DIY do-it-yourself stoves: construction manuals with diagrams and procedures

Modern private houses rarely resemble old village huts, more often they are better suited by another name - a cottage. However, even now, many owners of estates, especially suburban ones, follow traditions and consider Russian stoves with a stove bench as useful and functional heating and cooking facilities.

We will talk about what a stove with a trestle bed or stove bench is. Consider the technical side of the issue, together with you we will understand the design features. Independent home masters in the article we present will find a detailed description of the structure with diagrams and orders.

The content of the article:

The stove with a stove bench - Russian classics

It is impossible to imagine a Russian stove without a stove bench - it seems to be somehow too compact, modern and unusual. But the structure on which Emelya moved was fully consistent with the idea of a Russian person about a classic village stove.

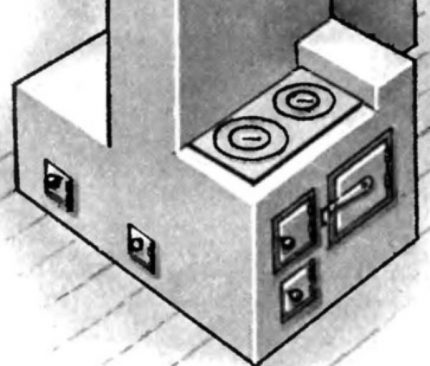

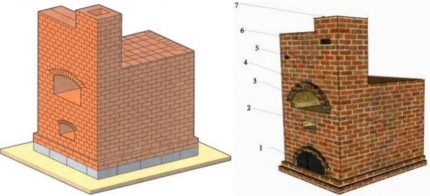

Today, large and comfortable designs, on which you can "warm the bones", are diverse in both form and design. Here are a few samples that you can make yourself if you wish:

Such a variety of design is dictated by the desire of the owners to decorate the interior, to make it unique.

Design Brief

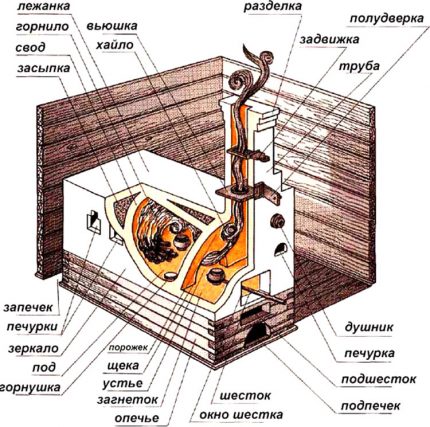

Many do not know how to properly build a Russian stove with a stove bench, because they do not know either the basic elements or the details of the masonry.

Crucible - the main, large chamber, which serves both for laying firewood and for baking pies. The upper part of the crucible - the arch - is heated and transfers heat to the bed.

In front of the crucible is sixth - a small compartment where it is convenient to put baking sheets and pots. Here, manipulations are made on laying firewood on a shovel. Sometimes under a sixth place a small niche - sub-sub.

Mouth - a hole leading to the crucible.

Under - an important part of the crucible, its lower plane, slightly inclined to the mouth. The smoothest polished surface of the furnace.

Podpeche - a niche under the oven, which serves for drying logs, storing large utensils, grips, shovels, panicles.

Overtube - a chamber between the furnace and the pipe, placed above the pole.

View - a damper covering the chimney after burning wood.

Lounger - A large horizontal surface for resting or drying.

Samovar - the hole into which the samovar tube was previously inserted.

If additional heating of the house or outbuildings (verandas) is required, a boiler is built into the furnace body and wiring is done in the necessary rooms.

Pros and cons of construction

The Russian stove has a lot of advantages over modern heating devices, so it is still popular, especially in country houses, in cottages.

Construction advantages:

- profitability - if you build a furnace with a complex construction, the efficiency reaches 70-80%;

- low cost of materials and work stoves;

- some models are heated not only by firewood, but also by other types of solid fuel;

- multifunctionality - heating, cooking, rest included;

- requires attention 1 time per day;

- favors health with dry heat from bricks.

If the construction rules are followed, then safety is guaranteed.

But there are also disadvantages due to which the owners of the buildings refuse to install the stove. Fuel must be prepared in advance, dried and selected. Modern electric and solid fuel boilers operate more efficiently, while taking up less space and do not require constant attention.

The Russian stove can only be installed in a single private house, for heating multi-unit, and even more so multi-storey buildings, it is not suitable.

The disadvantages include regular cleaning of the furnace from ash and soot.

DIY stove with stove bench

We offer three design options that you can do yourself. Of course, you will need to study a lot of thematic information, learn how to correctly make calculations, make masonry.

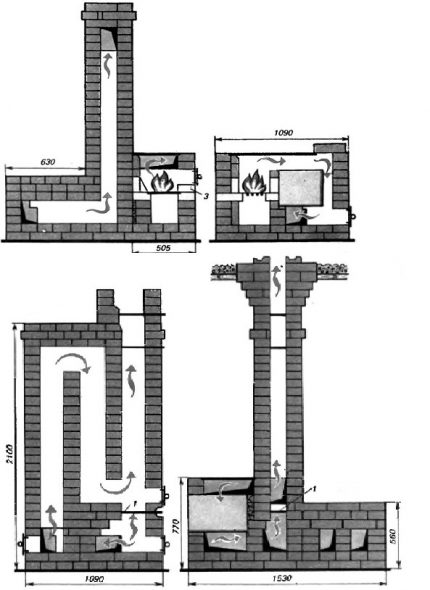

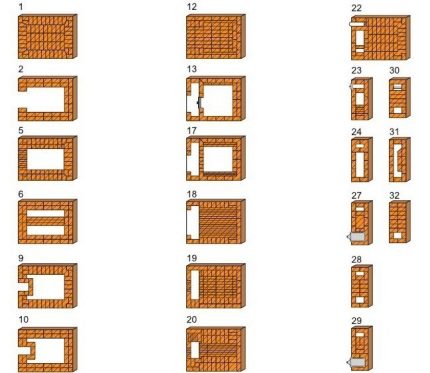

Option 1 - with a trestle bed and a shield

A couch is conventionally called a low couch, which you can climb onto right from the floor. Such a stove is convenient in that you do not need to climb stairs or stairs, so both older people and children can sit on warm bricks on their own.

The furnace is used for year-round operation. One of the elements - the summer valve - is not always used, sometimes the hole is simply laid.The main valve located in the pipe is made short.

So that the valve handle does not go beyond the outer part of the facade, it is “sunk” in the masonry, that is, a small recess is made along the edges for easy grip.

A heating shield with a width of 1.02 m is located above the stove. To comply with such dimensions, brick ledges are made along the edges of the cooking horizontal. You can increase the number of gas ducts of the shield to 5 pieces, but then they will have to be turned over the stove.

The dimensions of the trestle bed do not matter, they can be chosen arbitrarily, focusing on the area of the room and the purpose of use. One solution is trestle bed on brick pillars. Holes between posts 12 cm wide are used to release heat to the outside. Plus of this design is material saving, minus is faster cooling of the upper part of the stove bench.

To increase the heat transfer, arrange a solid foundation. On wooden floors, under the flues, place protection against heat - a sheet of asbestos. It reduces the heat transfer to the foundation and prevents the risk of accidental fire.

If you do not take into account materials for the foundation and pipe, then you will need:

- red brick - 655 pcs.

- fireclay refractory brick - 15 pcs.

- metal door 140 * 140 mm - 7 pcs.

- metal door 250 * 210 mm - 1 pc.

- plate 710 * 410 mm - 1 pc.

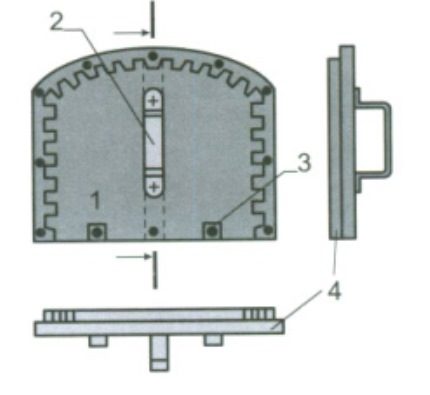

- box for the oven 450 * 365 * 300 mm - 1 pc.

- gate valve 210 * 120 mm - 1 pc.

- grate - 255 * 175 mm - 1 pc.

- iron sheet 750 * 500 mm - 1 pc.

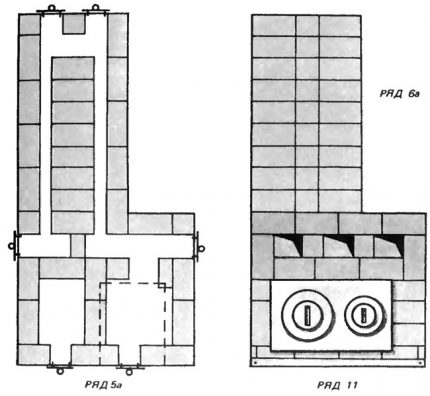

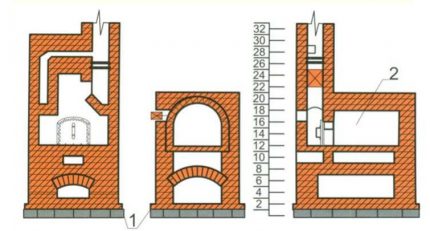

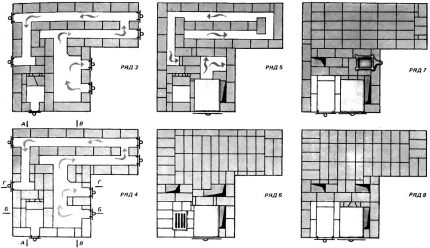

The laying of the furnace is carried out in the traditional way, using sand and clay mortar. The order looks like this:

If the furnace is heated by coal, refractory fireclay bricks are not necessary for the laying of the entire structure. Usually it is necessary in those places of the furnace where coal is put. In this case, the furnace is made in the form of a funnel and arranged 1 row below the door.

When heating with coal, 1 brick is placed across the door, and with wood heating it is simply removed so that the flame is closer to the stove.

You can take care of possible repairs in advance and cover the firebox with a brick installed on the edge. Heat transfer can be increased by increasing the wall thickness from 12 cm to 19 cm.

Option 2 - a classic stove with a stove bench

The dimensions of the structure vary, but usually for a village hut a stove was built with dimensions of 1.5 * 2 m. The hearth was raised relatively low - to a height of 0.45 m from the floor, and the bed was located almost under the ceiling - at a height of 1.8 m.

Under for convenience of service (cooking, baking bread) arranged at the height of the table, that is, about 0.7-0.8 m above the floor

The furnace is designed to heat a room of 30 m² and has the following heating properties:

- heat transfer at 1 furnace - 2100 kcal / h;

- heat transfer with 2 furnaces - 3000 kcal / h.

If the design of the furnace was planned massive, bulky, then the foundation was made appropriate. Large stones, fragments of bricks, and processed pine or oak logs were taken for its construction.

One of the main conditions for building a foundation is autonomy. It is always built separately from the foundation of the house, and all elements are insulated with asbestos gaskets or metal sheets to prevent fire.

Construction can be done independently or on order, by experienced craftsmen. In the second case, the simplest design will cost in the amount of 150 thousand rubles. Exclusive options with additional elements or exquisite cladding will come out more expensive.

You won’t be able to save money by completely doing the masonry yourself - you still have to consult with specialists and work under the supervision of an experienced stove maker. Any heating facility is always an object of danger, therefore it is better to get professional support and do everything according to the rules.

The basis of the furnace is a strong foundation, for which it is better to use high-quality material to avoid subsidence and cracking. Before installing the base, a double layer of insulating material is placed in a pre-prepared trench.

Traditionally, the foundation was laid lower than the level of soil freezing, and in no case was connected to the foundation of the house.

For construction, you will need:

- red brick - about 1.4-1.6 thousand units, depending on the size of the bed;

- sand - not less than 70 buckets;

- clay - not less than 60 buckets;

- samovar 130 * 130 mm;

- gate valve 300 * 150 mm;

- damper 430 * 340 mm.

Additional elements are possible if the design is planned to be modernized.

There are many orders of laying a stove with a stove bench, here is one of the simplest:

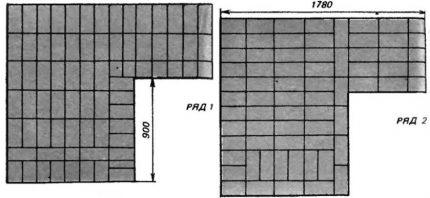

1 row - bricks are laid in a continuous layer using a solution for the foundation.

2,3,4 rows - they are arranged according to the type of well, and one should not forget about the additional space for furnace appliances - the under-fire. The suture dressing system is actively used.

5-6 rows - starting from this level, build a vault. For the erection of masonry, formwork is done, support heels for bricks are separately prepared.

7-8 rows - form a vault, which closes on the 8th row also using the technique of dressing the seams.

9-10 rows - spread in 1 brick.

11 row - final for the "cold stove." The well is covered with a slight slope.

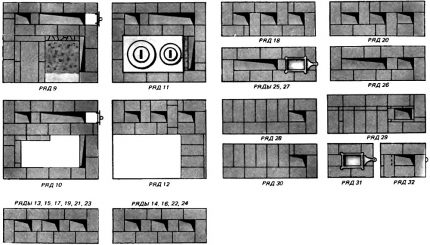

12 row - form the hearth flooring from a special brick - hearth. Seams are not sealed, but covered with sand, then the entire surface is ground.

13-16 rows - produce a masonry furnace - a large furnace department. The walls are built in ¾ brick, height - 190 mm. For the construction of locks, bricks are squeezed at an angle of 45 °. Apply dressing of the seams, without binding the material.

17 row - The mouth and back wall are completed. A frame is being erected for the construction of the arch of the cooking chamber. The heels are choking, the brick is placed on its side. After preparation, the vault of the cooking chamber is erected.

18 row - build a wall. The space between the side elements and the cooking chamber is filled with clay, sand, and broken brick backfill.

19 row - hemispherical, overlaps the opening above the sixth.

20 row - the walls of the structure are leveled, the hole above the pole is reduced. The overtube is laid out smooth, without steps - for this, the angles are chipped. Under the channel for the samovar arrange an overlap.

21 row - same as row 19.

22 row - the laying over the arch ends. The bars for mounting the samovar are constrained to ensure the free movement of gases inside the pipe. Spread the camera for soot.

23-32 rows - construction of an overtube. Mount the valve, finish the chimney (2 bricks 260 * 260 mm).

Then spread the channel. To install the damper, you need an angle of 25 * 25 mm with a thickness of 3 mm. It can be replaced with a strip or sheet. To make it convenient to use the valve, 1-2 handles are welded to it.

The damper is recommended to be made of a metal sheet - roofing steel. Its shape should correspond to the hole of the sixth shaft leading to the crucible.

The frame is pre-made and mounted in the masonry of the mouth, secured with a mortar or anchor method.It performs the function of formwork during the construction of the arch.

Option 3 - photo gallery of self-construction

For heating a large house, the best option is a stove with a stove, a stove bench, a cooking chamber and two fireboxes.

Ducts are located under a heating shield, which enhances heat transfer and is located on a stove with a stove. The thickness of the back wall is 28 cm, of which 12.5 mm is sand filling.

As a solution - a mixture of clay (local), which must first be soaked and filtered. Sand should also be sieved to eliminate debris and large inclusions. The main material for masonry is a red brick, which previously passes through a strict selection, and then is soaked in water. The process is long and tedious, but the result is excellent.

A brick cutting machine or a special machine with wet stone cutting may be required to cut bricks.

To reduce heat loss, a deflector is installed on the pipe. Gypsum plaster for finishing does not retain heat. The oven was dried for 10 days.

First steps:

The author did not provide the order of this furnace, but there is a photo showing the nuances of the masonry and the arrangement of the furnace elements. We offer phased photos with the recommendations of the wizard.

You can experiment with different segments of the furnace, change them as you wish. The main thing is not to change key details and masonry order.

Each stage of work requires a different amount of time - some elements are built quickly, others require drying of the solution. If the masonry has not been set, it is better to redo it immediately than to subsequently disassemble the entire furnace.

After finishing the masonry of the Russian stove with a stove bench, the last stage remains - the exterior design. Plaster is considered to be a traditional way of facing with a gypsum mixture, which is leveled and then dried or decorated with paintings, tiles, etc.

As you can see, some knowledge of the basics of furnace business and engineering skills can lead to a wonderful result - the construction of a stove with your own hands. By the way, the construction was erected by one person.

Conclusions and useful video on the topic

The order of construction of a structure with a stove bench and a flood:

Overview of a traditional technology kiln:

Overview of the Kuznetsov stove with a stove bench:

The presence of a stove bench at the Russian stove does not mean the complexity of its design, so you can start building a useful and even fashionable structure yourself.However, do not forget to carefully study the topic, delve into the nuances of masonry and enlist the support of a specialist - an experienced master stove-maker.

Want to talk about how they built a Russian stove in your country house or in the country? Do you know the technological subtleties that will be useful to site visitors? Please write comments in the block below, ask questions, publish photos on the topic of the article.

Russian stove with stove: masonry technology of the Russian stove with diagrams and detailed procedures

Russian stove with stove: masonry technology of the Russian stove with diagrams and detailed procedures  DIY masonry: a detailed guide + orders with diagrams and drawings

DIY masonry: a detailed guide + orders with diagrams and drawings  Brick stoves for giving on wood: the best orders and a step-by-step guide to the construction

Brick stoves for giving on wood: the best orders and a step-by-step guide to the construction  DIY miracle oven for a garage in a diesel fuel: step-by-step instructions for the construction

DIY miracle oven for a garage in a diesel fuel: step-by-step instructions for the construction  Do-it-yourself mini Russian stove: specifics and arrangements for the construction of a compact stove

Do-it-yourself mini Russian stove: specifics and arrangements for the construction of a compact stove  How to build a Russian stove: do-it-yourself masonry, the best orders and schemes

How to build a Russian stove: do-it-yourself masonry, the best orders and schemes  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements