How to calculate a pump for heating: calculation examples and equipment selection rules

The circulation pump is a small-sized device whose main task is to improve operation and increase the productivity of the heating system. It crashes directly into the pipeline, optimizing the speed of movement of the thermal carrier. Due to this, even a house with a large living area will be heated quickly enough.

To buy the optimal model, you have to figure out how to calculate the pump for heating and what nuances to navigate when choosing. These are the issues our article is devoted to - in this material we considered an example of equipment calculation, paid attention to the principle of operation and the main types of pumps.

We also made recommendations on the selection, installation and safe operation of pumping equipment, providing the article with visual and photo and suitable videos with the calculation of the required power of the device and tips for installing it in the heating circuit.

The content of the article:

Principle of operation and purpose of the pump

The main problem of residents of the last floors of multi-apartment buildings and owners of suburban cottages is cold batteries. In the first case, the coolant simply does not reach their housing, and in the second, the farthest sections of the pipeline are not heated. And all this is due to insufficient pressure.

When should I use the pump?

The only right solution in a situation with insufficient pressure is to upgrade the heating system with a coolant circulating under the influence of gravity. Installing the pump will help here. The main schemes for organizing heating with pump circulation reviewed here.

This option will be effective for owners of private houses, allowing you to significantly reduce heating costs. A significant advantage of such circulating equipment is the ability to change the speed of the coolant. The main thing is not to exceed the maximum permissible readings for the diameter of the pipes of your heating system in order to avoid excessive noise during operation of the unit.

So, for living rooms with a nominal pipe passage of 20 mm or more, the speed is 1 m / s. If you set this parameter to the highest value, then you can warm the house in the shortest possible time, which is important when the owners were away and the building managed to cool. This will allow you to get the maximum amount of heat with minimal time.

The principle of operation of the device

The circulation unit operates by an electric motor. He takes the heated water from one side and pushes it into the pipeline located on the other. And from this side a new portion arrives again and everything repeats.

It is due to centrifugal force that the heat carrier moves through the pipes of the heating system. The operation of the pump is a bit like a fan, only the air does not circulate through the room, but the coolant through the pipeline.

The case of the device is necessarily made of corrosion-resistant materials, and ceramics are usually used to make the shaft, rotor and wheel with blades.

The main types of pumps for heating

All equipment offered by manufacturers is divided into two large groups: wet or dry pumps. Each type has its advantages and disadvantages, which must be taken into account when choosing.

Wet Type Equipment

Heating pumps, called "wet", differ from their counterparts in that their impeller and rotor are placed in a heat carrier. At the same time, the electric motor is in a sealed box, where moisture can not get.

This option is an ideal solution for small country houses. Such devices are distinguished by their noiselessness and do not require thorough and frequent maintenance. In addition, they are easily repaired, adjusted and can be used with a stable or slightly changing level of water flow.

As for the disadvantages, the above category is characterized by low productivity. This minus is caused by the impossibility of ensuring high tightness of the sleeve separating the thermal carrier and the stator.

"Dry" type of devices

This category of devices is characterized by the absence of direct contact of the rotor with the heated water pumped by it. The entire working part of the equipment is separated from the electric motor by rubber protective rings.

The main feature of such heating equipment is great efficiency. But this advantage leads to a significant drawback in the form of high noise. The problem is solved by installing the unit in a separate room with good sound insulation.

When choosing, it is worth considering the fact that the “dry” type pump creates air turbulence, so small particles of dust can rise, which will negatively affect the sealing elements and, accordingly, the tightness of the device.

Manufacturers solved this problem as follows: when the equipment is working between the rubber rings, a thin water layer is created. It serves as a lubricant and prevents the destruction of sealing parts.

Devices, in turn, are divided into three subgroups:

- vertical

- block;

- cantilever.

A feature of the first category is the vertical arrangement of the electric motor. Such equipment is worth buying only if it is planned to transfer a large volume of thermal carrier. As for block pumps, they are installed on a flat concrete surface.

Cantilever devices are characterized by the location of the suction pipe on the outside of the cochlea, while the discharge is on the opposite side of the casing.

We talked in more detail about the design and operation of the pumps in this article.

What to look for when choosing a pump?

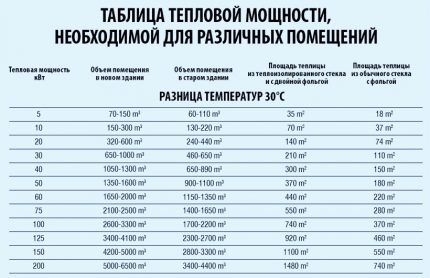

The selection of a pump for autonomous heating must be done based on the hydraulic characteristics of the heating system of a country house. Therefore, before visiting the store, it is necessary to calculate the optimal amount of heat that will be required to maintain the room temperature comfortable for living.

Competently execute hydraulic calculation Additional information to be read will help. Or you can use the advice of a competent specialist.

The optimal amount of heat for a particular object is influenced by many factors:

- material that was used for the construction and insulation of walls;

- climatic conditions;

- features of floors and floors;

- the presence of thermostatic valves;

- characteristics of double-glazed windows installed in the cottage.

When choosing a pump for autonomous heating, special attention should be paid to the scope of application of a particular model, the number of speeds and noise level. Also, the manufacturer and the price of the equipment play an important role.

Criterion # 1 - scope of equipment

In most cases, experts advise installing heating pumps, whose rotors are completely immersed in the heat carrier. Indeed, in addition to a small noise level, such units are more successful in coping with high loads.

As a result, a system with “wet” equipment will last longer, it will be easier to repair and will not require excessive attention.

Give preference to models for the manufacture of which are used strong steel and bearings, and the shaft is made of ceramic. Their advantage lies in the service life, which is at least two decades.

If the choice fell on a “wet” type heating pump, then you need to consider that it should not be installed in the heating system of an open-type cottage. Indeed, in this case, heated water, which lubricates the mechanism, contains various impurities in its composition.

For example, microparticles of sand can clog the gap between the rotor and the stator, which will lead to an early breakdown of the pump.

As for open systems, in them this kind of equipment can function for years. However, it will not need any specialized service.

Criterion # 2 - optimal power calculation

The performance of a pump designed to operate in a heating system can be calculated independently. To do this, you need the total length of the pipeline through which the equipment will pump the coolant.

For every 10 meters of length, we take 0.6 meters of the pressure of the device. So, for a small house with a heating circuit length of 70 meters, you need a pump with a pressure of 4.2 meters.

You can go the other way and calculate this indicator by the formula:

Q = 0.86 * R / TF-TR,

Where:

- R - the need for space in the building;

- TF and TR show the temperature of the coolant when supplied to the system and at its outlet, respectively. The values in degrees Celsius are used.

In European countries, two values are predominantly used as the parameter R: 100 W / m2 - for the house where one or two apartments are located, and 70 W / m2 - for multi-unit buildings.

The above method is just one of many ways to calculate the optimum capacity of a circulation pump. Only the qualified specialist can perform the most accurate calculations.

Criterion # 3 - number of speeds and pump noise

The main feature of modern pump models is the ability to configure them. You can adjust the power by switching the speed of the unit.

To date, the most common models with three speeds. This allows you to quickly warm the living quarters as quickly as possible during cold snap, and in case of warming, reduce the performance of the device, while saving energy.

If you need to buy equipment that makes the lowest possible noise, then the wet type pump is the best choice.

If the unit is installed with a “dry” rotor, an extraneous sound will be heard during its operation, which appears as a result of rotation of the fan cooling the electric motor. Therefore, such a device is better to install in a separate room, and for the residential to choose something less loud.

By no means always extraneous noise appearing at startup indicates a malfunction. Quite often this happens due to the air that remains in the heating system. To resolve this issue, it is recommended that before starting blow air using special valves.

Criterion # 4 - equipment manufacturer and price

After all the necessary calculations have been carried out, you can begin to view the catalog with circulation pumps. It is better to place an order on those web resources where there is a well-thought-out product filtering system. This will allow you to quickly find models with optimal characteristics.

The current market offers a wide selection of pumps for heating systems. Hundreds of manufacturers say their products are reliable, quality and durable. But far from always claimed characteristics correspond to real ones. Therefore, it is better to order equipment manufactured by manufacturers who have made themselves known to the whole world.

The following brands should be included in the list of well-known and reliable companies that produce pumps for heating systems:

- Halm;

- Wilo;

- Ebara;

- DAB

- AlfaStar;

- Pedrolo;

- Grundfos.

The cost of units for organizing the forced transfer of coolant completely depends on the power, type of pump and brand. As a rule, the price of equipment varies in the range from 60 to 220 dollars. We recommend that you familiarize yourself with top ten pumps for heating according to users.

As for domestic manufacturers, they do not produce household equipment, but offer only models designed for industrial use.

Features of mounting a circulation pump

To ensure the effective operation of the heating system at home, you should correctly select a place in the heating ring for installing equipment. It is recommended to find the area where excess water pressure is always observed in the suction area of the thermal carrier.Several methods are known by which this condition can be artificially achieved.

The first method is to raise the expansion tank by 0.8 m with respect to the highest section of the pipeline. This can only be realized in the house where the ceilings allow it. A good solution would be to install an expansion tank in the attic. But in this case, you will have to do roof insulation to avoid unnecessary heat loss.

The second method consists in transferring the tube from the expansion tank from the supply riser and plunging it into the place where the pump suction pipe is nearby. Due to this, you can create just ideal conditions for organizing the forced pumping of hot water in the heating system of the house.

Detailed recommendations for installing the pump, wiring diagram and step-by-step installation instructions are given in the next article.

Rules and nuances of equipment operation

The circulation pump is not bought for a year or even two. Therefore, each owner of a country house should take care that the equipment is in good condition for many years. To achieve reliability and correct operation of the device is possible only in the case of correct and timely maintenance.

The following aspects should be included in the list of basic rules for operating the heating pump:

- it is forbidden to turn on the device with zero feed;

- make sure that the equipment is grounded;

- check that the electric motor does not heat up above the permissible norm;

- check the connection in the terminal box for damage / absence, and all cables should be completely dry;

- make sure that during the start of the device there is no extraneous noise or vibration;

- the equipment should work with the recommended coolant flow rate;

- It is forbidden to start the circulation pump without water.

If the equipment is idle for a long time, then it is recommended to turn it on for 10-30 minutes every month. Such a simple rule will help to avoid oxidation and, as a result, blocking the shaft.

Particular attention must be paid to temperature. coolant. It should not exceed 60-65 degrees Celsius. If you neglect this rule, then sediment will appear in the pipes and inside the pump, which will negatively affect the operation of the entire heating system.

Common breakdowns

The most common problem, due to which the equipment providing the forced transfer of the coolant, fails - this is its long idle time.

Most often, the heating system is actively used in the winter, and is switched off in the warm season. But since the water in it does not differ in purity, with time, sediment precipitates in the pipes. Due to the accumulation of hardness salts between the impeller and the pump, the unit stops working and may fail.

The above problem is solved quite easily. To do this, try to start the equipment yourself by unscrewing the nut and manually turning the pump shaft. Often this action is more than enough.

If the device still does not start, then the only way out is to dismantle the rotor and then thoroughly clean the pump from accumulated salt deposits.

Conclusions and useful video on the topic

The video tells about the calculation of the performance of circulation equipment:

Proper installation is the key to the excellent operation of any device. Features of installing a pump for heating in the video:

The heating system, where a pump is used to organize the movement of the coolant, has many advantages. But in order to correctly install it, you will have to spend a little time analyzing the nuances and choosing the equipment. Only in this case can you make your house truly warm and cozy.

Do you want to add a pump to the heating system, but doubt the calculations? Ask your questions in the comments section - our experts will try to help you.

Or maybe you want to supplement our material with useful comments? Or offer another option for calculating the heating pump? Write your comments and recommendations under this article.

Heating elements for heating: types, principle of operation, rules for the selection of equipment

Heating elements for heating: types, principle of operation, rules for the selection of equipment  Water pump for heating: types, specifications and selection rules

Water pump for heating: types, specifications and selection rules  Circulation pump for heating: top ten models and tips for customers

Circulation pump for heating: top ten models and tips for customers  Selection of a circulation pump: device, types and rules for choosing a pump for heating

Selection of a circulation pump: device, types and rules for choosing a pump for heating  Gas heat generators for air heating: types and specifics of gas equipment

Gas heat generators for air heating: types and specifics of gas equipment  Collector for heating: principle of operation, installation and connection rules

Collector for heating: principle of operation, installation and connection rules  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I installed a standard circulation pump in the heating system. The house is with a basement, so the whole main system is there. The device was installed in front of the boiler at a distance of 1 meter. It does not come in contact with heated water, so I don’t worry about the life of the seals, rotor and bearings. The cooled coolant pump is pushed into the boiler, from where it is prepared into the system. When connecting, just consider the fact that you need to install it correctly so that the water is supplied in the right direction (not in the opposite). It works quietly, almost inaudibly.

In fact, only power engineers use formulas for calculating power when designing large communal or industrial systems. For private homes, selection is done based on experience, as there are few options. The area of private houses does not differ much, usually 300-500 square meters, two floors (with an attic or basement). Simply a pump is taken that is suitable for the diameter of the pipelines, and the required power is set by the regulator.