What to do if the gas boiler blows in the wind: causes of the boiler attenuation and methods for resolving the problem

Autonomous heating system provides a comfortable environment. When it fails, established order and comfort are disrupted. Agree, nobody wants to stay in the winter with a constantly fading heating boiler. And if a gas boiler blows in the wind, what should the owner do in such a situation?

We will help to deal with this problem - the article discusses the causes of boiler attenuation and methods for solving this problem. Visual photos and videos are provided.

The content of the article:

Reasons for the extinction of the burner flame

The attenuation of the boiler from the wind is not such a rare problem. This is less common for apartment owners - 95% of the equipment has a coaxial duct. But homeowners often face burner attenuation. Let's try to find the source of the problem and restore the device.

So, the boiler may go out due to inconsistencies in the technical parameters of the chimney and operating conditions. Another factor wrong arrangement of ventilation. It is reasonable to entrust the elimination of such malfunctions to specialists.

Often there is a situation when the air mass acting from outside creates pressure and the check valve is activated. A strong gust of wind returns it to the closed position, the gas supply to the furnace is stopped. In this case, reconstruction of the chimney is needed.

The boiler attenuation may be due to:

- Breakage flame detector. A worn-out thermocouple or ionization electrode knocks out automation after the slightest blow of the wind. The solution is to replace the defective part.

- Weak burning wick due to clogged or insufficient pressure at the inlet. If there is a regulator, you need to check its settings and increase the pressure. Plus clean the wick.

- Bad traction in the chimney.

- System availability for wind - no protection.Refers to single-story buildings and upper floors of high-rise buildings. The problem is solved by installing a weather vane-deflector.

- Incorrect chimney design - when there are not enough turns. If he leaves the boiler directly into the wall, the wind freely enters the boiler. But on the outlet pipe you can not do more than three turns.

- Incorrect ventilation system or lack of channels.

- Faulty safety sensors — traction sensorlimit thermostat. It is necessary to check the contacts of the protective equipment and clean them.

- Finding a chimney in the area of wind backwater.

Why else can a gas boiler go out in the wind? Sometimes the equipment is located in the kitchen with a balcony on the second or third floor of the building. It is enough to open the balcony door so that a strong draft is formed sharply, the wick began to oscillate and fade.

It is useful to inspect the exterior of the heating system for ice build-up.

It’s not worth knocking him down. It is necessary to shut off the gas, bring removable parts into the room for slow thawing. After returning them to their place, warm up the device, gradually increasing the gas pressure.

Ways to solve the issue of boiler attenuation

The option of restoring the operability of gas equipment depends on the cause of extinction. Next, we will understand what can be done to prevent the boiler from attenuating in the wind.

No. 1 - the fight against bad traction

The draft is an external force in the chimney that causes the combustion products to rise and go into the atmosphere, changing places with fresh air. This is due to the higher density of cold air compared to the density of warm combustion products.

In the context of the boiler attenuation problem, traction can be:

- Insufficient, which leads to the operation of the sensor and the attenuation of the burner.

- Excess - formed when there is an overabundance of ventilation ducts, the chimney is in the wrong position. In this case, the speed of the exhaust gases increases and the boiler goes out.

- Reversedue to which the flow of combustion products changes direction and returns to the furnace. Not only the extinction of the flame, but also the gas contamination of the premises is observed.

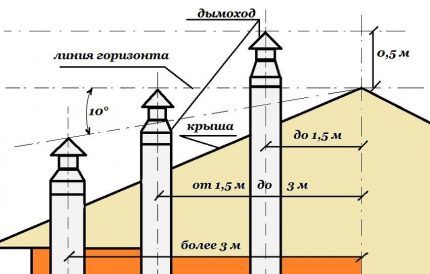

Sources of trouble lie in the design flaws of the chimney or current malfunctions. Particular attention should be paid to the location of the pipe - its upper part should rise at least half a meter from the extreme point of the roof.

It is necessary to check the tightness of the joints, the health of the fan, the presence of foreign objects in the pipe, debris, a large layer of soot and eliminate the defects. Among the current malfunctions is the damage to the insulation - the chimney must be warm.

No. 2 - installation of a weather vane-deflector

The current method for the attenuation of the boiler from the wind - installation in the chimney deflector. The aerodynamic device can be of different configurations.

In a conventional weather vane, air flow is directed to the outside. Their interaction with the surface of the deflector creates a rarefied atmosphere, which increases traction.

A simple weather vane increases the efficiency of any pipe by 15-20%. But he is not able to completely solve the problem of the extinction of the boiler. It is more profitable to use a device of complex configuration.

Suitable designs:

- Grigorovich;

- Volpert;

- spherical, rotating;

- others.

AT Grigorovich deflector all elements are subject to the laws of aerodynamics.The device is two-cone. The interaction of the forward and reverse cones distributes the passing air currents so that a low pressure zone forms around the pipe.

Wolpert baffle represents a design from two "glasses" - cylindrical and with expansion downwards. The top with a lid is somewhat on the bottom.

There is a joint device - Volpert-Grigorovich deflector. It contains an inverse cone, a curved surface of the diffuser and an umbrella cover. The design shows good efficiency in solving the problem of the extinction of the boiler and increases its efficiency by 25%.

The requirements for the deflector for the chimney of the gas boiler and installation instructions are given in next article.

Any deflector requires regular maintenance - cleaning and lubrication, otherwise the opposite effect will occur. Visors are not recommended to install umbrellas - they violate safety precautions.

No. 3 - gradual heating of the boiler

If the heating system has been shut down for a long time, the wind may blow out the gas boiler due to insufficiently heated chimney. This situation is typical for country houses, when after the first start-up of the equipment the burner quickly fades.

The explanation of the phenomenon is simple: it is difficult for spent combustion products to climb up the cold pipe, and gusts of wind interfere with the heating of the channel.

You need to act like this: start the system at low speeds and gradually increase the power of the device to optimal performance. This will create natural conditions for the release of hot combustion products.

Solving the problem for different types of boilers

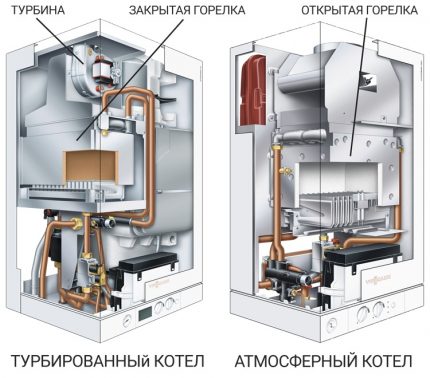

Equipment with a closed burner is referred to as turbocharged and it needs electricity to function. To prevent damage to the control board in the event of a power outage, install the boilers when installing Voltage regulator.

Boiler units with an open combustion chamber are called atmospheric. They are independent of the power supply system.

So, atmospheric and turbocharged boilers have a different device. Therefore, the principles for solving the problem with their attenuation will also differ.

AT atmospheric boilers natural traction. The device does not receive the set volume of air if it is insufficient or insufficient air flow. It is necessary to artificially increase the amount of oxygen taken in by means of arranging additional supply ventilation and a regular hole in the door with a grill.

You can also use one of the methods:

- reducing the diameter of the chimney through the installation of the inner pipe, which will accelerate heating and eliminate the effect of excessive dilution of the gas with air;

- deflector installation;

- increase in the length of the chimney.

Turbocharged boilers more stable in operation, but if installed on the leeward side.

In the opposite situation, installation of the deflector or reconstruction of the chimney by creating a system in it will help "Traction gap" - construction inside the chimney of the zone, preventing the reverse movement of combustion products.

Conclusions and useful video on the topic

Installation of a partition from the wind.

How to make a protective cover for a parapet boiler.

What is useful to know before installing and operating a weather vane deflector.

The effectiveness of the heating system depends on the competent thermal calculations when designing a home, proper operation and regular maintenance. Having considered the reasons why a gas floor or wall boiler blows out in the wind, we can summarize: the problem is eliminated by replacing (repairing) individual parts, checking or refitting the entire structure of the chimney.

Measures to restore the performance of the equipment should be entrusted to specialists. If you do this yourself, you must consult with experienced craftsmen.

Do you want to talk about your experience in solving the problem of boiler attenuation in wind? Write your recommendations in the comments section.

If you still have questions about the topic of the article, which we did not touch on in this publication, ask our experts. The feedback form is located below.

Why a gas boiler often turns on and off: the causes of malfunctions and their solutions

Why a gas boiler often turns on and off: the causes of malfunctions and their solutions  What to do if condensate in a gas boiler: methods for preventing the formation of “dew” in a chimney

What to do if condensate in a gas boiler: methods for preventing the formation of “dew” in a chimney  Why does the gas boiler go out? Overview of typical faults and how to solve them

Why does the gas boiler go out? Overview of typical faults and how to solve them  Water flows from a gas boiler: what to do if heating system equipment has flowed

Water flows from a gas boiler: what to do if heating system equipment has flowed  Errors of gas boilers Baltgaz: trouble codes and troubleshooting methods

Errors of gas boilers Baltgaz: trouble codes and troubleshooting methods  Conord gas boiler malfunctions: common breakdowns and solutions

Conord gas boiler malfunctions: common breakdowns and solutions  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements