Wiring diagrams for radiators: an overview of the best ways

Are you planning to change heating appliances in your own home? For this, knowledge of the types of battery wiring, how to connect and place them is useful. Agree, because the effectiveness of the selected connection diagram for connecting radiators in a particular house or room directly depends on it.

Proper battery connection is a very important task, because it can provide a comfortable temperature in all rooms at any time of the year. It is good when the fuel consumption is minimal, and the house is warm in the coldest days.

We will help you figure out what is required for the most efficient operation of radiators. In the article you will find a lot of useful information about how to connect batteries and their implementation without the involvement of specialists. Schemes are given, as well as video materials that will help to clearly understand the essence of the issue.

The content of the article:

What is needed for efficient battery operation?

An efficient heating system can save money on fuel. Therefore, in its design, it is necessary to make informed decisions. Indeed, sometimes the advice of a neighbor in the country or a friend who recommends such a system as his does not work at all.

It happens that there is no time to deal with these issues yourself. In this case, it is better to turn to professionals who have been working in this field for more than 5 years and have grateful feedback.

Having decided to independently install new batteries or replacing heating radiators, it must be borne in mind that the following indicators directly affect their effectiveness:

- size and thermal power of heating devices;

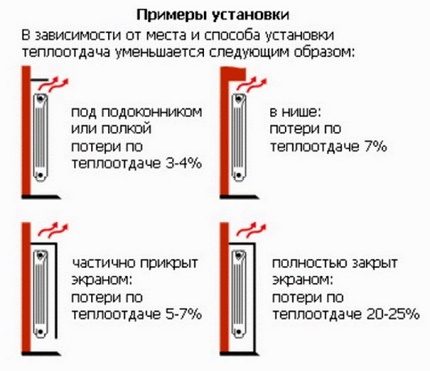

- their location in the room;

- connection method.

The choice of heating appliances strikes the imagination of an inexperienced consumer. Among the proposals are wall-mounted batteries made of various materials, floor and baseboard convectors. All of them have a different shape, size, heat transfer level, type of connection. These characteristics must be taken into account when installing heating appliances in the system.

For each room, the number of radiators and their size will be different. It all depends on the area of the room, the level of insulation of the external walls of the building, the connection diagram, the thermal power indicated by the manufacturer in the product passport.

Battery locations - under the window, between windows located at a fairly long distance from each other, along a blank wall or in the corner of the room, in the hallway, pantry, bathroom, in the entrances of apartment buildings.

It is recommended to install a heat-reflecting screen between the wall and the heater. You can make it yourself, using one of the materials that reflect heat - penofol, isospan or another foil-like analog.

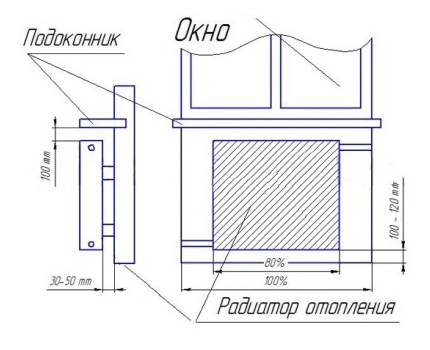

You should also follow these basic rules for installing the battery under the window:

- all radiators in one room are located on one level;

- ribs of convectors in vertical position;

- the center of the heating equipment coincides with the center of the window or is 2 cm to the right (left);

- battery length not less than 75% of the window itself;

- the distance to the windowsill is not less than 5 cm, to the floor - not less than 6 cm. The optimal distance is 10-12 cm.

The level of heat transfer of devices and heat loss depends on the correct connection of radiators to the heating system in the house.

It happens that the landlord is guided by the advice of a friend, but the result is not at all what was expected. Everything is done as he did, but only the batteries do not want to warm.

So, the selected connection scheme did not fit specifically for this house, the area of the premises, the heat output of the heating devices were not taken into account, or annoying errors were made during installation.

Features of connection schemes

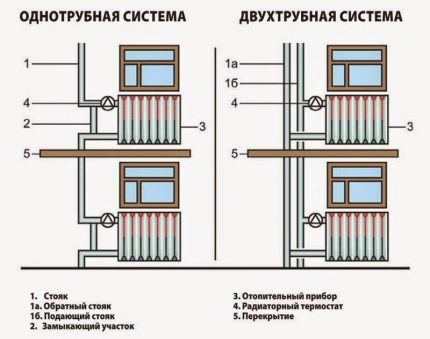

There is a fundamental difference in the connection diagrams of heating devices, depending on pipe routing. It is single-tube and two-pipe. Each of these types is divided into a system with horizontal highways or vertical risers.

Depending on the type of wiring chosen, the battery connection option will differ. For single-pipe and two-pipe systems, it is possible to use lateral, lower, diagonal connection of heating devices.

The main task is to choose the best option that can satisfy the needs of a particular home in the required amount of heat.

These two types of wiring belong to the tee pipe connection system. In addition to it, collector circuits are distinguished. They are also called beam wiring. Its main feature is the laying of the pipeline separately for each heating device.

The disadvantage is that pipes pass directly through the premises of the entire floor and a lot of them will be required. This will affect the cost of the system. A significant plus - they are most often mounted on the floor, without affecting the design of the room.

This option, which significantly increases the flow rate of pipes, has been actively used recently in the design of heating schemes. The collector connection of heating devices is used in the "warm floor" system. Depending on the type of project, it can serve as an additional source of heating or the main one.

Single pipe system features

The type of heating, in which all the batteries are connected in one pipe, is called a single pipe. The heated and cooled coolant moves along one pipe, entering one device at a time. It is important for her to choose the right diameter, otherwise the pipe will not cope with its responsibilities and there will be no effect from such heating.

At single pipe system There are disadvantages and advantages. Many beginning masters believe that choosing this type of wiring can save a lot of money on installing heating appliances and pipes. But this is a fallacy. Indeed, for the high-quality operation of the system, it will be necessary to connect everything correctly, taking into account a lot of nuances. Otherwise, the rooms will be cold.

The single pipe system is really capable of saving money when using a vertical riser. This is true for 5-story buildings, where it is beneficial to mount one pipe to reduce material consumption.

With this option, the heated water flows up the main riser, distributed further along the remaining risers. In turn, the coolant enters the heating devices of each floor, starting from the top.

The lower the water drops, following the riser, the lower its temperature. This problem is solved by increasing the area of radiators on the lower floors. Radiators of a single-pipe system are preferably equipped with bypasses.

This will make it possible to dismantle the heater without problems, for example, for repair, without disrupting the operability of the entire system.

In a single-pipe horizontal wiring system, you can use the associated or dead-end movement of the coolant. It works well for pipelines with a total length of up to 30 m. The optimal number of connected heating devices in this case is 4-5 pcs.

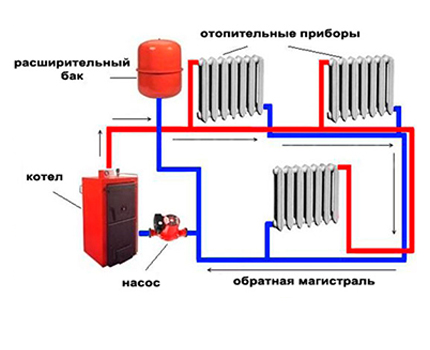

Two-pipe wiring: the main differences

Two-pipe wiring involves the use of 2 pipelines: one for the passage of the heated coolant (supply), the second for the cooled, heading back to the heating tank (return). As a result, each battery receives water at approximately the same temperature, which allows you to evenly warm all rooms.

Using double pipe wiring considered the most desirable. With this connection of heating appliances, the least heat loss occurs. Water circulation can be associated and deadlocked.

This radiator maintenance system is characterized by convenient adjustment of their thermal performance.

Many masters who independently install the heating system of their home, disapprove of the two-pipe. The main argument is the high consumption of pipes, which significantly increases the cost of the project.

A detailed examination of this statement reveals that with the correct connection of devices and the use of optimal pipe diameters in a private house, the system will cost not much more than a single-pipe one.

After all, for the device of the latter, a larger pipe diameter and a large area of devices are needed. The final price will be affected by the cost of pipes of smaller diameter, better circulation of the coolant and minimal heat loss.

Connection of heating devices in a two-pipe system can be carried out diagonally, sideways, from below. Permissible use of horizontal and vertical risers. The most effective option is a diagonal connection. It allows you to maximize the use of heat, evenly distributing it across all heating devices.

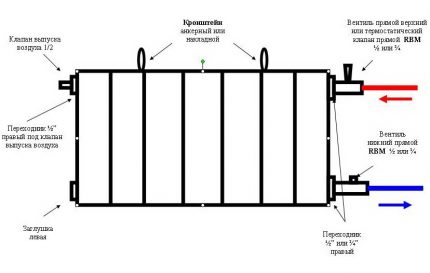

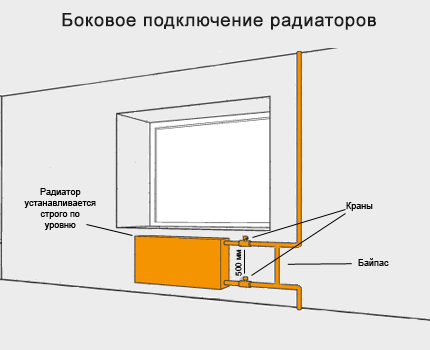

Side Battery Connection

Lateral connection is used in two-and one-pipe distributions. It is also called one-way. The main feature - the supply pipe and return are mounted on one side of the battery.

Such a system is used in multi-storey buildings with vertical flow of coolant. The main condition is to install a jumper before connecting to a pipeline called bypass, and taps so that it is possible to remove the radiator without disturbing the entire system.

One-way connection works most effectively with a small length of the heater - 5-6 sections. The connection of radiators of large length in this way will have large heat losses.

The specifics of the bottom connection

The scheme in which the lower connection is used is most often used to solve design problems. When you need to hide pipes by mounting them in a wall or floor.

Manufacturers of heating appliances offer various models and variations of radiators with bottom connection. The product passport indicates how to properly connect a specific model of a heating battery.

Inside the radiator connection node there are ball valves built-in by the manufacturer, which make it possible to dismantle it if necessary. Such information allows you to install devices into the system with your own hands.

The bottom connection is not recommended for use with natural water circulation. High heat losses from the lower connection are compensated for by the higher power of the radiators.

Diagonal wiring diagram

Diagonal connection is characterized by minimal heat loss. Its feature is that heat is supplied from one side of the device, passes through all sections and exits through an opening on the other side. It is used for single and double pipe systems.

This battery connection option can be implemented in two ways:

- Coolant enters the upper hole of the device, circulates along it and flows from the lower side hole on the other side.

- Water enters the lower hole on one side and, passing through the entire radiator, leaves its upper opposite hole.

The diagonal circuit works effectively when connecting long batteries, with a total number of sections 12 pcs or more.

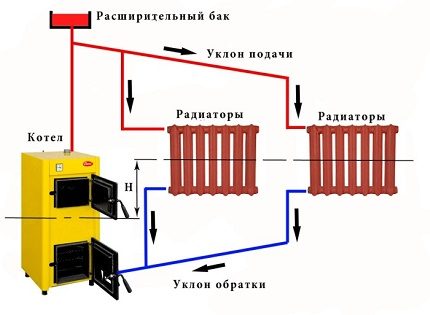

Natural or forced movement of water?

The option to connect the batteries depends on what type of water movement or antifreeze is supposed to be used for the functioning of the system. There are only 2 options: natural circulation and forced.

The first option involves the use of physical laws without buying and installing additional devices. Suitable when water is the coolant. Any ice-freezer will circulate worse through the system.

The system consists of a boiler that heats the water, an expansion tank, supply and return pipes, and batteries. Water, heating, expands and begins its movement along the riser, visiting in turn installed radiators. Chilled water from the system flows by gravity back to the boiler.

With this type of circulation, a horizontal pipeline is installed with a slight slope in the direction of movement of the coolant. This system is self-regulating, because its quantity changes depending on the temperature of the water. The circulation pressure rises, allowing the vodice to evenly heat the room.

In natural circulation, two-pipe and single-pipe schemes with an upper wiring, two-pipe with a lower one, are used. It is advantageous to use such methods of connecting radiators to the heating system for small rooms.

It is important to equip the batteries with air vents to remove excess air or install automatic air vents on risers. The boiler is best placed in the basement so that it is lower than the heated room.

For houses the area of which is 100 m2 and more to change the circulation system of the coolant. In this case, you will need a special device that stimulates the movement of water or antifreeze through the pipes. We are talking about installing a circulation pump. Its power depends on the area of the heated room.

The pump is installed in the supply or return pipe. To remove excess air from the system, it is necessary to mount automatic vents at the highest point of the pipeline or use batteries with Mayevsky cranes for manual bleeding.

The circulation pump is used in two- and single-pipe schemes with horizontal and vertical systems for connecting heating devices.

Rules for connecting radiators

Regardless of the type of radiator chosen and the connection scheme suitable for them, it is important to correctly calculate and install everything.

In each case, its own system will be optimal. For expensive large-area houses, it is advisable to turn to specialists who can offer the optimal project. This is not a question to save on.

For small residential homes, you can independently choose the appropriate scheme and install heating devices. Be sure to take into account the features of your home, the rules for installing batteries and the appropriateness of using one or another circuit.

When installing radiators, one should not forget that the type of material for the battery itself and pipes must be the same. Plastic pipes connected to cast-iron heaters will bring many problems, ruining the heating system.

Conclusions and useful video on the topic

Video about the difference between natural and forced circulation of the coolant in the heating system:

A video that demonstrates the differences between different schemes of the heating system:

Scheme of efficient connection of heating batteries with a two-pipe system:

The heating efficiency directly depends on the choice of the battery connection scheme for your home. With the right option, heat loss is minimized. This allows you to get the maximum effect with the least use of fuel. You can install the batteries yourself. It is important to take into account the peculiarities of construction so that cold batteries do not interfere with a comfortable life in a cozy house.

If you are interested in the material proposed by us for consideration, if you have questions and cause for discussion, we invite you to post comments.

Heating elements for heating radiators: purpose, types, selection criteria, connection features

Heating elements for heating radiators: purpose, types, selection criteria, connection features  Replacing heating radiators: a guide for dismantling old batteries and installing new appliances

Replacing heating radiators: a guide for dismantling old batteries and installing new appliances  Installing heating batteries: do-it-yourself technology for the correct installation of radiators

Installing heating batteries: do-it-yourself technology for the correct installation of radiators  Aluminum heating radiators: overview of technical characteristics + installation principles

Aluminum heating radiators: overview of technical characteristics + installation principles  What heating batteries are best for an apartment: classification of radiators and their features

What heating batteries are best for an apartment: classification of radiators and their features  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Please tell me what to do if my radiator pipes directly “stick” to the wall of the house, is this a minus? For example, when I was making putty myself at home, I noticed that it was not convenient, since I could not straighten the walls properly. And is it worth it to replace the old Soviet cast-iron radiators with new, but more beautiful steel or cast-iron appliances?

Good evening! I can say as a plumber with experience: in fact, you won’t feel the difference, but theoretically the difference is. A tightly pressed battery will have significantly lower heat dissipation. Well, something like this.

If there is no gap between the battery and the wall, then part of the heat goes through the wall into the street. If the batteries are warm, then they change only because of the aesthetics.

Good afternoon! Tell me, please, the apartment has floor heating: supply and return to each battery with a lower connection (only 2 batteries in the apartment), there is a tee on the main battery for the second battery. I want to redo it by putting a collector, and connect each battery with my two-wire route. Is it possible to do this, and is it possible to change the battery connection from bottom to side or diagonal. The area of the rooms is 12m2 and 18 m2. What scheme will work more effectively in a family of two young children. Thank!

Last year, they were very cold, they called the plumber from the management company, he said that it was necessary to change the battery, it was cast iron. Replaced by an aluminum radiator, 14 sections, located under the windowsill, a one-pipe connection diagram. After changing the battery, almost nothing has changed. Its top was warm, and to the bottom it was getting colder. The airiness was eliminated and it’s still cold at home. Room size is not more than 15 square meters. Where to go and what can be done?

Love, I also faced the same problem. The thing is not in the correct connection of the radiator. It will be correct - a diagonal diagram. For example: the hot feed enters the upper left node of the battery connection, and exits from the lower right node. It is important that the feed always goes into the upper ave. Or lion. heater connection unit.

Good afternoon, love. Two options are possible:

1. As you have been told here, not a very good connection option. For clarity, the connection diagram is single-sided and double-sided. Compare with the real picture and draw conclusions. Please note that it does not have to be diagonal. Diagonally considered to be the reference option.

2. The battery was replaced, but left the old ball valve or did not replace the tee on the riser. Quite a common mistake plumbers management companies. This fact is connected with the cost. Replacing a tap is much less than replacing a battery. Clearly in diagram 3.

That is, when you bleed air, the battery warms up evenly, picking up the coolant from the return. At the moment when you stop releasing water / air, the battery cools down. This means that the inner section of the pipe and the feed pressure in the system are narrowed by rust / deposits and not enough to push the return flow and start the natural circulation. In this case, initially the problem was not in the radiator, but in the pipes.

If you grate like that, the house will collapse!

Good afternoon. The system is a single-tube horizontal, cast-iron radiator of 14 sections, connected diagonally. A quarter of the radiator below is a little warm. Tell me what's wrong?

Good. Most likely, the reason is the accumulation of deposits in the lower part of the radiator. The type of wiring and connection has nothing to do with it. The calcium plaque that appeared on the walls of the device has lower thermal conductivity, which is why the heating is uneven. Rinse with reagent; wash radiators separately from the system.

As a rule, there should be a so-called bypass. The most effective way is to put a responding tap on this jumper, of course, you must close it. Thus, we will achieve complete circulation of water. But there is one caveat: when you close the battery, you must open the bypass, because without opening, suspend the circulation of water and other users who are hanging on this pipe. Everything will cool down for them too! This must be observed!

Good afternoon, Anton. Diagonal connection is the most efficient in terms of efficiency, but has one significant drawback - siltation of the lower left or right corners, depending on the particular case. For clarity, I am attaching a circuit. In the vast majority of cases, the problem is solved by flushing without turning off the radiator.

You invite a plumber who will remove the bottom plug and install a stationary ball valve in its place.

Further actions are very simple:

- shut off the coolant supply;

- substitute the container and open the lower tap;

- slowly open / close the feed as the tank is full.

Perform the procedure until completely cleaned. As the radiator is cleaned, the coolant will become transparent. Naturally, the plumber installs the tap in the non-heating time, and flushing is carried out after the start of the heating season.

There is no cheaper way to resolve the issue. The advantage of this method is that in the future you will not need to resort to the help of a paid specialist.

Good afternoon, tell me, please. Faced such a nuance: a private house, a one-pipe heating system is divided into 3 circuits, each circuit has 6 batteries. Each circuit is approximately 36 meters, the pipe uses 32 plastic, there is a circulation pump. Battery connection is both diagonal and bottom. I noticed that with a lower connection, the battery heats up completely evenly, and with a diagonal connection, only the top is hot. What could be the catch? (I am not a professional)

First of all, I attach a diagonal connection diagram so that there is no misunderstanding. I immediately say that it is necessary to check the most common cause of the cold bottom of the radiator in this case - a blockage.

Also, the case may be in valves, do not exclude this option. Low pressure can be eliminated, since you have one circuit.

Did you design and connect the heating system yourself? It is possible that some errors are made, so there is such an effect when the bottom of the radiator remains cold.

But what about convection? The heat always rises up ... Perhaps that is why when the radiator is connected diagonally, the lower corner on the supply side remains cold?

Hello, help! Tell me, is it possible and how to weld radiators in the case as in the photo?

Hello. You can mount radiators in the current wiring. As I understand it, the bottom is a return, so we will take it from this. First of all, let's discuss what exactly you will need:

- directly the radiator itself, in this case cast iron is better;

- mounts for the radiator;

- adapters, faucets, pipe fittings (metal, PP or PE decide for yourself).

Now, regarding the scheme by which it is better to connect a radiator. I do not see the whole picture of the heating system as a whole, but it is logical to assume that the system in this case will be two-pipe, so I deleted the one-pipe system from the proposed scheme. If possible, then draw a diagram of the current wiring to give a more accurate answer.

What problems will arise when connecting cast-iron batteries (new type) with PVC pipes with a single-pipe system, a gas boiler with a pump?

If everything is connected correctly, using normal adapters, high-quality fittings, then no problems should arise. But about PVC, the question is: do you have a typo, or are you really going to use PVC pipes? The fact is that the low operating temperature does not allow the use of PVC pipelines in heating systems - this is a fact! The heat resistance of PVC pipes is only 65 ° C; glass transition occurs at a temperature of 75-80 ° C.

Therefore, in heating systems, PP pipes (polypropylene) are used, in which the softening temperature starts from 130 ° C. However, the operating temperature at which the service life will not be reduced is up to 95 ° C.

I enclose a visual table of the operating temperatures of plastic pipes from different materials, plus a table of the features of the operation of PP pipes at different temperatures.

But this can be done as in the photo?

No, you don’t need to do that!

Good afternoon! Nowhere can I find information on how long the tube should be if the radiator is supposed to be installed in 10-12 sections. Tell me?

Good day, Sergey. The length of the metal-plastic pipe (outer diameter 16) is equal to the length of the radiator minus one section.

It is installed exclusively with a single-pipe system and side connection of the radiator.

The purpose is to create the effect of a pseudo-diagonal connection.

It is used if the last sections do not warm up (note that only the issue of the cold top of the radiator is solved, otherwise the flow extension will not fix the problem). With uniform heating of all sections of the radiator along the entire length, “just in case” is not recommended.

According to your words, you are at the stage of selection and subsequent installation of a new battery. Therefore, I would advise you not to rush with the purchase / installation of a flow extension, until you know for sure whether your situation is required or not.

Why advertise a diagonal connection? One MINUS eats all imaginary advantages. Replacing the battery leads to walling. Need to explain why?

When the need arises to replace the battery, it will be a big problem to find a battery with EXACTLY the same dimensions. Whatever the new one hangs straight, you have to play the pipes. And they are walled into the wall. Hence the swotting of the walls.

Diagonal connection is an extremely unsuccessful decision.

Hello? such a situation - in the circle of the house there is one pipe under the screed, and battery leads stick out under each window. Will the batteries warm if put? The findings are just spayed on tees.

Hello. I have replaced the risers. The battery is new, bimetal. The top is hot, the bottom is cold. It used to be cast iron. And her top was hot, the bottom warm. The system is two-pipe. Put cranes in front of the battery. Why such a result?

All new. The vertical risers used to be 15, now 20. After the water was supplied, the horizontal pipes to the battery were both hot, after a while the lower ones were cold. Water is supplied from above.Tell me why so?

Good afternoon, Anara. If we proceed from the fact that everything is new, then the problem is to reduce the diameter of the pipes from the riser, including on installed cranes.

Water moves at the lowest resistance and pressure in the heating system of the house is not enough to push the return flow. Coolantin simple terms, flies past your radiators.

Good afternoon. Installed a new bi-radiator in 18 sections. The connection is diagonal. Only the top warms up and completely 2-3 sections from the exit side. I think about the bottom connection. So at least the heat will rise up. How to make it work most efficiently. In the next room of the cast iron, 15 sections diagonally works fine.