How to make a heater yourself: instructing on the manufacture of a homemade device

In the cold season, the need for heat is increasing. But not every owner has the opportunity to purchase a factory-made heater. There is nothing complicated in assembling a heater with your own hands.

We bring to your attention four options for creating a heating device from improvised means, which will perfectly cope with the task assigned to it. We described in detail the process of making homemade products. They described the principle of operation and operation features.

To the walkthroughs we have attached diagrams, photo selections and video instructions.

The content of the article:

Devices for local heating

The simplest models of home-made heaters are designed for local heating. Their maximum heating temperature is about 40 ° C.

For the most part, home-made heating relate to radiating devices operating on the principle of IR heaters and electric radiators. They are connected to a single-phase network with 220 V, which is traditional for household objects. Those who want to engage in the independent manufacture of devices need knowledge in the field of electrical engineering and wiring.

Option 1. Homemade compact thermal film

The basis of the heater will be two glass cuts. These are the same rectangles 4x6 cm in size.

The length and width of the heater’s working area may vary. The main thing is that the area of each glass is about 25 square centimeters.

To create such a home-made heater, you will also need:

- two-core copper cable;

- multimeter;

- paraffin candle;

- wooden block;

- pliers;

- sealant; epoxy adhesive;

- cotton napkin;

- hygienic sticks.

Before starting work, the cable must be equipped with a plug.

First of all, the glass blanks are cleaned, removing dust and dirt with a napkin, degreased and thoroughly dried. The cleaned workpieces are cooled. This is necessary so that during subsequent firing, the carbon deposit settles better on the surface.

Set the candle set in the candlestick. And then, one after another, they grab each glass blank with pliers by the corner and carefully move them above the candle so that the glass is covered with soot. It is necessary to achieve uniform sedimentation of soot on the entire surface of the glass; burnt part and will act as a conductive element.

Manipulations with a candle will have to be interrupted periodically in order to allow the heated glass to cool slightly.

After cooling the blanks, each of them cleans the edges. To do this, with the help of hygienic sticks along the contour around the perimeter, 5 millimeters from the edge are removed.

On the burnt part, which will act as a conductive element, glue is uniformly applied, on top of which a previously prepared piece of foil is applied. The strips will serve as the terminals needed to connect the wires.

The same actions are performed with the second half. Both parts connect. To ensure the tightness of the device, the joints are treated with sealant, covering the end along the entire perimeter.

In order to calculate the power of the device, it is necessary using a tester to measure the resistance of the carbon coating. The multimeter probes are applied to the hanging “tails” of aluminum foil. The data obtained are used in the calculation using the formula:

N = i2 x R

where "N"- power,"I"Is the current strength, and"R"- resistance.

Power should not exceed permissible values of 1.2 watts. If the resistance exceeds a value of 120 OM, in order to reduce it, it is necessary to make the carbon layer a little thicker. Here the following rule applies: the more soot, the lower the electrical resistance.

If the parameters are within the normal range, they proceed to the final stage of assembly. To do this, the stripped edges of the preforms are lubricated with glue, and the free ends of the foil sections are bent and glued to one of the sides.

A structure assembled from glass and foil is installed on a wooden platform and the device is connected to a 12-volt source.

Option # 2. Leftover infrared heating panel

If film fragments remain after the heating infrared floor is installed, they should be safely put into the business of manufacturing a wall heater, for example, for a summer house or garage.

Infrared film consumes less energy than other heating electrical devices. For a small room of approximately 2 × 2 m, 1 m is enough carbon film system.

Now you need to carefully insulate everything so that the film does not spark on the contacts and does not create any threats in the process of its own work.

Option # 3. Available fan heater

We offer another affordable method of manufacturing a home-made device for local heating, which is based on the principle of operation fan heater. Its manufacture will take no more than two hours. The main advantage of such a device is the simplicity of manufacture and the availability of the necessary materials.

Among the design flaws is the fact that during heating it will burn oxygen, and in some cases even smell like burning.

In addition to the can for assembling the heating structure, it is necessary to prepare:

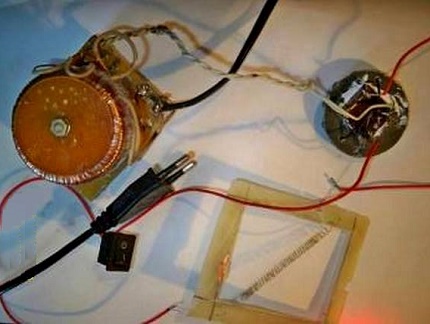

- 12 volt transformer;

- diode bridge;

- nichrome wire cross-section 1 mm2;

- fan;

- punch with a thin drill;

- soldering iron;

- computer fan.

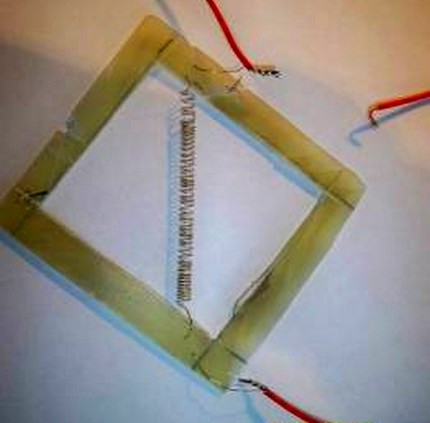

Two blanks must be cut from the PCB in advance, the size of which corresponds to the dimensions of the selected can. To connect the device to the network and switch modes, you will also need an electric cord and a button switch.

First of all, the foil is removed from the cut of the PCB and the inner part is cut out so that it looks like a frame.

The ends of the nichrome wire are deepened into the holes made. To the free ends of the wire brought under the frame solder the "tails" of electric wires cleaned from insulation.

The current density in nichrome spirals in contact with air is about 12-18A / mm2. Depending on the degree of heating, their color saturation will vary from maroon to bright red. The temperature of the outer surface of the emitter does not exceed 70 degrees.

A diode rectifier and a small 12 V transformer are needed to power the cooler.

To be able to adjust the temperature, it is worth considering the option of installing at least two separated spirals. In addition, by connecting the spirals in parallel, if one burns out, the others will not suffer.

The main thing when assembling the structure is that the wound spirals do not touch any parts other than the textolite frame.

The fan is mounted in a jar using a bracket in the form of a U-shaped metal part fixed by a bolt. The current will warm the coils of the wire, and the fan will blow the structure with a warm stream of air.

To ensure free air access in the lid and walls of the cans, 20-30 holes are drilled with a diameter of 1.5-2 mm. The assembled device is directly directly connected to a 220V network and its operability is checked. For safety reasons, the radiating surface can be covered with a protective net.

Such a fan heater is suitable for heating a small area. Like industrial fan heater models, in just a few minutes, it warms up the middle of the room without spending precious heat on the heat loss that goes through the walls.

Those who want to independently make a heater for the garage from improvised means will find a lot of useful information in another popular article our site.

Home-made low-power devices

The models described above are only suitable for local heating. To heat the room, it is necessary to build a more powerful heater, the manufacturing technology of which we will consider below.

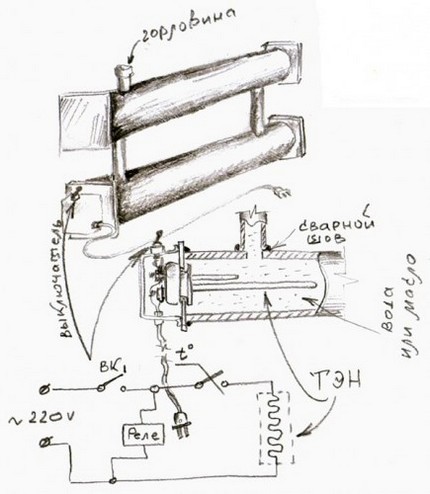

Option 1. Creation of an oil device

Do-it-yourself oil heater It has a high efficiency and, moreover, is quite functional and safe. The principle of operation of the device is based on the fact that the heater located inside the heater warms up the oil located near it, as a result of which the convection movement of flows is activated.

To ensure smooth power settings, the device is equipped with a rheostat or discrete switches. To automate the process, an additional thermostat and tilt sensor are installed.

To make an oil heater you need to prepare in advance:

- TEN with a power of 1 kW (for premises with an area of 10 squares);

- strong and tight case, the design of which completely eliminates leakage of liquid;

- clean and heat-resistant technical oil is taken at the rate of 85% of the total body volume;

- control and automation devices - are selected in accordance with the total power load of the device.

An important point when acquiring a cartridge tent, do not forget to check that silicone gaskets or their analogues made of oil-and-gas-resistant rubber are included in the kit.

In order not to mess with welding, you can use a dismantled body as a housing heating registerdismantled due to the modernization of the public building system.

An impressive construction will require the construction of a platform. It can be made from channels or steel corners. When drawing up a diagram, the frames are repelled from the capacity of the tank and the height of the product.

Complexity can arise at the stage of welding elements. After all, to complete the work you need to have the appropriate skills. The first step is to cut the profile pipe into segments of a given length. Rectangular frames are assembled from them.

A hole is cut out in the corner of the structure for the placement of the heating element. A hole is cut out at the highest point of the radiator to allow oil to be poured and equipped with a male thread fitting, on top of which a cover is installed.

When assembling the structure, attention should be paid to a number of points:

- It is better to place the heater in the lateral or lower part of the structure, fixing with bolted connections. This solution will provide better oil circulation. Under no circumstances should it come into contact with the housing.

- To activate the process of natural convection of fluid, supplement the design with a pump and electric drive. To fix the pump to the tank, you need to weld small metal plates.

- Be sure to provide valve-mounted openings for emergency pressure relief by draining the oil. The pumps are located at the bottom of the radiator in the corners.

- To ensure the durability of the structure, preventing the development of electrocorrosion, consider the compatibility of the body metal and the heater. Due to the potential difference between metals, it is not worth combining ordinary steel or aluminum with copper.

- Ground the heater without fail.

The design is not completely filled with oil, but only by 85%.This is necessary so that 15% diverted into the air is a buffer zone during oil expansion due to temperature increase.

After checking the tightness of the holes, it remains only to connect the heater, install the housing and fill in the oil. To increase the mobility of the structure, it can be equipped with wheels and additional fastening elements.

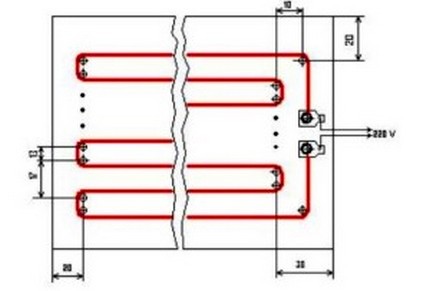

Option # 2. Making an infrared device

The indisputable advantage of such a device is that the generated thermal energy is released in the form infrared radiation. Thanks to this, a heater created on the basis of a carbon element warms up not only air, but also people and objects located in the infrared zone.

The basis of such a device, created by type factory-made heaterswill be two plastic blanks, the area of each of which is about 1 square. Fine-grain graphite powder will be applied on them, in structure somewhat resembling flour.

To make an effective IR heater do it yourself, you must also prepare:

- two copper terminals;

- epoxy adhesive;

- wooden blanks for the frame.

As in previous versions, an electric cord equipped with a plug is required.

Graphite powder can be “mined” from old batteries. To obtain the required heater power, experienced craftsmen recommend introducing up to two volumes of carbon filler. In the finished form, a thick and viscous mixture is obtained, which is quite difficult to apply with a thin film. To simplify the task, use a narrow spatula.

The sequence of actions:

- Graphite is mixed with epoxy adhesive in a ratio of 1: 1.5 or 1: 2.

- On the work surface, lay the plastic blank with the smooth side down.

- The finished mixture is laid out in a thin layer on plastic, forming a zigzag pattern.

- On top of the laid out pattern is a second sheet of plastic.

- Using the same technology, a second plate is prepared. Both blanks are tightly compressed and wait until the adhesive composition hardens.

- On the blanks on opposite sides of the graphite conductor, the terminals are fixed, adhering to the above diagram.

- The stripped ends of the electric cable are connected to the terminals.

- Connect the device to the network and check the performance of the system.

The measurement of the resistance of the conductor and calculation of the power of the assembled device is carried out, adhering to the technology described above.

The resistance parameter is affected by the amount of graphite in the mass. To increase the resistance of the conductor, you need to increase the dose of graphite in the composition.

To increase the rigidity of the structure, the device can be framed with a wooden frame. To improve the design, supplement it with a simple thermostat.

Conclusions and useful video on the topic

Video # 1. Overview of the spiral heater manufacturing option:

Video # 2. Homemade 1kW infrared heater:

We considered only a few options for manufacturing heaters from improvised means. In fact, there are a great many of them. If you wish, you can independently develop and manufacture such a device. And the reward will be the desired warmth in inclement weather.

Do you want to offer your own version of the heater? Have questions or is there any useful information for us and site visitors? Please leave comments in the block below.

How to make a fan heater with your own hands: a briefing on the manufacture of a homemade device

How to make a fan heater with your own hands: a briefing on the manufacture of a homemade device  Homemade heater for the garage: how to make a device yourself

Homemade heater for the garage: how to make a device yourself  Waste oil heat guns: species analysis + DIY instruction

Waste oil heat guns: species analysis + DIY instruction  DIY gas heater: instructions to help home craftsmen

DIY gas heater: instructions to help home craftsmen  Do-it-yourself diesel heat gun: homemade manufacturing instructions

Do-it-yourself diesel heat gun: homemade manufacturing instructions  DIY heat gun for used oil: step-by-step manufacturing instructions

DIY heat gun for used oil: step-by-step manufacturing instructions  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Have to tinker to make the first two heaters. Yes, it seems like nothing complicated, but you have to get confused, and the effect is insignificant. The heater, as described by the oil cooler, had to be assembled more than once in its life. Instead of oil, ordinary water was poured and tena was inserted. But with oil this is a problem. After all, transformer oil is very expensive. But it is necessary here a lot. Probably not much more expensive to buy an industrial heater. In addition, home-made devices are unsafe.

Homemade homemade strife. Another handy man will make such a heater, which in efficiency will not yield to the factory model and in safety.

As for the oil, mineral engine oil with a viscosity of 20W50 can be added. Or gear oil standard G-4. Synthetics are also possible, but it has a lower viscosity and because of this, the heater will work much more noisily. For money, all these methods are decently cheaper than transformer oil.

But in fact, with transformer oil it turns out not so expensive. You do not need a barrel, but 5-10 liters, depending on the size of the heater.

Yeah, with some homemade goods I would have to sweat. But from a tin can a cool device, really made from improvised materials. In general, these are all temporary options when there is no money / opportunity to buy a normal one. Of course, this one will do for the first time, but then it’s better to spend money and install the real one from the store. Although for the summer cottage and homemade can prokanat!

Guys, if you are looking for adventure on your own ... head, then you can experiment with batteries, mining graphite (I can recommend pencils, charcoal), make conductive substrates, just do not turn them on anywhere! I’m telling you like a fireman. Buy an ordinary oil heater if it is cold at home, and it is not necessary to heat the cottage.

“The power must not exceed the permissible values of 1.2 watts. If the resistance exceeds a value of 120 OM, in order to reduce it, it is necessary to make the carbon layer a little thicker. Here’s the rule: the more soot, the lower the electrical resistance. ”

The thicker the soot layer, the less resistance. And if the resistance decreases, the current strength increases. So the power is increasing.