Cast-iron radiators: characteristics of batteries, their advantages and disadvantages

Modern technological progress practically did not affect cast-iron heating radiators for all 167 years of their existence. Consumers are still opting for these devices due to the mass of positive product characteristics.

And even some of the shortcomings do not prevent the installation of cast iron batteries during the installation of heating systems. Next, we will talk in detail about all the advantages and disadvantages of cast-iron radiators, as well as about the characteristics that you need to pay attention to before buying.

The content of the article:

Advantages of Cast Iron Radiators

The use of cast iron batteries has many advantages that make these devices to choose for the installation of heating systems. Some positive qualities are not always voiced by sellers in stores, although you should also be aware of them and consider them when buying.

Among the advantages of cast iron batteries, resistance to aggressive parameters of the coolant should be noted. It is due to the material of their manufacture - cast iron does not corrode for a long time even at high temperatures.

Various chemical additives in the coolant, as well as iron oxides formed in the main pipes, also do not lead to the destruction of cast iron.

In addition to resistance to corrosion processes, such batteries have the following advantages:

- the possibility of repair in the event of clogging and leaking;

- inertia of heat transfer;

- reasonable cost;

- the ability to operate at high temperature and high pressure;

- high percentage of heat transfer due to radiation;

- ease of installation;

- long term of work.

Blockages and battery leaks can occur due to the coolant. Thus, the circulation in raw iron radiators of untreated water with a high content of calcium and magnesium salts leads over time to a narrowing of the internal cavities. This affects the heating rate of the sections and the efficiency of heat transfer.

In addition, due to the high temperature of the water in the batteries of the old model, intersectional gaskets gradually wear out and a leak may appear.

The problems associated with the long-term operation of cast-iron radiators can be quickly eliminated in the summer. The internal cavities of the sections are easily cleaned of deposits with a special tool.

Due to the resistance of cast iron to machining, the quality of the radiators does not suffer. When reassembling sections, you can immediately replace worn gaskets.

The increased inertia of the heat transfer of cast-iron radiators is ensured by the weight of the structure and the large internal volume of the coolant.

As for the cost of one pig-iron section, it is in the same framework as the price of its aluminum or steel counterparts. Therefore, the cost of purchasing batteries from cast iron will be no more than radiators from other materials.

However, cast iron products are much better tolerated. water hammer, steadily resist short-term pressure increases up to 16 bar.

The possibility of operation at high temperature and high pressure is provided by a small coefficient of thermal expansion of cast iron. Among all the materials from which the radiators are made, he has the smallest.

Because of this, cast iron is most resistant to microcracks during prolonged use. The same property ensures stable tightness of threaded joints and gaskets at a pressure of 8-9 atmospheres.

And such an advantage as high heat transfer due to radiation allows you to place cast-iron radiators wall-mounted.To maximize the direction of thermal radiation deep into the room, it is recommended to mount special reflectors on the wall behind the battery.

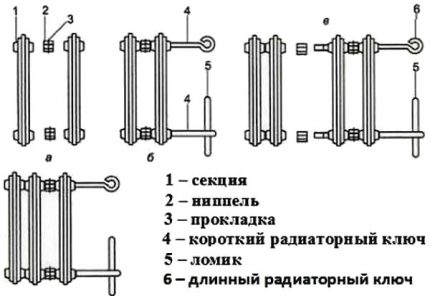

In addition, cast iron radiators are conveniently and simply mounted. The sections of cast-iron batteries are connected to the pipes and to each other by means of a threaded connection and paronite gaskets. A special key allows you to disconnect any sections without removing the extreme radiators.

And the long term of operation once again confirms the quality and reliability of this heating equipment - cast-iron radiators are guaranteed to last 50 years.

But they will work out such a period only with regular service, which consists in the periodic removal of internal deposits and the replacement of gaskets.

The listed advantages of cast-iron batteries make them indispensable in large rooms with an extensive heating network and high working pressure.

Disadvantages of Cast Iron Batteries

Despite the many advantages, cast-iron radiators are endowed with a number of disadvantages. This was facilitated by both structural features and the properties of cast iron itself. For example, cast-iron batteries have difficulty integrating automatic temperature control systems.

Due to the inertness of heat transfer, it is quite difficult to control the temperature set in the room. After all, after turning off the boiler, cast-iron radiators will give off their heat for another hour, warming the surrounding air.

There are also other disadvantages, including:

- a large volume of coolant;

- significant weight of one radiator;

- design uniformity.

The large amount of water in the battery has its drawbacks. Warming up the entire coolant requires more time and energy.

In addition, the load on the pump increases, which is forced to pump a significant amount of water in one warm-up cycle.

The large weight of the devices is also a drawback that concerns installers and after-sales services more than residents. However, with self-assembly of the heating system, you can not do without an assistant when attaching a cast-iron battery. The weight of one of its sections is about 7 kg.

Such a minus as designer uniformity is due to the technological features of cast iron casting - they do not allow to create elegant details from this material. Here the batteries look the same.

To diversify the lineup, manufacturing companies produce cast-iron radiators with a beautiful pattern on the surface, but their cost is 10-20 times higher than the price of simple models.

However, if there is no money for expensive exclusive models, you can buy ordinary radiators, and then disguise them with screen for batteries.

Another disadvantage is the vulnerability of equipment to water hammer. The fact is that cast iron is a durable, but rather fragile material. According to GOST 8690-94, radiators must withstand short-term pressure of 1.5 MPa.

But sometimes the pressure can exceed this value. This occurs when the pump starts abruptly and there are no compensators. As a result, cast iron batteries may crack or burst.

In many cases, the advantages of cast iron radiators far outweigh their disadvantages. It is this fact that helps these batteries maintain a good position in the heating market.

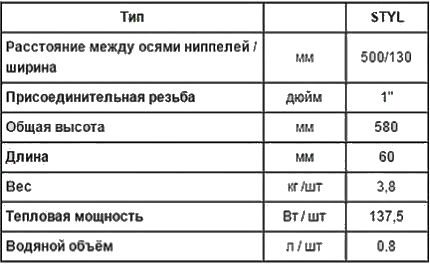

Technical characteristics of radiators

Competition in the radiator market is extremely high, so not many manufacturers produce and sell pig-iron batteries in the domestic market.

Before buying, you should familiarize yourself with the technical specifications of the most common cast-iron radiators. This will allow you to choose exactly the products that are most suitable for the planned or existing heating system.

Cast Iron Battery Manufacturers

The market feature of cast iron batteries is a large share of transport costs in their final cost. Therefore, models of manufacturers from far abroad are not represented on the domestic market.

The main factories that offer cast iron batteries are:

- Adarad (Turkey);

- Cheboksary Aggregate Plant (Russia);

- Viadrus (Czech Republic);

- Demrad (Turkey);

- Minsk Heating Equipment Plant (Belarus);

- KIRAN (Ukraine);

- Konner (China).

There are many European manufacturers of cast iron radiators, but their products are not competitive. It has a high price, and the quality is comparable to domestic samples.

Devices for organizing heating in a vintage style are offered by the St. Petersburg manufacturer:

Overall dimensions of radiators

The sizes of radiators in the post-Soviet space were standardized. The distance between the center of the axes of the supply and exhaust pipes was 300 or 500 mm.

The depth of the sections and their width were not regulated and differed from different manufacturers. Most modern radiators are also adapted to these standards.

The most common cast iron battery model is the MS-140.It is she who stands in most Khrushchev and nine-story buildings built in the 60-80s of the last century.

The dimensions of its section are: center distance - 500 mm, full height - 588 mm, width - 93 mm, depth - 140 mm.

The main goal of creating cast-iron radiators with various sizes is to enable the buyer to choose the model that fits into the interior as much as possible. Batteries with a total height of up to 400 mm, for example, fit perfectly into rooms with low sills.

Appearance and arrangement of equipment

Almost all cast iron radiators are typesetting. They are made of gray cast iron and consist of detachable sections that are connected using nipple sleeves. This design allows you to form a solid battery of the required length and power. Between the sections are placed paronite gaskets.

In a horizontal plane between sections, water moves in only one direction. Vertically, fluid flow occurs through one or more channels. With their number increases the area of radiators and their power.

The disadvantage of multichannel sections is their high cost and increased hydrodynamic resistance.

The classic look of the "accordion" in radiators is a thing of the past. Due to the predominantly radiative method of heat transfer, manufacturers seek to increase the battery facade area, which translates into a flatter appearance. An example is the Konner Modern500 model.

A number of imported models have decorative patterns on the surface, but the cost of such batteries is incomparably high.

The weight of the cast-iron sections is quite large. The need to maintain the strength of the walls and the maximum area of the heating surface does not allow engineers to significantly reduce the mass / power ratio. The weight of the section of the standard model MS-140 is 7.1 kg.

A large mass of cast iron radiators requires good fasteners. Batteries usually do not have special structural elements for fixing to the wall. They simply hang on special brackets that stick in between the sections. There are special feet for installing batteries on the floor.

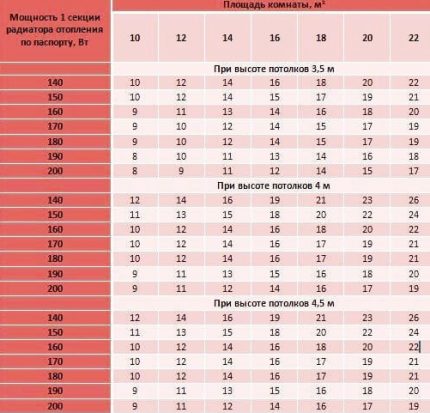

Thermal power of devices

The power of radiator equipment is characterized by the ability to give off thermal energy at the maximum working temperature of the coolant. This indicator in cast-iron radiators mainly depends on their surface area.

Depending on the model, the power can range from 80 to 200 watts per section. These are passport values, which in real conditions can be much lower.

There is a classic formula for calculating the required power of a cast-iron heating battery, based on the volume of the room: for every 25-30 m3 radiators with a total capacity of 1 kW should be installed. In the presence of 2-3 external walls, this indicator should be adjusted in the direction of increasing power. For more information on how to calculate the required number of batteries for heating, read this stuff.

To enhance heat transfer due to convection, some models of cast-iron radiators are equipped with ribs between the columns. This design can increase the power section by 20-40%. Keep in mind the need for regular cleaning of such jumpers from dust.

Other equipment specifications

When choosing radiators, you should pay attention to their other characteristics:

- maximum working pressure;

- coolant volume in the section;

- maximum heat carrier temperature.

All of the above indicators for cast iron batteries are higher than for aluminum and bimetal analogues. But the characteristics may differ for different models, which should be taken into account when selecting the components of a new heating system.

Maximum parameters are especially important when replacing batteries connected to a central heating system. During its autumn pressure testing, excessive pressure is applied to the pipes, which can break inappropriate radiators.

This can result in flooding of both your own and lower apartment, therefore, it is necessary to pay special attention to the operating values of pressure and temperature of the coolant.

Conclusions and useful video on the topic

The presented videos on cast-iron radiators will help in choosing a specific model and further explain their technical characteristics.

Overview of the cast iron radiator:

Comparison of the thermal characteristics of radiators from various materials:

The choice heating radiators, including cast iron, should be made with the obligatory consideration of their technical characteristics. This will avoid breaking the heating circuit at maximum loads and provide sufficient heat for the heated rooms.

Please write comments, share your experience using cast iron radiators, ask questions in the box below. We are always ready to clarify incomprehensible points.

Electric heating radiators: the main types, advantages and disadvantages of batteries

Electric heating radiators: the main types, advantages and disadvantages of batteries  Steel heating radiators: varieties, characteristics and advantages of batteries

Steel heating radiators: varieties, characteristics and advantages of batteries  Vertical heating radiators: types + advantages and disadvantages + brand overview

Vertical heating radiators: types + advantages and disadvantages + brand overview  How to choose bimetal heating radiators: technical specifications + analysis of all the pros and cons

How to choose bimetal heating radiators: technical specifications + analysis of all the pros and cons  What paint to paint heating radiators: a comparative overview of the types of paint for batteries + the best manufacturers

What paint to paint heating radiators: a comparative overview of the types of paint for batteries + the best manufacturers  How to choose heating radiators for an apartment and a private house: selection criteria and advice to customers

How to choose heating radiators for an apartment and a private house: selection criteria and advice to customers  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

In our house, too, cast-iron heating radiators. My wife has been dreaming for a long time and asks me to replace them with registers or bimetal convectors. After all, cast iron batteries are very difficult to clean from dust and repaint. The house is large, heating appliances up to a dozen, to wash everything takes a lot of time. But it turns out that they have a lot of advantages and a very long life. So now I won’t go for any persuasion; my wife will have to put up with such radiators for a long time. At the same time, we will save on unnecessary reconstruction of the heating system.

And I'm just one of those wives who do not like to wash cast-iron radiators.Wash all the dust inside is unrealistic, besides it takes a lot of time. I also dreamed of replacing these batteries with something else. True, the husband did not want to and argued for, such as described above. And recently I bought two brushes, especially for painting inside such radiators. The brush has a long handle and it is curved at the end at an angle (approximately 130 *) with a long pile. Such a simple device at first glance, but it is very convenient to wash and paint these hard-to-reach places of these cast-iron monsters. Buy the same ones and it will be much easier for your wife to take care of radiators.

Hello. Any wife does not like to wash radiators 🙂 I will share my experience. I fix a wet rag on the back of the radiator. I blow off the batteries with a hairdryer and all the accumulated dust settles on a rag. I remove the rag and also brush the knees from the inside. Outside, melamine sponges help a lot.

I would not say that cast iron is of the same type. It’s just that our market was flooded with aluminum radiators, which by the way are no less the same type, and cast iron is a thing of the past. Many people want to buy a beautiful cast-iron battery with drawings and engravings, but when they compare the price with ordinary aluminum, they immediately change their mind. I myself am the same. Now cast iron is the lot of rich guys. As for his technical qualities, he certainly keeps the heat better, but in the current realities, this is completely unnecessary. Aluminum perfectly copes with its task no worse than cast iron, plus it does not need to be painted from year to year and cleaned.