Repairing a gas boiler valve: how to fix a unit by correcting a typical malfunction

Gas boilers are reliable equipment that provide heat and hot water to our country houses and part of city apartments. Unfortunately, they cannot work completely without breakdowns. And among the violations, valves often appear - protection devices and supply of fuel to the units.

We will tell you how and what kind of repair of the gas boiler valve can be done with your own hands. In detail we will analyze the situations that signal the occurrence of related violations in work. Let’s show you whether it’s worth making your own efforts or is it better to turn to gas workers.

In the article we present, you will find step-by-step instructions for restoring the functionality of gas boilers by repairing or replacing a gas, safety, and three-way valve.

The content of the article:

Varieties of valves in a gas boiler

The normal operation of gas equipment intended for heating sanitary water and preparing a coolant is provided by a wide range of systems, parts, devices, each of which clearly fulfills the important function assigned to it.

The design of gas boilers has the following valve types:

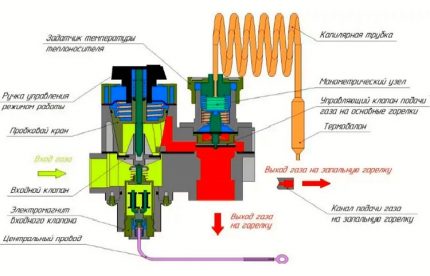

- Gas valve. A component of the gas system that is responsible for the proportional supply of blue fuel to the gas burner, ensuring a stable combustion process in accordance with the instructions of the electronic board. As part of this electromagnetic device, there are also shut-off and control valves.

- Safety valve. Hydraulic component designed to discharge surplus coolant from the heating circuit in case of exceeding the standard pressure values.

- Three way valve. Detail of the hydraulic system of dual-circuit boilers only. Redirects the flow of heated water from the heating circuit to the domestic hot water while consuming it for hygiene purposes. Depending on the class of the boiler, it happens with and without a servo drive.

All of the listed types of valves involved in the operation of the gas boiler can be replaced or repaired in the event of a breakdown.

Let's get acquainted with the technology for restoring their performance. Having mastered simple repair principles and techniques, you can significantly increase the life of the boiler itself.

Typical failures and repair methods

The types of valves listed above perform ambiguous functions and vary in design. The reasons why they become unusable and the ways to eliminate the breakdown differ.

Gas valve malfunctions

The main purpose of the gas valve is to adjust the pressure of the gas supplied through the nozzles to the burner. You can adjust the flow so that 25 to 100% of the flow enters the chamber. It all depends on what type of gas to be used in the operation of the equipment, how much air will flow for normal combustion.

In fact, this is an electromagnetic device, the main work of which is carried out only with the connection to the power supply. However, when its electromagnetic coils are de-energized, the gas valve acts as a safety part. In this case, it tightly overlaps the channels through which the gaseous fuel moves.

Generated thermocouple gas column or the heating boiler, the charge falls on the electromagnet (coil) of the gas valve, as a result of which the metal washer of the shut-off valve is magnetized to the coil. The washer opens the membrane so that gas can pass to the igniter and nozzles of the burner block.

When the flame attenuates or decreases below the standard values, the thermocouple stops generating electricity. As a result, there is a demagnetization of the coil holding the washer. The blue fuel supply channels are closing.

The need to take measures will be reported by a drop or increase in static pressure, i.e. inlet pressure when the boiler is idle. For units that process main gas, it must be at least 17 mbar. For boilers powered by liquefied fuels - not lower than 35 mbar.

The list of typical gas valve breakdowns includes:

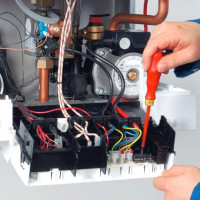

- Violations in the electrical circuit supplying the electromagnetic device. In this case, all wiring and contacts in the connection areas should be checked with a multimeter.When a break is detected, it is eliminated in a commonplace way: by replacing a damaged wire, stripping and tightening the contacts.

- Clogged gas valve. The channels of the device may periodically become clogged with mineral particles coming together with low-quality gas, elemental carbon deposits and calcium salts formed in the event of condensation in the supplied fuel. The simplest mechanical cleaning saves.

- Thermocouple failure. Often requires a complete replacement due to the complete burning of the working edge. At the same time, no current is transmitted to the electromagnet at all, as a result the boiler does not light at all or is blocked after a couple of minutes of operation.

- Mechanical damage to the gas valve. For example, the above washer. It either ceases to be pressed tightly and ensures tightness, or does not respond to adjustment, due to which an uncontrolled volume of gas enters the chamber. To eliminate this, either a valve or a damaged part is replaced.

- Short circuit on the body of the coil of the electromagnetic coil. Most often, it occurs due to short-term overheating and subsequent melting of the plastic sleeve, on which coils of the electromagnet are wound.

It is clear that the list of all breakdowns can be divided into two groups: violations in the electrical part and mechanical damage to parts.

We immediately warn that when carrying out any repair measures for which it will be necessary to remove the unit body, it automatically deprives the owner of the right to use the warranty from the manufacturer. In addition, neither the company nor the organization with which it is concluded service contract, will not bear the slightest responsibility for a negative result.

It happens that instead of learning how to correctly repair the electromagnetic valve of a gas boiler, the unit owner is trying hard to turn it on. At the same time, continuously presses the button of the gas supply device, trying to start the burner. This is absolutely impossible to do.

If you independently open the path to the gas flow, the boiler burner will still not light up. But the gas will flow uncontrollably into the room, while the owner will hold his finger literally "on the trigger." What does this threaten? At best, light poisoning, at worst - explosion.

The following selection of photos will introduce the steps to restore the electromagnetic coil of a gas valve:

Repairing the gas boiler valve is not too easy, but it is much cheaper than buying and installing new equipment for the preparation of coolant and hot water.

Having completed the repair, for the purpose of prevention, all components of the gas system should be cleaned of contaminants. Flux should be removed from the solder sites using a suitable solvent. Next, you need to check the operability of the valve by feeding it from a 1.5V battery.

Relief Valve Problems

The design of a new generation wall-mounted gas boiler has at least one safety valve. AT gas columns and old floor units for heating, it was not provided. It was believed that this protective device should have been mounted on the pipeline after the boiler.

Double-circuit units that process the heating system and branches of the sanitary water supply can be equipped with a pair of safety valves. One of them is put on heating, the second - on the DHW pipeline. In both cases, this device opens up from excess pressure in the system and releases excess water. Then it closes automatically.

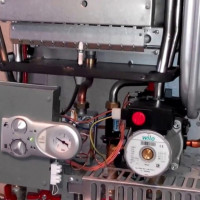

Problems with the safety valve to the owners of the gas boiler will be reported by a leak in the area of this protective device. It is located at the bottom of the unit, not far from the circulation pump. The technical data sheet will familiarize you with the exact location.

If there is a serious breakdown, it does not make sense to repair the safety device. Only a replacement is made. If a grain of sand gets stuck under the seal or in the mechanical part, there is a reason to tear apart the device and assemble it again.

Maintenance valve problems

We repeat - only three-way valves are supplied double-circuit boilers. Their task is to redirect the flow of water from the heating to the domestic hot water and vice versa. More precisely, at the command of a three-way valve, water enters the plate heat exchanger for its subsequent supply to the water points or to the main heat exchanger associated with the heating system.

Violations of the three-way valve can be determined:

- To reduce the temperature of the coolant in the heating circuit.

- By cold water entering the plumbing fixtures when the heating equipment is running.

- By the absence of a switching effect, i.e. for heating either only coolant, or only sanitary water.

The most common cause of a three-way valve failure is the appearance of mineral deposits on the inside walls of the device. This happens because of the simplest clogging, because the filter was not installed on the water supply in front of the gas boiler.

The servo drive burns out much less often or its individual components fail. If a drive problem is found, the three-way valve will have to be replaced completely. It is selected according to the specification specified in the data sheet by the manufacturer of the unit.

However, mercilessly throwing away the switching device in case of failure does not need to work. You can try to restore the operability of such a device in order to leave it as a backup device.

The steps for repairing a three-way valve are detailed in the following photo gallery:

Do not forget that the water redirection device is connected to the power supply. So, if the valve itself is not damaged, there may be a malfunction in the wiring. They are eliminated in an elementary way: first, they check the wiring, they ring, then the damaged wire is changed.

If everything is in order with the wiring, then you need to check the contacts. All joints are checked with a multimeter. For prevention, they need to be disconnected, wiped with an alcohol-containing composition, reconnected, tightening with effort.

It happens that the failure of the three-way crane to do the job is not to blame for himself or the wiring, but the electronic board sending the commands. In the workshop, of course, they can restore it, replace the burned-out resistor. But most often they change completely to a similar model.

Conclusions and useful video on the topic

The following video will introduce the gas valve device, the causes of malfunctions and repair methods:

Solving the problem with a three-way valve of a gas heating unit:

Dismantling and cleaning the safety valve:

Repair of valves of gas equipment will significantly extend the operational life of units. Repairing them is much simpler and cheaper than buying a new model. Not all repair operations are recommended to be carried out independently, but the simplest actions are quite accessible to home masters.

Want to share your own experience in restoring the functionality of gas boiler valves? Do you have useful information on the topic of the article, which is worth sharing with site visitors? Please leave comments in the block below, ask questions, post photos.

Repair of a gas boiler "Proterm": typical malfunctions and error correction methods

Repair of a gas boiler "Proterm": typical malfunctions and error correction methods  Repair of a gas boiler Vaillant: decoding of encoded irregularities in work and methods of dealing with problems

Repair of a gas boiler Vaillant: decoding of encoded irregularities in work and methods of dealing with problems  Pressure switch for a gas boiler: device, an overview of popular faults and their repair

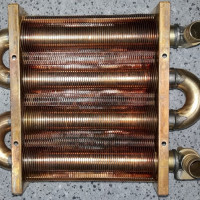

Pressure switch for a gas boiler: device, an overview of popular faults and their repair  Do-it-yourself gas boiler heat exchanger repair + instruction on repair and part replacement

Do-it-yourself gas boiler heat exchanger repair + instruction on repair and part replacement  Gas boiler repair: an overview of common failures and how to fix them

Gas boiler repair: an overview of common failures and how to fix them  Repair of gas boilers Ferroli: how to find and fix an error in the operation of the unit by code

Repair of gas boilers Ferroli: how to find and fix an error in the operation of the unit by code  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements