How the Russian stove works: design features and an overview of popular types of Russian stoves

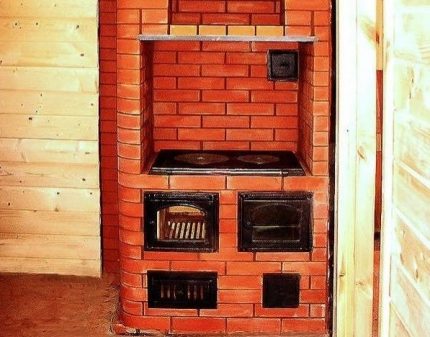

When it comes to the heating system of a private house, many owners primarily recall a traditional heat source such as a Russian stove. This is a universal structure that does not require a power connection and performs the function of heating a house.

The hob, together with the furnace, completely replace the stove with the oven, therefore, it is also a great alternative to kitchen equipment for cooking. Let us dwell in more detail on the features and types of the Russian stove.

The content of the article:

The device of the Russian stove

Once an adobe or brick building towered in almost every village house, since without it it was difficult to maintain heat in the cold season, and throughout the year to bake pies, cook soups, cereals, vegetable and meat dishes.

The variety of furnace designs is amazing: besides the traditional “beds”, which were previously built in five-wall huts, there are structures with fireplaces, dryers, additional stoves and even hot water boilers. But all of them are united by the presence of two fireboxes and a furnace for baking bread.

Purpose and main functions

One of the advantages of Russian stoves is their versatility.

Here is a list of only the main tasks that can be solved with the help of these useful facilities:

- heating the entire house or individual rooms;

- cooking on the stove and in the crucible;

- drying herbs, mushrooms, berries, fruits;

- use of a couch as a berth;

- heating water for household needs;

- clothes drying;

- warming up a samovar.

The construction of the furnace is calculated so that it heats the house.For this, a brick structure is erected in the center of the building or positioned so that heat enters adjacent rooms. If the building is small, then there is enough heat so that the temperature in all rooms is comfortable for living.

For spacious houses, structures are being built that differ in large sizes or additional heating details - shields, boilers for heating water.

To save on fuel and make the house more comfortable, the owners of stove-heated buildings carefully consider the thermal insulation, since a lot of heat is lost through the cracks in the door and window openings, cold walls and floors.

Thanks to this method of cooking, soups, cereals, fries, stews retain the beneficial properties of the products that make up their composition.

Owners of Russian stoves often like to “warm the bones” on a bench - a wide horizontal surface that heats up in the process of heating and slowly cools down. Thus, the bed remains warm until the morning. Dry heat is good for people with certain diseases, such as joints or respiratory organs.

The stove is also used for household purposes - for example, for drying everything that is in the house. During the construction, small niches are thought out, in which hats, mittens, and pants that were wet after a winter walk used to be folded — in the morning they became dry and warm.

Often near the stove, bathes were built - wooden plank canopies that continued to lie down and performed the same functions. Since the dresses were under the ceiling, they were also always warm.

Features of construction and masonry

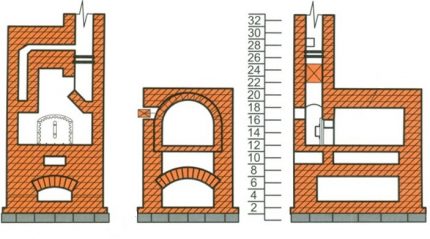

How many stove-makers, so many stoves. Each master has his own secrets of the selection of materials, masonry, the device of the Russian stove. However, there are common structural elements, without which the functioning of the heating structure is simply impossible.

Depending on the design, the installation location is also selected. Usually this is a well-lit area of sufficient area, located opposite the windows in the center or adjacent to one of the walls. Building in the corner was not considered the best option, since with such an arrangement, heating the building is the least efficient.

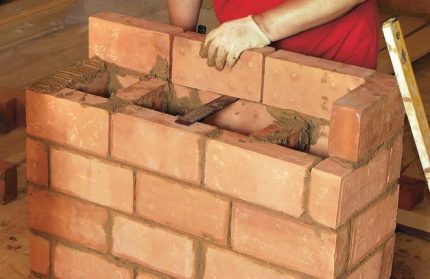

The construction is built on a solid foundation; it is protected from asbestos or non-combustible cladding from the wooden elements of the house. Isolation from felt is also used, which is presoaked in clay mortar, laid in 3 layers and upholstered with galvanized or painted roofing steel.

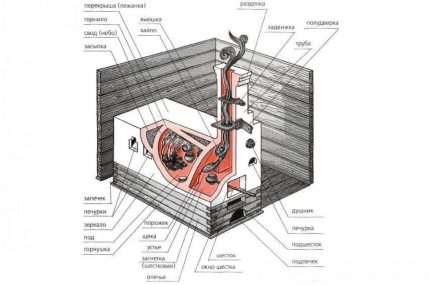

The main details of the Russian stove:

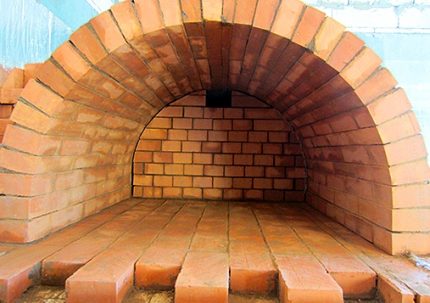

In order for the stove to work efficiently, heat up well and retain heat longer, there are special secrets. One of them is the shape of the arch of the cooking chamber (semicircular, barrel-shaped, etc.). Masters make them flat or steep, often in the form of arches, reinforced with steel wire or screeds of metal battens.

In addition to the listed parts, there are stoves in the furnace design - small side recesses for drying products or things. Dimensions - no more than 20 cm in height and width, depth depends on the size of the walls.

In villages, but less and less, you can still find stoves that were heated "black", that is, did not have such a structural element as a pipe. Smoke came out through the window of the hearth and went up to the ceiling, and from there moved to the air vent - the porch above the front door.

Subsequently, in order to increase the energy efficiency of heating, they began to use a special hole in the wall (fiber window), which made it possible to reduce heat loss.

The firebox “in black” caused a lot of inconvenience, and with the advent of the first stoves with a pipe, the “chicken” devices, as they were also called, practically disappeared.

Variety of cladding and other design

Outside, Russian stoves are faced in different ways: they are plastering and whitening, coated with clay, tiled with tiles, tiles or wooden elements, covered with hand-painted.

It must be remembered that the thick lining retains heat, prevents it from spreading around the room, so if the hut needs to be heated well, the brick is simply covered with a clay-sand mixture - plaster. To give the building a traditional look, the surface is painted with whitewash or special white paint.

Some interesting design options:

The design can be any, it all depends on the material capabilities, the imagination of the owner and the skills of the master. However, it must be remembered that not all materials tolerate heating, and some - for example, granite and marble slabs - look too pathetic and simply do not fit into the concept of "folk" art.

Popular types of stoves

Over the centuries, the design of the Russian stove has been modified and improved. Some master engineers added new elements to increase heat transfer or speed up / slow down the process of burning wood. Knowing how the Russian stove is arranged and works, you can make changes without losing its functionality.

Consider several modifications of the Russian stove, which are actively used in the construction of modern residential buildings.

Option # 1 - Simple

The main details of the so-called simple furnace are a cooking chamber, a furnace and a pipe. Nothing extra, no additional elements that complicate the design.

This option is ideal for a seasonal country house, as it takes up little space and perfectly fulfills its purpose - it heats the room and helps to cook food.

Food is prepared by placing dishes also near the mouth. Now the bread is baked on baking sheets and in special forms, and before it was just “planted” with a spatula on a previously cleaned and swept under.

To increase the heating efficiency, the underflow chimneys are made separate, placed near the walls. Subflooding can also be arranged in the hearth, equipping it with a cast-iron stove for quick cooking and heating of ready-made dishes.

For the construction of a simple furnace, approximately 1,610 pieces of solid brick, about 70 buckets of masonry mortar on clay, a pair of smoke dampers, a damper and a samovar will be required.

Option # 2 - adobe

The main difference between the adobe kiln is the use of adobe - a clay solution prepared in a certain way. Brick is used only for laying pipes and hearths. One medium-sized oven will require about 3.5-3.6 m³ of well-mixed, correct solution consistency.

One of the important indicators of the clay composition is density. It is easy to check the desired level: it is necessary to form a brick and put its central part on a stick. If it retains its shape and does not bend, the solution is mixed correctly.

Elements for masonry are prepared as follows: clay and sand are poured onto a flat surface with a layer of about 15 cm, then fragments of the required size (usually 20-25 cm wide) of rectangular shape are cut out of the formation. In fact, you get homemade bricks.

A common mistake for beginners is to use water to wet the bottom row. This weakens the solution and provokes the appearance of cracks. During breaks, the upper row is protected from drying out: they are covered with rags dipped in water and wrung out.

The constructed oven is dried for about a week, then heated with dry firewood. In the process of heating clay bricks emit steam, and the "bricks" acquire the necessary structure. Only after 5-6 days the oven becomes ready for use.

Option # 3 - “Teplushka”

There are several modifications of the Teplushka stoves, which differ in size and small structural nuances.

The advantage is the variety of fuel used. In addition to traditional firewood, you can use coal, dung, straw briquettes, pallets. If you compare any of the "Teplushki" and the traditional Russian stove, then the first option requires much less fuel.

Cooking does not require much effort. It can begin to be prepared after burning wood and stored in a preheated form for about another day. The furnace process at the same time takes a short period of time - from half an hour to an hour.

The two main structural elements are the chambers: the lower (heating) is located under the hearth, in the underfloor, and the upper (cooking) - at the hearth level. But the furnace can be carried out in two ways - both through the crucible and through the lower heating chamber.

Models of furnaces differ in size. For example, "Teplushka-2" without a stove, but with a small hot water boiler - 1.68 x 1.29 m, and "Teplushka-4" with a stove that is built into the hearth - 1.29 x 1.29 m.

Option # 4 - “Housekeeper”

The name of the stove “Housekeeper” speaks for itself - the heating device is simple in execution, compact and economical. Moreover, not only firewood with a low tar content, but also any other types of solid fuel are suitable for the firebox.

The main sizes:

- length - 1, 4 m

- width - 0.89 m;

- height to the level of the pipe - 2.24 m;

- the distance from the floor to the sixth - 0.77 m;

- the distance from the floor to the bed - 1.4 m.

The design consists of two separate chambers: a heating chamber, which is located below, and a cooking chamber, raised above for ease of operation.

The furnace is equipped with two fireboxes: one is usually located on the front side, the second on the right. A cast-iron stove is placed so that it overlaps both fireboxes at once, but the large burner should be above the main one, respectively, the small one should be above the additional one.

It is not recommended to use both fireboxes at the same time. Usually large is used in winter, for general heating, and small - in the warm season, for cooking. If any of the fireboxes is “idle”, all its doors (furnace, blower) must be closed to create traction.

The "housekeeper" is good because cooking on the hearth can be done for a long time after the furnace. Even after 10-12 hours, the desired temperature will remain in the crucible.

Option # 5 - Potapov designs

V. A. Potapov dwelled on two of the most effective modifications that differ in design:

- A rectangular oven 0.51x0.64x1.82 m with a heat transfer of 850 kcal / h per day, provided that there is one firebox.

- A rectangular furnace 1.16x0.64x1.89 m with a heat transfer of 2400 kcal / h per day, provided that there is one firebox.

Distinctive features of the first option - the presence of a cooking chamber with a stove made of cast iron, an oven and a ventilation hole.

The number of views and latches can be different, their presence is easily combined. For the construction of this modification, 260 pieces of solid brick and about 12 buckets of mortar on clay are required.

The second version of the furnace is attractive because it runs on different types of solid fuel. But when using anthracite or coal during construction, the following nuances are taken into account: the grate is lowered below the usual row, and all the heating parts of the chambers are laid out of refractory bricks. In total, 580 pieces of red brick and 20 buckets of clay mortar are required.

There is a simple way to increase the heat transfer of a structure: you need to repeat the last rows, due to which the height increases. If the ceiling is involved, then the ceiling above it must be plastered.

Option # 6 - Volkov designs

I.F. Volkov improved the heating and cooking stove, which functions not only from firewood, but also from other types of solid fuel. Dimensions: 0.89x1.02x2.24 m. If the furnace is produced once a day, the daily heat transfer will be 2260 kcal / h.

Both traditional firebox methods are used: winter and summer. The movement of hot gases and heat distribution are controlled by valves. If you heat in the summer, then the gases heat the stove, and the oven, and the hot box.

Construction requires approximately 520 pieces of red brick and 20 buckets of mortar. A crucible will require approximately 50 kg of refractory clay.

Drying grates and doors can be made independently or purchased at a specialized store. Purchased cast iron products look more presentable and are an element of interior decor.

Option # 7 - “Swede” Buslaev

The compact thin-walled furnace K. Ya Buslaeva is loved by the owners of private houses for good heat dissipation, which with two furnaces per day reaches 4500 kcal / h.

Necessary conditions for the construction of a heating device:

- pre-soaked brick;

- strong foundation;

- thin, high-quality seams.

Various types of solid fuels are suitable - coal, firewood, briquettes, pallets.

The cooking chamber has a special structure: to ensure steam exit during cooking, it is equipped with a separate ventilation duct.

The firebox and the cooking chamber are most strongly heated, respectively, they are usually laid out with refractory bricks.

Construction requires: 550 pieces of brick, about 40 buckets of clay mortar, as well as doors (furnace, blower, for the cooking chamber), grate, view, oven box, cast-iron stove, gate valves.

Detailed lists of materials with sizes and orders of the presented types of Russian stoves can be found in specialized literature.

Conclusions and useful video on the topic

Traditions in the design of furnaces:

Overview of the Russian stove with cladding:

Stages of construction:

Start of the furnace - the first kindling:

The arrangement of the internal parts of the Russian stove, decor elements, additional extensions for efficient heating, cooking and interior design - literally everything is important. And this means that before the construction of the heating device, every little thing needs to be thought out - from the location to the materials used.

Independently deal with masonry, especially for beginners, we do not recommend. It is better to enlist the support of an experienced master stove-maker.

Gas bath stove: TOP-10 rating of sauna stoves for Russian and Finnish baths

Gas bath stove: TOP-10 rating of sauna stoves for Russian and Finnish baths  Heat-resistant paints for stoves and fireplaces: an overview of popular heat-resistant compounds

Heat-resistant paints for stoves and fireplaces: an overview of popular heat-resistant compounds  Russian stove with stove: masonry technology of the Russian stove with diagrams and detailed procedures

Russian stove with stove: masonry technology of the Russian stove with diagrams and detailed procedures  Do-it-yourself mini Russian stove: specifics and arrangements for the construction of a compact stove

Do-it-yourself mini Russian stove: specifics and arrangements for the construction of a compact stove  Types of brick ovens for the home: types of units according to purpose and design features

Types of brick ovens for the home: types of units according to purpose and design features  A furnace with a water circuit for heating a house: features of furnace heating + selection of the best option

A furnace with a water circuit for heating a house: features of furnace heating + selection of the best option  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

A modern analogue of the Russian stove is the TeplEko heater and the like micathermic devices. Although even without them it’s now easy to find bath stove and productive wood burning machine for heating the whole house.