The Lemax gas boiler does not turn on: frequent breakdowns and ways to deal with them

You do not turn on the gas boiler Lemax, which worked properly last season or even yesterday? Perhaps some problems arose earlier, and now he completely refuses to work? Agree, staying in the cold without heating in the house is not a bright prospect.

Most gas heating Lemax boilers have a fairly simple, fully mechanical automation. This means that you yourself can eliminate most of the problems. This article will help to find and eliminate the reason why the boiler does not burn.

Consider both external factors that interfere with the operation of the unit, and its internal breakdowns. We give instructions for actions in different situations, as well as describe the features of boilers with electronic control.

The content of the article:

Non-volatile boiler does not light

Most owners of a Lemax gas boiler choose a power-controlled mechanical control device. This choice is justified, because it not only allows you to save heating when the lights are turned off, but also significantly reduces the number of potential breakdowns and the cost of components.

Perhaps the only weak point of such boilers is the ignition system, which is responsible for the correct and safe start-up of the apparatus.

Among the causes of failure in the start of the boiler there are both external ones - lack of draft in the chimney, insufficient ventilation, gas supply problems, and internal breakdowns of the boiler. We will discuss each option in more detail below.

Reason # 1 - weak traction

In non-volatile boilers, combustion products rise naturally through the chimney, due to the difference in temperature and pressure. These devices are demanding on the quality, cleanliness and proper design of the chimney.

There are several ways to check for traction:

- if the air intake is from the room, place a sheet of paper under the boiler. If he pressed against the bottom of the combustion chamber - everything is fine, there is a craving;

- if there is a through window in front of the burner, bring a lit match into it with the boiler turned off. The flame should extend and lean forward, deep into the furnace;

- boilers with coaxial chimney or two separate pipes pick up air from the street - do a test with paper or a match there.

If the draft is normal, you should look for the cause of the problem further, for example, in the connection of the draft sensor.

The lack of traction can be caused by various reasons on which the methods for solving this problem depend.

Firstly, the chimney becomes clogged over time - with soot, garbage, etc. Need him clean regularly, best of all - in the fall, before turning on the Lemax gas boiler after downtime, do not forget that not only the vertical part of the pipe needs to be cleaned, but also its bend coming out of the boiler.

Secondly, the pipe for exhaust gases must meet the requirements of the boiler in diameter and height. Also at the top should be deflector, protecting against blowing out, and partially, and from blockages.

Thirdly, if a part of the chimney outside the heated room is not sufficiently insulated, a cold air plug is formed in it, which prevents the removal of combustion products.

Finally, traction can be prevented by soot clogging of the burner and heat exchanger inside the boiler. However, cleaning them yourself can only be done superficially, with a brush. For complete cleaning, with the disconnection and washing of these nodes with soap and water, we recommend using our instruction.

Reason # 2 - the gas supply is not adjusted

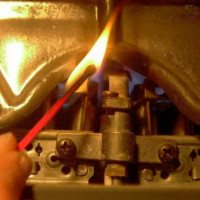

Quite often, owners complain that when they try to start, the Lemax boiler flares up, but immediately turns off. Most often, the problem is precisely in setting the gas supply to the igniter.

If it is minimal, then when you turn on the pilot burner first flares up, and then its flame is knocked down, blown off by the main burner turned on. Protection is triggered and the boiler completely shuts off the gas supply.

Another option is possible when the flame on both the pilot and the main burner is set to a minimum. In this case, the wick lights up, but does not reach the gas stream from the main burner, cannot ignite it. If you take a chance and wait, the boiler may flare up with a delay and pop, when the gas accumulates in the furnace a little, or the automation will turn off everything sooner to avoid an explosion.

If the igniter is burned too actively or with excessive draft, the flame may break away from it and not get onto the thermocouple sensor and the main burner, which also makes it impossible to start the boiler.

Lemax boilers are equipped mainly with Italian automation 630 Euro SIT or 710 MiniSITless often - 820 NOVA SIT. On all these units, the gas supply to the burners is regulated equally. Do not rush to turn the screws on the left side of the machine, which are not covered by a cover. Despite the availability, they are intended only for professionals - these are gas pressure measuring fittings.

To begin, remove the block cover by unscrewing one screw on its upper edge. Under it, you will see only 2 screws that can be turned with an ordinary flat screwdriver, larger and smaller - they are responsible for adjusting the flame of the burners.

The smaller screw is located in the far left corner of the upper panel, it controls the gas supply to the igniter.By twisting it, you reduce the flame, until the gas is blocked. In order for the pilot burner to work more actively, gently turn this screw counterclockwise to the desired result, but not more than 2 turns from the fully tightened position.

The larger screw is responsible for adjusting the minimum flame of the main burner; its reduction will help increase the efficiency of the boiler. However, do not overdo it: when firing up, the burner should turn on all at once, and not gradually, and without clap - otherwise it is unsafe.

On the side panel, near the gas hose connection, there is a screw for adjusting the maximum gas flow, but it is better not to touch it yourself, if necessary, ask to set up a specialist for the nearest maintenance.

Possible breakdowns and their repair

The failure of the boiler to start is not always associated with inaccurate settings or external causes, but almost always the malfunction can be eliminated independently.

Before any repairs, turn off the boiler, let it cool completely and shut off the gas supply to the riser. Even if you only burned the igniter, the risk of getting burned is very high.

Breakdown # 1 - Thermocouple Fails

According to the instructions, if the boiler with SIT automation does not turn on, the problem should be sought in the thermocouple and only in it. A thermocouple is a flame monitoring sensor that provides gas shut-off during burner attenuation.

When firing up, you need to hold the knob or special button pressed for 10-60 seconds, just so that the thermocouple has time to warm up from the flame and fix the solenoid valve in the open position.

However, there are a number of situations where this protection system fails:

- fire does not reach the thermocouple sensor;

- the sensor is smoky, oxidized, dirty;

- the thermocouple copper tube is burnt out or no longer conducts electrical impulses;

- the thermocouple is not sufficiently screwed into the adapter to gas valve.

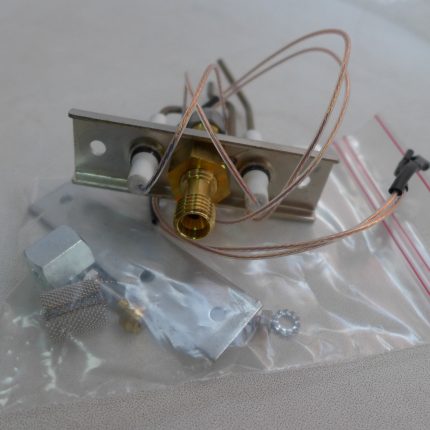

This component is not difficult to find in the boiler: it is a red, copper tube, one end of which is screwed into the control unit, from below, and the other into the socket near the igniter and piezo ignition.

First of all, try to slightly tighten the nut fastening to the automation. Bad contact can cause a malfunction. Carefully unscrew the lower end of the thermocouple, which is heated by a flame.

Inspect the sensor and clean it with a thick cloth or the thinnest sandpaper. Screw into place and try to start the boiler.

Did not help? Look through the window to see if the flame from the igniter hits the tip of the thermocouple. If not, bend it by unscrewing the socket with 2 bolts, or adjust the flame of the pilot burner, as we described above.

If you have a multimeter, you can independently check the performance of the thermocouple. To do this, unscrew both ends of it and pull out the part from the boiler. At the end that is screwed into the automation unit, you will see a lead tip that transfers charge to the gas valve. Clean it to a shine.

Position the thermocouple sensor so that it is exposed to fire from a gas stove burner or dry alcohol tablet. Connect the multimeter sensors to the lead tip and the thermocouple copper tube and measure the voltage. If everything is in order, look for the malfunction further, and if the problem is in the thermocouple, you will have to purchase a new part.

Breakdown # 2 - traction sensor is not working properly

The draft sensor is installed at the base of the chimney and is designed to shut off the gas supply by turning off the boiler if combustion products cease to be discharged.

Otherwise, it is possible to poison the residents of the house with carbon monoxide, therefore this protection system is mandatory in all gas boilers.

In non-volatile Lemax brand boilers, the sensor is connected to an adapter that attaches the thermocouple to the gas valve. If its circuit opens, the solenoid valve shuts off the fuel supply and the boiler shuts off.

If the design provides for an overheating sensor, it is also included in this circuit. Accordingly, with a non-working sensor, the boiler cannot be started: gas will be supplied only when the handle or the special button is pressed.

The sensor itself rarely fails, usually problems are caused by poor contacts and wires. First of all, disconnect the contacts and clean them with a thick cloth, solvent or alcohol. Inspect the integrity of the wire and its insulation, if possible - ring with a multimeter, if conductivity is broken - replace.

Dry the cleaned contacts, insert them into place as tightly as possible, the wires to the sensor itself can be soldered. Try to start the boiler.

If the situation has not changed, try to close the contacts on the adapter to the gas valve by wrapping them with wire.

If this helped, and the boiler worked, it means that the problem is still in the traction sensor. Do not leave the contact closed for long - this threatens your safety! Replace the sensor or call a specialist.

Breakage # 3 - nozzle clogging

It happens that when you try to turn on, even the wick does not light up and the hiss of gas is not heard, that is, nothing happens. This behavior of the boiler probably indicates that the nozzle or injector of the pilot burner is clogged.

To figure out how to light the pilot burner of the Lemax gas boiler, disconnect the tube going to it from the automation unit. On the panel near the burner, the gas supply pipe is the average of 3 connections; for convenience, you can first unscrew the thermocouple.

The nozzle supplying gas in a thin stream may be the end of this tube or a separate part. Use a toothpick to clean the nozzle hole and blow out the pipe making sure that air is passing through.

Remove the panel on which the tube was fixed by unscrewing 2 screws on the sides. You will see the mesh on the gas supply pipe - air is taken in through it to mix with the gas.

Given that the air supply is from below, along the floor, and near the boiler pets like to warm themselves, this mesh can become clogged with dust and wool, which does not always burn out. Blow this net - only without fanaticism.

Reassemble everything in reverse order and try to start the boiler. A positive result should be heard right away - this is the hiss of gas supplied to the ignitor.

Breakdown # 4 - problems with piezo ignition

Piezo ignition allows you to light the boiler without matches, at the touch of a button. The block under the button generates an electrical impulse, which is transmitted through the wire to the candle and forms a spark at its end.

Automatic ignition of Lemax boilers breaks down quite rarely, but if this happens, you need to accurately determine the place of failure. To do this, disconnect the wires from the candle located near the igniter, and try to press the button. If a characteristic click is heard, then the electrode is faulty, but if there are no clicks, the block is under the button.

You can try to clean the candle from soot by unscrewing the panel with a burner and a thermocouple. If necessary, buy a new part and replace. To remove and replace the block with the button, just remove the cover of the automation unit.

Failure # 5 - gas valve defective

The gas valve is responsible for supplying fuel to both burners, and also shuts off gas in emergency situations.From below, the solenoid valve is controlled by a thermocouple and a draft sensor, and from above, the pressure is regulated by a cylinder-bellows thermostat.

The system is multi-component, and the part is perhaps the most important in the boiler, so it is not recommended to intervene in its operation on its own.

Having heard from a specialist about possible problems with the gas valve, do not rush to be upset: you may not need a replacement. During prolonged use of the boiler, grease may develop and adjustment may be required.

You can get to the valve yourself by unscrewing the adapter into which the thermocouple is mounted and unscrewing the valve itself. It is not easy to do this - the valve is tightened very tight to avoid leaks.

From above, the SIT control unit can only be dismantled with a special screwdriver or key with a head TORX T-20. Before disassembling the control unit, be sure to mark the position of all the knobs and adjusting screws.

Electronically controlled boiler

The range of Lemax boilers that connect to the 220V network is actively expanding and now includes wall-mounted double-circuit models Primeas well as floor Clever and Wise.

Unlike foreign competitors, whose control boards often burn out due to power outages, these devices are designed to work in the conditions of Russian networks.

However, such models can sometimes fail.

To ensure safety, the main protection systems are still mechanical:

- the thermocouple controls combustion and shuts off gas, if the burner goes out - error E1;

- the draft sensor gives a shutdown signal if the combustion products are not discharged - error E3;

- the membrane gas valve will shut off the fuel supply if its pressure drops below a critical value or the gas is disconnected from the network - error E1;

- the overheat thermostat controls the temperature of the heating circuit; when overheating, it turns off the boiler with error E2.

All these systems are arranged in the same way as in boilers with mechanical control, and their location depends on the model. Therefore, we will not describe the inspection and repair of each unit again, and the instructions for it will help you find them in your boiler.

In addition, the electronically controlled boiler does not start if it detects a malfunction of any of its circuit board or sensor, or if its readings are unsatisfactory - for example, low water pressure or supply voltage less than 170V.

In order not to have to sort out the entire boiler, the error code and its interpretation in the instructions will indicate the location of the fault.

If the boiler does not respond at all to an attempt to turn on, even the screen does not light up, most likely - a problem with the power supply. No matter how trite, check if the plug is plugged in, if the machine is raised, if there is any light in the house.

The child could pull the plug out of the socket, and the machine could disconnect from the voltage drop, so do not neglect this advice.

If everything is normal with the power supply and the boiler display does not light up, call the after-sales service to diagnose and repair or replace electronic controls.

Conclusions and useful video on the topic

It is explained in detail and clearly why the wick on the boiler with EuroSIT 630 automation, which many Lemax models are equipped with, does not light up, is described in this video:

The Lemax electronically controlled boiler can be found in the following overview:

Now you know what to do if one day your gas boiler fails to start.Keep calm and check everything step by step - and you will surely be able to restore heating in the house.

And what model of the Lemax gas boiler is installed with you? Have there been problems with its launch and how did you manage to solve the problem? Tell other visitors to our site about this - join the discussion in the comments.

Why a gas boiler often turns on and off: the causes of malfunctions and their solutions

Why a gas boiler often turns on and off: the causes of malfunctions and their solutions  How to turn off the gas boiler for conservation: methods, detailed instructions and safety requirements

How to turn off the gas boiler for conservation: methods, detailed instructions and safety requirements  Conord gas boiler malfunctions: common breakdowns and solutions

Conord gas boiler malfunctions: common breakdowns and solutions  What to do if the gas boiler blows in the wind: causes of the boiler attenuation and methods for resolving the problem

What to do if the gas boiler blows in the wind: causes of the boiler attenuation and methods for resolving the problem  Why does the gas boiler go out? Overview of typical faults and how to solve them

Why does the gas boiler go out? Overview of typical faults and how to solve them  Why the gas boiler is noisy: why the unit is buzzing, clicking, whistling, clapping + how to fight

Why the gas boiler is noisy: why the unit is buzzing, clicking, whistling, clapping + how to fight  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements