Liquid fuel heating boilers: device, types, overview of popular models

Productive and economical boilers for heating with liquid fuel allow achieving complete autonomy from the centralized gas pipeline. Reflecting on the installation of the unit, it is necessary to deal with its device, the principle of operation and operation features.

The choice of boiler should be based on a comparative assessment of the characteristics and functionality of different models. An important factor is the reputation of the manufacturer.

In this material we will talk about the varieties of liquid-fuel models of heating boilers, their advantages and disadvantages, and also consider several popular devices from well-known brands.

The content of the article:

Advantages and disadvantages of liquid fuel boilers

Liquid fuel boilers, despite the ability to efficiently heat a building and technical excellence, are not as common as gas or solid fuel heat generators.

Equipment operating on diesel fuel or development is very popular in Western Europe.

Significant advantages of a liquid fuel heating boiler include:

- High work efficiency. The efficiency of most models reaches 95%. Fuel is consumed with virtually no loss.

- Great power. The performance of the units allows heating both compact living spaces and spacious production workshops.

- High level of automation. The boiler operates for a long time without human intervention.

- Autonomy from energy sources. Excluding electricity. If necessary, you can do with a generator.

- The possibility of switching to gas fuel.

There are additional advantages of such equipment. To install the boiler does not require coordination and obtaining permission.In addition, the absence of a gas pipeline greatly facilitates installation work.

Difficulties of installation and operation of a liquid fuel boiler:

- High costs for the purchase of fuel. With intensive use of the equipment, the annual fuel consumption can reach several tons.

- A separate building is being built for fuel storage. Alternatively, a warehouse with containers of opaque plastic or steel is equipped in the ground. An important condition is protection from sunlight.

- The unit must be placed in a separate room with good ventilation and a powerful exhaust hood.

- If the diesel boiler room is located close to the house, then additional sound insulation is required - the burner makes noise during operation.

When equipping underground fuel storage facilities, the hydrogeological characteristics of the terrain must be taken into account.

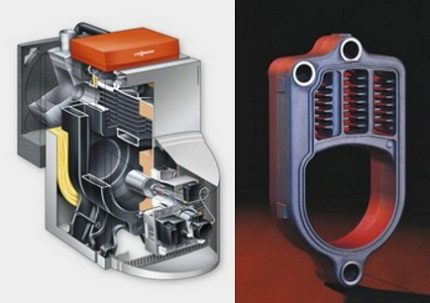

The device and principle of operation of the boiler

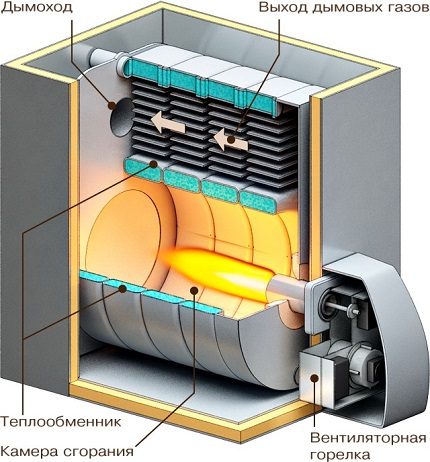

Fuel oil units operate on the same principle as gas units. The main difference is the use of a fan burner (nozzle). The type of device largely determines the efficiency and efficiency of the boiler.

The main working units of the heat generator

Structural elements of a liquid fuel boiler:

- burner;

- the combustion chamber;

- heat exchanger;

- chimney;

- Control block;

- body.

The oil heating installation is equipped with a main line with a pump providing fuel supply and a tank for storing fuel.

Heating unit burner

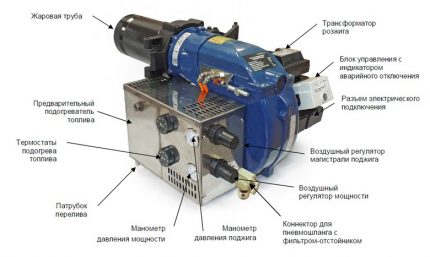

The main module of the installation, responsible for the preparation of the fuel-air mixture and transmitting it in the amount necessary to maintain the operation of the heat generator.

Standard burner for liquid fuel boilers:

- Ignition transformer. Generates a spark that ignites the fuel.

- Control block. It determines the start-up phase, monitors and stops the operation of the burner. A photocell, an ignition transformer and an emergency shutdown sensor are provided.

- Solenoid valve. Corrects the supply of fuel to the combustion chamber.

- Air regulator with filter. The device normalizes the air supply, preventing the ingress of solid particles.

- Preheater. Changes the condition of the fuel, reducing its viscosity. The more liquid fuel enters the nozzle opening, the more economical it is spent.

- Fuel overflow pipe. It is connected to the tank where the fuel is heated.

- Flame tube. Thermal energy flows through the mains to the place of heating of the coolant, which then circulates in the heating system.

The burner can be initially integrated into the boiler without the possibility of increasing the power of the unit. Hinged modules allow you to modify equipment.

Boiler combustion chamber

In fact, it is a heat-resistant tank with an inlet and an exhaust hole. As a rule, it has a round or rectangular cross section.

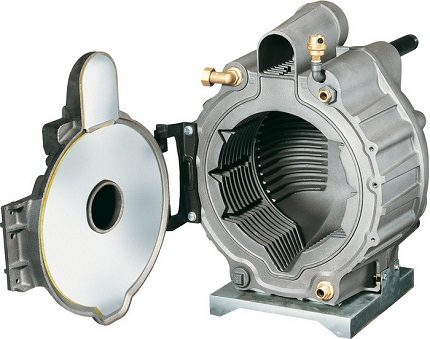

Device heat exchanger

Through the walls of the heat exchanger transfers heat energy to the coolant. In modern models, the coating of this element is made according to the principle of a radiator device - this allows the maximum use of the thermal energy obtained in the combustion process.

Fluid chimney

Air intake is carried out from the street or from the boiler room, which you should properly equip in this stuff.

When supplied from the outside, air is supplied through coaxial chimney or on a separate channel. To increase efficiency, smoke channels are supplied with steel plates - the exhaust gases form turbulent flows that reduce their speed. The thrust is maintained.

Device control unit

Automation is designed to maintain the set temperature. Auxiliary functions reduce the cost of boiler operation. From a technical point of view, the most advanced are weather-dependent units that change the heating temperature of the coolant based on the readings of external sensors.

Boiler body

All elements of the system are enclosed in a durable heat-insulating casing. Such a “shell” reduces heat loss and increases the efficiency of the boiler.

Outside, the body is glued with a layer of heat-insulating film, which, when heated, remains cold and protects the operator from burns.

How is the room heated?

The whole process of generating heat in a liquid fuel boiler and transferring thermal energy to heating radiators can be divided into several stages.

Stage 1. Diesel fuel or other fuel is poured into the storage. The fuel pump delivers fluid to the burner - pressure is created in the pipeline. At the same time, the fuel pump using sensors determines the quality of the fuel and the percentage of its thickening.

Stage 2. Diesel fuel enters the preparation chamber. Here is the mixing of fuel with air, heating and liquefying the mixture.

Stage 3. The fuel and air composition is fed to the nozzle. Under the influence of the fan, the mixture is sprayed and the fuel mist ignites in the combustion chamber.

Stage 4. The walls of the camera are heating up. Due to this, the heat exchanger is heated and coolant. The latter enters and circulates in the heating system.

Stage 5. During the combustion of a combustible substance, gases are formed that are discharged through a chimney. Rushing out, smoke passes through a series of heat exchange plates and also gives off its heat.

Varieties of liquid fuel models

All liquid fuel boilers can be classified according to the following criteria: field of application, functionality, type of adjustment, material of manufacture, type of fuel used and installation method.

By application

The main indicator that determines whether a boiler plant belongs to one of the types is power. Household models are available with power from 6 to 230 kW. This is enough to heat small houses of 50 square meters. m and large rural cottages on 2200 square meters. m

The performance indicator determines the fuel consumption in a liquid fuel heating boiler - it takes about 1 kg of diesel per hour to generate 10 kW of heat. Domestic units are designed for the maximum allowable working pressure - 4-6 bar.

The power of industrial liquid fuel boilers ranges from 500 to 12,000 kW. Heavy duty models work on heating buildings with an area of more than 15 thousand square meters. m. Management of industrial heating units is fully automated.

Industrial boiler equipment is divided into hot water and steam boilers. The former perform heating of water under pressure, and the latter generate superheated or saturated steam.

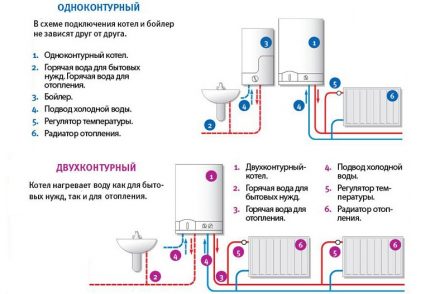

By functionality

Single-circuit boilers are designed exclusively for heating the room. They are connected to radiators, and the coolant circulates through a closed heating system. Such a unit does not heat water for domestic consumption - this should be taken care of separately by installing a boiler.

Dual-circuit models are more functional. Boilers provide heating of the house and the supply of warm water to different points of the intake (shower, wash basin, etc.). The equipment design provides for an additional heat exchanger to ensure hot water supply.

According to the method of regulation

The operation mode of the boiler is determined by the type of burner installed.

By the type of adjustment, all devices are divided into several groups:

- single stage;

- two- and three-stage;

- modulated.

Single-stage modules operate on the principle of variable on and off. After heating the coolant to a certain temperature, the flame goes out, and after cooling, the burner turns on again. Such burners are ineffective - they lead to excessive consumption of fuel.

Two- and three-stage devices operate in the following modes:

- Two stage modules operate at 30 and 100% power. After maximum heating of the water, the burner is rebuilt to a mode of reduced productivity. This allows you to reduce fuel consumption by 5-10%.

- Three stage operate at 30-60-100% power. Efficiency and high heat efficiency of the device are achieved.

Modulated - the process of fuel combustion is regulated automatically. The flame intensity is affected by: temperature inside and outside the building, fuel quality and preset mode. The range of power changes is 10-100% of productivity.

Microprocessor automation determines the composition of the fuel-air mixture, the optimal feed rate to the nozzles and pressure.

By type of material

Manufacturers equip heating units with cast-iron or steel heat exchangers. The material of manufacture affects the efficiency and durability of the boiler.

Cast iron models have a long service life of more than 30 years. However, they are quite "capricious" and with a critical temperature difference between the "return" and the "feed" can crack. The temperature difference of water at the inlet and outlet should not exceed 20 ° C.

If the boiler will be used periodically, for example, during visits to the country, it is better to choose a model with a steel heat exchanger. Heat-resistant steel is less durable, but stably tolerates temperature changes.

By type of fuel

As fuel material in liquid fuel boilers, diesel (diesel fuel) or used oil is most often used. Externally, diesel plants do not differ from fellow workers working on the "development". The main difference is in the technical component.

The boiler uses clean, certified diesel fuel. When burning fuel, ash formation is minimal. This allows the use of a smaller combustion chamber and smoke tubes in the design.

The waste oil is burned with abundant ash. In the “working out” boilers, there is no turbulizer inside the smoke tubes, and all the sediment is deposited in a special smoke collection chamber. We recommend reading our other article, which is considered in detail. calorific value different types of fuel.

By installation method

According to the installation method, wall and floor units are distinguished. Mounted boilers - compact, easy to install, but inefficient. Their power is enough to heat a room, the area of which does not exceed 300 sq.m.

Floor-mounted liquid fuel boilers are more bulky and productive. These include all industrial units and high-power household models.

Overview of models from leading companies

Liquid fuel boilers of foreign manufacturers: ACV, EnergyLogyc, Buderos Logano, Saturn, Ferolli and Viessmann occupy a worthy niche in the heating equipment market. Among domestic companies, Lotus and TEP-Holding have proven themselves well.

Universal boilers ACV Delta Pro

The Belgian company ACV sells models of the Delta Prо S line - double-circuit boilers with a built-in boiler. The power of heating units is from 25 to 56 kW.

Technical and operational features:

- heat exchanger manufacturing material - steel;

- polyurethane foam insulation;

- work on diesel fuel or gas;

- control panel with thermometer, control thermostat.

The oil-fired boiler "adjusts" to the season - a winter / summer switch is provided.

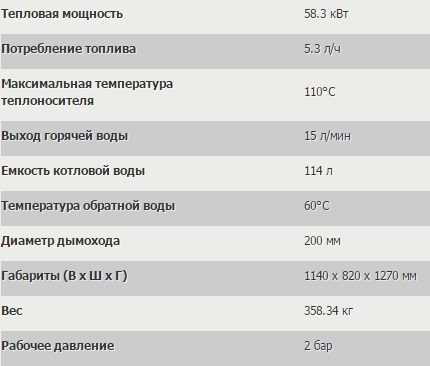

EnergyLogyc Aggregates - Intelligent Automation

The waste oil boilers of the American company EnergyLogyc differ from their analogues in their automated burner adjustment and fuel combustion processes.

As fuel, used oil, diesel fuel, vegetable oil or kerosene are used.

EnergyLogyc fuel oil units are available in three versions:

- EL-208V - power 58.3 kW, fuel consumption - 5.3 l / h,

- EL-375V - productivity 109 kW, fuel consumption - 10.2 l / h;

- EL-500V - thermal power - 146 kW, fuel consumption - 13.6 l / h.

The maximum coolant temperature in the presented models is 110 ° С, working pressure - 2 bar.

Buderos Logano - German quality

Buderos (Germany) produces diesel boilers, nozzles, burners and other equipment necessary for the operation of the heating system. The range of power characteristics of the units is 25-1200 kW.

Buderos Logano boiler plants are produced in two series:

- Buderos Logano category "G" - designed for private use, their power is 25-95 kW;

- Buderos Logano category "S" - industrial equipment.

The units are characterized by a streamlined design, a convenient control system, and an integrated silencer.

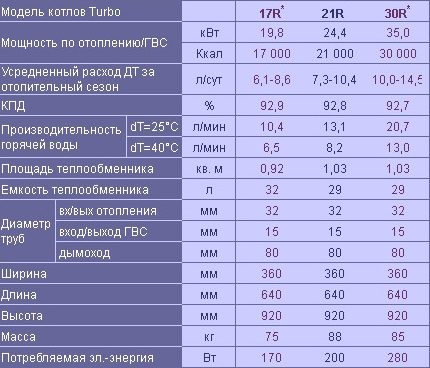

Boilers of the Korean company Kiturami

Kiturami Turbo series floor-mounted boilers are designed for domestic use. Power units 9-35 kW.

Distinctive features of the model:

- providing heating and hot water supply to premises up to 300 sq.m;

- the boiler heat exchanger is made of high alloy steel;

- 99% additional hot water heat exchanger consists of copper, which increases the heating efficiency;

- antifreeze and water are suitable as a heat carrier.

A distinctive feature of Turbo models is the presence of a turbo-cyclone burner. It operates on the principle of a turbocharged car engine.

In a special metal circuit board, secondary combustion occurs due to the high temperature. This allows fuel economy and reduces the emission of harmful substances into the atmosphere.

Conclusions and useful video on the topic

Watching videos will help to understand the device and the principle of operation of heating units using liquid fuel.

Comparison of the diesel boiler and the unit working on the "development":

The rules for choosing liquid fuel heating equipment will be discussed in the following video:

Oil boilers are highly automated. Heating on the basis of diesel devices allows to achieve autonomy, and the absence of rigid frames for documentary design makes them an attractive offer. However, a number of significant shortcomings in the maintenance of the boiler installation, holds the demand for diesel units.

If you are concerned about the choice of a liquid fuel boiler, please leave your questions in the box below. There you can write practical advice on the topic of the article or share experience in using such heating equipment.

Wall-mounted gas heating boilers: types, how to choose, an overview of the best models on the market

Wall-mounted gas heating boilers: types, how to choose, an overview of the best models on the market  Solid fuel boilers: main types and criteria for choosing the best unit

Solid fuel boilers: main types and criteria for choosing the best unit  Floor gas heating boilers: types, how to choose, an overview of the best brands

Floor gas heating boilers: types, how to choose, an overview of the best brands  Induction heating boilers: types, an overview of the advantages and disadvantages of how to choose a good model

Induction heating boilers: types, an overview of the advantages and disadvantages of how to choose a good model  Pyrolysis heating boilers: principle of operation and types of boilers for long burning

Pyrolysis heating boilers: principle of operation and types of boilers for long burning  Wood-fired boilers for heating a private house: rating of TOP-10 models and tips for selecting a unit

Wood-fired boilers for heating a private house: rating of TOP-10 models and tips for selecting a unit  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements