Types of heating a country house: a comparison of heating systems by type of fuel

All existing types of heating for a country house can be classified both by the fuel used, and by the heat transfer method. There is no single principle by which they are chosen.

The effectiveness of home heating depends on the climate in the region, the area of the house, personal preferences, and other factors. In this article, we will consider heating with wood, gas, and electricity. We highlight the main advantages of each of the options. We will also talk about the types of heating equipment needed to implement each of the heating systems.

The material presented is supplemented by visual diagrams and photo illustrations. To fully understand the essence of the issue, we have selected a thematic video on the organization of autonomous heating.

The content of the article:

Wood burning stove in home heating

The principle of operation of the wood-burning stove is simple - the fuel, when burned, emits heat. The walls heat up and give off heat to the room air. Furnace heating, like any other, has its advantages and disadvantages.

Significant advantages of a wood stove include:

- a special cozy atmosphere, which no other type of heating can create;

- relatively small financial investments;

- the opportunity to make it an original element of the interior;

- environmental friendliness, fuel availability.

At the same time, the furnace selects a useful area and has a small efficiency. The larger the house, the larger this heat source will be. Before heating the air in the room, you need to load firewood into the furnace, then periodically repeat this procedure.

It is necessary to wait until the fuel flares up well and warms up the structure. Only after this ritual will the long-awaited warmth spill over the room.

Types of wood-burning stoves

Traditional wood stoves are laid out of brick. The presence of serpentine chimneys in them allows you to well heat the air in the room and maintain heat for a long time. It can be used as a fireplace and cook food on its surface.

There are 3 categories of brick kilns:

- With a stove or heating. They can heat several rooms at once, and they also prepare food.

- Russian. As a rule, this is a massive structure with an appendage in the form of a couch. On such an oven not only prepare various dishes, but also dried herbs, fruits, mushrooms.

- Fireplace stove. In addition to the heating function, this building is designed to decorate the interior, bring it notes of romance, a special home comfort.

They make wood stoves and cast iron. They are compact, so they fit into any corner of the house. Combustion products are usually removed through the chimney from the corrugation. Such stoves allow you to quickly warm the room.

Heat-resistant steel stoves also quickly warm the air in the house. But the comfortable temperature is not kept for long. Sometimes stainless steel is used to make metal wood stoves. It keeps heat longer, but the seams do not withstand fast heating and are often damaged.

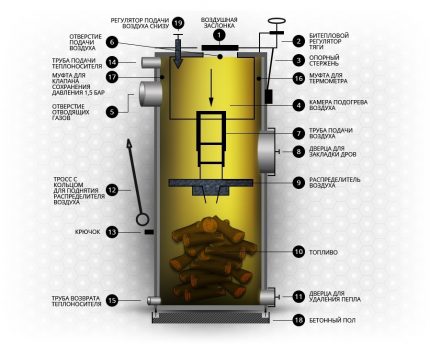

It is permissible to heat a country house with firewood without the mandatory construction of a stove in its direct sense. Pyrolysis boilers are often installed, such as Butakov’s stove or Buleryan. The last option is to make it yourself. Although firewood is also fuel here, the principle of operation is different - similar to a gas generator.

Heat enters the room during afterburning. For this, firewood is laid in large quantities. Establish a regime in which only part of the wood burns, and the other smolders. The duration of the process depends on the volume of the room and the capacity of the heating equipment. The efficiency of pyrolysis furnaces is quite high - from 75 to 85%.

Strupov and Bubafony ovens operating without load up to 48 hours also belong to gas-generating furnaces. Characteristic of these structures is the presence of a tall column. Almost to the edge, firewood is laid in it and set on fire, like a fire, from above.

Instead of firewood, you can lay in the stove sawdustpeat or other type of solid fuel. The denser it is laid, the longer the process will continue

The combustion process is supported by the air supplied through the telescopic tube at the top of the furnace. The fuel burns down, and the combustion zone gradually drops along with the pipe supplying air to the level of the grate.

As an alternative to heating a country house with wood, there are other options for solid fuels such as pellets. Compared to firewood, they burn longer. Pellet boilersin which they are burned are safer, because protected against overheating, equipped with flame control.

The boiler is able to work at least 3 hours on one load. If the system is supplemented with a heat accumulator, heat will accumulate and then enter the room.

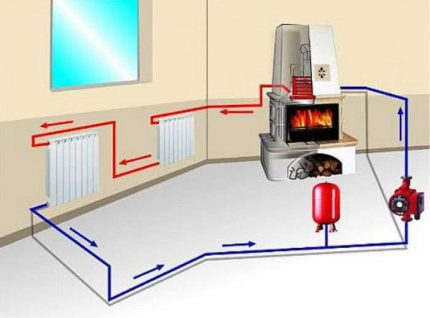

For a small country house, one stove is enough to warm it and cook food. If the house is large, you need a carefully thought-out heating system, when the whole building is heated from one furnace. To this end, arrange steam or water circuits.

In a one-story house, the circuit is connected to an ordinary brick stove or to a purchased cast-iron. If the mansion has 2-3 floors, you need to purchase a cast iron stove-boiler.

Improving stove heating performance

Improves traditional stove heating water circuit by significantly increasing the heating area and rational distribution of heat.The heating process includes both the walls of the furnace and the smoke channels, as well as the coolant itself. Heat enters the radiators during the burning of firewood, but the heat in them persists for some more time.

The inclusion of a conventional wood-burning stove in a water heating system implies the presence of a heat exchanger. Its purpose is the heating of water and ensuring the circulation of the coolant.

A heat exchanger is made of sheet steel or metal pipes. Its dimensions are individual. The main thing, during installation, leave a gap of 10 - 15 mm between the register and the walls of the furnace, taking into account the expansion.

If there is a second floor in the house, the system is included electric pump. He intensively drives the coolant, accelerating the heating process during the kindling of the furnace. You can also include a tank in your system to create a supply of hot water.

Electricity heating at home

Heating a house with electricity is based on two principles. The first is the heating of each room individually using appliances connected directly to the electrical network. The second is indirect heating with the injection of a heat carrier heating the radiators in each room.

An example of a direct heating method is the use of oil cooler. With its ribbed shape, it resembles a classic cast-iron battery. The device itself is heated to a high temperature, and sends heat to the environment in the form of heat rays.

The surface of the radiator cools down slowly due to the fact that the coolant has good thermal inertness. Most often use such devices as additional ones. It is economically unprofitable to include oil coolers in the main system.

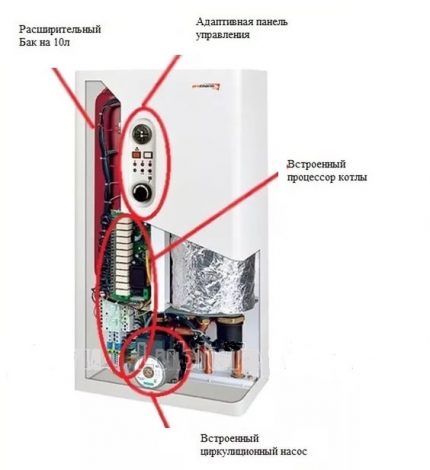

Option # 1 - using an electric boiler

The water system connected to the electric boiler has its own characteristics. To spend energy rationally, the circulation of the coolant in the system should only be forced. Natural circulation will increase energy consumption.

In addition, this will entail uneven heating of the room, a decrease in the heat transfer rate, and power loss.

When using an electric boiler, an expansion tank equipped with a control unit and safety elements must be included in the system. An open system device does not make sense, because will result in high operating costs.

To be able to heat your country house with electricity, you must have a power line of sufficient power. Therefore, before buying a boiler, you need to perform simple calculations.

It is necessary to start from the fact that, according to experts, 1 kWh is enough to heat a room of 10 m². If you have to heat 200 m², you will need 20 kW. Since in addition to the boiler, the house also has other electrical equipment, about 5 kW is added to the calculated value.

Type No. 1 - electric boilers with heating elements

In electric boilers, heating elements, electrodes, magnetic induction are used as a working element. The first type is the most common. Water or other heat carrier is heated inside the boiler from the walls of the heating elements enclosed in a moisture-proof casing, then it goes into the heating system.

The efficiency of such a boiler is not very high - the heat transfer process is accompanied by large losses. A boiler equipped with multi-stage connection and electronic control is considered more efficient. When the set temperature is reached, such a boiler is switched off.

The main disadvantage of an electric boiler with heating elements is the formation of plaque on the spiral heating elements.Because of this, increased energy consumption amid a decrease in efficiency.

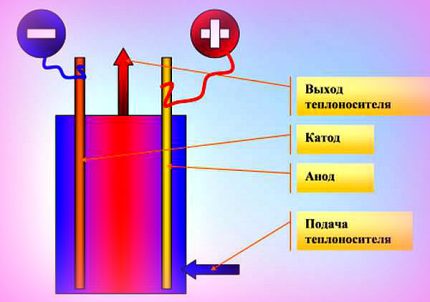

Type No. 2 - electrode assemblies

The main feature of these boilers is that they do not have an element heating the coolant. Heating occurs when electrical impulses transmitted by a special electrode pass through water.

As a result of this effect, water molecules decay into ions that carry a positive and negative charge. Since this uses alternating current with a frequency of 50 Hz per second, the polarity of the electrodes in the aqueous medium changes at the same frequency.

Under such conditions, ions begin to oscillate and change direction. All this happens with a large resistance of the aquatic environment to this process. As a result, thermal energy arises, which the heat carrier transfers to heating radiators. At the same time, hard coating does not have time to settle on the electrodes, which is a big plus in favor of boilers of this type.

There are single and three phase boiler models. Their difference is only in the design of the electrodes and dimensions. The design includes a cylindrical all-metal casing coated with polyamide. In the cylinder there are nozzles through which the coolant enters and exits.

The efficiency of ion boilers is high - from 95 to 98%. They have small dimensions and they heat up very quickly, but also cool at the same speed. The boilers do not have a “dry run”, so if there is no water in the system, they simply will not start. They are not affected by voltage fluctuations, when it falls, the power simply decreases, but the unit does not completely turn off.

The minuses of this type of boilers include their increased demands on the coolant. Water must have good conductivity, otherwise the power of the equipment begins to fall.

Such a boiler will not be able to operate on battery power, as only a variable power supply is needed. During its operation, it is necessary to exclude the ingress of air into the boiler, as this triggers an enhanced corrosion process.

Single-phase units have a power of 2 - 6 kW, three-phase - 9 - 50 kW. For use in country houses, the former are suitable; the latter are used to heat large industrial buildings. The average diameter of the boiler is 32 cm, the maximum length is 0.6 m. The lower the temperature of the water inside the boiler, the less electricity it consumes.

Electrode boilers, depending on the principle of distribution of the coolant, are open and closed. In the first case, natural circulation is carried out, and in the second, an expansion tank and a pump are included in the system.

Most models have automatic control, a start-up unit and protection against unstable operation of the mains. Expensive models are complemented by a controller that maintains optimal temperature and remote control.

When installing the electrode boiler, it is necessary to carry out reliable grounding of the power network at home. The boiler heat exchanger must be cleaned once every 12 months. Also, control of the chemical composition of water and its correction if necessary.

Type No. 3 - induction equipment

The operation of the induction boiler is based on the principle of electromagnetic induction. The electromagnetic energy generated by the coil is transformed into heat. The core is heated by the electromagnetic field of the coil, and it gives off the received heat to the fluid passing inside it.

The boiler is used in both open and closed systems, in which the coolant is circulated by force.

Boilers of this type are massive. In their case there is a primary coil that is not in contact with the coolant. The secondary winding is the internal pipe system with fluid flowing through them. Energy in the process of very fast heating is not lost, therefore, according to manufacturers, the efficiency is close to 100%.

As a result of self-induction, the boiler additionally produces reactive power of a significant magnitude. This increases the efficiency of the equipment. Any coolant can be pumped into the system - both water and antifreeze, oil, glycerin. The cost of boilers of this type is quite large, but if desired, you can make induction boiler do it yourself.

The heating system with an induction boiler, in addition to the heater itself, includes:

- circulation pump;

- membrane tank;

- heating radiators, and sometimes underfloor heating;

- security group;

- remote control.

Mount the boiler in an upright position. In this case, the distance to the nearest objects is at least 0.3 m on the sides and 0.8 m from the bottom and top. They start it only when the system is full and checks it for airing. It is also necessary to ground both the boiler itself and the components of the system: controller, pump and other elements.

Option # 2 - heating with electric convectors

Visually, a convector is the same battery located under a window or on a wall. But inside are the heating elements. The design provides for the penetration of cold air from below. Inside, it heats up and exits through the upper grill.

The user sets the temperature mode. Thermostats built into the convector control the temperature and turn off the appliance when it reaches the set value. The advantage of heating with convectors is the absence of the system itself with its complex wiring and "bonuses" in the form of freezing or leaking.

Since these heating units do not have open elements, and the outer panel does not heat up much, they are completely safe. They work silently, and the design allows them to be used without compromising the interior. They produce mobile and stationary convectors, which allows you to create comfortable zones with their help.

We gave a rating of the best manufacturers of electric convectors for home heating and selection recommendations in this article.

Option # 3 - heating the house with underfloor heating

You can heat a private house from the mains with the help of underfloor heating.

They are produced in several versions:

- Single or twin cable. They are usually laid in a screed, which then accumulates heat and transfers it to the surrounding atmosphere.

- In the form of heating mats. In fact, this is the same cable, but located on a fiberglass mesh. A screed device is not a requirement for their installation.

The design of the warm floor provides for the presence of temperature sensors. The heating mode is maintained automatically after pre-setting the temperature. The room warms up evenly.

Installation information for cable and film versions of the underfloor heating is described in detail in the next article.

Option # 4 - infrared heating

A comfortable microclimate is created by long-range waves transmitted by an infrared heater. He first heats everything that is in the room, and only then excess of this heat gets into the air. Heat is deployed at the floor, and not at the top, as when heating by a convector. This mode is most favorable for all the inhabitants of the house, including plants.

There are 3 types of IR heaters:

- Ceiling

- floor;

- wall mounted.

The former can become an element of a false ceiling, and if you place the IR above the window, it will cut off cold air. The direction of radiation is regulated using special suspensions.

Floor models are mobile. They can be moved to any desired place, taken with you to nature. Wall mounted IRs are involved in creating the interior. They can be disguised as a panel, a picture, a wall lamp.

The most convenient PLENs or film electric heaters in operation. They are strips of heat-resistant transparent film with a maximum thickness of 0.4 mm in different sizes. The emitters are located between the layers of plastic and are interconnected by means of conductive busbars made of copper.

The film is sometimes used as a warm floor without screed. It itself warms up to an average of 50⁰, so it can not burn or cause a fire. The disadvantage of an infrared heater is its constant glow.

Gas for heating a house

This type of heating is leading both in popularity and in cost. The main gas is especially advantageous in this regard, but it is not always present in the locations of suburban settlements. If we consider such a case, then a good way out for gas heating of a country house is the use of gas holders. This option is not the cheapest, but still cheaper than electricity.

To install the heating system, you need a project, after the approval of which a boiler is selected.

In this case, several factors are taken into account:

- Appointment. The boiler can be used purely for heating and then a single-circuit option is suitable. When it is necessary to provide a hot water supply, a double-circuit boiler is chosen.

- Installation method. For a house with an area not exceeding 200 m², wall-mounted design is suitable. For larger buildings, you need a floor boiler.

- Type of heat exchanger. It is made of steel, cast iron, copper. In wall-mounted boilers, copper is most often used, in floor-standing boilers - cast iron, steel. The latter are more durable.

- Smoke exhaust. As a rule, it leaves through a chimney that creates natural draft.

If the heating system is connected to cylinders filled with propane-butane, you can use the same main boilers after a small upgrade. Here you just need to change the burner, often available in the kit.

To select the maximum gas from the cylinder, it is necessary to purchase a boiler with a lower gas pressure indicator.

The best way is to connect several cylinders. Thus, it is possible to change gas supply sources less frequently. The pressure in such a pipeline is always stable and this is a great advantage of autonomous gas supply.

Are you most attracted to the option of using gas as fuel? In this case, we recommend that you read the detailed information on autonomous gasification private home.

Conclusions and useful video on the topic

An economical option for autonomous heating:

Having enough information about the different methods of heating a country house, you can choose the most suitable option. In addition, in one building a combination of different types is permissible. A good solution is a multi-fuel boiler, which allows the most efficient use of available fuels.

Choosing the right heating option based on the most affordable type of fuel in your area? Maybe you still have questions after reading our article? Or do you want to supplement the material with useful information? Ask questions, write your advice and comments - your opinion is important to us.

Gas consumption for heating a house 200 m²: determination of costs when using main and bottled fuel

Gas consumption for heating a house 200 m²: determination of costs when using main and bottled fuel  Designing heating systems for country cottages: how not to make mistakes

Designing heating systems for country cottages: how not to make mistakes  Calculation of the heating system of a private house: rules and examples of calculation

Calculation of the heating system of a private house: rules and examples of calculation  Typical schemes and rules for designing a heating system for a one-story private house

Typical schemes and rules for designing a heating system for a one-story private house  How to arrange the heating of a private house with your own hands: schemes for organizing an autonomous heating system

How to arrange the heating of a private house with your own hands: schemes for organizing an autonomous heating system  Which is cheaper: gas or electricity? Arguments for choosing a practical option for a private house

Which is cheaper: gas or electricity? Arguments for choosing a practical option for a private house  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Informative enough. I didn’t know about the existence of electric heating, I think this way of heating will instantly strip off half your monthly salary if you are a simple hard worker. But if out of pocket a banknote, then you can try. I think that after all, heating with wood is the most effective and not particularly expensive method. I’m burning a wood stove myself, there are no problems.

Hello. And let's calculate approximately. Heating a house of 43 squares per 2 kW and a tariff of 4 rubles costs an electric boiler of about 6 thousand rubles a month - 30%, since we enter the preferential category of citizens (I don’t think at once, since not everyone is included). At the same time, the installation of heating with a pipe scan (suitable in the future for connecting gas) and natural circulation cost a total of 15 thousand rubles.

Connecting to gas is 250 thousand, for some people the amount is completely different, it depends on the region, gas workers estimate and so on (-50% regionally for the benefit, but again, we don’t think so). The difference with electro - 235 thousand rubles (not including equipment).

I don’t remember gas tariffs in that area, but the approximate monthly payment is 2 thousand rubles for heating. 6-2 = 4 thousand difference. It turns out without a gas connection, we could heat the house for 4 years in the difference in the cost of connection. Apart from maintenance (if we are only talking about the boiler, there are few, 400 rubles a year). But this does not mean that we must strive for electrics. For 4 years, gas will rise in price so much that an electric boiler will cost more. It was just the need for such a connection.

Now firewood. A chopped firewood machine costs 10 thousand rubles (in our region). There are enough cars for the heating season - 4-5 months. These are costs of 2 thousand rubles a month, approximately. Build a stove - 150 thousand rubles (regional prices are different).

It turns out that stove heating is the most advantageous if the connection does not exceed millions. But for the time being, until the connection to the gas pays off (and for someone it has no more than 100 thousand + equipment, it’s cheaper). Yes, and the stove must be constantly monitored, cleaned. So everything is individual here.

Cognitive enough, but I think half of these methods are very expensive. Electricity heating is too expensive a pleasure. I tried to heat my private home in many ways. I even used the stove for working off, it was possible to get out of the way, the constant stink from this junk was too unbearable a side effect of my attempt to save some money. I prefer to heat either with wood or gas. But perhaps the other methods listed above are also very relevant, albeit expensive.

During the construction of a country house, it was finally possible to realize a long-held dream - to acquire a fireplace. This is not only a decoration option, but also a cost-effective solution. The house is heated in a couple of minutes, and does not require much effort. Fortunately, firewood is everywhere in our area. It remains to make only physical effort. A considerable amount goes beyond the housing and communal services and in the city; there was still not enough money to spend.

Hello. In a conventional fireplace, the chimney is always vertical, with the possibility of slight deviations and closing the damper only after burning wood. The walls of the fireplace are not a stove, they do not heat up, that is, the heat goes exclusively directed from direct fire.My friend, about 5 years old, tried to heat a house in 43 squares with a fireplace only. Despite the fact that the house is perfectly insulated and you can sleep on the floors in winter, not the slightest draft. The efficiency of the fireplace (new) is not more than 30%, and while coal is burned in, if there is no screen, moreover, the heat goes into the pipe. It is impossible to melt at full power - the crucible will burst. It’s not worth it to bother like that. Unless barbecue can be fried year round :))

I completely agree with both Daniels (it coincided) that when heating the house with electricity, there will only be worries that pay crazy money for electricity. Since childhood, I grew up in an area where the only type of heating was firewood, in every house there was a stove. And although the forests around were sea and firewood were relatively inexpensive, but my mother is dear - how troublesome it is every day to burn the stove.

To relatives from the city who came to visit, exotic, pleasure and entertainment, they willingly helped, even with pleasure did it, but for us it is a routine care and trouble. But the living heat from the stove is something, I agree, you can’t argue here. Now I live in the house where the gas boiler is, turned on, set the temperature and grief do not know. And cheaper electric comes out. I believe that gas heating is the best option.

Luke, gas, of course, is an ideal option, but not everywhere it is. For example, holiday villages - they are not gasified in principle, and people live there in winter.