Wall-mounted gas boiler installation: do-it-yourself installation

At home, by definition, it should be warm. It can be provided in a variety of ways. However, a prudent owner seeks to do this as efficiently and economically as possible. Among these options is the installation of a wall-mounted gas boiler. And this is quite justified, since gas heating is very profitable, and the equipment is quite simple to operate and install.

If you also began to think about purchasing a wall-mounted boiler, then be sure to read our material. In it we will try to tell you as much as possible about the principles of operation of such equipment and the types of wall devices. And also consider all the nuances of connecting such a system.

The content of the article:

The principle of operation of a wall-mounted gas boiler

The installation and connection of the heater depends on its type. Therefore, you need to understand exactly how the device works and which of its varieties to deal with.

Any wall mounted gas boiler is a compact device with a maximum power of 42 kW.

The main elements of the system include:

- Gas burner. It delivers gas to the chamber where the combustion process takes place. Using nozzles, the fuel is distributed as evenly as possible. Modern modulated burners can maintain the set temperature and regulate the power of the flame.

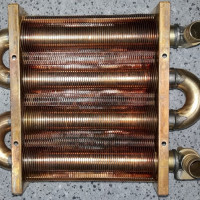

- Heat exchangeralong which the coolant moves. The best efficiency of a copper device. In condensation boilers, there can be two such elements.

- Expansion tank. Designed to compensate for excess water resulting from heating.

- Circulation pump. Powerful models can have two of these elements.

- Boiler automation or a system of devices whose task is to maintain a given temperature in a heated room. May include appliances powered by electricity or non-volatile.

- Devices that control and regulate boiler operation.

- Fan. Used only in turbocharged models.

- Security system. It stops the boiler in dangerous situations.

Modern models are additionally equipped with self-diagnosis systems that can determine about 90% of boiler malfunctions. The number of the diagnosed failure is displayed, which is promptly corrected by the wizard from the service.

Varieties of Wall Devices

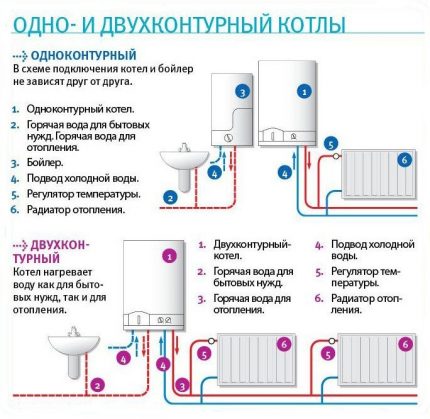

According to their functional purpose, gas heating units are divided into two groups:

- Single-circuit. Designed for heating only. They are connected to the heating circuit and heat up the coolant. The organization of the supply of hot water in this case is carried out by installing an electric or gas water heater of any type.

- Bypass. They heat the room and provide hot water. An additional circuit for heating water is built into the boiler. The technological feature of the device is the impossibility of simultaneous heating of water and space heating.

Priority action double-circuit units is water heating, the heating operation stops at this time. Given that water can be heated quickly, the boiler heats the building quite efficiently.

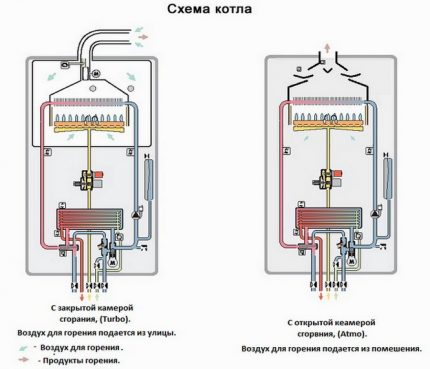

According to the method of fuel combustion, all devices are divided into the following two groups.

Group # 1 - devices with an open combustion chamber

Such appliances are also called natural draft heaters. Oxygen, necessary for combustion, they take from the room in which the device is located.

To divert combustion products, they need a traditional chimney. Thus, a mandatory requirement for the installation of such a boiler is the arrangement of good ventilation.

If the heater is mounted in a residential building, high-performance fresh air ventilation must be equipped here.

The best option for installing a heater with an open firebox is considered to be the presence of a separate room, the so-called furnace, where it is placed.

Systems with natural ventilation are quite popular due to their low cost and non-volatility.

Group # 2 - devices with a closed combustion chamber

Turbocharged devices are equipped with a closed combustion chamber. The air, without which the combustion process is impossible, they take from the street. For this, the devices are equipped with coaxial type chimneys.

Such a chimney is made in the form of a structure of two pipes, one of which is embedded in the other. Through the inner pipe, the products of combustion are discharged to the outside.

At the same time, street air enters in the opposite direction through the gap between the two pipes. It is clear that boilers with a closed firebox do not affect the composition of the air in the room, which makes it possible to equip them even in living rooms.

In this case, it is necessary to equip the coaxial chimney system, which is characterized by a higher cost and more complicated installation compared to a separate traditional chimney.

Is self-installation possible?

With your own hands you can carry out the installation of a wall-mounted gas boiler of the simplest modifications. Such as single-circuit devices with an open combustion chamber.

To install them, you will need to connect a heating system, supply gas and organize a chimney. However, some manufacturers of boilers in the technical documentation for their products indicate that the installation should be carried out only by specialists.

In this case, self-assembly of even the simplest models is prohibited. Thus, if it is planned that the equipment will be installed independently, you must make sure that the manufacturer permits this before purchasing it.

Checking the correctness of the installation and connecting the device to the gas line should be carried out only by a specialist with special approval.

In addition, the representative of the gas service must also issue a permit for the operation of the installed equipment. Serious fines await without this owner of a self-installed and running appliance.

Thus, without inviting specialists, you can only connect the device to the heating system and to the water supply. Moreover, it is advisable to do this only if there is a certain experience.

Where to start installation?

First of all, you need to prepare the documentation that is necessary for installation. Start by initializing gasification of the room. It can only be started if a gas pipeline is connected to it.

Then the owner submits an application to the appropriate services, in which he indicates the volume of gas consumption he needs in a month or year. In the case of a satisfactory answer to the statement, the gas pipeline suitable for the premises is necessarily equipped with a meter.

The owner receives permits and technical specifications on the basis of which a project for connecting equipment should be developed.

The latter includes a scheme for laying gas pipes from the heater to the point of insertion into the main and all installation conditions for the equipment. The developed project must be approved by the gas service.

Together with the project, the owner of the room where the boiler will be installed provides a certificate of conformity and a data sheet of the purchased equipment, an expert opinion on its compliance with all safe requirements and instructions for use.

Only after the project is approved, you can start installing the heater. In this case, all points of the design documentation should be clearly followed.

Boiler room requirements

Gas equipment is classified as explosive and fire hazard. Therefore, the premises in which it will be installed are subject to special requirements.

First of all, it should have natural light. At the same time, for every cubic meter of the room should be at least 0.03 square meters. m openings of a window without a frame, that is, only glazing. The window must be equipped with a window leaf.

Another prerequisite is availability supply ventilation, which can provide a change in the air volume of the room within 3 times in one hour. Thus, the gas contamination in the room can be minimized.

Also from power of the selected boiler the volume of the room in which it will be installed depends. Equipment with a capacity of 30 kW and below can be placed in 7.5 cubic meters. m boiler room.

For heating appliances, the power of which varies from 30 to 60 kW, a furnace volume of 13.5 cubic meters will be required. m and above. If the heater will be placed in the apartment, it is usually installed in the kitchen.

This is possible if all the requirements of SNiPs are met. An important nuance: in this case, the total heat output from all the heating appliances in the kitchen should not exceed 150 kW.

According to the norms for installing wall-mounted gas boilers, to improve the air exchange in the kitchen door, it is necessary to make a hole with an area of at least 0.02 square meters and close it with a grill.

Experts recommend that for installation in an apartment building only equipment with a closed firebox equipped with coaxial chimney. In the kitchens of 7.5 cubic meters. m and less, it is forbidden to install more than one heating device.

In private houses for gas boilers, it is recommended to allocate a room separated from the living rooms by fireproof solid partitions.

It is optimal that the materials used to decorate the premises have a fire resistance of at least 45 minutes.Preferably, the layout of the premises would prevent the rapid spread of flame to living rooms.

The gas boiler can only be fixed on a solid base. Partitions from plywood or drywall for these purposes will not work. The wall on which the heater will be placed must be finished with refractory materials.

If this is not the case, a non-combustible substrate is mounted under the boiler. The minimum distance from the device to the supporting structures is 0.5 m to the ceiling or walls and 0.8 m to the floor.

Step-by-step installation of equipment

Before installation, you need to unpack a brand new boiler and do a check of the completeness of delivery. The presence of parts is checked according to the operating instructions, which must be attached to the device.

If any item is missing, contact the supplier immediately. Another nuance. The boiler must have an ideal appearance without dents, chips or signs of repair. If this is not the case, you need to call the sellers.

It is important to make sure that the technical data indicated in the technical passport of the heating device exactly matches those on the device itself. In addition, they must correspond to the numbers indicated in the instruction manual of the device.

Immediately before starting the installation, you need to rinse the boiler pipes, which may contain various debris that got inside during the manufacture of the device and its transportation.

It is also advisable to rinse and heating system lines. After the preparation is completed, you can proceed with the installation.

The specifics and the procedure for its implementation determine the features of the equipment: the number of circuits involved and the type of combustion chamber.

Most often in houses they put double-circuit devices with a closed firebox. We will consider in detail the installation of just such a modification.

Stage # 1 - Preparing the Wall Mount

To fix gas boilers, a special bracket is used, which should be included with the device. Reliable fasteners are used for its mounting on the wall. They should be selected for the material of which the wall is made.

It is possible that those that the manufacturer packaged with the heater will not work. Then you will need to choose and purchase others.

The task of the bracket is to support the weight of the boiler and additional equipment, as well as to provide it with a smooth, precisely calibrated position without distortions.

For accurate marking of the wall, you can use a paper stencil, which usually comes with the boiler. With its help, you can easily outline the holes for fasteners.

After this is done, the bracket is fixed in place and the boiler is hung on it.

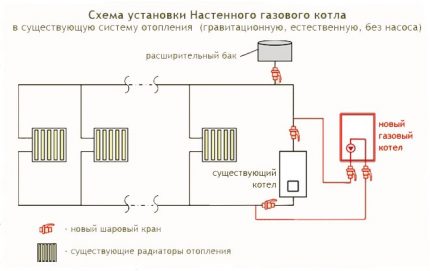

Stage # 2 - connecting the heating pipes

Depending on the type of heating system, and it can be single pipe or double pipe, the number of pipes connected to the boiler may vary. In any case, we begin by removing the plugs from the device nozzles.

To protect the boiler from dirt particles from the heating line, it is recommended to install a strainer at the inlet of the return.

If the water in the system is hard or in other parameters does not meet the requirements stated by the manufacturer of the heating devices, it is worth taking care of installing additional treatment equipment.

These can be, for example, polyphosphate dispensers. If this is not done, the device will break quickly. All connections must be made in compliance with all rules and regulations.

Sealing is required.For this, special sealants are used: traditional paint or tow or modern thread seals. In addition, experts recommend the mandatory installation of shut-off valves for supply and return.

This is necessary to facilitate the repair of the boiler if it fails. In addition, the fittings will help prevent possible airing of radiators.

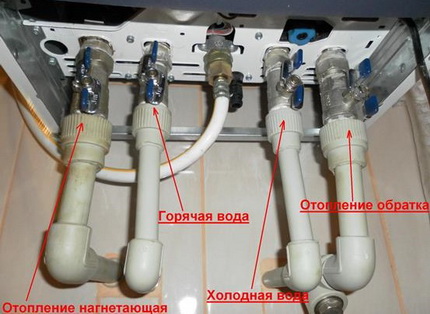

Stage # 3 - connecting to the water circuit

These works are almost similar to connecting heating pipes. The main difference is the taps used and the diameter of the pipes.

A cold water supply must be equipped with a filter, which will eliminate the possibility of contaminants entering the heater. Otherwise, the equipment will deteriorate.

The taps used to cut off the boiler from the water supply must be with detachable connections.

Such models are also called "American". They greatly simplify installation, and in case of unforeseen situations make it possible to quickly replace a worn crane.

It must be remembered that the pipes supplying cold water are located on the heating device on the left side relative to the center, the pipes supplying hot water are on the right.

Stage # 4 - connecting to the gas main

This part of the work should be carried out only by a specialist with tolerance, since the cost of an error can be very high. In any case, at the end of the connection, the representative of the gas service should check its correctness. He will also conduct the first start-up of equipment.

All operations during independent work should be carried out extremely carefully. They start by connecting the branches of the gas main with the corresponding pipe on the boiler.

A special filter must be installed on the tap that cuts off the gas supply from the line. Experts strongly recommend that you do not save on this detail.

A cheap low-quality filter will not work for long, which can cause a gas boiler to fail. When arranging a connection, special attention should be paid to its sealing.

It should be understood that the weight of the gas is much less than air, and with an insufficiently tight connection it will ooze from the pipeline. The consequences can be most dire. Therefore, thorough sealing is required.

The main materials for sealing threaded joints are paint and tow, the use of seals like fum tape is unacceptable.

After the filter element, a special flexible connection is established. You need to know that it is strictly forbidden to use rubber hoses for its arrangement.

This is due to the fact that over time, the material from which the part is made dries out and becomes covered with cracks, through which gas begins to leak. Therefore, the best choice for arranging such a connection is a corrugated hose.

For its manufacture, high-quality durable stainless steel is taken. This is a very strong and durable material, which is especially resistant to high humidity and the adverse effects of gas.

The hose is secured to the heater pipe using a union nut. In this case, a paranitic gasket is necessarily used, which provides the necessary sealing of the connection.

Stage # 5 - connection to the electric network

Such an operation is only necessary for appliances with a closed firebox that need electricity.It feeds a fan that removes combustion products and automation that controls the system.

Usually a standard three-wire wiring diagram is used. Experts recommend connecting the boiler to the network only through the stabilizer, which will make it possible to avoid power surges and thereby extend the life of the boiler.

it is advisable to purchase an uninterruptible power supply - this will protect the equipment from sudden surges

voltage

Stage # 6 - arrangement of the chimney outlet

The easiest way is to connect a heater with a closed firebox to the chimney. For them, special coaxial pipes are used. In apartment buildings, the boiler must be connected to a collective chimney.

In individual buildings, a coaxial-type chimney is led outside through a wall. The height of the suspension of the pipe in this case does not matter much, since the built-in fan creates the necessary draft.

Devices with an open firebox are required to be connected to an individual chimney. The boiler is connected to it by a pipe of the desired section.

The material for its manufacture is selected so that the part is resistant to the effects of combustion products, high temperature and mechanical wear.

Before starting work, you need to make sure that there are no soot, mounting debris, etc. in the chimney. When installing the chimney, it should be placed with a slight slope towards the gas boiler.

At the exit from the device, a vertical pipe segment is installed, its length before turning must be equal to at least two pipe diameters. The total length of the connection to the chimney must be kept to a minimum.

Stage # 7 - preparation for the first launch

Before a test run, the heating system is filled with water. The fluid is pumped to a pressure of 2 atmospheres. Water is pumped as slowly as possible to remove the maximum amount of air collected inside.

In addition, the system is checked for leaks. All leaking connections must be sealed immediately.

To identify insufficiently tight compounds on the gas line, dilute the soap solution and lubricate all the compounds with it. Then watch.

In low-quality areas air bubbles will appear. All found malfunctions should be eliminated and repeated check. The first start-up of equipment should be carried out only in the presence of a gas service representative.

Conclusions and useful video on the topic

The video details the regulatory requirements for installing gas wall-mounted boilers:

The video talks about the connection scheme of a wall-mounted boiler:

The video demonstrates the installation process of a wall-mounted boiler:

Installation of a gas heating unit is a responsible and rather complicated operation, the safety of all who live in the house depends on the quality of its implementation. Therefore, representatives of gas services insistently do not recommend doing it yourself..

Yes, and manufacturers of heating appliances insist on this. Therefore, it is better for even experienced home masters to turn to professionals for help, which guarantees long-term, and most importantly safe operation of the device.

Please leave your comments if you have questions about the topic of the article. Or maybe you yourself had to deal with the installation of gas wall equipment and you have something to advise our readers?

Do-it-yourself installation of a floor gas boiler: technical standards and algorithm of work

Do-it-yourself installation of a floor gas boiler: technical standards and algorithm of work  How to increase the efficiency of a gas boiler with your own hands: the best ways to increase the efficiency of the boiler

How to increase the efficiency of a gas boiler with your own hands: the best ways to increase the efficiency of the boiler  Installing a solid fuel boiler: do-it-yourself nuances of installing a boiler

Installing a solid fuel boiler: do-it-yourself nuances of installing a boiler  Do-it-yourself gas boiler heat exchanger repair + instruction on repair and part replacement

Do-it-yourself gas boiler heat exchanger repair + instruction on repair and part replacement  Installation of a gas boiler Protherm: features and main stages of installation + wiring diagrams

Installation of a gas boiler Protherm: features and main stages of installation + wiring diagrams  Voltage stabilizers for a gas boiler Baxi: TOP-12 of the best models according to consumers

Voltage stabilizers for a gas boiler Baxi: TOP-12 of the best models according to consumers  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

There are lots of examples when people install such equipment themselves and still make some kind of error when connecting, but this is fraught with a leak with all the consequences or abnormal work. I believe that this business should still be entrusted to the official state gas service, and to call professionals to their homes!

I’m friends with my head, and my hands are growing from where, but I can’t even think about installing the gas boiler myself. How much easier it is to change the pipe to the gas stove for flexible eyeliner. The tool was, the desire was, strained with money, and then he did not, but called the gas service. I completely agree with the previous comment, such things should be done by specialists.

It’s better to overdo it than overdo it.

Good evening! Tell me, is it possible to install a boiler with a closed combustion chamber in a multi-apartment 2-storey building on the 1st floor? Someone said that it’s impossible, because the exit of the combustion residues from the pipe will interfere on the 2nd floor ...

But the windows are not above the chimney ... Nowhere can I find an answer to this question. Tell me and if possible with reference to regulatory documents.

You will definitely not find such documents. Because they simply do not exist. I work as a locksmith in a gas company, so last summer we transferred a multi-story building to such boilers. From the 1st to the 5th floor they were installed and everything is in order. People live and rejoice that the apartments are warm and the gas savings are decent.

Personally, when I draw water from a spring into a glass, I must blow it, and what if there’s a double-circuit boiler? And I only dig professionals to dig potatoes with a certificate for a shovel, maybe the pin on my shovel is not correctly clogged. And getting behind the wheel I call the traffic police to check everything I need in the car and check the rules of the movement for me.

Maybe it's time for us to hammer a nail according to certificates? What's this? Russians write or where, did you grow your hands from the wrong place? To fasten five nuts? Give it 12,000? Or did I get to the majors?

Ah ha ha, it’s fun with a shovel :)) Of course, nobody will hammer nails according to certificates. But with gas equipment is heavier.

Of course, you can, in general, yourself, like a real Russian craftsman, assemble a gas boiler and, without obtaining any permissions, put it where you want. But don’t forget about the safety of neighbors, because you are not the only one living in the house, rather. The rules of those blood safety are written.

Why then are you not installing gas boilers yourself? See: “fasten 5 nuts - 12 thousand rubles.” (I quote you), and if you turn 50 nuts a day, then in general you can earn 120 thousand rubles. in a day! I don’t even know why all of this is not going to work together in gas workers

Most likely, you need to learn, get a specialty, twist not only nuts! And like a cherry on a cake - bear constant responsibility for the connected equipment.

I'm not saying that 12 thousand rubles. connection is an adequate price, but there are different cases, boilers, piping and more. Plus, the tariffs for connecting gas boilers in each city will differ. If you need to remove the old gas boiler and connect a new one, then in this case you can cope on your own. But in any case, you need to get a conclusion from the gas organization that the boiler is connected in accordance with all norms and rules, without this in any way.

Hello. Art.7.19 of the Administrative Code of the Russian Federation for independent connection of the highway, you may be fined for unauthorized and uncontrolled connection of gas equipment in the amount of 10-15 thousand rubles. And in case of fire / explosion - 300 thousand and / or imprisonment (depending on the damage).

ПП №410 - connection of gas-using equipment without involvement of specialists with a permit and license can lead to disconnection from the gas main. So what's with the documents on the shovel?

By the way, my friend was arrested and fined for the lack of documents / checks for a 20-year-old HAMMER when he was carrying her around the city. They hardly imputed the theft 🙂 So you gently swing the shovel with the wrong pin in it 🙂

To install a gas boiler (tighten 5 nuts), I think the gas service is not needed, but to connect it to gas, you can’t do without gas specialists. If they ask 12,000 for the installation of the boiler, this is generally some kind of nonsense.

Hello. This is really possible with laying a pipeline, connecting a full range of gas-using equipment (stove, boiler, column), IPU, as well as access to operation ... Although I can be wrong, the price list for cities is different, and it was possible to have a private organization in mind, and they 100 thousand may request 🙂