Do-it-yourself mini Russian stove: specifics and arrangements for the construction of a compact stove

The advantages of the Russian stove can be listed for a long time: it heats and feeds, and provides a warm bed for sleeping. But in a small house there is not always enough space to accommodate a bulky structure. The stovemakers masters came up with a smaller copy - the built mini Russian stove with their own hands is not inferior in functions to a full-fledged design.

If you want to try yourself in the furnace business, we suggest considering one of the options for building a mini-stove with procedures and a description of the technologies. If you enlist the help of an experienced craftsman, you can independently build a beautiful, efficient, useful heating unit that will last for more than a dozen years.

The content of the article:

Distinctive features of the Russian mini-oven

Fundamentally, a miniature stove does not differ from an ordinary Russian stove - it has a similar design, the same functions, the same design. The main distinguishing feature is the size: it takes up significantly less floor space due to the fact that the stove and the crucible are arranged and located nearby.

The floor area occupied by the structure is usually not more than 1 mx 1.3 m, but other options are possible, a little more or less. The height of the structure is the same as usual: the main part at the top is smoothly rebuilt in the annulus and ends with a pipe going into the ceiling.

Both the large cooking chamber and the stove are actively used for cooking. The small firebox is heated quickly enough, therefore it is used in the summer, when the heating of the whole house is not needed. On the burners, you can easily place immediately 2-3 pots, and if the large oven is melted, then bake the bread.

The stove also remains hot for a long time, so it can be used to warm up or just to keep breakfast or lunch in a warm state.

A feature of the compact stove is the preservation of two fireboxes, which are used with the same activity.But they are often located on two opposite sides - in this case, a free approach will be required both in front and behind.

It must be remembered that the mini-copy in terms of danger does not differ from a large Russian stove, therefore, during construction, it is also necessary to isolate the foundation and nearby surfaces subject to fire. Walls, wooden sections of the floor, the edges of the opening in the ceiling are sheathed with metal or asbestos sheets.

DIY construction technology

In everyday life, there are many options for mini-designs, which have different names. Often they are called simply Russian stoves or "housekeepers." If you plan an independent construction of a heating structure, then it is better to stop just on the construction of the Russian mini-furnace - it is made both easier and faster.

The first two stages are universal and suitable for the construction of any Russian stove. Starting from the 3rd stage, we present development by A. Emshanov - An excellent example of a compact and multi-functional mini-stove.

Stage # 1 - Preparing Tools

Even for simple masonry, a special stove-maker tool is required. Despite the apparent primitiveness of the devices, each of them has a clear purpose. We list the main tools that are best prepared in advance.

Rule - a wooden crossbeam with even edges 1-2 m long, with the help of which the straightness of the masonry is checked. If you divide on one of the sides, the rule can replace the ruler (meter).

Square It performs its direct function - it serves to check the corners of the furnace and the foundation.

Roulette or folding meter useful for measuring any distance between the elements of the furnace and individual parts.

In addition to the listed tools, you may need:

- urine brush for grouting;

- plumb to check the vertical;

- rasp for processing tiles;

- stitching for finishing the seams of the masonry.

Also suitable are containers for mortar, a special tool or a machine for cutting bricks, benches, scaffolds or pallets.

Stage # 2 - selection of materials

Materials and metal furnace elements are selected depending on the type and design of the furnace. The main thing is to take into account the technical characteristics, otherwise the stove will crack after the very first furnace.

In places of direct heating, metal parts are not used, which during the furnace also expand and destroy the brickwork.

The ban applies to any combustible materials, as well as those that when heated melt, deform and begin to produce smoke hazardous to health.

It is recommended to use high quality materials of natural and artificial origin. The first group includes rubble stone and cobblestone, and the second group includes brick.

You can use the old brick left over from disassembled stoves. Before masonry, it is sorted, cleaned of the solution, and then plastered.

Each element should have smooth edges, without chips and cracks. The mass of 1 cubic meter of brick, which includes 480 pieces, is about 1700 kg. When using the mortar, the amount of brick varies - depending on the thickness of the layer.

For the mini-furnace, the order of which is located below, two types of bricks were used: red kiln and chamotte. The second is necessary for laying the internal "core", which transfers the maximum temperature load.

The solutions are different: with the content of clay, cement, limestone, gypsum, etc.

Clay solutions are prepared according to the formula 1: 1, that is, one part of sand accounts for one part of clay. Other options are possible: 1: 1,5, 1: 2, 1: 2,5.

The solution is kneaded in well, tap or rain water. One of its main qualities is plasticity. The composition should be thick enough, but easy to apply. After drying, it should not form cracks.

Stage # 3 - ordering of the Emshanov mini-oven

The author of the scheme and ordering of the mini-furnace is Alexey Emshanov. Its development resembles the Russian stove by Y. Porfiryev, but differs in more efficient and uniform heating of the side walls.

A couple of years after construction, the furnace showed excellent results:

- fast and uniform heating;

- stable draft with a pipe with a cross section of 20 cm and a height of 5 m;

- no cracking in the absence of lining of the second firebox;

- 2 hours after kindling, the oven temperature is 40-45 ° С, after 4 hours - from 55-80 ° С.

If the furnace is installed in a room with a volume of about 100 m³, then it will warm up to a temperature of 30-35 ° C. The amount of firewood burned daily is 10-15 kg.

Thanks to the black blotches, the stove looks attractive and does not require additional cladding, although if desired, it can be coated with plaster and painted.

The lining is used in masonry: for firebox use chamotte brick ШБ-5, for one of the caps - flask ШБ-6.

Let's dwell on the order of the Russian mini-stove.

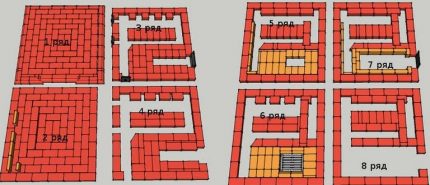

1 row - continuous laying. The side bricks on the outer edge are rounded, which looks aesthetically pleasing and neat.

2 row - also solid masonry, with a total area of slightly less than the base. Dimensions: 6 bricks to 6.5 bricks.

3 row - The beginning of the construction of the ash chamber. Installation of three cleaning doors 14x14 cm and one blow 25 (28) x14 cm.

4 row - continued construction of cameras, fixing doors.

5 row - overlapping of the two lower channels for the formation of two caps on opposite sides. The channel at the rear wall of the furnace is approximately 2 times larger than the channel located in the center - for better heating of the rear part.

Here, the first row of fireclay brick is laid out - this is underflooding. The rear hood is lined with a hem.

6 row - the overlapping of the lower channels ends, the rest is a continuation of the previous row.The second row of fireclay bricks must be laid out, forming a funnel with bevels - it is here, on the grate, that the coals will drop for burning out.

Installation of grate RD-6. At the edges you need to leave gaps of about 5 mm wide for free expansion when heated. Continuation of the lining of the cap.

7 row - masonry of the external circuit, where the door of the combustion chamber DT-3 or DT-4 is installed and fixed in a box made of stainless steel. The laying of the side walls of the firebox begins with chamotte brick mounted on the edge. Lining with a flapper cap continues.

8 row - masonry, as in the 7th row. The wide cap is narrowed - for this, the brick is cut at an angle of 45 ° and placed with the wide side up and bevel down.

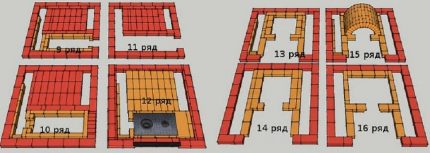

9 row - overlapping a wide cap, which at the same time serves as the basis for the arch of the Russian stove. The 4th row of fireclay masonry with the dressing of the previous row is produced.

10 row - overlapping the furnace door with a jumper of halves of bricks, inside of which a stud is inserted. Bricks are pulled together by nuts through washers.

11 row - dressing of the previous row, alignment with the installed jumper, the height of which is about 14 cm. Masonry of the 5th row of the firebox with fireclay bricks with the formation of an outlet for flue gases. Usually this output is called “hailo”, and its peculiarity consists in the strongest heat load.

For reinforcement, 2 rows of bricks are laid out, which over time can be replaced through a cast-iron plate.

12 row - looks like a ledge, repeats the shape of the first row. The brick is rounded on both sides and looks aesthetically pleasing. The internal jumper of the firebox is the plate ШБ-94 or ШБ-96. It is laid “dry”, without mortar and laid with basalt cardboard 2-3 mm thick.

Do not forget that between the two clutches of the firebox - made of red and fireclay bricks - a distance of 5-8 mm. The gap is necessary for the free expansion of chamotte during strong heating.

Under also laid out of fireclay bricks. The edge of the firebox is overlapped on top of the tiles, basalt cardboard or kaolin wool is used at the joints. Hailo takes on a finished look, the cross-sectional area is about 30 cm².

Installation of a 2-burner cast-iron plate 71x41 cm and a protective 5-cm metal corner on the edge of the brickwork opposite the plate.

13 row - masonry of the outer contour and the 7th row of fireclay bricks. Along the edges of the cast-iron plate 2 halves of the sawn chamotte plate (94 or 96) are stacked, the solution is connected only along the edges. In the lower part there are grooves of 5-7 mm for a free-wheeling of a cast-iron plate.

14 row - dressing of the previous row, masonry of the cooking chamber, lining of the hood.

15 row - repetition of the 13th row. Preparation of the foundation for the construction of the arch of the furnace and its construction. The arch must be made strictly along the radius.

To strengthen the walls, lay a perforated galvanized metal tape through 1-2 rows. Due to this, the side parts will be able to withstand stress during overflows.

16 row - repetition of the 14th row of the outer contour. Fireclay masonry is erected around the vault.

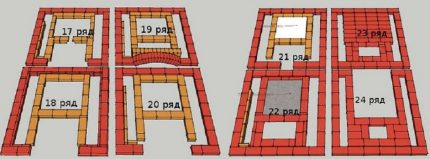

17 row - laying of the mouth of the Russian stove with fireclay bricks, narrowing of the upper part. Instead of the traditional arched decoration, curly is used. It is simple and protects the mouth from overflows. To prevent the bricks from dispersing, use a perforated tape.

18 row - Another “belt” - a protrusion of rounded bricks along the outer contour. At the joints of red and fireclay bricks, it is necessary to lay basalt 3-mm cardboard or kaolin wool to maintain tightness between the outer red "shell" and the inner fireclay "core".

19 row - Installation of the entrance arch of bricks placed on the edge. Inside the same arch is made of fireclay bricks. To strengthen the structure, a stud was missed inside it, fixed on both sides with nuts. The inner arch protects the outer from overflow, since the cast-iron plate during heating is heated to 500 ° C.

20-22 row - continuation of the masonry of the previous row. To preserve heat, a thick layer of kaolin wool - 50-60 cm, is laid over the arch, and covered with a slab of refractory concrete or simple reinforced concrete.

Starting from row 22, only red brick can be used.

23 row - narrowing of the smoke collector from 3 sides at an angle of 22 or 45 degrees. As a result, the dimensions of the smoke collector should be reduced to a cross section of 25x25 cm. Continuation of the lining of the side channel.

24 row - overlap of the refractory plate above the forge arch and the continuation of the narrowing of the smoke box.

25 row - narrowing the smoke box. Laying the internal contour around a horizontal surface (mini-beds or dryers) "dry" to provide expansion and protection against microcracks. Later it can be tiled with ceramic tiles. The design of the side channels.

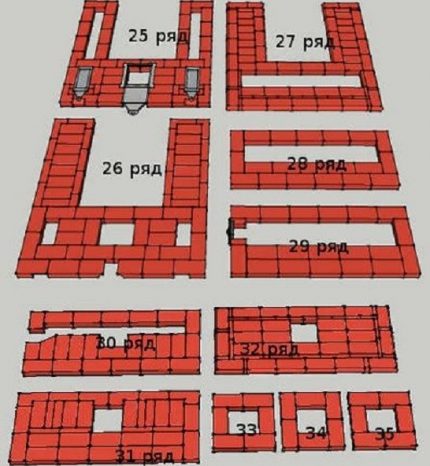

26 row - overlap of both caps in the front. The smoke collector has narrowed to the final size - 25x25 cm. Installation of 3 valves: Russian stove, summer run and winter run.

27 row - overlapping gate valves and caps.

28 row - Another "belt" of rounded bricks. Three chimney channels are connected into one chamber.

29 row - masonry of the main smoke collector 25 cm wide.

30 row - Installation of a cleaning door for cleaning the smoke box.

31 row - narrowing the smoke collector, preparing it for overlap.

32 row - overlapping of the cleaning door, dressing the entire smoke collector completely. There is a hole of 25x25 cm.

33 row - along the contour of the front part - a "belt" of rounded bricks, re-dressing of the smoke collector, the beginning of the laying of the pipe.

34-35 row and further - laying a pipe about 1 m high.

After passing the ceiling, a sandwich chimney with a cross section of 20 cm is installed. The diameter is small, therefore it can withstand a weight of not more than 1 ton. This must be taken into account when selecting a chimney - a brick height of more than 2 m is undesirable.

A heavy pipe is best pushed to the side. If it is planned to center it, then it is impossible to raise above 1.5 m. Ideally, right in the pipe, under the ceiling, you need to install another valve. However, it is often neglected due to its height - it is really problematic to reach the pipe.

The nuances of construction technology

The construction of the furnace is subject to certain rules, which are not recommended to be violated. Simply put, you must strictly follow the order, without retreating half a brick to the side. Consider some of the nuances of construction and masonry.

The quality of the masonry can be judged by the first furnaces, which are carried out for drying the furnace. Good draft, the correct direction of movement of flue gases, opening doors and gate valves without effort, sufficient heating of the walls and mini-beds indicate the correct execution of actions and compliance with technology standards.

Conclusions and useful video on the topic

Compact furnace with one underfloor:

Review of "Housekeeper":

One of the advantages of a mini-stove is the lack of complex internal channels, so it is built very quickly. Its design is simple and understandable, so you simply can’t come up with the best option for the first experience in building a Russian stove!

Please write comments in the block below, post a photo on the topic of the article, ask questions. Tell us about how you built a Russian stove in your country house or in a country house. Share useful information that is useful to site visitors.

How to build a Russian stove: do-it-yourself masonry, the best orders and schemes

How to build a Russian stove: do-it-yourself masonry, the best orders and schemes  Russian stove with stove: masonry technology of the Russian stove with diagrams and detailed procedures

Russian stove with stove: masonry technology of the Russian stove with diagrams and detailed procedures  Do-it-yourself gas bath stove: manual for the installation and installation of a gas stove

Do-it-yourself gas bath stove: manual for the installation and installation of a gas stove  DIY masonry: a detailed guide + orders with diagrams and drawings

DIY masonry: a detailed guide + orders with diagrams and drawings  How the Russian stove works: design features and an overview of popular types of Russian stoves

How the Russian stove works: design features and an overview of popular types of Russian stoves  DIY garage oven: an overview of the best homemade options

DIY garage oven: an overview of the best homemade options  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

On the one hand, a smaller Russian stove might be suitable in a situation where the house is small. On the other hand, a stove bench is one of the undoubted advantages and a distinctive feature of the Russian stove, and it is not provided for in this design. That is, such a mini-stove is devoid of most of the charm of a traditional Russian stove. And by efficiency you can find more successful designs.