Do-it-yourself gas boiler heat exchanger repair + instruction on repair and part replacement

Agree, you do not always follow the boiler and try to check it as little as possible. At the same time, you can love to repair household appliances yourself and not necessarily for the sake of saving. If you have been using boilers for a long time, you know about the features of their heat exchangers, as parts that often cause breakdowns. If you want to repair the gas boiler heat exchanger yourself, read our instructions and make sure that it is not difficult at all.

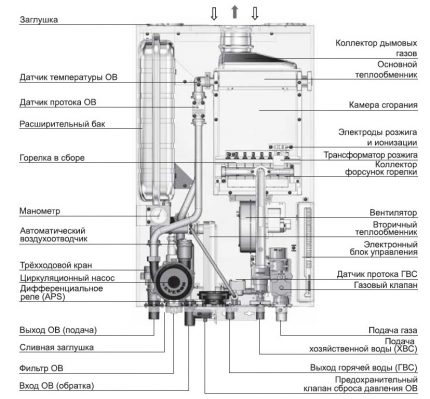

From our article you will learn how to get the primary and secondary heat exchangers from the boiler. In addition, you will learn how to care for and repair these parts. If you are not familiar with the structure of the boiler, then, among other things, you will understand the design of the exchangers, learn about their location, the principle of operation.

A lot of water passes through the heat exchangers of the boilers, over time they become clogged, sometimes deformed. In the article, we submitted important information about their cleaning, repair and replacement. We will talk about heat exchangers enough so that you can repair these boiler parts alone.

The content of the article:

Primary heat exchanger of a gas boiler

The primary, or simply a heat exchanger, is a large part in the form of a pipe with bends through which thin plates pass. This form and the device itself is also called a coil.

Manufacturers make stainless steel heat exchangers like copper and stainless steel. Different brands of boilers, they almost do not differ in structure - shell-and-tube in the form of a coil.

A device transfers heat energy from a gas to a coolant — usually water. Units differ in power, and the greater the length of the pipe and the number of ribs (bends), the higher it is. The heat exchanger works well until soot outside and salts inside accumulate in excess.Then the circulation is disturbed and the thermal conductivity of the walls decreases. Heat exchangers should be cleaned and protected on time with water filters.

In the design of the boiler, the primary exchanger is located in the combustion chamber, above the flame of the main burner. A material with a high heat transfer retains heat well and loses it quickly enough, as necessary. Thanks to the narrow plates, thermal energy is distributed more evenly. The primary heat exchanger is the main heating element of a gas boiler, except for the burner.

Primary heat exchanger repair

The exchanger deteriorates due to poor-quality coolant or materials from which it is made, as well as other factors. Pressure, high temperatures and their differences lead to cracks, because of which the element starts to work less powerfully, and breaks over time. The life of the heat exchanger can be extended if clean water is supplied and the boiler is not overloaded.

Crack repair will be harder than clogging. The heat exchanger is soldered for this. Solder is selected from the same material as the unit itself. Boiler heat exchangers are usually made of copper, less commonly of cast iron or steel. Aluminum, silicon, manganese, nickel and zinc are added to the composition.

Additional solder requirements:

- melting point not lower than 700 ° C;

- sufficient viscosity;

- fluidity is the same as that of a heat exchanger.

Copper-zinc solders are considered one of the best. They are used for soldering most non-ferrous metals with a higher melting point than that of the auxiliary material itself. For the human body, solders with inclusions of silicon or tin are safer - up to half a percent.

Copper-phosphorus materials are best avoided, and if they solder exchangers, then without a load, such as shock or vibration impact. A well-chosen solder is half the battle.

Heat exchangers are soldered by gas burners and blowtorches. Before soldering, the desired place is cleaned with fine-grained sandpaper and wiped with a rag with a solvent, and then heated. The area is heated with a hairdryer or a weak burner / soldering iron. At this moment, the main thing is to get into the temperature corridor and take into account the subsequent cooling. Barely noticeable lesions are found on small spots of a greenish tint.

Before heating, water is drained, and its residues are removed with a compressor or blown through a flexible hose. The hose is fixed by thread if it has a union nut and design features allow this. If you leave water, then it will take part of the thermal energy.

Solder is preferred in the form of a wire or bar: the molten end when soldering is well immersed in the flux, which adheres to it. If the wire lies too intermittently or loosens on the exchanger itself, the preliminary heating was weak. After work, the place of soldering is sometimes coated with heat-resistant paint - for better insulation.

In the next two weeks, the soldered area is checked for integrity daily. At the first detected leak, it is worth contacting the master. If she appeared in the first half a month, then the soldering was of poor quality.

The flux is suitable universal, as well as solder flux gel. Avoid rosin, unusual options like aspirin and more.

Primary heat exchanger cleaning

Buy a solution for washing the heat exchangers - it eliminates even severe pollution. Use special brushes and scrapers for manual cleaning of accessible places inside and outside the exchanger. Remove the soot.

In a difficult situation, order a chemical flush. Masters will clean the exchanger through a booster, in which they add acid - sulfamic acid, for example. After special treatment, there will be no old and persistent deposits. And you can wash the heat exchanger yourself. For this we suggest using following instruction.

Cleaning is possible without disassembly - with hydrodynamic flushing. Fine particles under high pressure will remove any contamination.

Replacing an old or broken heat exchanger

To pull out the exchanger for flushing or replacement, first of all, you need to disconnect the boiler from the gas supply and the mains. Then the front panel of the boiler is removed and the supply and return pipes of the heating are closed. The coolant is lowered through a drain valve on the boiler.

Further actions require greater accuracy and concentration of efforts:

- We remove the fasteners on the tube supplying gas to the combustion chamber. Disconnect this pipe.

- We release the cover of the combustion compartment from suitable communications: we set aside the ignition and control electrodes.

- Remove the sensors from the combustion chamber. Unscrew the fasteners on its cover and remove the latter.

- We disconnect and get the fan.

- We remove the clamps from the pipes suitable for the primary heat exchanger. We divert these tubes.

- We unfasten the combustion chamber from the boiler wall and transfer it to the outside.

- Unscrew the hardware of the upper cover of the combustion compartment. Remove the top.

- We remove the fasteners that hold the primary heat exchanger, and remove it.

Now we can replace the failed exchanger with a new one. We fix it in the combustion chamber, separately from the boiler. We fix along the perimeter with hardware and return the top cover to its place.

We attach the combustion compartment back to the inside wall of the boiler. Fasten the front cover. We return to the place all disconnected parts and removed components near the combustion chamber.

Look at how the gaskets inside the gas boiler look and even before installing the heat exchanger, replace them with the necessary connections. After complete assembly, prepare the boiler for work and make a trial run.

Secondary heat exchanger of a gas boiler

It is also called a hot water heat exchanger (DHW). This is a rectangular device with interconnected inner plates of food stainless steel. The more of them, the higher the performance of the unit. Inside they form from 8 to 30 layers. The high thermal conductivity of the materials and the wide area of interaction give the necessary heat transfer during the rapid movement of water.

Each of the layers is a channel insulated within the heat exchanger. The plates have a relief from which these moves are formed. The thickness of the partitions is usually 1 mm. The channels have angles, and the sharper they are, the higher the fluid velocity and vice versa. The pattern of water movement is one-way and multi-way - with a change of direction. In the second case, higher efficiency is achieved.

After opening the hot water valve on the mixer three way the valve directs part of the heated coolant to the secondary exchanger. Further, the hot liquid gives off heat to the cold tap water in the unit, after which the heated water leaves the heat exchanger for supply through the mixers in the kitchen and bathroom.

The cooled coolant then goes into the pipe, where it is mixed with the return - waste heat from the heating system, and again enters the primary exchanger.

The secondary heat exchanger is usually located below the combustion chamber.In different boilers it is mounted vertically or horizontally on its side.

In boilers also use combined heat exchangers - bithermal. They communicate with hot water channels with a coolant for the heating system. First, the gas transfers energy to the coolant, and then the latter sends part of it to the hot water supply. Since gas boilers with such heat exchangers are simpler, a three-way valve is not needed.

Secondary heat exchanger repair

Secondary heaters are often clogged, especially narrow channel models. Without cleaning, they break down over time and finally fail. A layer of scale inside the unit reduces heat transfer, which is why the boiler consumes more gas.

Problems with heat exchangers will be reported by codes on the boiler display. In this case there is an action plan.

Let us consider in more detail the problem with the secondary heater:

- We get the secondary heat exchanger.

- We look at the joints, internal and external threads. After the last cleaning, their condition could worsen. This happens due to aggressive acids. Replace worn removable elements.

- Check integrity. With a heat exchanger could happen water hammer. Only a specialist will find a very small fistula (hole).

- We inspect the exchanger better, and for this we call the master. Heavily damaged unit is replaceable.

- At the very beginning you can find pollution. We are looking for plaque visually in the inlets. We blow air into the part and also orient ourselves by sound. We clean if the exchanger is clogged. Scum pieces may fall out of it even after a light knock.

- You need to choose 1 of 3 cleaning options: home remedies like detergents and solutions with citric acid, special mixtures or professional cleaning.

First of all, flush the exchanger with a stream of water from a cold tap. Then pour citric acid into the appliance and place in a bucket of water. After - take out the heat exchanger and fill it with water to check patency.

If it enters slowly or does not move, then prepare a saturated solution of vinegar in water and pour it there. Then rinse with hot water and blow. Use an air pump whenever possible. Do a few cycles with vinegar.

If the steps described do not help, try special cleaning solutions: a cleaning gel or a low-percentage adipic acid solution. If this method also did not work, then call the wizard or order a professional cleaning.

How to replace a part?

Special knowledge is not needed for this. To remove the old exchanger for inspection or replacement, you must follow these steps:

- Disconnect power and shut off gas.

- Remove the front cover of the boiler.

- Shut off cold water for the domestic hot water circuit. Close the valves on the supply and return pipes of the heating circuit.

- Remove the plug on the drain hole. Drain all water from the boiler.

- Reduce pressure in the system when needed and remove air.

- Pull out the electronic board. Remove the necessary fasteners for this.

- Take the terminals from the gas valve.

- To get the boiler elements that impede convenient extraction of the secondary heat exchanger: cold water supply inlet pipe, water fittings, etc. Remove the appropriate brackets, nuts and clamps.

- Insulate all electrical components and wires with waterproof material.

- Remove fasteners holding secondary heat exchanger. Use a handy tool. Sometimes this can be done with a hexagon. Manufacturers try to place the exchanger in a convenient place so that boiler elements do not suffer during its extraction.

- Remove the secondary heat exchanger, remove water from there.

At the time of removal, it is worth remembering the location of the exchanger in order to install it back or put a new one in the same way.

Treat with copper grease the connections with which the unit is fixed inside the boiler. So you protect it from oxidation.

Also, replace worn seals before replacing a part.

Conclusions and useful video on the topic

How to get a heat exchanger from a Baxi boiler, how to clean it:

Cleaning the primary exchanger using reagents, a review of the means and the final result:

Idea for repairing a broken inlet of a primary heat exchanger:

We talked about two types of heat exchangers. Primary - above the burner of the combustion chamber and secondary - to heat running water. Now you better understand the structure of gas boilers and understand the importance of heat exchangers in their work. We also presented two partially similar algorithms for exchanging exchangers.

If necessary, you can begin to solder this part. You will be able to do home washing. Do not forget about the quality of materials, if you still have to buy a new part.

Leave comments and ask questions. Tell us about your boiler. Write how many heat exchangers are in it. Did you change them, and how long did the old exchangers last? Write about it in the contact form, which is under the article.

How to brew a gas boiler heat exchanger: manual repair

How to brew a gas boiler heat exchanger: manual repair  How to increase the efficiency of a gas boiler with your own hands: the best ways to increase the efficiency of the boiler

How to increase the efficiency of a gas boiler with your own hands: the best ways to increase the efficiency of the boiler  Flushing the gas boiler heat exchanger: cleaning methods and means for removing mineral deposits

Flushing the gas boiler heat exchanger: cleaning methods and means for removing mineral deposits  Wall-mounted gas boiler installation: do-it-yourself installation

Wall-mounted gas boiler installation: do-it-yourself installation  Do-it-yourself installation of a floor gas boiler: technical standards and algorithm of work

Do-it-yourself installation of a floor gas boiler: technical standards and algorithm of work  Gas boiler repair: an overview of common failures and how to fix them

Gas boiler repair: an overview of common failures and how to fix them  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements