Heating elements for heating: types, principle of operation, rules for the selection of equipment

Electric heating elements for decades do not change their design and remain in demand in heating equipment. The shape of these devices, structural materials are changing, but the principle of action and efficiency remains unchanged. For proper selection, information about differences and characteristics is useful. Do you agree?

You will learn what are and how do heating elements for heating. We have described in detail the varieties of heating elements, we have given indisputable arguments for a reasonable choice of the optimal type. Based on our recommendations, you can purchase the required device without errors.

The content of the article:

Purpose of heating TENOV

Electric heating elements have gained popularity due to its versatility and high efficiency. All the energy they consume is consumed for its intended purpose - to heat the surrounding area.

The main heating devices where the heating elements are used are:

- Portable and stationary oil electric heaters.

- Water heating radiators.

- Heated towel rails for the bathroom.

- Electric fireplaces.

- Electroconvectors.

- Electric boilers.

The specified equipment can be used as the main or additional source of heating. It is inexpensive, easy to install and does not require special skills during operation.

The internal structure of electric heaters

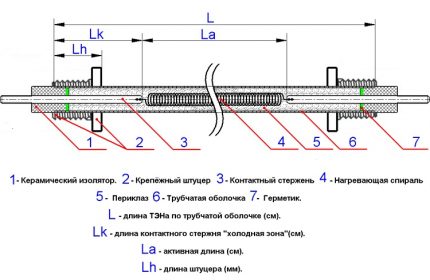

The device is conveniently considered as an example of a tubular model.An electric heater is a ceramic or metal tube filled with a thermal conductor with a spiral located inside. In the place where the tube is fixed to the flange, there are insulating sleeves that make it impossible to contact the conductive spiral with the housing of the heater.

The electric heater is mounted mainly with a flange connection, which allows you to seal the internal environment of the heater from the outside. The disadvantage of this design is the inability to replace the spiral during its internal burnout.

The principle of operation of the heating elements

TEN works according to the following principle. When connected to the network, the internal spiral is heated and energy is transferred to the thermal conductor and the outer shell. Subsequently, heat is transferred to the surrounding liquid, air or solid material.

When heating a heating element immersed in oil or water, convection flows are created around the tube, which mix the coolant and contribute to its uniform heating.

In non-liquid heaters, the heating temperature is usually limited so as not to damage the surrounding parts and not cause a fire.

To accelerate heat transfer, a fan is often used in them, which provides air circulation both inside the device and in the room surrounding it.

Types of heating elements for heating appliances

The simplicity of manufacturing of heating elements does not always turn into user-friendliness. Many manufacturers produce electric heaters with a specific shape and mount. In the event of a breakdown, they are quite difficult to buy in the store. Therefore, for the right choice, it is necessary to study all possible constructive options.

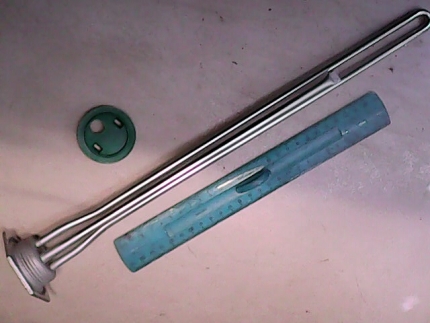

Tubular models for domestic heating

The tubular design of electric heaters is the most common in mobile oil heatersportable and wall mounted electric radiators. Heat transfer in them can occur using: convection, infrared radiation or thermal conductivity.

The shape and length of the tube in such devices can be any and is dictated only by design features. For example, TEN micatremic heater represents a coil located behind a mineral plate. When heated, the plate emits infrared heat.

The most common are its characteristics:

- diameter - 5-18 mm;

- length - 200-6000 mm;

- sheath material - steel, stainless steel, ceramics, copper;

- power - 0.3-2.5 kW.

Heating elements with a power of more than 2.5 kW are not used in domestic heating appliances, because apartment wiring simply can not withstand a greater load.

Finned version of electric heaters

Ribbed devices are a modification of a tubular heating element. Their feature is the presence of many thin steel plates located along the entire length of the device. This design dramatically increases the area of contact with the environment, providing a high rate of heating.

Used finned models mainly in heaters for air heating. They provide a quick increase in room temperature, especially with an integrated fan.

Block constructions of heating elements

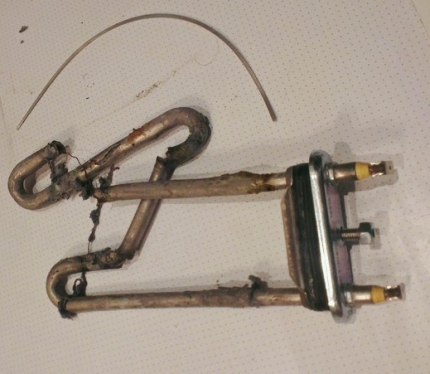

The block version consists of several tubular heaters combined on the basis of a single fastener.

This design is used when a combination of two factors:

- The need for increased power of the device and a high heating rate of the working environment.

- The inability to quickly transfer thermal energy from the spiral to the environment due to the small area of the outer shell.

In fact, in a block heating element, the load on each heating tube decreases and the heat transfer rate increases. Such devices are part of domestic heating boilers and industrial electric heating plants.

The power of block models can be 5-10 kW, therefore, when they are placed in the apartment, an additional power cable is required to be drawn into the room.

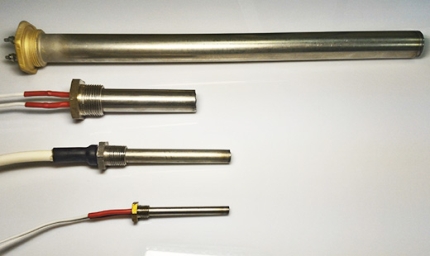

Cartridge type devices

Cartridge heating elements have the form of a tube with one free end, which is due to the peculiarity of their installation. The outer shell is usually made of polished steel to provide maximum contact with the surrounding material. Such tubes are tightly inserted into the corresponding hole in the heater.

The fixing of cartridge models is carried out mainly by means of a flange connection. They are usually used in industry for heating the working parts of extruders.

There are other structural types of heating elements, but they are mainly used in industrial production and do not affect the subject under discussion.

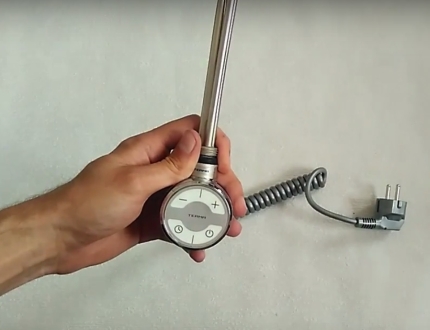

Additional functions of electric heaters

The simplest designs of devices that do not have any built-in adjusting mechanisms were considered above.

But electric water heaters can be equipped with the simplest automation, providing the device with additional functions.

These include:

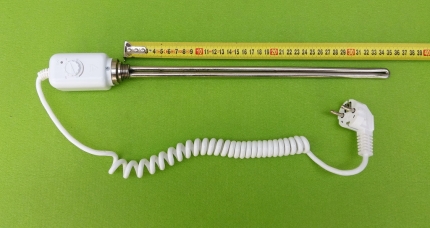

- Thermoregulation. TENY with a built-in thermostat for heating have a temperature sensor, which is triggered when the medium is heated to a certain level. The electric heater is adjusted on the outside of the flange.

- Antifreeze. This function is provided by a simplified thermostat, which only works when the temperature drops to 0-2 ° C. It prevents freezing of water in the heating pipes, consuming a minimum of electricity.

- Turbo heating, which provides forced heating of the working environment during the initial start-up of the equipment. It must be remembered that the wiring of the room must withstand a short-term increase in power.

There are not so many devices that support additional functions, because often the regulation of the operation of heating devices as a whole is carried out using a separate automation unit.

How to choose a heater for heating equipment?

Choosing Heater for replacement in a water heater or in a radiator, you need to pay attention to its power, design, tube length and the availability of additional features. Therefore, before buying, you need to know as much as possible about all its characteristics.

Calculation of the power of the device

The high power of the heating element is not always a positive quality.

When choosing, it is important to consider several factors that are associated with the level of energy consumption:

- ultimate heat transfer power of the heater as a whole;

- wiring options;

- volume of the room.

You can not buy a device with a capacity that is more than 75% of the maximum level of heat transfer of heating equipment.

For example, there is a radiator with 10 sections, each of which gives air 150 W of heat, only 1.5 kW. When you install an electric heater with a power of 2 kW in it, the surface of the battery will not be able to quickly give all the generated energy. As a result, the heater will be constantly turned off due to overheating.

In apartments with worn-out wiring, the constant load on the outlet should not exceed 1.5-2 kW, otherwise it can catch fire and lead to sad consequences. Therefore, before buying a heater, you need to check the condition of the wiring and, if necessary, dismantle the old and lay a new power grid.

When the issue with the electrics and equipment capabilities is resolved, you can begin to calculate the required power to maintain a comfortable temperature in the room.

In well-insulated houses and apartments, a level of 40 W / m will be enough3. And if there are gaps in the windows, the heating power should be increased to 60-80 W / m3. Buying a specific model is possible only after taking into account all the above energy factors.

Design considerations

Most heating elements have an alloy steel shell that provides strength and corrosion resistance. Copper devices are mainly used in water heaters, although there are no restrictions on their use in makeshift radiators.

Also, when choosing, it is necessary to take into account the direction of the thread of the plug, which can be right or left. Different models of electric heaters differ in the diameter of the flanges. They can have a size of 0.5 to 1.25 inches.

Usually, a brief instruction is attached to the heater of a good manufacturer, which describes its design parameters. Studying them will help you buy a device that is exactly suitable for your heating equipment.

Heating tube length

The length of the tube is one of the main characteristics that determine the efficiency of the device.

Its large length with equal power leads to an increase in the surface area of the electric heater and acceleration of heat exchange with the working medium. This has a positive effect on the durability of the heating element and the rate of circulation of the coolant.

It is advisable that the tube runs along the entire length of the working area of the heating device, not reaching the opposite wall by 6-10 cm. This recommendation will allow you to quickly and evenly heat the coolant.

The presence of additional functionality

It is not always necessary to overpay for additional features of heating elements. If the heater is used as an auxiliary and does not have its own built-in automation, then buying a model with a thermostat makes sense.

But if there are own temperature sensors and temperature control mechanisms in the radiator or electric convector, additional functions will remain unclaimed.

Therefore, it is recommended to purchase expensive electric heaters with built-in automation only if there is a clear need for such equipment. If necessary, in the individual selection of the temperature background, it is better to buy thermostat to the outletwhich can be used periodically.

As for the manufacturers of heating elements, their choice is not fundamental. The main suppliers are firms from Russia, Ukraine, Turkey and Italy.The quality of their products is about the same, so there is no point in overpaying for the brand.

Conclusions and useful video on the topic

Video # 1. Practical review of various types of heating elements:

Video # 2. Overview of heating elements with a temperature controller:

Video # 3. Features of the block TEN used in heating electric boilers of heating:

Buying a heater for heating appliances is not an easy task. For this, it is necessary to clearly know the characteristics of the equipment into which the electric heater is built. Therefore, it is only necessary to choose a specific model after a careful analysis of its parameters.

Please write comments, ask questions, publish photographs on the topic of the article in the block below. Tell us about how to choose a heater for replacement in an electric boiler or in a mobile heater. Share what you personally was the decisive argument in the choice.

How to calculate a pump for heating: calculation examples and equipment selection rules

How to calculate a pump for heating: calculation examples and equipment selection rules  Water pump for heating: types, specifications and selection rules

Water pump for heating: types, specifications and selection rules  Gas heat generators for air heating: types and specifics of gas equipment

Gas heat generators for air heating: types and specifics of gas equipment  Collector for heating: principle of operation, installation and connection rules

Collector for heating: principle of operation, installation and connection rules  Selection of a circulation pump: device, types and rules for choosing a pump for heating

Selection of a circulation pump: device, types and rules for choosing a pump for heating  Safety valve in the heating system: types, purpose, diagrams and installation

Safety valve in the heating system: types, purpose, diagrams and installation  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I have an idea to try electric heating instead of gas. I have my own boiler, so my hands itch to experiment. I want to put on the last point of the heater. Bimetallic radiators, coolant - water.

This is still at the level of plans, because I can’t figure it out, it will be profitable for money, or taking into account the costs of heating elements and additional electronics is a waste of money?

Hello. I don’t know how your project, but in general, any electric is usually more expensive than gas, as Alexei correctly noted.

I have a 6 kW electric boiler installed in one house. In winter, we include on ordinary days at 2. 24 hours a day. We multiply by 2 = 48 kW x 30 days = 1440 kW x tariff 3.40 = 4896. If the winter is very frosty, the amount is doubled.

Gas in the second house, equivalent in warmth and quadrature, costs me half as much. Plus, change the wiring here and your costs for heating and so on.

As a reserve, yes, in exchange for a gas one - silly, it will come out much more expensive. I’m drowning in solid fuel (coal) + electro, if I only heat it with electric heating, I get about 10k in the cold months (-20-30 + wind) account (day / night tariff 5.09 / 1.32 Khabarovsk). If only at night, until the morning tena leave, up to 5k comes. I would love to connect the gas, but there are no pipes, and it’s inconvenient for us to carry cylinders.