Layout of a gas heating boiler: general principles and recommendations

Connecting gas heating is one of the most critical stages of building improvement. Comfort of the house for many years depends on the quality of the selected materials and installation work. The correct piping layout of the gas heating boiler protects the system from overloads and ensures uniform heating of all rooms.

In the article we have proposed, the rules and proven schemes for binding heating equipment are given. Recommendations are given that ensure build quality and further faultless operation of the boiler. The information we provide is based on building codes.

The content of the article:

Why is proper strapping so important?

Tying is called pipes and mechanisms designed to supply coolant from the boiler to radiators. This is almost the entire heating system, with the exception of batteries.

The system consists of many nodes, however, even a layman can mount the simplest piping of the boiler. But if you need a complex scheme, it is better to contact an experienced master.

The choice of strapping scheme for each particular house depends on the type of boiler, construction features, type of heating system.

Any gas equipment is dangerous. Incorrect connection is fraught not only with heating problems, but also with explosions and destruction, therefore, it is necessary to strictly follow the norms and rules, comply with the requirements of safety. The main documentation on which the gas heating system is based is SNiP.

Need to plan carefully heating circuit, location of equipment, features of laying pipelines.

The boiler piping performs several significant functions at once:

- Pressure control. If the harness is mounted correctly, the thermal expansion is compensated, which means that the pressure in the system will not increase to critical values.

- Air removal. Air bubbles form plugs, because of which the efficiency of water heating is reduced: radiators do not warm up completely, and the consumption of resources remains the same. High-quality boiler piping is necessary to prevent this problem.

- Prevention of blockages in the system. If the boiler is not properly tied, the risk of scale formation in radiators and pipes increases. Small debris in the coolant contaminates the system, which leads to an excessive consumption of fuel and an increase in the cost of heating while reducing its quality.

- Ability to connect other circuits. You can install a floor heating system, a storage boiler.

In many respects, the heat supply depends on the correct connection of the boiler to pipelines and other important nodes, therefore, the piping layout of the gas boiler must be carefully thought out and installed as efficiently as possible.

A properly selected and installed boiler piping will serve for many years without accidents and repairs, and its cost will be optimal.

The main components and elements of the system

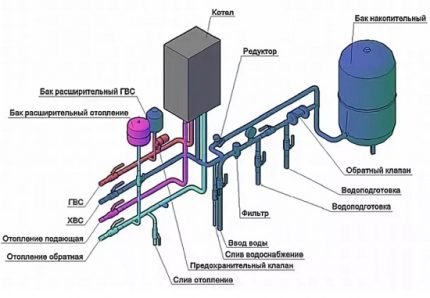

To equip the gas piping, the following devices will be required:

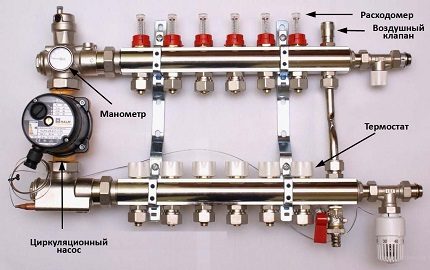

- pressure gauge;

- circulation pump;

- expansion tank;

- drain cock;

- ball valve;

- balancing valve;

- filtration system;

- valves (distribution, return, safety, etc.).

Each of the nodes performs its own functions, and the need for their installation is determined by the design of the heating equipment. So, if the pump is initially included in the boiler’s package, then it does not need to be purchased separately.

In the piping of the gas boiler, locking devices, pressure monitoring devices and protective systems must be installed. Moreover, all nodes should be carefully selected, and saving on them is fraught with breakdowns.

It is worth overpaying for equipment and pipes from manufacturers with a good reputation. It is much cheaper than repairing heating later.

Polypropylene - the best solution

Many experts favor binding of gas equipment with polypropylene. Their main argument is universality and the ability to implement any scheme without any problems. On the other hand, an inexperienced master is unlikely to have to deal with systems of increased complexity.

The main advantage of polypropylene pipelines is reliability. According to the manufacturers, their products last 40 years or more.

The material is resistant to high pressure (can withstand up to 25 bar), well tolerates water hammer and a temperature of 95 degrees. There is a drawback that must be taken into account: such a boiler piping reduces the efficiency of the heating system.

The connection of the boiler to the gas pipeline must be rigid ("American", metal overhang). Of all types of gaskets, only paronite ones are suitable, because plastic materials (rubber, fum, tow) are deformed, which leads to loss of tightness or to a decrease in the internal diameter of the gas pipeline.

Location and installation of a gas boiler

The basic rule for choosing a location floor boiler: It should not be above the batteries. If you do not stick to it, air bubbles and the formation of plugs in the system may occur. The pipe extending from the boiler must be positioned strictly vertically.

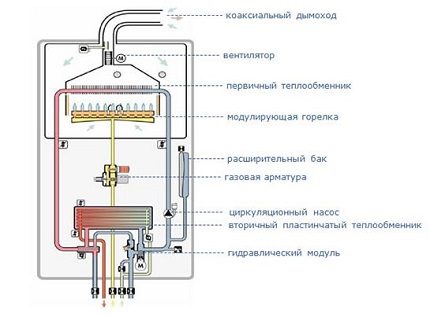

If the choice is made in favor of the wall-mounted model, then it should be equipped with an automatic air vent. When developing a strapping scheme, such nuances must be taken into account.

Many modern models are pre-equipped with all necessary additional devices: expansion tanks, protective systems, pumps. Their disadvantage is the high price compared to simpler boilers.

Features of different strapping schemes

The coolant moves through the pipeline due to the slope of the system or is forcedly pumped circulation pump. Depending on this, a boiler piping scheme is selected.

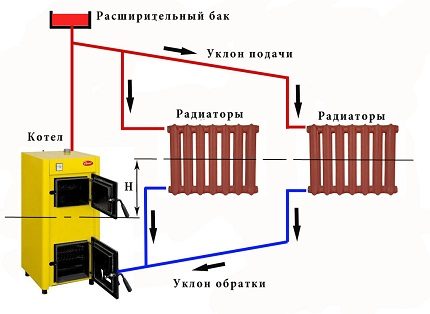

Method 1: strapping in gravity systems

Boiler piping in gravity heating system simple, and it can be mounted by anyone who knows how to handle tools. The coolant moves in accordance with physical laws.

No instruments are required for this. The system does not depend on electricity, so a sudden shutdown will not affect the quality of heating.

Tying the boiler will cost minimal money, because you don’t have to buy additional devices, pay a team of masters for installation. The operation of such a system is also cheap, and breakdowns can be fixed independently.

The only negative: this scheme can only be used for a small house. In addition, you will have to carefully calculate the diameter of the pipes and repeatedly check the data, otherwise normal heating of the house cannot be guaranteed. A large-diameter pipeline spoils the interior, and it is problematic to disguise it.

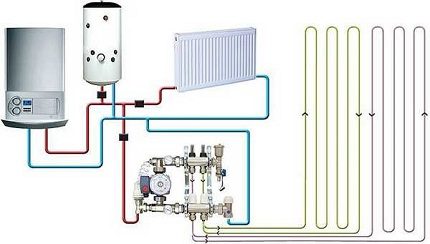

Method 2: piping the boiler with a circulation pump

Systems with pumping equipment are easier to manage than gravity ones. At forced heating device tying the boiler is more complicated and more expensive, but the result is a comfortable temperature in all rooms.

This heating is energy-independent, therefore it is advisable to play it safe and mount it so that when the power is turned off, you can switch the system into gravitational circulation of the coolant.

The boiler piping scheme is complicated by additional devices that require regular maintenance during operation.Without experience, it is difficult to handle it yourself, so you have to hire craftsmen and pay for their work.

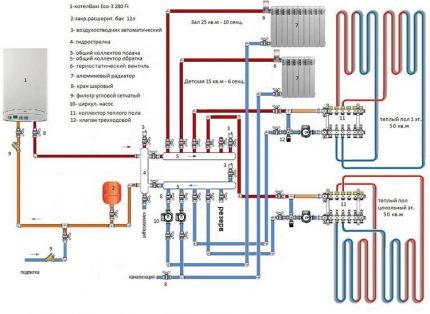

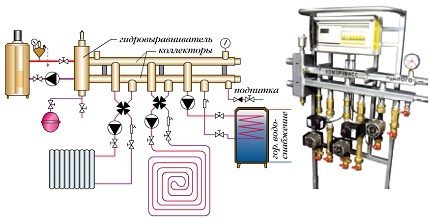

To minimize the number of additional devices, it is possible to implement a scheme with primary-secondary rings with circulation pumps in each of them. If the boiler power is less than 50 kW, then collectors should be included in the circuit, otherwise the batteries will warm up unevenly.

The best boiler piping for heating a small house is the simplest. No need to install extra devices, because the simpler the design, the more reliable. However, for a spacious building with several heating circuits, it is worth choosing a scheme with forced movement of the coolant and a comb-collector.

7 recommendations from experienced craftsmen

For each heating system, the strapping scheme is selected individually, and the methods for its implementation can also vary greatly.

However, there are a few general recommendations that should be followed:

- The boiler is mounted in accordance with regulatory requirements below the level of radiators. If the model is floor mounted, then there should be a non-combustible material under it - metal, concrete or clay. If wall mounted, then access to it should be free. Ventilation and lighting are required.

- The gas boiler piping includes a coaxial chimney. When you connect it, you must take care of the tightness of the joints.

- After installing the boiler and the chimney, they begin to install the safety group in the following order: a pressure gauge, then a safety valve, and after it an automatic air vent.

- A 1.25-inch pipeline is brought to the collector, along which protective systems, a pump, a hydraulic gun, and another air vent are mounted.

- To supply the coolant to the radiators from the comb, 3 one-inch pipes are diverted, and the remaining pipes are closed with plugs. After that, radiators and return pipes are already installed and connected.

- If the system is combined (“2 in 1”), then the floor heating circuit is equipped with a separate pump.

- An expansion tank is placed between the hydraulic arrow and the boiler.

Sometimes you have to install boiler automation devices. This is required if the boiler piping involves a complex heating control system. Then the temperature sensor is mounted on the street, and a thermostat is placed in the room.

With the rules and guidelines for adjusting the automation for a gas heating unit will introduce next article, which we strongly recommend reading.

Conclusions and useful video on the topic

We offer several video tutorials that will help solve the problem of tying a gas boiler.

Video # 1. Tips of the master on tying the boiler with polypropylene (simple scheme):

Video # 2. Installation instructions for complex strapping of the wall model of the boiler:

Video # 3. Nuances of connecting a floor model:

It is advisable to choose a gas piping scheme that can be mounted without assistance. However, if in doubt, the advice of a professional does not hurt.

Pay particular attention to the choice of piping material, take care of installing a filter to clean the coolant. Smooth inner walls of pipes and clean water in them are the key to a long and stable operation of the heating system.

Please write comments in the block below. It is possible that you know the technical details of the boiler piping that are not noted in the article. Share useful information, ask questions, post a photo on the topic of the article.

Adjusting the gas boiler: recommendations for setting up the device for correct operation

Adjusting the gas boiler: recommendations for setting up the device for correct operation  The principle of operation of a dual-circuit gas heating boiler and features of its connection

The principle of operation of a dual-circuit gas heating boiler and features of its connection  Connecting a double-circuit gas boiler to the heating system: requirements and norms + installation steps

Connecting a double-circuit gas boiler to the heating system: requirements and norms + installation steps  Water flows from a gas boiler: what to do if heating system equipment has flowed

Water flows from a gas boiler: what to do if heating system equipment has flowed  Conord gas boiler malfunctions: common breakdowns and solutions

Conord gas boiler malfunctions: common breakdowns and solutions  Voltage stabilizers for a gas boiler Baxi: TOP-12 of the best models according to consumers

Voltage stabilizers for a gas boiler Baxi: TOP-12 of the best models according to consumers  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I have an old house, I got it from my grandmother, there was stove heating. There is gas in the village, they connected us, I put a boiler. Itself made the simplest strapping and wiring. Metal pipes, assembled everything on the drives, only an expansion tank was ordered from stainless steel.

The diameter of the pipes, of course, is large, one and a half inches, the view is not very good, but it will do. Natural circulation, working fine.

True, I want to put the pump through the bypass so that it warms up faster and the return line does not cool so much, but this is still a dream come true.