DIY gas heater: instructions to help home craftsmen

With the onset of cold weather, there is a need to heat the premises. It is not always possible to carry out central or autonomous heating to such premises as a garage, a barn, a corral, a greenhouse. The reasons may be different: lack of funds due to the high cost of connecting such systems or lack of technical ability.

If you make a gas heater with your own hands, it will effectively heat the utility rooms. Now in the market you can choose and buy many different models of gas heaters at various prices and with different characteristics. However, the price includes the biting margin of the seller.

We will tell you how to assemble an almost free homemade product from improvised means. Here you will find a detailed description of home-made devices and instructions on their manufacture. To help independent craftsmen, we offer assembly guides and valuable recommendations.

The content of the article:

Features of a makeshift design

The main task that the future home-made device will perform is heating the room, tent, garage and other rooms. With self-assembly, the appearance of the device and its decorative qualities go by the wayside.

An important role will be played by the sufficiency of the amount of heat generated, the safety of operation and the ease of transportation of the device.

For heating purposes, a variety of home-made gas structures are used. To make heaters from gas burners or from gas stoves with your own hands is not difficult. For quick assembly, you will need a pre-prepared scheme, the material from which the heater will be made, and a variety of tools.

Often, a home-made gas heater is taken on a camping trip out of town or fishing, traveling, for a variety of fees as a source of additional heat. In such cases, it will be enough to assemble the device, check its operability, inspect it for leaks and proceed directly to heating.

Sometimes homemade heater planned to be used as an alternative source of heating. For example, in a country house, in a barn, in a shelter, in a garage and in other premises in order to save money on paying for utilities and on the purchase of gas equipment.

In such cases, it is necessary to take care of the maximum reduction in heat loss within the heated room. This is done by warming the outer and inner walls, floor and ceiling of the structure. It is most effective to carry out procedures of both internal and external warming. Then the heat will be kept as long as possible, and the gas consumption will be much reduced.

If it is not possible to conduct two types of insulation at the same time, then you need to insulate the building at least from the inside. It is more efficient. During the procedure, it is necessary to use material suitable for thermal insulation, as well as refractory materials and coatings.

When using gas equipment, you must always observe safety precautions and adhere to the rules for installing equipment and warming rooms. If the heated building is finished with refractory materials, then it will be fire resistant. This significantly reduces the risk of fire and unforeseen fires.

To place a homemade gas heater is best in the center of the heated room. In this case, the heat generated is not lost or absorbed by the walls, since there is no contact with them. Warm air will go up to the ceiling of the room. If you also install special reflectors on the ceilings, then the effect of a heat cap will be created in the room.

This positive phenomenon can significantly save money on space heating with the help of homemade gas structures. Warm air circulates throughout the space and does not leave it. It is worth knowing that the effect of the heat cap is created when the heater emits a fairly intense air flow.

According to the assembly results, a home-made heating apparatus should have the following parameters:

- safe and uncomplicated operation;

- economical consumption of energy, in this case gas;

- efficient and fast heating of rooms;

- quick start-up of the device, the possibility of long-term operation;

- simplicity of assembly and ease of replacement of failed parts;

- the ability to transport the device;

- dimensions suitable for transport, transportation and operation.

All of the above characteristics are quite difficult to fit into one design. However, some craftsmen manage to independently make a gas heater of sufficient power, convenient, easy to use, which serves the user for a long time.

The advantages of homemade gas heaters include:

- Economical work. Sometimes one full bottle can last for 12 hours of continuous operation of the device. Of course, it all depends on the size of the container.

- The ability to quickly turn on and off.

- Compact and light weight. Some home-made designs are convenient for hiking. They do not take up much space and weigh several kilograms. And the beneficial effect of their use is difficult to underestimate.

Among the shortcomings of homemade designs highlight the need for selection suitable cylinder or the presence of an adapter. Therefore, you need to take care in advance of purchasing additional cans. Or be able to transfer gas from a large cylinder into a small tank.

Some gas heaters, made independently, do not withstand severe subzero temperatures and do not start if the air temperature is below a certain point. Encountering such a problem can overshadow a hiking trip. However, indoors, the temperature usually does not drop to very low levels.

If the heater works indoors, then it is imperative to ensure the supply of fresh air. It is also important to consider that the level of carbon dioxide in the room increases. Humidity is significantly reduced.

It is impossible to leave the switched on device unattended, and also to bring flammable objects to it. This may cause fire and fire.

The efficiency of a self-designed device is determined by its main characteristics.

Efficiency. This indicator is determined by the ratio of the energy that is used for heating to the energy that is spent to generate it. Gas heaters have different efficiency values.

Safety device. Often, on improvised structures, the installation of devices that ensure safe operation is neglected: valves, sensors that automatically turn off the burner.

Fuel consumption and area heated by the device. Depending on the size of the device, fuel consumption also changes. The larger the room, the larger the burner required.

Gas heater device

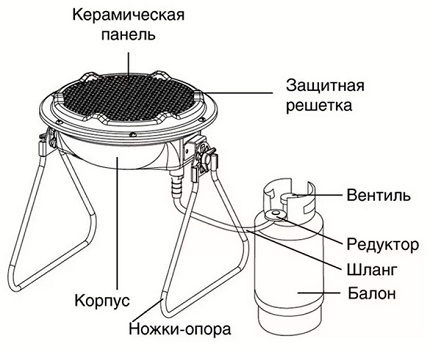

Combines all the designs with a single gas supply system. As a source of fuel, gas cylinders with propane-butane or others types of gas mixtures. Also, for small heaters, gas cartridges for burners are used. You can carefully fill and pour them with your own hands. The main thing is to observe safety precautions.

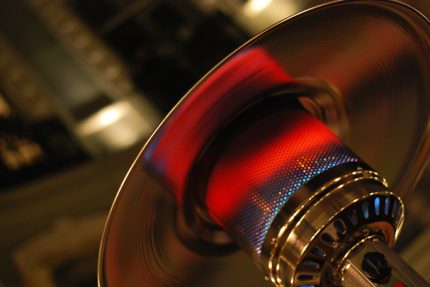

Many homemade gas heaters work on the principle of infrared radiation. It consists in the fact that the fuel gradually burns out in the burner and thereby heats the heating element, which, in turn, generates heat in the infrared range. Thus, all items of the room or tent are heated. After that, heat is transferred to the air.

DIY gas heaters are quite diverse and can have different weights from half a kilogram to a dozen kilograms. It all depends on the complexity of the design and the required level of heat generated at the output.

Usually, the home-made of their following basic elements is constructed:

- fans that evenly distribute heated air throughout the room;

- a power regulator that allows you to adjust the level of heat and temperature in the room;

- a gas burner that directly burns gas and heats the system;

- thermal radiator - an element that accumulates thermal energy and gives it to the air or to objects in the room;

- gratings that protect the heat radiator from direct contact with objects.

In addition to the basic elements, additional ones will be required, which may include handles, grilles, reflectors, covers, mounts, gas hoses and other blanks.

A device made in this way is suitable for heating small and medium rooms, and small rooms. There is no need for electrical appliances and electricity. When the next cylinder is used up, it will be possible to refuel or buy a new one.

Some homemade gas infrared heaters also perform additional functions, which include heating water, drying clothes and various items. Using some device you can also cook food. At night, such a heater glows and is a source of additional lighting.

Homemade device from a gas burner

Our proposed method can be assembled not too powerful, but convenient, compact, portable gas heater. Such a device is suitable for heating small rooms, a garage, a small greenhouse, basement or tent.

To assemble the structure, a gas stove-primus is used. It is used for cooking. This scheme is also applicable when using collet valve cylinders.

In addition to the burner, the following improvised material will be required:

- tin sheet of a small area;

- round metal sieve;

- rivets.

Some tools will also be needed: an electric drill with a small drill, a riveting device, and metal scissors.

The assembly of the device is as follows. First you need to take a pre-prepared tin sheet and attach a sieve to it. The sieve should be circled with a marker or construction pencil around the circumference.

After that, a sieve is laid down and a pencil with a ruler on tin over a circle neatly draws rectangular ears or the so-called sweep. One eye should be slightly longer than the remaining three.

Then you need to take the scissors and carefully cut out the cut blank. It is important to cut parts so that there are no bumps on their surface.

After the circle is cut from the sheet, it must be attached to the burner using bolts. To do this, you need a drill with which to accurately drill even holes. Then you need to trim the drilled holes and erase the remaining metal with a file or cut (grind) with a grinder.

In the resulting structure, you need to bend the rectangular ears from above and attach a metal sieve. The main task of the sieve during heater operation will be heat dissipation. This design can be improved by the additional use of mesh.

First of all, another circle with ears is additionally cut out of the tin sheet. Its dimensions must match the dimensions of the first part. Then, using a drill, you need to drill holes in the cut circle, which should be located at a small distance from the edge of the workpiece. After that, you need to cut a small strip of mesh.

The cut narrow strip is attached above the sieve to the first and second tin circles behind the ears with the help of rivets. The ears should be bent at an angle of 90 degrees. As a result, the design will resemble a metal cylinder.

After making such a gas heater with your own hands using a gas burner, the design must be checked. You need to make sure that it can be used safely. The gas canister is connected to the burner, the gas supply is turned on, the burner is ignited, and the device starts heating the room.

Using an adapter hose, you can connect such a burner to a large gas bottle. Then you do not have to spend extra time on replacing and refueling the gas tank. The cylinder must be installed gas reducer, which protects the structure from the reverse movement of gas and allows you to adjust the pressure.

It is worth remembering that manufacturers of gas sprays do not recommend using their products repeatedly and refill cans.

Using a similar approach, you can design a larger homemade gas heater. Such devices will already resemble gas stoves and can be powered directly from a gas pipe or large cylinder. Naturally, the capacity of such a furnace is enough to heat a larger room.

However, such structures are not so easy to move from one place to another; they take up a lot of space and often require additional construction of a chimney and a ventilation system.

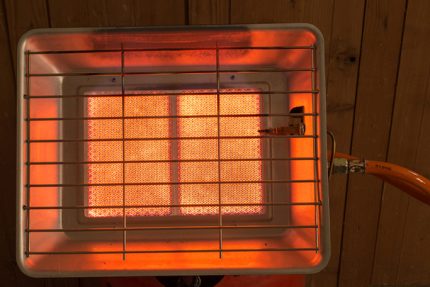

Tile heater

Small-sized rooms, a garage, a greenhouse, a tent are conveniently heated with a portable desktop gas heater. Such a device is constructed from a quadrangular flat tile equipped with a metal grill.

The collection of this device involves attaching part of the gas stove to a metal casing. Due to the installed combustion chamber, air is heated to the desired temperature, and several or one fan provide the supply of warm air and its circulation throughout the room. The assembly of such a device consists of several stages and does not require special technical knowledge.

The first stage is working with measuring instruments. Using a ruler or tape measure, you need to take accurate measurements from a quadrangular tile. This is required to determine the parameters of the heater body. After the measurements, you need to cut the blanks from the tin sheet with scissors. Next, the workpieces are fastened with rivets to the casing.

Then the casing is fixed with hooks on the tile. In order to be able to quickly remove and mount it back, you need to make a movable bar. It is easy to make such a bar using a small spring, which is connected to the lifting lever.

Thanks to this decision, it will be possible in the future to easily remove the casing for cleaning or transportation. The home-made scheme under consideration requires a special ventilation system. To install it you will need a banal fan without any additional complex devices or materials.

To install ventilation, a small fan from any home device is suitable. You can use scissors to fit the size.Cutting and shaping the size of the fan blades takes about half an hour. After carrying out these steps, you need to install a ready-made fan at the back of the heater casing, so that there is draft inside the casing.

You also need to install a metal combustion chamber. The housing of the combustion chamber must be littered with many small holes. They can be made using an electric drill and drill for metal or with a hammer and nail. The holes should be a short distance from each other.

You also need to buy a rubber hose with an adapter to connect the flat tile to gas pipe or gas bottle. A fan installed behind the casing provides the supply and distribution of warm air over a fairly wide range in the heated space.

Such a home-made gas heater copes well with the task of heating the room, not only in the autumn-spring period, but even in the winter season. Also, such a device economically consumes gas and has a high efficiency.

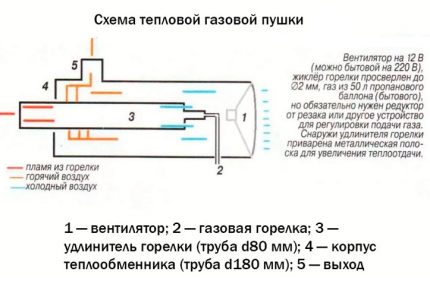

Pipe heater construction

This homemade design is also called thermal gas gun. It emits significantly more heat than previous heaters, and absorbs more energy resource. Also, such designs are often equipped with chimneys, which makes them bulky and difficult to carry.

To assemble the heater yourself, you need to collect the following material:

- three meter pipes of various diameters (two of 8 cm and one of 18 cm);

- steel plates with which the fastening will be carried out;

- Metal sheet;

- gas torch with piezo ignition;

- axial fan.

You will also need a variety of tools: drill, welding machine, tape measure, level, grinder, scissors for metal. Pipes can be replaced with cylinders or fire extinguishers of suitable diameters. A grinder will be needed to cut the bottom and top, as well as shorten the workpieces.

Two holes of different diameters are drilled in a pipe with a diameter of 18 cm: 1 cm and 8 cm. They need to be drilled opposite each other.

A cut of 30 cm is cut from a pipe with a diameter of 8 cm, which will be a combustion chamber. Fasteners are welded to this pipe and a hole with a diameter of 1 cm is drilled in it. Then this pipe is inserted into the first pipe.

From the sheet of metal you need to cut the plug. It will close the gap between the heater body and the combustion chamber. A combustion chamber is welded to the body, and a nozzle for removing hot air is connected to the hole with a diameter of 8 cm. After that, a plug is welded. After making sure that the gas burner is firmly attached to the combustion chamber, you can push the hose through the centimeter holes.

A fan is installed on the back of the device, and a chimney on top. In order for the heater to stand steadily on the surface, legs should be welded. Gas heat gun efficiently heats rooms, economically consumes gas. However, safety precautions should be followed when using it.

Conclusions and useful video on the topic

Canister gas heater:

Homemade infrared gas heater:

Anyone can assemble a gas heater according to the considered schemes of the house.It is only necessary to follow the safety precautions and not neglect the instructions for putting the devices into operation. If you assemble a heater yourself, you can save money. In addition, the effectiveness and efficiency of such devices is not inferior to the store ones.

If you plan to heat a small room or tent, as well as take the device on trips and hikes, then it is better to make a heater from a gas burner or from a gas stove. They are more compact, take up less space and are easy to transport. Heat gas guns are suitable for heating larger rooms, emit more heat and require an electrical connection for the fan to work.

Homemade heater for the garage: how to make a device yourself

Homemade heater for the garage: how to make a device yourself  How to make a heater yourself: instructing on the manufacture of a homemade device

How to make a heater yourself: instructing on the manufacture of a homemade device  DIY gas convector: installation steps for factory-made appliances + homemade assembly

DIY gas convector: installation steps for factory-made appliances + homemade assembly  How to choose a gas heater for a summer residence: choosing a device for outdoor heating

How to choose a gas heater for a summer residence: choosing a device for outdoor heating  Catalytic gas heater: varieties, recommendations for selection + review of the best brands

Catalytic gas heater: varieties, recommendations for selection + review of the best brands  Do-it-yourself heat gas gun: step-by-step assembly instructions

Do-it-yourself heat gas gun: step-by-step assembly instructions  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements