Pressure switch for a gas boiler: device, an overview of popular faults and their repair

The pressure switch in the design of a gas boiler is a device that is not familiar to every owner of gas equipment. The mechanism, which is, in fact, a differential pressure switch, is triggered by the force of the smoke flow traction generated by the fan system. But how is the pressure switch arranged for a gas boiler, why is it needed and what kind of malfunctions is it prone to?

We will consider these issues in more detail in our article - we will talk about the design features of this part, which acts as a controller for the normal operation of the fan and the flue gas removal system. Technical analysis of the pressostat will help to understand the operation of the gas burner, fully master the operation of the boiler, and respond correctly to emergency shutdowns.

The content of the article:

Gas boiler pressostat design

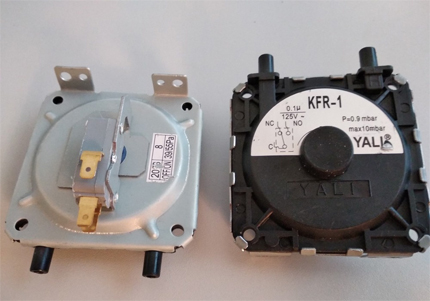

The execution of the pressostat is not distinguished by pronounced mechanical or electrical complexity. However, the pressostat device of a domestic gas boiler still has unique details, for example, a sensitive membrane.

This element is associated with a microswitch acting as a signal switch. To work on burner control, a group of three contacts is usually used (control in normal mode or emergency). In fact, one contact is “shared.”

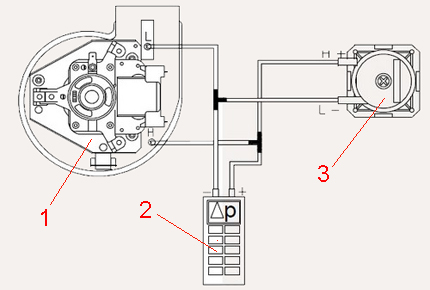

The normal functioning mode of the boiler equipment is accompanied by the operating state of the thermostatic membrane, in which the circuit remains closed through one configuration of the boiler pressostat contacts. If the operating mode of the equipment is violated (the smoke stream changes the characteristic), accordingly, the position of the sensitive membrane changes.

In this state, the working group of contacts of the microswitch breaks, while the second group (emergency start), on the contrary, forms a conductive circuit. Through this circuit, power is supplied to the automatic locking system, as a result of which emergency control of the gas burner and the water circulation system are activated.

Due to the presence of a pressostat, the following are effectively implemented:

- temperature control;

- smoke pressure monitoring;

- control condensation.

All of the above functions dramatically affect the operation of water heating equipment, provide not only effective functionality, but also boiler operation safety.

How to check the functioning of the device?

Diagnosis of the proper functioning of the pressostat of gas equipment is a necessary and useful matter. As a rule, such verification is carried out by representatives gas companies using special devices.

However, the owner of the gas boiler itself can also perform a kind of “testing” with simple actions. Just keep in mind - such actions violate service rules gas equipment.

If, however, the owner decides to break the rules, it is enough to reduce the supply of network water entering the boiler, for example, by partially covering the shut-off network tap of the water supply.

As a result of reducing the mass of the water duct in the gas boiler system, the temperature and pressure of the flue gases inevitably begin to change. The fan increases the speed in order to create a larger vacuum in the chamber.

Accordingly, according to the theory of operation of the pressostat, this device is triggered by turning off the boiler due to insufficient vacuum through the supply line of the silicone tubes. The operation of the device also occurs in the opposite case, when the vacuum value exceeds the set value.

Pressostat breakdowns and repair tips

Before considering how to independently fix the pressure switch installed on a gas boiler, we will deal with typical malfunctions affecting this structural element.

Identification of major faults

As the practice of operating domestic gas boilers shows, the defects of a differential relay are usually indicated by:

- the absence of a characteristic “click” when starting the fan of the gas exhaust system;

- the inability to start gas equipment;

- error signal output through the indicator or on the display;

Any of the errors noted may be related to defects in pressure switch elements, as well as with such a rather ordinary moment as the appearance of an oxide film on the contacts micro switch pressostat.

Also, a fairly frequent reason for the inoperability of gas equipment becomes physical membrane wear differential rele. This part of the device is traditionally made on the basis of silicone rubber.

As long-term operation, the rubber partially loses its elasticity (dries). As a result, the malfunction of the mode microswitch is noted.

Among other things, physical fan wear flue gas exhaust can cause emergency operation of the pressure switch. Similar conditions are not excluded due to clogging condensate assembly system, damage to system piping and etc.

We also recommend that you review the health check instructions. traction sensor and three way valve in a gas boiler.

How to repair a pressure switch on a gas boiler?

If the causes of the malfunction of the pressostat of a domestic gas boiler are specifically identified, then most often the best way out is to completely replace it.

This approach is explained by the fact that most of the differential relays of gas boilers have a "cast" design. Accordingly, it is simply more expensive to repair such a device than to buy a new one.

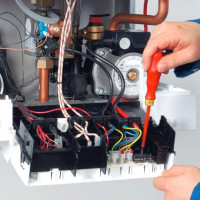

However, if there is a desire, skills and abilities, an attempt is not torture. First, you will have to dismantle the device by turning off the power to the gas boiler and by shutting off the linear gas supply valve.

Then you can start extracting the pressure switch, for which you have to:

- open the boiler body;

- remove the air intake cover;

- disconnect the silicone tube from the fan nozzle;

- unscrew the fasteners and dismantle the pressure switch;

- disconnect a pair of “faston” contacts from the device;

- disconnect the silicone tube from the device fitting.

The first step is to check for contamination of all the silicone tubes included in the system. If there is contamination inside the tubes, respectively, it is necessary to rinse and purge the inner area.

It is also recommended to rinse and purge the inner area of the differential relay using special technical fluids neutral to silicone.

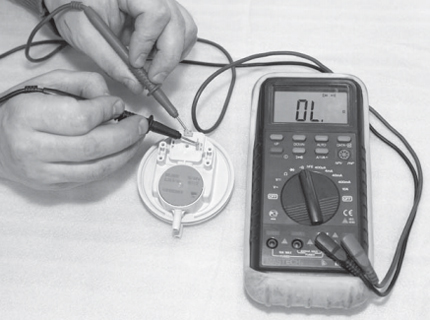

Then the microswitch, namely the contact group of this element, is subject to verification. The conductivity of the contacts is checked using a measuring device - a tester. In the event of a conductivity violation on any of the contact groups, the microswitch should be repaired or replaced with a new one.

When checking the micro switch of the pressure switch of a gas boiler, a simulated pressure vacuum may be required. To do this, it is enough to connect a small segment of the silicone tube to the pipe of the pressostat of the gas boiler, marked with a minus sign. The second (“positive” pipe) is simply closed, and air is sucked in through the connected tube with the mouth with little effort.

In the process of performing such manipulations, the measuring tester is connected to the contact groups of the microswitch and the presence or absence of current flow through the contacts is checked.

This testing technique, of course, is purely “everyday” in nature. Professionally, these same actions are performed using service equipment.

In addition to a breakdown in the pressure switch, the user of the gas boiler may encounter a number of other breakdowns. An overview of popular faults and recommendations for their repair we gave in next article.

Conclusions and useful video on the topic

The video below details the repair of the boiler pressure switch:

It is quite possible for the user to operate the differential relay of the gas boiler on their own, using special service terminals for these actions. Almost every model of equipment has such - fittings for connecting a device that measures depression.

At the same time, it is strictly forbidden to carry out any technical work on gas boilers or columns without the appropriate permission and admission of special services. Failure to comply with such rules and requirements threatens to result in accidents, which practice has repeatedly confirmed.

Want to talk about your experience in detecting a pressostat malfunction and successfully resolving it? Or do you still have questions that we did not address as part of our publication? Ask them to our experts and other site visitors - the feedback block is below the article.

Gas boiler repair: an overview of common failures and how to fix them

Gas boiler repair: an overview of common failures and how to fix them  Junkers gas boiler malfunctions: breakdown codes and troubleshooting

Junkers gas boiler malfunctions: breakdown codes and troubleshooting  Rinnai gas boiler errors: trouble codes and ways to fix them yourself

Rinnai gas boiler errors: trouble codes and ways to fix them yourself  Voltage stabilizers for a gas boiler Baxi: TOP-12 of the best models according to consumers

Voltage stabilizers for a gas boiler Baxi: TOP-12 of the best models according to consumers  Repair of a gas boiler "Proterm": typical malfunctions and error correction methods

Repair of a gas boiler "Proterm": typical malfunctions and error correction methods  Gas boiler draft sensor: how it works and works + subtleties of functionality testing

Gas boiler draft sensor: how it works and works + subtleties of functionality testing  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements