How to equip a boiler room in a private house: design standards and devices

When there is no access to a centralized heating system, it is necessary to build an autonomous boiler room.

If professionally approached, the boiler room in a private house will provide high return (efficiency) of the heating system as a whole, and its operation will be safe and durable.

In this material we will analyze in detail the process of choosing a heating device and tell you what points you should definitely pay attention to. In addition, we will focus on choosing the right place for the boiler room and the rules for its arrangement and ventilation.

The content of the article:

The choice of boiler equipment

Boilers differ in a number of parameters - fuel used, power, installation method, principle of operation (single-circuit and double-circuit).

Fuel for heating boilers

Boilers in private homes can operate on such fuels:

- natural and liquefied gas - cheap fuel resource, gas boilers can be transferred from one type of gas to another;

- solid fuel - the operation of a solid fuel boiler must be monitored and regularly thrown into it firewood, coal, peat briquettes, coke;

- liquid diesel fuel (diesel fuel) - liquid fuel boilers help out in a situation where there is neither a gas pipeline nearby, nor the ability to deliver liquefied gas in cylinders, and if over time there is a prospect of acquiring gas, then it is easy to reconfigure it to the best type of fuel;

- electricity - An expensive but environmentally friendly fuel resource.

It’s good to have two boilers, an electric one and a solid fuel one, to reduce energy consumption.

How to determine the power of the boiler?

The larger the heated space, the more powerful the boiler should be. We add power consumption for heating water for shower, bath, kitchen and natural heat loss.

Approximate calculation (example):

To heat 10 sq. m at home, 1 kW of power is required. If the total area of the house is 150 square meters. m, then the required boiler power is 15 kW + 10% for hot water supply, heat loss + 20% for reserve stock, otherwise the equipment will physically wear out, working at the peak of technical capabilities. We get the power of the heating boiler at least 19.5 kW.

You can read more about calculating the power of a heating boiler in this material.

Comparison of installation methods

According to the installation method, heating boilers are divided into two groups:

- outdoor - they require a separate room (boiler room) and compliance with some mandatory requirements;

- wall mounted - the heat exchanger, circulation pump, expansion tank, exhaust system, automatic control and safety automation, temperature sensors, etc. are assembled in a compact-sized case.

The maximum power of the wall mini-boiler is 60 kW. If the power does not exceed 35 kW, it can be installed in the kitchen, hallway. Small dimensions wall models provide an opportunity to do without a separate room - all this is relevant for private homes of small and medium size.

Floor standing boilers are indispensable for heating large areas. In floor execution heating units take up much more space, they have to be equipped on their own, but there is one very significant plus - they have a long service life.

Differences in operation

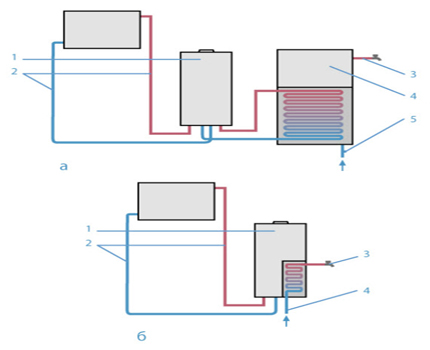

Single-circuit boiler Designed for building heating only. To supply water to the hot water supply system, such a unit must be supplemented with a 100-150-liter storage tank for water heated from the boiler (boiler).

A single-circuit boiler with a boiler is advisable if a lot of hot water is poured from the taps in the house. Otherwise, we have an excessive consumption of energy, since the boiler will have to constantly heat water, which is almost never used. In addition, for the boiler will have to allocate free space in the room.

AT bypass boiler two functions were originally laid down - it heats the building and heats the water. A flow coil is installed inside it.The boiler supports the heating system, but when someone opens hot water in the house, the heating medium in it stops and the system switches to the hot water supply.

a) 1 - single-circuit boiler, 2 - heating system, 3 -

hot water supply, 4 - boiler, 5 - cold water

b) 1 - double-circuit boiler, 2 - heating system, 3 -

hot water supply, 4 - cold water

Double-circuit boilers are rationally designed, water for hot water supply is heated only if necessary. Depending on the capacity of the unit per minute, 10-15 liters of hot water are produced.

This is not enough if several people use hot water in the house at the same time, but the problem is easily solved, since you can buy double-circuit boiler with a small boiler of 25-50 liters mounted in the housing in order to have its supply.

Determine the optimal location for the boiler room

Let's say you started a large-scale repair of an old private house. The boiler room in it should certainly be, but the outdated layout limits the possibility of placing it in the house. You cannot squeeze the boiler equipment into a tiny room without ventilation, you cannot pull the chimney from top to bottom through the bedroom or living room.

Of course, it is possible to build an extension to the country house for the boiler room, however, this architectural excess is unlikely to fit into the general view. There is still the construction of a separate boiler room - a good, but expensive idea.

And with new construction, the design procedure for the boiler house inside the house does not cause any problems if you study the requirements for installing boiler equipment in advance:

- the volume of the room for heating boilers with a capacity of up to 30 kW should be at least 7.5 m3, from 30 to 60 kW - 13.5 m3, over 60 kW - 15 m3;

- ceiling height - not less than 2.2-2.5 m, entrance door width - 80 cm;

- standard of natural light - 300 sq. see glazing per 1 m3 of the room, the window should be with a transom for ventilation;

- pipes for gas supply to gas boilers should be taken only metal, flexible hoses should not be used;

- in the boiler power supply circuit it is necessary to provide a thermal protection relay, and in rooms with a gas-fired boiler, it is necessary to install a gas analyzer - a device that detects a gas leak and gives a signal for emergency shutdown of the gas pipe;

- the boiler room should be separated from neighboring rooms by walls made of material with a zero flame spread index - concrete, brick, wood with fire retardant impregnation;

- on issues of explosion and fire safety, the project is consistent with the fire inspection.

Details of all rules and regulations are written in SNiP cipher boiler plants II -35-76Code of Practice SP-41-104-2000 on designing autonomous heat supply systems, document MDS 41-2.2000, which sets out the requirements for the placement of units for heating and water heating in low-rise residential buildings.

Compliance with numerous requirements is not dictated by bureaucracy, but by safety procedures. A free-standing boiler house is a chore with the construction of a foundation, capital walls, piping and heat insulation.

But in the house you get the absence of 100% harmful chemical impurities that inevitably accompany any combustion process, and full confidence not to suffer during an accident, the probability of which is scanty, but theoretically not excluded.

We also recommend that you read our other article, which describes in detail boiler room schemes for a private house.

What you need to know about boiler room ventilation?

A working boiler needs oxygen to maintain the combustion process, and it must be taken from the air. It is also necessary to prevent carbon monoxide from accumulating in the boiler room and entering the house. The influx of fresh air into the boiler room in relation to the outflow is supposed to be three times.

In the boiler room it is necessary to make supply and exhaust ventilation. For natural ventilation of the boiler room, a channel with a diameter of 13-15 cm is cut through in the wall opposite the boiler with a boiler power of up to 35-40 kW and 17 cm with a larger power. A ventilation pipe equipped with a shutter and a mesh is inserted into it.

If the boiler room is located in a separate room, then air supply from the outside can be provided through louvres installed directly in the entrance door - in its lower part.

The standard for the size of the supply holes is at least 8 cm2 transverse area per 1 kW of boiler power, if air draft occurs from the street. The ventilation of the boiler room is also associated with the ventilation system of the whole house. If air enters from the inside, the hole size must be calculated based on another standard - 30 cm2 per 1 kW.

An alternative to natural ventilation or in addition to it is forced ventilation. To reduce energy consumption, it is connected to boiler equipment - the fans will rotate only when the boiler is running. In gas and diesel boiler rooms, the ventilation system should be placed in the housing to prevent ignition and explosion.

An innovation for those who are interested in the specifics of a boiler house in a private house will be automated climate systems. They maintain the specified climatic parameters in the room in automatic mode and change them if necessary without human intervention.

All heating boilers are equipped with an open or closed type combustion chamber. For equipment with a closed combustion chamber, there are no restrictions on the volume of premises; the presence of a window is also not necessary.

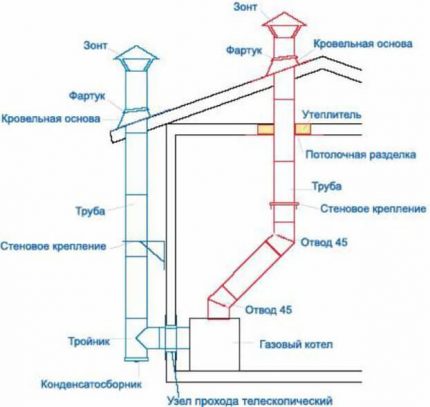

In the first case, smoke is vented out through natural draft through a vertical chimney. Part of the air from the room goes there, and therefore it is necessary to ensure constant ventilation of the room.

In the second case, the combustion products are forcibly removed from the chamber by a fan through a special double chimney - coaxial. In it, one pipe is embedded in another. Smoke moves on the inside, on the outside, the air necessary to maintain combustion enters the opposite direction.

The chimney according to the principle “pipe in pipe” is shorter and can be directed horizontally. For both types of chimneys, it is important that the cross-sectional area of the chimney is not less than the cross-sectional area of the pipe to which it is connected.

And finally, a few words about the design of the burners. They are atmospheric and supercharged. The devices of the first type are used only in gas boilers. Gas is supplied to them due to the pressure generated in the gas line or cylinder. One can hear the flame burning, there is no other noise.

In devices of the second type, the fan mixes gas with air so that combustion is more even.You have to put up with the noise of the fan. Boilers with pressurized burners operate both on gas and diesel fuel, they require a smaller chimney.

Boiler interior decoration

Brick and concrete walls of the boiler room are plastered and painted with water-based paint. Additional decorative finishes - ceramic tiles, metal cladding panels. Leaving the wall surface in its original form is not worth it. It is dusty, and this harms the operation of boiler equipment.

In a wooden house, the walls are impregnated with a flame retardant. On top of them, it is recommended to sheathe sheets of non-combustible drywall and also plaster, and attach aluminum sheets to the wall surface behind the boiler for reinsurance.

Plastering is another protection against wet fumes, fire, and other influences. You can increase the level of fire resistance with the help of special heat-resistant plaster. It can withstand high temperature heating and even an open flame of 30 minutes. up to 2.5 hours.

The floor is leveled with a cement-sand screed. The strength of ordinary ceramic tiles is not enough to cover the floor with it, since the boiler equipment is quite heavy, and there is a risk of dropping any weighty object. Porcelain stoneware will be more reliable. Tiles from this material are heavy-duty, not afraid of heating to high temperature and fire.

The drain chute will protect against accidental leakage. If this does not work out, then it is necessary to lay waterproofing around the perimeter to a height of 5-10 cm from the floor, and raise the boiler on a pedestal, thereby eliminating possible contact with water. It is easy to build from bricks and veneered with porcelain stoneware designed for the floor.

Ceramic granite on the floor is better to choose light with a matte texture. Traces of shoes and dust are not so noticeable on it.

Under the ceiling in the boiler room are pipes, wires. To disguise them, they make a box from the same drywall that was used on the walls. The box is plastered and painted from the outside. It makes sense to leave the inspection windows and close them with removable metal grilles.

It makes no difference which windows to install in the boiler room - plastic or wooden. In a fire, both will burn. In addition, plastic will melt and release toxic substances.

Modular boiler house construction

But what if there is no place for installing boiler equipment in the house, there is no possibility to erect a separate building, and the boiler room for a country house is very necessary? In this case, the modular boiler room will help out. It has factory equipment and is mounted quickly.

The maximum volume of premises for heating in this way is 1300 m3. The module itself is a small mobile house (container), the length of which does not exceed 2.5 m. It is made of a double strong metal frame with a heater made of special fiber.

The modular boiler room has a 3-layer pipe with thermal insulation for supplying a house with a length of 6 m, which can be extended if necessary. The equipment is delivered ready-made and requires only a connection.

To operate a modular-block boiler room, you need:

- install a container near the house;

- bring electricity (220V);

- prepare fuel (solid or diesel, depending on the type of boiler);

- fill the heating system with water.

The device of the modular boiler house provides backup power, which is enough to support normal operation in the event of a power outage during the day. The coolant temperature is automatically adjusted.

A modular boiler room can be purchased as standard or designed to order based on your own needs. Installation is recommended to be entrusted to specialists.

Conclusions and useful video on the topic

The principles of operation of an autonomous boiler room in a private house:

Boiler room in a 2-storey private house with a floor gas boiler:

There are a lot of rules for arranging a boiler room and installing equipment - perhaps you don’t need to delve into all the nuances. Entrust the matter to specialists. The main thing to understand is that a boiler room in a private house is a guarantee that you will always be warm and with hot water.

Are you going to equip a boiler room in a private house, but do not know where to start? Or maybe this topic is well familiar to you and could you give our readers sensible advice on arranging it? This can be done in the block below. There you can ask your questions on the topic of the article.

Window for a gas boiler house in a private house: legislative norms for glazing a room

Window for a gas boiler house in a private house: legislative norms for glazing a room  The scheme of the boiler house of a private house: the principle of automation and equipment location

The scheme of the boiler house of a private house: the principle of automation and equipment location  Fire safety requirements for gas boiler rooms: subtleties of arranging rooms for gas boiler rooms

Fire safety requirements for gas boiler rooms: subtleties of arranging rooms for gas boiler rooms  Chimney for a boiler room: calculation of height and cross-section according to technical standards

Chimney for a boiler room: calculation of height and cross-section according to technical standards  Safety group for heating: device, principle of operation, rules for selection and installation

Safety group for heating: device, principle of operation, rules for selection and installation  DIY heating manifold: schemes and assembly features

DIY heating manifold: schemes and assembly features  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I searched for a long time, but still found and installed a Soviet floor gas boiler (AOGV-11) in my new home. Its main advantage over everyone else is, of course, durability and resistance even to extremely high loads. The metal in such models is very solid and will not rot in a couple of years of use. In the event of a gas outage, such an unit can easily be converted to firewood simply by disconnecting the automatic gas supply system!

I advise everyone to buy professional equipment and install it strictly according to the technology in accordance with the design documentation. I had a bitter experience: there were two tanks from the military each of 8 cubic meters and a small boiler furnace on wood with elements of layering. I installed all this stuff in the house, made wiring in all rooms and recycled, but since the tanks were large in volume, they simply began to freeze at the bottom in winter. We live in Transbaikalia, the temperature overboard - 43. Such things.

A strange calculation of power is given. Yes, 1 kW per 10 m2, but all reserves have already been laid here, nothing needs to be added. And this is for a mediocre such house, not very warm, and for severe frosts.