DIY gas stove: rules and guidelines for the assembly of gas heat generators

What problems do owners of household buildings often encounter: garages, utility units, baths, small pools, summer kitchens? Indeed, in addition to conducting a series of communications, it is necessary to deal with heating and heating. For those who have made a gas oven with their own hands, issues are solved simply and cheaply.

Everyone can buy special equipment for heating. However, its value painfully bites. Not many are willing to spend large sums of money on the installation and installation of a heating system in such premises.

We will tell you how to assemble and run an efficient and inexpensive heat generator in utility buildings with your own hands. Our home-made designs, made according to previously developed drawings, are easy to install and cheap. Information confirmed by practice.

The content of the article:

Preparatory stages of work

If the room is not heated in winter, then one of the main problems is the occurrence of condensation on the inner surfaces of the walls and on all objects inside.

This leads to a gradual rusting of metal structures and an increase in humidity inside the building. It becomes impossible to store things in the winter in such conditions, as they will deteriorate.

Some car owners use electric heaters and homemade wood stoves for heating the garage. However, this solution subsequently turns out to be disadvantageous: the power of the electrical appliance is often not enough, and the electric meter winds up astronomical indicators.

If everything else is not insulated, then heat loss increases several times.Then the heater must be purchased appropriate - very powerful and expensive.

In such cases, even a gas furnace may be unable to maintain a temperature of at least 24 degrees Celsius. Therefore, the owners should first deal with the external and internal insulation of the building.

It is better to carry out two types of insulation. But everyone carries out the procedure based on technical capabilities. Sometimes there is no access to the ceiling or side walls, for example, if the garage is insulated.

It is also necessary to take into account the future heating of the building with a homemade gas-fired stove. It is highly recommended to insulate walls, ceilings and floors with refractory materials. Then the room will be fireproof, and the owner will save himself from unnecessary reasons for concern. It is recommended to plaster the walls from bricks, and from metal - to ground and paint.

After all thermal insulation measures have been taken, garage heating significantly increase, and fuel costs will be much lower.

The best place to place a homemade gas stove is the center of the room. If the heat source does not come into contact with the walls, then the heat will not go through them and a certain heat cap will be created in the building.

The principle of operation of the heat cap is that first, warm air rises from the center of the room up to the ceiling. There, he encounters a cold stream of air and begins to go sideways to the walls, where he again encounters cold streams. During this circulation, warm streams will gradually fill the entire room and heat it.

In the image, the circulation of warm air in the room would resemble the movement inside a schematic mushroom-shaped figure. A positive heating effect is achieved even with the use of weak power furnaces. However, they must form an intense air stream.

Advantages and disadvantages of gas furnaces

The market offers consumers a wide variety of energy sources. At the present stage of economic development, one of the most profitable and effective fuel options is gas.

The use of gas as a power source for heating equipment is advantageous in that its cost does not hit the consumer's pocket. In addition, gas has a high coefficient of performance. The operation of gas-fired heating devices is characterized by ease of use, economy and safety.

When arranging a gas furnace in a room, the best option for owners will be the situation when a gas pipeline is directly connected to the building. However, in modern realities this is a very rare case. Many will have to purchase gas cylinders and other containers for storing and supplying fuel to the furnace.

The advantages of using gas furnaces include:

- fast, efficient and high-quality space heating;

- mobility and compactness of gas equipment;

- the ability to quickly move the furnace to the right place;

- independence from government communications, power outages and many other factors.

Gas equipment, like any other, has its drawbacks.However, they are relative and easily walkable.

The disadvantages include:

- the use of gas is strictly regulated by regulations;

- owners of non-residential premises will have to obtain a number of agreements and permits in the gas sector and other government bodies;

- drawing up the necessary project can cost a round sum;

- the use of reduced and bottled gas requires compliance with safety measures.

In order for the gas furnace to fulfill its function as efficiently as possible in the room, protective shields are required. Such designs are equipped with reflective surfaces, thanks to which warm air does not escape, but reflects and heats the entire area of the box.

Open burning furnaces require design and installation ventilation system and providing humidification. When the device burns oxygen, the air is dry. This often leads to headaches and sore throats.

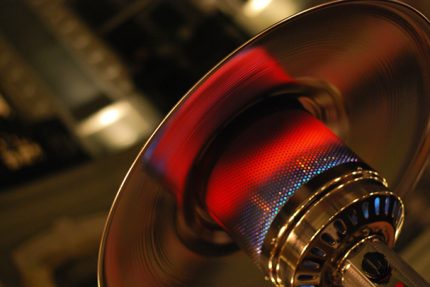

Homemade gas burner heater

Independent manufacture of a gas-fired furnace from metal or from other materials is carried out in accordance with previously developed schemes. Consider one of the options for independent phased collection of a gas stove.

The assembly will require the following materials and tools:

- metal scissors and bench tools;

- a sheet of metal with a thickness of 0.5 mm to 1 mm;

- mesh netting to be used as a grill;

- a metal sieve of suitable sizes (it can be used, but without significant damage);

- gas burner with safety valve, which should be purchased on the construction market;

- gas bottle of suitable volume;

- reinforcement with a thickness of approximately 10 mm, with which the structure will be connected to the cylinder.

After collecting all the necessary materials, proceed to the immediate start of the manufacture of the structure.

First you need to put a sieve on the prepared metal sheet and circle its circumference with a pencil. Then mark the scan in the form of a rectangle. Its length should be enough to grasp the sieve and the bottom of the metal stove. The scan must be cut carefully and without bumps.

Next, it is necessary to mark the mounting points of the gas burner, drill holes and fix the burner on the back of the sweep. Parts are interconnected using rivets and a small flanging made in advance.

A drilled plate is attached to the sieve from above with rivets. On the plate you need to attach a netting net with metal plates. Next, using a riveter, legs of suitable length are installed.

The burner valve is equipped with a hose attached at the other end to the gas bottle. Having started gas, it is necessary to check up tightness of all connections. This is easy to do with a soapy solution.

Such an installation can also be connected to a gas pipe that removes combustion products from the apartment. However, in this case, permission and coordination with the HOA, LCD or HBC will be officially required. It will also be necessary to carry out a ventilation system, and install the furnace on a separate foundation. Still need to buy a gas meter.

When installing a home-made oven, all the required distances between different surfaces should be observed. The distance from the stove to the floor or walls of combustible materials should be specified in the standards.

When using a large stove, the owner of the room will need to additionally hold a chimney. If the gas appliance needs to be installed on the wall, then the wall must be necessarily supporting. Installation of gas appliances on non-load-bearing walls is prohibited.

Before starting the equipment directly, make sure that it is working properly. ventilation and in the absence of gas in the air in the room. In addition, then every time after turning off the equipment, all taps and valves should be shut off, both on the gas cylinder and on the gas furnace.

The pressure reducer installed on the cylinder protects it from a back stroke and also makes it possible to regulate the pressure.

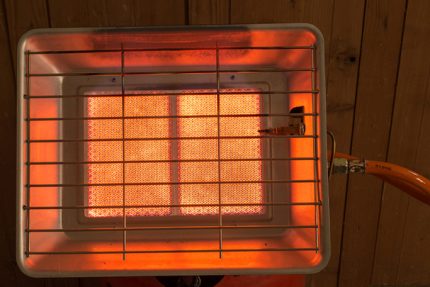

Gas stove heater

For some small rooms for heating it is enough to use a small desktop heater. The device is assembled using a quadrangular flat tile, which is initially equipped with a grill.

The design is assembled by connecting the tiles to a metal casing. The casing is equipped with a combustion chamber and a fan. It is not difficult to assemble such an installation yourself.

First of all, you need to measure the length and width of the future case. Thus it is necessary to be based on the sizes of a tile. After the casing is made, it must be fixed with hooks.

On the one hand, you need to make a movable bar. This is easily done using a spring that attaches to the lifting arm. This measure in the future will provide the ability to remove the case in case of need.

In this design, a ventilation system is provided in advance. For its device, you do not need to use any unusual materials. A handy fan will be enough. For example, from a window air conditioner. The blades can be neatly trimmed and given the necessary shape and size. The fan is mounted on the back of the chassis.

To create traction inside the housing, it is necessary to fix a metal combustion chamber. On the surface of the combustion chamber, many holes are made at a small distance from each other.

The device effectively heats rooms even in winter and has a high coefficient of performance. If you warm the room in advance and install reflectors, then such a heater will most effectively carry out its task.

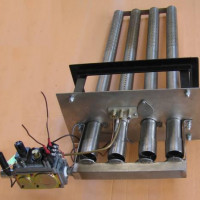

Heat gas gun

Thermal gas guns are characterized by high power and a high level of released energy. Typically, the design is equipped with a chimney.

To independently make such a device, the following materials will be required:

- meter pipe with a diameter of 18 cm;

- meter pipe with a diameter of 8 cm;

- a pipe 30 cm long and 8 cm in diameter;

- metal plates for future fastening;

- a metal sheet;

- piezoelectric gas burner;

- axial fan with a round flange.

In addition to these materials, you will additionally need to acquire a welding machine, tape measure and a level with two ampoules. Some craftsmen advise using old gas cylinders or a fire extinguisher instead of pipes.Their bottom and top are previously carefully cut off by a grinder.

If you collect all the necessary materials and tools, then assembling a gas gun will not take much time.

The first step is to drill two holes in the first pipe with a diameter of 18 cm. They should be located opposite each other, and their diameters: 1 cm and 8 cm. The second meter pipe with a diameter of 8 cm is used to make the combustion chamber. For this purpose, you will need about 30 cm.

The fixing plates must be welded to the second pipe. Also, a hole with a diameter of 1 cm is made on this pipe. After this, the pipe must be inserted inside the first pipe.

The next step is to cut out the plugs from the metal sheet, which will be used as overlapping the space between the heat gun frame and the combustion chamber.

Then you should use the welding machine and weld the pipe from which the combustion chamber will be made to the inner frame. After that, a pipe is welded through which hot air will be discharged to the hole with a diameter of 8 cm. Next, a plug is welded.

The gas burner must be firmly and firmly installed in the chamber. Check the stiffness of the mount. After that, a hose is passed through the drilled centimeter holes in two pipes. Then a fan heater is mounted in the heat gun. A chimney must be installed on the front of the camera.

To prevent the device from turning over and standing steadily on a flat surface, you need to weld the legs. You can also turn on imagination and attach wheels or other parts to facilitate transportation of the structure.

It is convenient and simple to heat a room with a heat gas gun. It is also economical. However, there is always a risk of structural failure. Therefore, you should very carefully and thoughtfully approach the assembly process of the device.

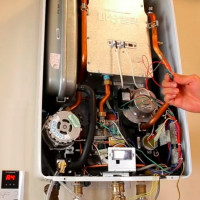

DIY gas fireplace

Another convenient option for space heating is a gas fireplace. Buying such a device will cost a round sum, although the most savvy ones can independently assemble and equip a fireplace in their box without particularly large financial investments.

This kind of fireplace can be powered either directly from a gas pipe or from a gas cylinder.

The design consists of the following main elements:

- ordinary fireplace insert or decorative, decorating the room;

- the fireplace body made of refractory metals - cast iron or other alloys;

- burner that delivers gas;

- gas supply system.

After determining the place where the structure will be installed, it is necessary to prepare it to begin the construction of brickwork. There must be a solid foundation. You also need to install the chimney. After the construction of the fireplace, it can be decorated with a variety of decorative elements to the taste of the owners.

The fireplace is stacked only from a refractory type of brick. When erecting a structure, it is worth taking care of providing access to the gas valve. After the internal masonry elements are installed and communication is connected to the gas burner, make sure that the entire system is tight.

With the help of a valve in the future it will be possible to regulate the power of gas supply and, consequently, the amount of heat generated. Gas workers advise turning the burner down the holes - this will protect them from pollution and moisture.

Also, the burner should be strengthened with protective mesh elements. This will reduce the load on the burner from the decorative material.

The introduction of some modern devices will allow a little automation of the fireplace. So you can connect a gas supply control system, depending on the level of heat generated or a system to automatically turn off the gas supply. All modifications are freely available on the market, and their purchase depends on the desire and ability of the owners.

Beautiful decoration of the fireplace bowl is made using a variety of stones, glass, and ceramics. In addition to the interior decoration on the outside, the fireplace can be decorated with tiles or in another way. The main thing is that it be refractory material.

A gas oven is easy to assemble yourself with your own hands. To do this, you must adhere to the design scheme and safety precautions.

First of all, before installing a gas furnace to heat the room, it is worthwhile to carry out a number of preparatory measures. If you do not insulate the room, then even the most powerful equipment will not give a serious result. Therefore, it is important to carry out procedures for external and internal warming, as well as equip reflective surfaces.

Conclusions and useful video on the topic

Handmade heat gas gun:

Gas stove made by a craftsman on his own:

Homemade gas stove with chamotte brick body:

For heating small remote non-residential premises, a home-made heater from a gas burner and a heater from a gas stove are suitable. To provide sufficient heat for a medium-sized room, it is worth considering installing a heat gas gun or gas fireplace.

All considered devices can work both from gas pipes brought to the room, and from gas cylinders. It is worth remembering that when connecting to a gas pipe, you must install a meter and officially register the procedure with the gas control authorities. With the device of a self-made design, this procedure will be greatly complicated.

If you use gas cylinders, then you can effectively heat your room in the winter. It is important to remember that compliance with safety precautions is the key to successful work with any gas devices.

Rules for connecting a dual-circuit gas boiler to gas

Rules for connecting a dual-circuit gas boiler to gas  Types of gas burners for heating furnaces: device options and installation methods in the furnace

Types of gas burners for heating furnaces: device options and installation methods in the furnace  Error codes for the Master Gas boiler: decoding symbols and troubleshooting guides

Error codes for the Master Gas boiler: decoding symbols and troubleshooting guides  How to increase the efficiency of a gas boiler with your own hands: the best ways to increase the efficiency of the boiler

How to increase the efficiency of a gas boiler with your own hands: the best ways to increase the efficiency of the boiler  Do-it-yourself pyrolysis boiler: device, circuits, principle of operation

Do-it-yourself pyrolysis boiler: device, circuits, principle of operation  Wall-mounted gas boiler installation: do-it-yourself installation

Wall-mounted gas boiler installation: do-it-yourself installation  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements