Rinnai gas boiler errors: trouble codes and ways to fix them yourself

The Japanese corporation Rinnai, has established itself as a global manufacturer of reliable gas boilers. But like any gas-using devices, for some reason they can malfunction. To identify possible malfunctions, the errors of the Rinnai gas boiler are displayed on the display in the form of indicators or numbers and make it possible to accurately identify the reasons for quick troubleshooting.

If you think that all this is very difficult, then you are mistaken. In fact, there is nothing complicated in automatic diagnostics and thanks to these numbers, if you even have a little technical knowledge of heating units, you can fix many problems yourself without calling the wizard.

And we will help you - we will describe the most common boiler errors of this company, possible solutions to them, and also lay out some manuals for the convenience of identifying those codes that are not in our article.

The content of the article:

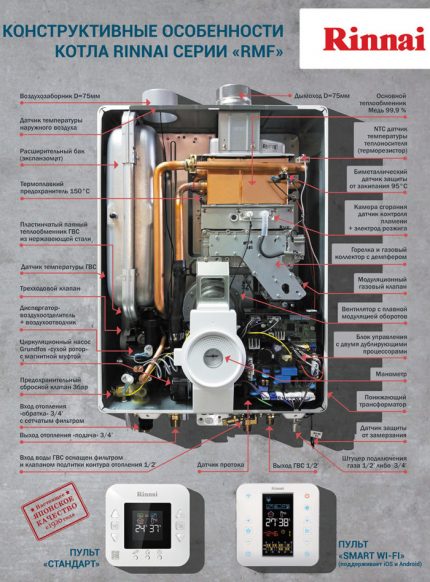

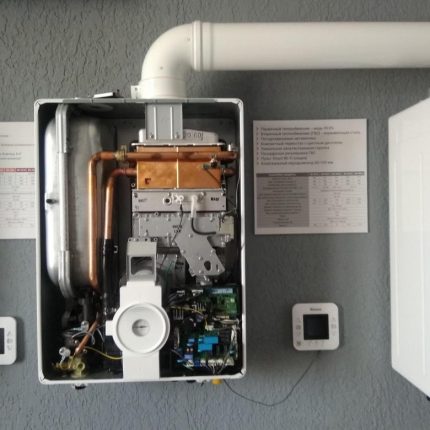

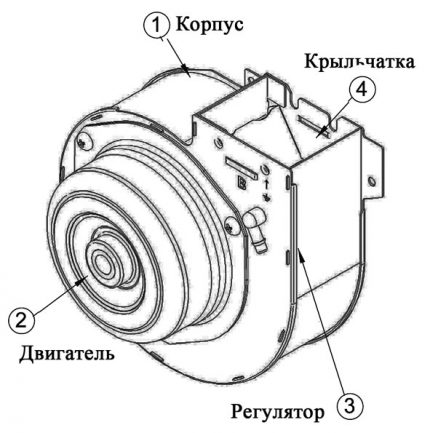

The device of gas boilers Rinnai

Typical dual-circuit device this company, with all its functionality, is quite simple. If you are even a little versed in the design of heating boilers, it will not be difficult for you to find one or another element for its diagnosis.

So, 2 branches extend from the upper part of the device body. One pipe is exhaust, and the second is air intake. Both elements go tocoaxial type chimney. Accordingly, through it both oxygen intake for combustion and the withdrawal of combustion products occur.

2 pipes also come out of the lower part - gas and water supply.

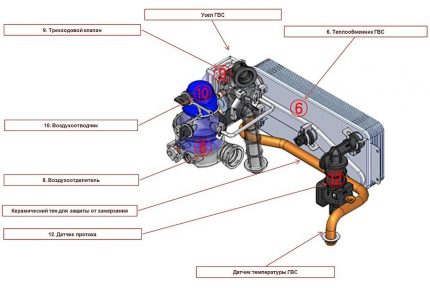

In the closed combustion chamber there is a three-stage type burner.

Above the nozzle is the main heat exchanger with copper plates.A secondary one, consisting of copper and stainless plates, is located below, it is used to heat the hot water supply system, and a three-way valve is attached to it.

There is an expansion tank at the top, and a circulation pump at the bottom, which usually works universally for open and sealed systems.

And now for the fun part. This is a remote control with a display. Thanks to this technological device, the temperature regime is regulated both for heating and for domestic hot water. And besides, self-diagnosis indicators are displayed on its high-contrast display.

How is the error output?

As already mentioned, error identification occurs with the display of the remote control panel.

The first and second digit is the error code. For example, 16. The third digit (stands after a space from the first two) is the boiler output.

It is indicated by numbers from 2 to 6, and reads something like this:

- 2 = 167;

- 3 = 207;

- 4 = 257;

- 5 = 307;

- 6 = 367.

And the last, fourth digit, the type of chimney: 2 - ME, 3 - MF.

In the event of a malfunction, the remote control begins to signal (beep) to the owner about difficulties in the system and displays an error code on the screen.

The most common series instrument errors RB RMF, we will now consider with you, and begin with prevention, so that you are less likely to encounter such problems.

Troubleshooting and preventive diagnostics

If you have any malfunctions with the heating and hot water supply of Rinnai boilers or you want to check the operation of this system, you will need to perform several diganostic actions.

Here is a brief overview of the general work on this procedure:

- Necessary inspect the gas valve — GSA VALVE and the state of its performance. Typically, with such problems, error 11 is displayed.

- Check the opening status of 1 and 2 electronic valves.

- Measure the voltage at the piezoelectric source (AC 220V).

- Pay attention to the connection of the proportional valve. This causes an error 52

Another valve to be inspected is warm water. By the way, its minimum working amount is approximately 1.7 l / min and this parameter is also recommended to be checked.

AT errors 15 and 16 we will look at options for malfunctions related to boiling and overheating.

To diagnose such problems, you must:

- inspect the electronic valve and the water supply for operability. Their operating voltage is 220 volts; when it stops, it is zero;

- pay attention to the pump. It can stop due to pollution, also in the case of this element, one can consider the breakdown of the relay and the contactivity of the capacitor wires;

- check heat exchanger for blockages and rinse it if necessary;

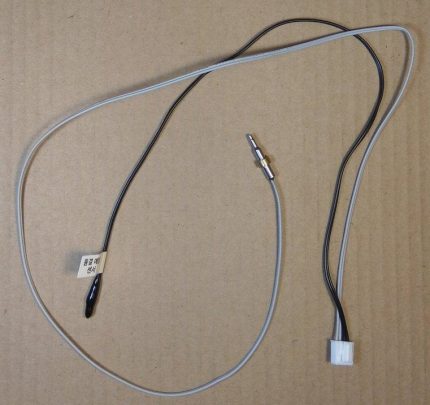

- If the temperature rises sharply, pay attention to the malfunction of the thermistor.

It should be noted that these recommendations do not apply to those owners of boilers who have a very poor understanding of the device and the principles of operation of gas-powered equipment.

And now we will analyze the most common error codes and their solutions.

Rinnai boiler error codes

A flashing heating light indicates a blockage in the system where filters must be cleaned.

Error 7 in hot water mode.The boiler thinks, or so it really is, that hot water is continuously used for 8 hours.

If you do not, first of all:

- pay attention to the water flow sensor - if there is no PULSE mode, if the “water drop” indicator on the remote control is on while using hot water;

- check if the taps are closed;

- inspect hoses and pipes for water leakage;

- if yes, eliminate the leak;

- restart the boiler via the control panel.

Error 11 associated with ignition problems. Its symptoms include the absence of a flame on the burner or its short burning, that is, the inability to ignite a gas boiler.

The cause may be a low pressure of the incoming gas, and in this case, you just need to light the gas stove to check.

If everything is in order with the gas pressure and the valves leading to the aggregate are not blocked on the main pipe, then it is necessary to diagnose and repair the Rinnai gas heating boiler, which should be trusted by professionals.

For diagnostics, the equipment will have to be checked:

- the presence of all boiler connections, which include proportional valves and electromagnetic (operating voltage: 220 V, stop - 0 V) fan, ignition electrode, and so on;

- check the load during ignition, triggered in order;

- Check for clogged heat exchanger plates.

- check bimetal fusible fuse;

- be sure to inspect the connection of the chimney and its condition.

There is also the possibility of a problem with the electronics.

Error 12 occurs when the boiler is extinguished more than 20 times. Symptom - the flame lights up and immediately goes out. Possible causes are leakage of blue fuel, blockages in the filtration system, and insufficient pressure. It is necessary to check the primary pressure and whether the filters are clogged.

Error 14 indicates that you have problems with the temperature sensor, for some reason the connection with the temperature fuse or electronic safety module has been disconnected.

From what a person with experience in working with gas boilers can do, check the connection at the terminal and the fuse for a short circuit. But in most cases, a specialist visit is required to replace the electronic module.

Error 15 due to malfunctions arising from the overheating sensor, the absence or problem of circulation of the coolant in the heating system.

What do we have to do:

- Check if there are leaks in the device or the system as a whole, and if there is a shortage, make up for them (in particular, low pressure on the pressure gauge).

- Inspect the filter.

- Check mains voltage and condition of thermistor.

- Restart the boiler after all actions.

- Check if there is a problem after restarting.

Error 16 characterizes overheating in the system when the temperature of the coolant is more than 95 degrees and lasts for 3 seconds or more.

In this situation, you must:

- check if the taps of the heating system are closed - valves for opening and distribution;

- if there are any air plugs in the pipeline;

- eliminate the possibility of blockages in the line and inverse filter;

- check the presence and level of coolant;

- inspect the condition of the three-way valve and thermistor, measure the resistance at the terminals of the thermistor;

- Be sure to check the pump's performance.

Error 17 indicates a water leak and occurs after 3 water make-up signals.

Occurs in the period from 24 to 64 hours after the start of heating. Eliminate the error after diagnosis - checking for water leakage in the device itself, the pipeline system, inspection for the presence of airing system.

Error 18 It is connected directly with the power supply of the device. A ground fault is detected. It is necessary to diagnose the voltage between the third pin of the electronics module and the “ground”, inspect the boiler wiring for exposure of insulation, a short circuit on the device’s operating line, the status of the control panel

Error 20- Dip SW switches are set incorrectly or are not detected. For reference, this is a manual control. To eliminate the malfunction, it is recommended to check the correct location according to the instructions.

Error 28indicates that a malfunction has occurred in the control panel. And in this case, you just need to check its communication, the status of connections.

Error 31 - These are malfunctions of the thermistor that occur during its breakdown or short circuit.

Error 32 typical for problems with the freezing thermistor that occurs when it breaks or shorts.

Error 34 for a domestic hot water inlet thermistor.

Error 35 and again a thermistor, only this time the one that scans the room temperature. This occurs when the contact circuit breaks or short circuit.

Error 43 appears in sealed-type boilers and occurs when the electrodes see a lack or complete absence of coolant for 43 seconds. Of course, you immediately need to check the coolant level.

And then:

- determine the wiring contact with the sensor electrodes;

- inspect the system for obstruction;

- find out if there is a problem with the functionality of the make-up solenoid valve;

- see if the recharge system as a whole is working.

Also, to eliminate the malfunction, with a low coolant level - open the water supply tap, turn on the water supply, and then close the DHW valve. When the pressure is equal to 0.5-1.5, turn off the recharge.

Error 44. These are problems with the level gauge when it starts to “fail”. That is, when there is water, but there is little of it and it fixes that it does not exist at all, when there is too much of it and it determines it continuously for 30 seconds (in an unpressurized system).

It is necessary to check the condition of the connection of the electrodes of the level gauge and whether the water separator in the upper part is clogged. If it is impossible to eliminate it yourself, call a specialist from the service or gas service.

Error 52 Suitable for problems with modulating gas valve, proportional valve. More information on how to repair a gas valve can be found in this stuff.

Error 56 in open systems, it shows problems with recharging the water of the solenoid valve when it does not end the cycle 5 minutes after starting the supply. In this case, it is recommended to check the voltage, water sensor and call the wizard to troubleshoot the valve, if you can not do it yourself.

Error 61 indicates a problem with the fan. As the official representative of the manufacturer of boilers Rinnai in Russia assures, it is necessary to check correct installation of the chimney, eliminate in the presence of blockage, measure the voltage and try to restart the boiler.If you do not resolve the error, be sure to call the wizard.

Error 71. If these numbers appear on the display, be aware that they indicate a problem with the solenoid valve, its bias, or mismatch with the gas outlet point. If the problem persists when the boiler is restarted, turn off the gas supply and call the wizard.

Error 72 indicates problems with the solenoid valve, as well as difficulties in recognizing the ionization sensor. In this situation, the gas during the ignition attempt is not supplied to the burner, and the flame is fixed.

Experts advise to check whether the valve is open on the gas supply and if everything is in order, immediately shut off the supply and call a professional diagnostician from the service center or from the company with which service contract gas equipment.

Error 89 signals that the sensors have detected freezing of the system. This problem also requires a specialist to solve.

Error 90 Recognized as defective during the initial fan current during pre-blowing. The cause may be a chimney blockage, voltage problems.

If after restarting, if it is not detected and it is impossible to fix it yourself, the problem recurs - call the wizard.

Error 96 connected to dhw. It is recognized during a test run of hot water and is characterized as an incomplete air vent after 10 minutes.

Error 97 relates to heating functions. Again, when during a test run, the air outlet lasts longer than 120 minutes after turning on the heating. What to do - check the coolant access, measure the pressure and try to restart your gas-using device.

Error 99 - chimney and related malfunctions. This error is related to security features. This may be a depressurization of the chimney, blockages in it or a fan, and so on. If an error occurs, it is necessary to check the functionality of the fan, the heat exchanger for blockages and the chimney.

Rules for safe use

Any gas boiler is used to process fuel that is dangerous to the life and health of consumers in the event of its leakage, the outputs of its utilization products, and the leak of a heat carrier heated by it.

All work on the repair and replacement of gas-powered equipment should be carried out by specialists from the after-sales service or the gas distribution station. Otherwise, you may face a gas outage at best, and at worst a threat to health and life.

Moreover, the cost of such devices, especially from well-known manufacturers, is not always budgetary, and the warranty is long. An invasion of the gas boiler system can be regarded as a violation of the guarantee of warranty and, therefore, it is not worth waiting for the service department to work on free repair and replacement of individual elements.

But then again, some points in boiler malfunctions can be completely eliminated independently or knowing them, you can determine what kind of work to call a master and ask how much the repair will cost.

Conclusions and useful video on the topic

More on error 99, fan cleaning:

In general, the malfunctions of most Rinnai gas boiler models are easy to repair. Knowing the decoding of error codes and having a manual on the operation of a particular device, you can easily diagnose, if not even the breakdown itself, then at least the area in which it occurred.

Have you had any problems with Rinnai heating units? Maybe you displayed a code that is not in our article? Share your experiences and ask questions in the comments.

Junkers gas boiler malfunctions: breakdown codes and troubleshooting

Junkers gas boiler malfunctions: breakdown codes and troubleshooting  Immergas gas boiler errors: error codes and solutions

Immergas gas boiler errors: error codes and solutions  Kiturami gas boiler errors: trouble codes and troubleshooting

Kiturami gas boiler errors: trouble codes and troubleshooting  Errors of gas boilers Baltgaz: trouble codes and troubleshooting methods

Errors of gas boilers Baltgaz: trouble codes and troubleshooting methods  Error codes for a gas boiler Viessmann: methods for troubleshooting and recovery

Error codes for a gas boiler Viessmann: methods for troubleshooting and recovery  Ariston gas boiler errors: how to find and eliminate the fault by code

Ariston gas boiler errors: how to find and eliminate the fault by code  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements