5 people, cleaning the cesspool once a month and water consumption of 150 l / person, the volume of the cesspool is: V = 30 • 5 • 150 = 22.5 m3.

We increase the obtained volume by at least 10% (filling the pit to the top is prohibited by the norms) and we obtain the volume of the cesspool: V = 22.5 + 22.5 • 0.1 = 24.75 m3. Round the value to 25 m3 - Better more than less.

The correct value of daily water consumption depends on the household's need for bathing and washing, i.e. from their daily habits. According to statistics, townspeople spend more water than villagers.

Digging deeper than 3 m is not worth it. Its bottom should not directly contact the groundwater horizon; according to the standards, it must be at least 1 m above their level. Let us assume that in the spring-autumn rainy season the overhead water is at a depth of 3.5 m. This means that the depth of the drain hole can be no more than 2.5 m.

Since it is easier to lay the walls of a rectangular cube than a round tank, a rectangular cesspool will be considered. But a round septic tank in terms of operation is more reliable, since the pressure of the soil on its walls is much lower.

Volume is calculated by multiplying the sides of the cube. We determine the long side (width) at the place of future placement of the cesspool, taking into account the convenient access of the cesspool machine. Let the width be 5 m. Then the length will be 25: 2: 5 = 2.5 m.

It is not necessary to get carried away with the capacity of the drain pit. The capacity of the sludge tank, as a rule, does not exceed 10 m3. This means that such special vehicles are not capable of emptying a crowded sewer bunker of a larger volume (as in the example above) and taking out the waste at a time.

It is more rational to arrange a cesspool of up to 10 m3 and empty it every two weeks. After all, a large sewer bunker will take up usable area on a suburban area, which can be used for something no less important.

Construction of an independent sewer system

If a factory-made septic tank is easier to install, then building a single-chamber brick cesspool is cheaper. Such a stockpile of wastewater is quite suitable if there is little space on the site and the daily discharge of sewage does not exceed one cubic meter. We will figure out how to dig and erect brick pit.

Porous or silicate brick is not suitable, you need a material made of fired clay. Only burnt brick walls are capable of holding mechanical loads from soil movements for years, not collapsing under the constant influence of moisture, and generally do not let them pass into their own thickness.

The best option for a brick single-chamber drive is a fully waterproofed design, which is periodically emptied by sewers.

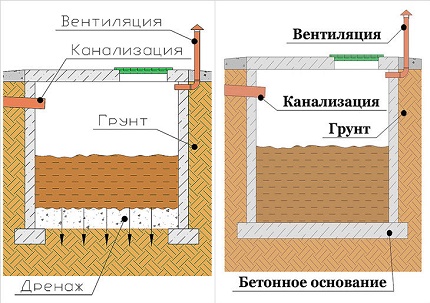

If a drain pit is arranged for the disposal of gray drains coming from a kitchen sink, bath, shower, etc., then a brick structure is arranged with a permeable bottom according to the type filter well.

The bottom of the filtering or otherwise absorption well is filled with a soil filter composed of sand poured in layers, fine, then large gravel or gravel.

The power of the cleaning backfill should be at least 1 m, between its conditional base and the highest level of ground water noted in the rainy period, should be at least a meter.

In the case of installing a brick sewer on sandy soil, the filtration properties of which are not enough for the free passage of treated effluents, its throughput is increased. This is done by forming holes in the lower part of the walls made during the masonry.

We will analyze the construction of the simplest option - a storage pit for waste disposal that does not perform absorption functions. The bottom and its walls will not pass into the environment the waste mass, clarified and disinfected with a soil filter.

Step 1. Digging a pit

Choosing the best drain pit dimensions, proceed to the preparation of the pit. It is necessary to increase the distance between its walls so that from the masonry to the slope of the pit a half-meter indent is preserved. Otherwise, applying external waterproofing to the walls of a brick septic tank will be an impossible task.

Step # 2. Preparing the base of the container

A 200 mm layer of sand pit is poured onto the leveled bottom of the pit, carefully rammed. A ruberoid overlaps on top, it blocks the leakage of cement milk into the ground during concreting.

A mesh reinforcement cage (8-10 mm reinforcement, mesh 100-150 mm) is exposed on the ruberoid flooring. Carry out the frame of the steel flexible wire. Welding is not good, because worsen the strength of reinforced concrete.

Step # 3. Concrete bottom casting

To achieve better waterproofing, a solution of concrete grade M300 and higher should be used. The thickness of the concrete base of the cesspool is 150 mm. From the moment of pouring the bottom with concrete, you should wait 7-10 days, only after you start laying the walls.

Step # 4. The construction of the walls of the drain pit

It is permissible to carry out masonry "in half a brick", using an ordinary solution. However, in the final stage, filling the cavity between the brick walls and the slopes of the foundation pit with a dry cement-sand mixture will be required.

Upon receipt of sedimentary moisture, the mixture hardens and becomes a protective cover for the waste hopper.

Step # 5. Waterproofing

As the brick walls rise, they need to be waterproofed externally with liquid bitumen materials. You can use roll, but their waterproofing efficiency is weaker. Waterproofing should not be postponed - the higher the walls, the more difficult it is to waterproof them.

Step # 6. Finishing the walls of the inside

It is enough to plaster them by introducing liquid glass (potassium, sodium) into the solution. A plaster layer containing liquid glass will significantly reduce the moisture absorption of the walls. Mandatory surface ironing of the plaster with cement.

Step # 7 Overlap of a drain hole

The waste bunker must be blocked with a factory-made concrete slab. Mandatory hatch - through it will be pumped sewage.

Instead of reinforced concrete slabs, wooden boards can be used, tarred and laid on top of roofing material on both sides. The overlap of the sewer structure must be insulated with expanded polystyrene plates, covered with 150-500 mm layer of soil.

A single-chamber cesspool, designed for periodic cleaning with sewage disposal equipment, is suitable for suburban households with temporary residence of people no more than 4. And to ensure the life of a large family, a drain pit with soil filtration of wastewater is needed. The following describes such a complex, designed for a family of 9 people.

The following photo gallery will familiarize you with the device of the drain pit by pouring concrete into the formwork:

Local sewage system with sewage treatment

A cottage equipped with modern sanitary equipment - a bathtub, a toilet bowl and a bidet - there will be fewer bunker-type sewer drives.

The wastewater treatment complex will minimize the number of calls to specialists with treatment equipment, completely close the needs for sewage and avoid local problems with contamination of the soil with sewage.

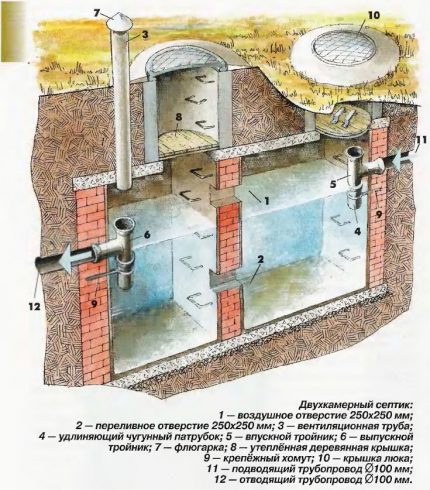

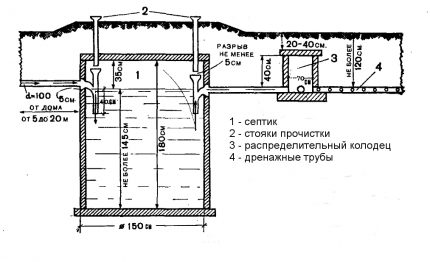

The principle of clarification (treatment) of domestic wastewater through a system of drainage pipes is based on the natural order of filtration of fecal waste, "working" in nature. According to the riser in the house, sewage flows into the pipeline connecting the cottage and the septic tank. Sufficient sewage well - 2.5 m3.

In such a drive, domestic wastewater is clarified with the precipitation of suspended solids. It will require hiring a sludge truck with a team to clean the sludge deposited in the septic tank twice a year.

Self-cleaning with decontamination of sediments in a specially designed compost bin is also acceptable (see below). The clarified sewage water is sent to the drainage network, from where it goes into the ground.

The well of the drain hole is carried out at 5-20 m distance from the house. The main requirement for the location and positioning of the drainage network is a sufficient distance from the building so that the waste water entering the ground does not wash the foundation, does not flood the cellar.

From the sewer-settling tank, the clarified waste stream is first transferred to a distribution well, then from it to a system of perforated drainage pipes made of polymer or asbestos cement.

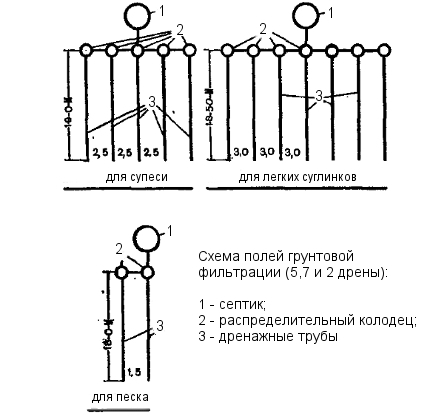

Drainage pipes are laid at a depth of not less than half a meter, actually at the level of development of the soil and plant layer. If the soil developed on sandy soil, then the length of the drains is calculated taking into account 10 m per person.

In soil with a sandy loam base, the length of the perforated pipe should reach 14-17 m, with a loamy base of about 20 m.

Sewage pipes from the well to the accumulation or discharge point should be placed with a slope of 0.02, i.e. per meter should have a 2 cm slope. It is desirable that the main part of the pipeline lay below the freezing depth noted in the region.

Areas above this mark are thermally insulated with a detachable cylindrical insulation made of polystyrene foam, polyurethane foam, polyethylene or slag backfill.

Laying a channel of 100-150 mm of a pipe that drains sewage water into a storage pit is performed at least 50 mm above the distribution well with the piping, through which the clarified drains are directed to sealed drainage pipes.

Inlet and outlet of the pipeline into the pit is performed through tees of 100 mm diameter. Their upper ends must be left open, placing pipes for cleaning above them, having an equal cross section with trays, inlet and outlet drains.

A gap of 50 mm is maintained between the open end of the tee and each cleaning pipe. Sewer pipes made of polyvinyl chloride or polyethylene are used, the diameter of which is 100-150 mm.

A pipe is attached to the lower end of each tee. It must be brought out 400 mm below the calculated water level in the discharge hopper.

All components of the drain pit together with the point of the soil filtration system need ventilation. This function is assigned to the sewer riser inside the house, the upper end of which is displayed above the roof level, the cesspool itself and each sewer pipe.

In the trenches dug under the filter system, pipes are laid with perforation down. Joints of drainage sewer pipes are insulated with roofing material, adhesive tape, simply polyethylene or similar material.

Drainage complex

The body of the wells, in which there are elements of the wiring of the drainage system, designed to collect and drain groundwater, is best done round. When making their walls of brick, 400 mm of the inner diameter of the circle is convenient, of concrete - 700 mm diameter.

The distribution well is not erected above 400 mm, otherwise it will be inconvenient to work with the wiring inside it. Brick walls from the inside must be plastered and iron. Outside, it is permissible to waterproof them with clay or bitumen coating.

The necks of all distribution wells must be closed with covers made of reinforced concrete, plastic or tarred boards. A heat insulator is placed on top - plate polystyrene foam with a surface filling of soil with a layer of 200-400 mm.

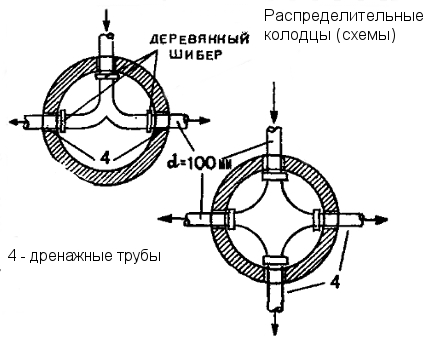

According to the direction of the drains, the wells are equipped with one-, two- and three-sided water inlets - open pipe outlets blocked by vertical gate valves. Wooden gates will be needed to adjust the water supply and during the repair of the well.

Open trays of concrete are formed at the bottom of the water distribution wells leading from the supply pipe to the receiving drainage pipes. The height of the trays should be equal to the diameter of the largest pipe entering the well. Their bottom is brought to the level of the lower wall of the pipes.

In polymer drainage pipes (their lower part), slits of 15 mm wide are cut, up to about half the diameter of the pipe. Saws with a pitch of 1000 mm will ensure a uniform flow of clarified drain water into the ground.

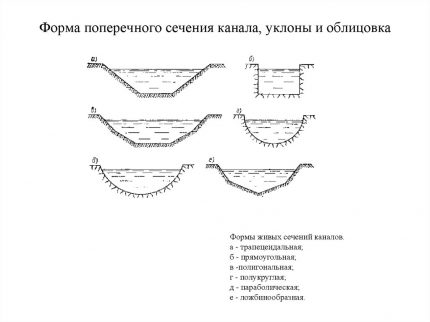

A trapezoidal shape is attached to the bottom of the drainage trenches. In them, a gravel or crushed stone pillow with a grain size of 15-25 mm is poured with a layer of 100-150 mm. In principle, the thicker the underlying layer of crushed stone (gravel) - the better will be the filtration of effluents.

After giving a given slope to the surface of the dump, drainage pipes are placed on it. Above them, gravel or crushed stone is poured with a 50 mm layer, then the soil is flush with the soil level.

Distance between septic tank and distribution wells depends on the type of soil on the site. The required number of wells, from which parallel drains are stretched - two or more.

Characteristics of the sewage-filtration complex depending on the type of soil:

- Sand. Two drains with a length of 18 m each, with 1.5 m intermediate distance between them. Filtration field area - 70 m2;

- Sandy loam. Five drains, each 19 m long, a step between them 2.5 m. The area of the filtration field is 231 m2;

- Light loam. Seven drains 18.5 m long, 3 m distance between them. Filtration field area - 495 m2.

In order to prevent air congestion from forming in the drainage pipes and to discharge methane, which is characteristic of the process of wastewater treatment, the drainage system will need an air flow. At the end of each drain, it is necessary to build a riser from a pipe of 100 mm diameter, lifting it 400-500 mm above the ground.

Septic tank decontamination

With self cleaning the drain pit and attempts to place sewage sludge on top of the ground, the result is one - an abundance of flies and infections among households. Garbage can and must be converted to compost, completely disinfecting them from germs.

Choosing a place - from the house 15 m, from the well 25-30 m - you need to dig a hole half a meter deep and the required size. Its foundation pit is waterproofed with crumpled clay of a 200-300 mm layer, concreted or bricked with the output of the sides above the ground.

Sides are required - sewage collected in a compost pit must not penetrate the soil and infect it. To completely eliminate moisture exchange, a cement mortar is applied to the walls of the pit, followed by ironification. It is also useful to coat with bitumen on top.

The bottom of the compost pit is sprinkled with a 150 mm layer of peat or dry soil, garbage is placed on top. Having built up a layer of sewage sludge up to 250-300 mm, you need to fill it with 100-150 mm with a layer of peat or dry soil.

After laying out a compost heap 1000 mm high above the ground in layers, you need to fill it completely with earth or peat 150-200 mm thick and leave it for 8 months to mature.

If in the process of laying the compost pit, pour the layers of garbage with a small amount of ash and pour a little water, then the compost will ripen faster and in better quality.

Conclusions and useful video on the topic

Video # 1. Self-creation of a brick drain pit in loamy soils:

Video # 2. Masonry drain pit of stone, with a headband of brick:

A drain pit in a suburban area is not only a need to provide for everyday life, it is a responsibility. It is necessary to seriously assess the possibilities of arranging a local sewage system, choosing, albeit an expensive, but safe solution.

Please write comments in the block under the text of the article. We are interested in your stories about the hand-made device of a drain pit in a suburban area. Ask questions, share useful information and thematic photos.

DIY drain pit from tires: step-by-step instructions for arranging

DIY drain pit from tires: step-by-step instructions for arranging  How a cesspool is constructed in a private house: a review of structures + rules for their arrangement

How a cesspool is constructed in a private house: a review of structures + rules for their arrangement  Do-it-yourself cesspool: analysis of popular options for arranging

Do-it-yourself cesspool: analysis of popular options for arranging  How to build a drain pit of brick: options and methods of arrangement

How to build a drain pit of brick: options and methods of arrangement  Plastic cesspool: how to choose a container and properly equip a plastic pit

Plastic cesspool: how to choose a container and properly equip a plastic pit  How to make rings for a cesspool of concrete or plastic

How to make rings for a cesspool of concrete or plastic  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Even with my grandfather, we made a drain pit with square-type brick walls. At that time, reinforced concrete rings were expensive, plus you still have to pay to hire workers. We tried on about 5 m from the house. There are no difficulties in the construction and operation. The smell is present only when you are close due to the fact that they made a simple frame of thick bars and boarded up on the sides. Serves for about 14 years.

In a country house you can’t do without a drain pit. It is important to remember some requirements when arranging it. We do it for more than one year, so you need to choose the appropriate place: as far as possible from the well or well and from the foundation of the house. Also consider how you will clean the contents of the pit. A swarm of foundation pit and we fall asleep with a small layer of gravel and concreted, the masonry walls of the half brick will be sufficient. We lay a concrete slab and a hatch for pumping out from above.

We also have an old drain pit, my grandfather did it too. There was a problem, the asphalt began to fail, every year the hole becomes more and more. The hatch practically does not hold. What can be done, how to strengthen?

Hello. Only as soon as possible to remodel the ceiling and at the same time check the integrity of the internal order, you yourself understand that such a structure can hardly be called safe. And also, replacing the unusable part in time, you will extend the pit's service life - a collapse will cause its filling, it will be problematic to clean it.