What should be the coolant for heating systems: fluid parameters for radiators

Despite the advancement of alternative methods of space heating, in the vast majority of cases, the liquid heating circuit acts as the main source of heat. Due to its economy and efficiency, it is optimal in conditions typical of our long latitudes for long winters.

The downside is that water can freeze. Therefore, in addition to it, an anti-freeze coolant is also used for heating systems, replacing water. In this article, we will take a closer look at its main varieties, consider their significant advantages and main disadvantages.

We also give an algorithm for calculating the required volume of coolant for a particular system and recommendations for choosing the type of fluid for heating circuits.

The content of the article:

List of coolant requirements

The main task of the fluid in the pipes is the transfer of thermal energy from the boiler to the radiators.

For the heating system to be safe and energy efficient, the coolant must meet a number of important requirements, including:

- preservation of pipes from corrosion;

- chemical inertness to seals installed in the pipeline;

- a range of operating temperatures suitable for the operating parameters of the pipes (from freezing to boiling);

- high heat capacity to accumulate as much heat as possible;

- minimum ability to form scale;

- complete safety: no toxic fumes and maximum explosion and fire resistance;

- stable chemical composition - the liquid should not decompose and change its physical properties under the influence of high temperatures.

And now the main question: what antifreeze for modern heating systems meets all the requirements?

The answer may disappoint, but today there is no such fluid in nature.Such an ideal chemical composition has not yet been created. Therefore, the question of selecting the best option is a very urgent task for today.

When is antifreeze necessary?

Before you begin to consider alternative fluids, do not discount water. If heating is installed in a house where residents live constantly, then water will be one of the safest and most reliable options.

It as a coolant has optimal parameters for circulation along the contours of heating systems.

However, at the peak of winter frosts, the slightest crystallization of water can cause a serious accident with the destruction of the pipeline and components of heating equipment.

If we are talking about a country house, which is periodically hit, or when the family often leaves their monastery on weekends, leaving the heating unattended, then the heat carrier used must be resistant to the typical low temperature range for the region.

Only for the use of chemical compounds as a carrier of thermal energy, it is necessary to prepare heating circuits. The system must be completely sealed, as the liquid is toxic and flammable to varying degrees.

The owner must take into account that non-freezing fluid must be periodically changed, which is fraught with additional costs.

Some models of boiler equipment have specific recommendations on the use of a coolant of a certain brand. If you use a liquid of a different composition, then you can lose the warranty on the boiler.

Overview of popular coolants

To protect ourselves, we deal with each type of coolant in more detail.

Option # 1 - water with additives

70% of modern systems use water, including its modified formulations using additives.

What explains this popularity:

- complete harmlessness - leakage can only cause domestic difficulties;

- highest heat capacity - about 1cal / g * C (each liter of water is able to transfer more heat than any other liquid);

- low cost and availability - water has a minimum cost compared to non-freezing compounds. At any time, the water system can be replenished without significant investment of time, labor and money.

True, it is undesirable to replace the water in the heating circuit without a good reason. When heated, it is freed from salts and oxygen.

The water that has boiled over several times in the boiler does not already have the composition and amount of salts that it was when it was poured into the system. Unlike the new portion, it is practically devoid of free oxygen.

The flip side of the coin is as follows:

- Relatively high freezing point, so leave unattended water heating system it is impossible (otherwise, during freezing and expansion, water may break pipes and radiators);

- The salts contained in the composition can provoke deposits on pipes and heating elements, which reduces heat generation and overall system efficiency;

- Water is an oxidizing agent, and oxygen dissolved in it can cause corrosion of metal heating elements, including radiators.

There is nothing to be done with the freezing point, but other negative properties can be significantly reduced. For starters, you can reduce the concentration of salts using softening. Reduce the amount of bicarbonate salts by boiling.

Sodium orthophosphate, which can be bought at the store, allows you to soften the water. In this case, you need to remember about the right dosage, because excess reagents can adversely affect the thermal properties of water.

In order not to be confused with the dosages, you can use distilled water, but it will cost an order of magnitude more expensive. Now you don’t have to worry about the radiators clogging with scale. To cheat and save, you can use melt or rain water.

It is already distilled naturally. But its purity can only be partial. It could well be saturated with atmospheric pollution, but in any case it will be much softer than water from wells, wells or a tap.

Manufacturers offer distilled water enriched with inhibitory additives. They significantly reduce the likelihood of corrosion.

Also, surfactants are introduced into such a distillate. Their content in water minimizes the formation of deposits on the inner surfaces of radiators.

Surfactants cause existing deposits to exfoliate (followed by their removal from the system using a filter), and also reduces the chemical activity of water. As a result, all gaskets and seals will last longer.

Option # 2 - non-freezing antifreeze

Even distilled water with an optimal set of additives is not without its main drawback - freezing at 0 degrees Celsius. Special fluid for metal radiators does not have this flaw, in addition to having a lower crystallization temperature.

Low temperatures act differently on antifreeze than on water. Even if the minimum operating values are exceeded, the liquid does not crystallize and does not expand, but turns into a gel-like substance. Therefore, pipes and radiators are protected from deformation and damage.

As the temperature rises, the consistency of thickened antifreeze becomes more liquid, and the yield indicators increase, although in the normal state they are 15% lower than that of a traditional rival - water.

Concentrated non-freezing composition can be diluted according to the manufacturer's instructions, taking into account local climatic conditions. To obtain a liquid with a freezing limit of -30 ° diluted with water by half, for -20 ° part of antifreeze is mixed with two parts of water.

Most formulations can withstand up to -65 degrees. In most areas of the north and middle zone, the temperature rarely drops below -35, so antifreeze is often diluted with distilled water, lowering the threshold to -40.

Manufacturers of high-quality solutions make the composition as stable as possible, so it can last up to 5 years. After that, its full replacement will be required.

To achieve these properties, I had to sacrifice some of the benefits that water has:

- heat transfer of antifreeze is 15% lower, sometimes this may necessitate installation of additional radiators or sections;

- may contain toxic substances, therefore it is impossible to use antifreeze in 2 circuit systems, where the composition can get into the hot water supply circuit;

- high fluidity compared to water, due to which it is necessary to use specific seals that can prevent leaks;

- increased viscosity, which will require the use of a more powerful pump - recommendations for choosing a pump and an overview of the top ten models we reviewed here;

- a higher expansion coefficient will require the installation of a larger expansion tank.

When using all types of antifreeze, it is impossible to carry out the wiring of heating with galvanized pipes, as in contact with them, the ice-freezer loses some of its original beneficial properties.

The use of non-freezing liquids as coolants forces us to make changes to the design of the heating system. Due to the viscosity of antifreeze, it transfers heat more slowly to heating appliances, so it is better to increase the number of sections of radiators or purchase appliances with a higher heat capacity.

It is still necessary to reduce friction in pipelines by replacing fittings with analogs that are one size larger than those used in water circuits.

Modern non-freezing liquids, depending on the composition, can be divided into three main types:

- glycerin;

- based on propylene glycol;

- based on ethylene glycol.

We will consider each separately to choose the most suitable option for existing equipment and conditions.

Option # 3 - ethylene glycol-based non-freezer

One of the most popular antifreezes takes its place of honor on store shelves due to the most affordable price in view of the simple production process.

The liquid contains about 4% additives that prevent ethylene glycol from foaming at high temperatures. This also includes inhibitors that prevent corrosion from attacking metal surfaces.

Due to the aggressiveness of ethylene glycol, the product is used only in diluted form to protect the inside of pipes and radiators.

The main disadvantage of ethylene glycol is its toxicity. The minimum amount of this substance in the human body can cause serious health problems. Therefore, the entire heating system must have the highest degree of sealing.

Another gap in the use of ethylene glycol is constant temperature control. If the boiler heats the liquid to a temperature close to the boiling point, the composition will begin to decompose with the precipitation of a solid precipitate and the release of acids, which is destructive to all heating equipment.

The specified antifreeze is suitable only for those systems where it is possible to accurately maintain the temperature regime, but not all boiler equipment is equipped with such an opportunity.

Option # 4 - propylene glycol based fluid

This is a more modern antifreeze, which got rid of some of the shortcomings of ethylene glycol.

Benefits:

- non-toxic - in the composition there are additives that are used in the food industry;

- can be used in dual-circuit systems, as even a random mix in the drinking circuit does not harm human health;

- higher heat engineering properties;

- operated for 10 years;

- act in the heating circuit according to the principle of lubrication, which reduces the hydraulic resistance in the pipeline and increases the efficiency of the system.

But, one drawback could not be eliminated - this is incompatibility with zinc. Special additives lose their quality when flowing through galvanized pipes. Another relative disadvantage is the twice as high price.

Option # 5 - glycerin antifreeze

Glycerin antifreeze is equated to water, as it is close to an ideal set of properties, but at the same time it is criticized. Opinions differ, so it makes sense to voice all the points.

Proponents of the glycerin composition reveal the following benefits:

- environmentally friendly and safe solution;

- wide operating temperature range - -30 + 100;

- when freezing expands to minimum values;

- not aggressive to galvanized pipes and radiators;

- cheaper than propylene glycol;

- service life of 7-10 years.

The glycerol-based variant is non-explosive and non-flammable. A significant plus is that it practically does not destroy seals.

Among those who are against this coolant, there are such arguments:

- large mass, which causes an additional load on the pipes;

- lack of quality standards for glycerin mixtures;

- when overheating and evaporating water, it loses its properties, turning into a gel-like mass with hardening;

- increased foaming;

- at temperatures above 90 degrees, it can begin to decompose;

- lower heat capacity compared to propylene glycol;

- due to its increased viscosity, it contributes to faster wear of equipment.

It is worth noting that in some countries where ethylene glycol is prohibited, there is no production of glycerin coolants at all. In view of the contradictions in the use of glycerin liquid, the responsibility for its use lies entirely with the owner.

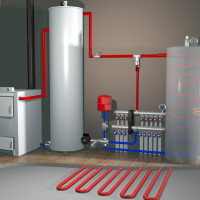

Option # 6 - coolant for the electrode boiler

This type of equipment must be noted separately, because electrode boilers require a special type of coolant. In this case, the liquid is heated due to ionization from the action of alternating current.

Antifreeze must have a certain chemical composition, which could provide three conditions: the correct values of electrical resistance, electrical conductivity and ionization.

Manufacturers of electrode boilers give their own strict recommendations on the use of specific brands of coolant. Therefore, it is necessary to select antifreeze with special care so as not to lose the guarantee.

Recommendations for choosing a tool

It is necessary to take into account not only the characteristics of the coolants for the heating system, but also the configuration of the equipment in order to make the heating safe and efficient.

If you decide to focus on the use of antifreeze, let's look at the conditions in which its use is excluded:

- lack of a heating temperature controller in the boiler;

- when using seals from linen winding with oil treatment;

- in the heating circuit used pipes, radiators, valves with galvanized surface;

open heating system

Evaporation of water from a non-freezing liquid can change properties, and ethylene glycol vapors are toxic.

Compliance with the following rules will allow owners to get rid of a number of troubles with incorrect use of non-freezing liquids:

- in places of compaction, the linen tow should be lubricated with sealing paste;

- sectional radiators need to be sorted out to replace the seal with gaskets made of Teflon or paronite;

- do not use automatic air vents (it is better to install for venting excess air Mayevsky cranes for manual adjustment);

- radiators and pipes should have an increased volume and diameter;

- the presence of a circulation pump of increased power;

- install membrane expansion tank with increased volume.

Antifreeze is poured into the heating system only after quality flushing the heating circuit, for which it is better to use special formulations. For the safety of all residents, experts recommend the use of propylene glycol.

The boiler must not be immediately after filling system output at peak power. It is necessary to raise the temperature in steps. This is necessary for the antifreeze to gain optimal performance and expand within the normal range.

When diluting the liquid with water, concentrations higher than -20 degrees must not be allowed. Excess water will lead to scale deposition and a change in the working properties of glycol. Only diluted with distilled water.

How to determine the volume of coolant?

The easiest way is to use a water meter or water meter. This is in almost every house or apartment with a centralized water supply.

Before starting measurements, the heating circuit must be completely emptied.Then the readings on the meter are taken, and the filling of the system with a small pressure of water begins. This is necessary so that there are no air jams that distort the readings.

As soon as the heating pipe is filled with water, you need to take the meter again. It must be remembered that 1 cubic meter is 1000 liters, and acquire the appropriate amount of liquid.

The second method is less convenient, but effective when there is no counter. The filled system is emptied through a measuring tank (tank or bucket of a certain volume). The main thing is not to get lost with the number of buckets.

Another method is mathematical. The initial data are the values of the volumes of radiators and expansion tank, pipe diameters, and the volume of the boiler heat exchanger. Using simple geometric and arithmetic formulas, you can calculate the total volume.

Detailed examples of the calculation of each of the elements of the heating system we examined in our following articles:

- Pipe volume calculation: calculation principles and calculation rules in liters and cubic meters

- Expansion tank for open heating: device, purpose, main types + tips for calculating the tank

Conclusions and useful video on the topic

The video will familiarize you with the opinion of a specialist on whether it is worth changing water to an anti-freezing liquid:

A detailed analysis of the features of filling the heating system with coolant and recommendations for the correct start of the system in the following video:

The above facts reveal a complete informational picture for each host, which is determined by the choice of coolant. He will know what kind of liquid he needs, what conditions are necessary for its use and how to create them.

And what kind of fluid circulates in your heating system? Why did you choose this coolant and are you satisfied with its operation? Share your opinion in the comments section.

Or are you just determining the type of coolant, but you did not find the answers to your questions in this article? Ask your questions in the comments - we will try to help you.

Flushing gas heating systems: flushing methods and procedure

Flushing gas heating systems: flushing methods and procedure  Types of heating systems for a private house: a comparative overview + the pros and cons of each type

Types of heating systems for a private house: a comparative overview + the pros and cons of each type  Bypass in the heating system: why is it needed + how to install it

Bypass in the heating system: why is it needed + how to install it  Filling the heating system with coolant: how to fill with water or antifreeze

Filling the heating system with coolant: how to fill with water or antifreeze  Thermostat for heating boiler: operating principle, types, connection diagrams

Thermostat for heating boiler: operating principle, types, connection diagrams  Removing air from the heating system: how to bleed air

Removing air from the heating system: how to bleed air  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

When we installed radiators in the new house we just built, we used glycerol-based liquid as the heat carrier, because it does not destroy the seals and is completely safe to use. Since glycerin is not explosive, and also it is not aggressive to radiators. And most importantly, it is a very cheap and economical tool to solve this problem.

When they made repairs in the apartment, they also wondered which liquid to use. For a long time I was looking for information, asking friends. Initially, I thought about not steaming and pouring ordinary water, but still I turned to the professionals for advice. They suggested that for our climate it is still recommended to use antifreeze, that’s what I did. In general, there is nothing to complain about, perhaps the only problem is the need to replace antifreeze every 3-5 years (depending on quality), no more shortcomings were noticed.

Is it possible to use a car anti-freeze / antifreeze / antifreeze in the heating system?

If you are carefully reading the article, then a separate paragraph in the material highlights that it is impossible to use antifreeze in its pure form in the heating system! Since this can lead to accelerated corrosion. Accordingly, it is necessary to choose the right concentration that protects the heating system from freezing and does not harm it during operation.

Antifreeze should be filled only after thorough washing of the heating circuit; for this purpose, it is best to use propylene glycol, which practically does not pose a health hazard.

The best option would be a solution in the form of glycerol-based antifreeze. The liquid does not burn and is not explosive, while its undeniable advantage is that it does not destroy the seals. Glycerol based antifreeze has a low corrosivity. I can’t tell you anything about ice-freezing and antifreeze.

A useful article, focusing on it, was poured into the Thermagent -30 ECO antifreeze system, consisting of propylene glycol and organic additives.