Heating from an electric boiler: options for organizing heating based on an electric boiler

If it is impossible to connect a suburban area to a centralized gas supply for some reason and is not planned at least in the coming years, then heating from private boilers is often used to heat private houses - the solution has several advantages, although it is not without drawbacks.

In order for the use of the device to be effective, it is important to correctly select the electrical equipment and circuit diagram. We offer you to understand the design and functional features of different types of electric boilers, as well as evaluate the features of various options for connecting the units to the heating system.

For those who plan to organize housing heating from an electric appliance, it will be useful to learn how to use the double tariff in order to reduce electricity charges.

The content of the article:

Classification of equipment and principle of operation

An electric boiler converts electrical energy into heat and, depending on the design features, can be:

- TENOV;

- electrode;

- induction.

Regardless of the type, modern models are equipped with thermostat, with which you can adjust the power of the device and the degree of heating of the coolant.

Usually there is the ability to receive information from an external sensor to control the temperature of the air mass in a particular room.

Device with heating heater

Inside the tank intended for water, install heating elements - heating elements. They can be made in the form of tubes or plates. To adjust the degree of heating, the heaters are turned on alternately.

Water enters the tank, heats up, then transfers to the circuit. As it cools or heats up, individual heating elements turn on or off. The coolant movement is controlled by an integrated circulation pump.

Can choose dual circuit models of such boilers, they heat water not only for heating, but also for water supply. TEN devices are popular due to their simple design and relatively low price. With proper operation, they break extremely rarely.

In addition to water, various concentrations of antifreeze or oil compositions are used as a heat carrier. But the sizes of such devices are usually quite large, which limits the possibilities when choosing a place for their installation. Over time, plaque settles on the heating elements, periodically the heating elements must be replaced.

Electrode boiler for heating

For heating, the potential difference at the two electrodes and the natural resistance of the water arising from the salts dissolved in it are used here. These are compact devices that can quickly heat small volumes of water.

An integrated circulation pump is not needed here. This is a simple device that almost never breaks. And if this happens, it is not difficult to repair it. The price of devices of this type can be called affordable.

But oil and antifreeze for such a boiler will not work, only water is acceptable as a heat carrier, but not distilled. Over time, the electrodes wear out, dissolve in water. They need to be periodically replaced with new elements.

Induction heating device

In such boilers, the heating element is made of a dielectric casing with a coil and core wound around it. The current in the coil causes a potential difference in the core, which heats up quickly enough. Thermal energy is transferred to the coolant.

This is a boiler with high efficiency and a long service life. Industrial models are quite expensive, but you can make them if you wish. homemade induction analog. Any liquid coolant is suitable, and cases of breakdowns are extremely rare.

Heating system connection options

Electric boilers are used in systems with a liquid coolant that circulates through pipes.

These can be traditional radiator options:

- with the natural movement of the coolant;

- with forced circulation;

- combined options.

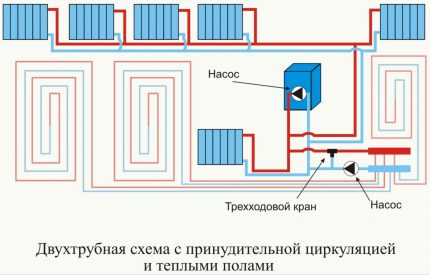

In addition, boilers are successfully used in water floor heating systems. They are also suitable where they combine radiators as the main source of heating and heating as a complement to it. When heating on the basis of an electric boiler, a suitable circuit should be selected.

Natural type system

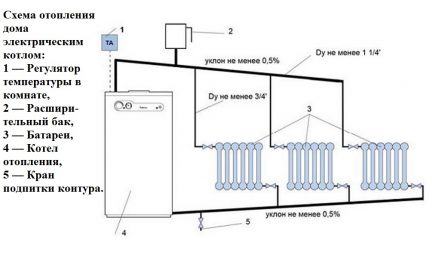

Such a system works by exploiting the ability of water to expand upon heating. The hot fluid rises, displacing the cooled water from the circuit. It returns to the heat exchanger, heats up, replaces the cooled liquid, etc. The electric boiler in this case is placed in the lower part of the circuit.

Implementation natural circulation systems water along the circuit requires competent calculation and proper installation.

You will need a significant number of pipes of a certain diameter, which must be laid with the desired slope. Problems may arise if you need to adjust the power of the device and change the level of heating of the coolant.

Forced Circuit

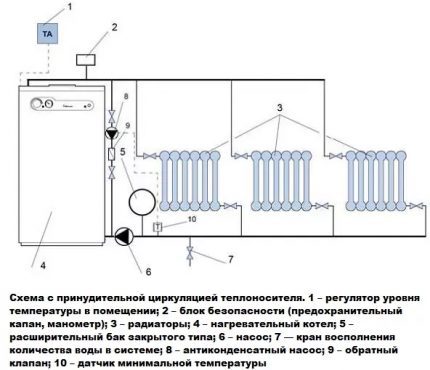

Here, the movement of hot water through the pipes is provided by a pump connected to the system. In addition to it, you will also need a membrane expansion tank and equipment to ensure its operation: pressure gauge, shut-off valves, etc.

The electric boiler is placed below, then an expansion tank is connected to the system, after which mount the circulation pump.

This type of circuit is less sensitive to the characteristics of pipes and radiators, which provides ample opportunity to choose suitable components. It is in such systems that antifreeze can be used. The possibilities for regulating the water temperature in the circuit are also expanding.

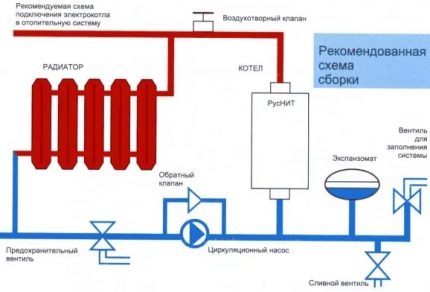

Combined version of the system

Such a circuit is carried out initially on the basis of the same principles as a system with a natural movement of the coolant flow. Therefore, the boiler is placed at a lower point to ensure the free movement of warm water.

But the system is supplemented with an expansion tank and a circulation pump, so that there is the possibility of forced movement of the coolant. This is done so that you can freely choose the mode of operation of the heating system.

The combined version combines the advantages of both of the systems described above. For the operation of the circulation pump, with which the quality of heating is usually much higher, electricity is needed.

If for some reason its flow is interrupted, the movement of the coolant in the forced system will stop, but in the combined system it will not.

Water will continue to move along the contour naturally. For heating in this case, you can use an alternative source of electricity or another type of fuel. There are options that allow you to switch the system from electric to solid fuel or gas boiler.

Water floor heating

This type of autonomous heating, whose popularity is steadily growing. It is considered more economical to operate than radiator systems. The heating circuit from a narrow plastic pipe is laid in a screed under the floor covering.

The heat carrier can only be heated to 26-28 ° C to provide the house with sufficient heat. The maximum allowable temperature is about 50 ° C, but such strong heating is usually not needed. For water floor heating boilers with a heating element are well suited, which allow you to widely vary the temperature of the water.

If it is supposed to provide hot water with the same heater, you will have to take a model with a heating element. The binding must include indirect heating boilerso that the water in the DHW circuit is warmer than for heating by about 15 ° C.

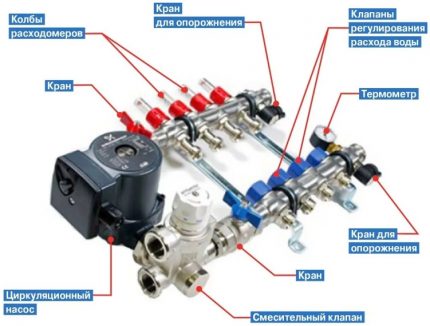

In electrode devices, heating is typically 60 ° C. or more. They can be used for TP, but additional installation of the mixing unit will be necessary to cool the coolant to an acceptable level.

In any case, a hydraulic comb containing such a unit will be needed for the proper installation of this type of heating. Heating control is carried out using a temperature sensor that determines the current temperature of the coolant.

There are automatic control modules that allow you to additionally take into account the heating of air in the room.

For a warm floor to function successfully, a number of important elements are needed. For example, the pipe for each individual circuit must be integral, no connections are allowed. It is necessary to carefully calculate the length of such a structure, given the scheme laying of a contour of TP.

You can use special formulas to do this manually. It is convenient to use the calculators available on specialized sites. After entering information about the area, layout and other characteristics of the TP, the program will provide the necessary information.

Typically, the estimated pipe length is slightly increased to have a small margin. If it seems too short, you just have to buy a new one. For a warm floor, a filtration system is needed so that the coolant is clean enough.

Electric boiler and double tariff

One of the significant reasons for using an electric boiler for heating is the possibility of using double charging for the use of electricity. Reducing fees during the night period can significantly reduce costs.

You will need to purchase and install a two-tariff counter. It is worth noting that double-circuit models of equipment with a heating element supply hot water to a collapsible tap with a characteristic noticeable delay. As a result, part of the heat is lost, which reduces the effect of saving electricity.

It makes sense to supplement such a design with an external heat accumulator capable of maintaining a high temperature of heated water for a long time. Such a device is quite effective when using a two-rate counter.

Water is heated at night, stored in a warm form and used throughout the day, energy consumption in the daytime is reduced, as are bills for electricity used.

Conclusions and useful video on the topic

Electric boiler installation procedure:

Although the use of an electric boiler as a heating device is considered too costly, its advantages are obvious. Such devices are safe for people and the environment, operate automatically, accessible and easy to operate.

If the type of heating system is chosen correctly, and all its components are professionally mounted, the boiler will work for a long time without unnecessary costs.

Have experience using an electric boiler to heat your home? Or want to ask questions on the topic? Please comment on the publication and participate in the discussions. The feedback block is located below.

Autonomous gas heating of a private house: device options and an overview of the best solutions

Autonomous gas heating of a private house: device options and an overview of the best solutions  Heating systems in caravans: heater options for a comfortable temperature in the camper

Heating systems in caravans: heater options for a comfortable temperature in the camper  Connection diagrams of the heating pump: installation options and step-by-step instruction

Connection diagrams of the heating pump: installation options and step-by-step instruction  Pressure in the expansion tank of a gas boiler: norms + how to pump and adjust

Pressure in the expansion tank of a gas boiler: norms + how to pump and adjust  Infrared heating of a private house: an overview of modern infrared heating systems

Infrared heating of a private house: an overview of modern infrared heating systems  Installing a pump for heating: how to properly install pumping equipment

Installing a pump for heating: how to properly install pumping equipment  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Boilers with heating elements have already proven themselves from the best side. Simple and reliable, efficiency - over 95%. What else to be smart? Electrode and induction strongly depend on the composition and conductivity of the fluid in the system, which is not clear how to control.

And we have an electrode boiler of 9 kW. Works 8 years without interruptions. Before that, there was a Tenovy boiler that consumed more energy, they paid 35% more than we pay now. Profitable. There were no problems.