Heating elements for heating radiators: purpose, types, selection criteria, connection features

With the onset of cold weather, the issue of housing heating becomes more relevant. In the dank off-season, centralized systems often do not include “until the last”, and then alternative heating systems come to the aid of the freezing inhabitants.

One of the simple solutions are heating elements for heating radiators, which can become an effective addition to the heating system. In some situations, the device will quite cope with the role of the main source of heat, for example, in seasonal accommodation.

Before deciding to purchase a device, you need to find out more information about it, agree? We have prepared a review article on the design of radiator heating elements, their classification, advantages and disadvantages. The material outlines the main criteria for choosing an electrical appliance and describes the features of its installation.

The content of the article:

TEN for a radiator: why is it needed?

Like any other heating element for heating, radiator is designed to heat the coolant and maintain its operating temperature. The device can be installed in almost any heating device that has an internal cavity filled with liquid. Due to this, the scope of its application is quite wide.

Radiator heating elements can act as the main or additional source of heating. They are very good as heat sources for rooms with a relatively small area, which are periodically used in the cold season.

For example, various utility rooms or for garage heating. In this case, the heater is mounted in an autonomous radiator, usually it has impressive dimensions.

The battery is not connected to the heating system and is filled with coolant, which circulates exclusively within the radiator body.

In such cases, technical oil with a reduced viscosity is chosen as the heat carrier, which allows us not to be afraid of complete freezing of the radiator after hours. It turns out an analog of an oil-type radiator, only of large sizes.

Radiator heating elements have proven themselves quite well as the main heat source for country houses, which are periodically heated. The system is equipped in the same way as described above, but only the heating elements are mounted in the batteries installed in each room.

It is possible to organize such heating for houses with permanent residence. In this case, the batteries can be filled with plain water, since it is not planned to allow the system to freeze. True, such options are used extremely rarely due to the high cost of electricity.

More widely radiator heating elements are used as additional heat sources. They can be built into an existing heating system with a liquid coolant and included in the work when the main heating for some reason does not work.

This solution is especially successful for houses with central heating. In the period when it is turned off, the heating elements literally save the residents of the apartment from freezing.

Another good option is to connect appliances to an autonomous heating system with solid fuel boiler. This will help maintain a comfortable temperature in the rooms even at a time when the owner is not able to lay fuel on time.

If there is the possibility of using a multi-tariff meter, it may be practical to switch to night heating with electricity, when it is relatively cheap. In the afternoon, the boiler will work again.

Practice shows that it is economically unprofitable to use radiator heating elements as an additional heat source for autonomous systems operating on gas. This type of fuel in itself is relatively cheap, so replacing it with more expensive electricity does not make sense.

If indoors are used liquefied gas boilers or on diesel, the benefits will be obvious. But only in the presence of a two-phase electricity meter.

How is the appliance

The design of the device is practically no different from other types of heating elements. The casing of a tubular electric heater is made of a seamless or electric-welded thin-walled metal tube. Its diameter may vary, and the cross section may be flat or rounded.

Carbon steel is most often used as the material for the manufacture of the case, but stainless steel can also be selected if the working surface of the device is heated to temperatures above + 45 ° C.

To protect the metal from corrosion and extend the life of the heater itself, the steel casing is chrome-plated or nickel-plated. As a heating element, a spiral of nichrome wire is used.

The element has a high resistivity, so it quickly heats up. The spiral is placed inside the body, in the remaining free internal cavity - filler.

The case has high electrical insulation properties and at the same time transfers heat well. As a filler, purified quartz sand or periclase can be used - this is the name of a mixture of crystalline magnesium oxides.

After the body is filled with filler, it is pressed and bent, giving the necessary shape. All insulators are coated with an organosilicon moisture-proof compound.

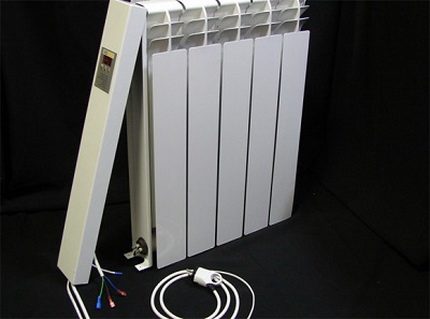

Such a device can be installed in a radiator of any type: copper, cast iron, bimetal, etc. The device is capable of generating up to 2.5 kW of power. Models for industrial use deliver up to 6 kW.

The design of the electric heating element is such that the device converts all incoming electrical energy into heat without any loss.

The principle of operation of the device is extremely simple. When activated, it begins to heat up quickly, warming up the coolant located in the immediate vicinity of it. According to the laws of physics, a heated liquid is lighter than a cold one, so it begins to move up.

In its place the colder coolant falls. Having risen to the upper part of the radiator, the heated liquid gives up its heat there, cools and falls down.

The cycle is repeated many times. Thus, the appliance creates a unidirectional fluid flow inside the battery. Its speed is higher, the greater the power of the device.

Based on practice, transformer oil is considered one of the best types of coolant. The liquid quickly heats up and does not cool down for a long time, gradually losing its heat to the radiator body.

Cons and pros of radiator heater

Tubular-type electric heaters make it possible to assemble a practical and sufficiently effective heating system for the main or additional heating.

The advantages of the devices include:

- Extreme ease of installation. Every novice master will cope with this work.

- Low cost of the device, however, we mean the price of one heater, without additional equipment.

- Greater reliability compared with oil coolers. In addition, batteries with heating elements are repairable. If the equipment fails, it will be enough to replace the heater.

- Availability of additional options and functionality.

- Auto control option heating system, but this will require additional equipment.

We have listed the main advantages of radiator heating elements, consider their significant disadvantages. There are a lot of them. First of all, these are impressive operating costs, due to the high cost of electricity. They can be reduced if the control of the heating system is fully automated.

In this case, the heating elements will be included in the operation only after the room temperature has dropped to a certain minimum value. And turn off when it reaches a temperature defined as comfortable. Work in this mode is as economical as possible.

However, automation equipment will require financial investments. If we consider the purchase of a heating element complete with a radiator and with automation, the cost of such a set will be much more than the price of an electric convector or an oil radiator.

But at the same time, the latter are not inferior in terms of the level of comfort provided, and in some ways even surpass radiators with heating elements. For example, the latter require a stationary installation, whereas electric convectors and oil coolers are more mobile and compact.

In addition, like any other electric device, in the process of operation, the heating elements generate a magnetic field. Its danger to the body is not proven, as well as safety.Therefore, it is worth attributing the presence of such a field to the negative qualities of the devices, because they are mounted in radiators, that is, they are in close proximity to people.

In other heating systems powered by electricity, this drawback is somewhat leveled. For example, electric boilers are located in non-residential premises, where the presence of a person is short-lived.

One of the most significant drawbacks of radiator heating elements is their relatively low efficiency. If we compare it with the efficiency of traditional systems working with a liquid coolant, it will be significantly lower.

This is due to the fact that in the first case, the coolant moves at a fairly high speed. Thanks to this, the radiator warms up quickly and completely.

The functioning of the heating element is not able to provide such a high speed. As a result, the heating of the battery case will be uneven. At the bottom, the temperature will be much higher than at the top.

Considering that for safety reasons it should not be allowed to warm the battery above + 70ºС, this temperature will be present only in the lower part of the radiator, where the heater is located. Therefore, in order to prevent overheating of the equipment, it will be necessary to reduce its power by about a third.

Varieties of tube heaters for radiators

Despite the simplicity of the design, various variations of radiator heating elements can be found on sale. First of all, the power of heating devices varies. Models with a minimum power “give out” about 0.3 kW, with a maximum - 6 kW.

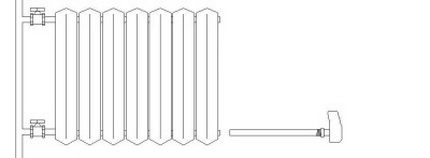

Devices differ in the execution of the case. Given that the configuration and location of the radiators can be different, there are heating elements with left or right-hand threads.

The diameter of the device may also vary. This is due to the cross-section of the plug of the radiator cap, in place of which the device is mounted. The standard size is 40 mm.

There is no fundamental difference between devices designed for installation in radiators of various materials. Their design is similar, only the diameter can differ. On sale you can find single and double heating elements.

The latter is more convenient to use. At the moment of switching on, both elements are activated immediately, due to which the heating medium is heated as quickly as possible. After that, one of the elements is turned off, which saves energy. Some models are equipped with additional functionality.

The manufacturer uses only two functions:

- Turbo heating. It makes it possible to maximize the increase in temperature in the room. A temperature controller is necessarily built into the device, which allows you to change the heating intensity.

- Antifreeze. This mode prevents possible defrosting of the entire system when the temperature drops to negative values. The heater automatically maintains the minimum allowable temperature, while consuming a small amount of electricity.

In addition, heaters for radiators differ in the length and presence or absence of a temperature regulator.

How not to make a mistake in choosing

Radiators for heating elements are quite simple to choose, because they do not imply a special variety of design and technical characteristics. Before buying, you should consider the following points.

Calculation of electric heating power

In order to correctly determine the required power of the device, it is desirable to know the heat engineering standards in force in a given area.As a last resort, you can use the average indicator, which can be used in the middle zone of Russia and make some amendments if necessary.

Based on this, for 10 square meters. meters of the heated area, provided that the heater will be used as the main heating, 1 kW of its power is required.

If the device will be used as additional heating, the required power will be 3-4 times lower. In addition, when choosing a device, the specifics of a radiator heater should be taken into account.

Due to its design features, it will be able to run smoothly only with 75% heat transfer of the radiator. With more power, the device will overheat, and it will constantly turn off.

Based on this, the power of the device is calculated. The exact values of the heat transfer of a radiator can be found in its technical documentation. However, on average, one section of an aluminum battery has a heat transfer of 180 watts, cast iron - 140 watts.

We calculate for example, which heater is suitable for a 10-section radiator. We multiply the data by 10 and we get that for an aluminum battery it is worth taking a heater with a capacity of up to 1.35 kW, for a cast-iron battery - up to 1 kW.

Instrument Design Features

For each radiator, it is necessary to select a heater that is suitable for it in size and direction of thread. The equipment has a different length of the rod, which may affect the efficiency of its work.

With an insufficient length of the heater, the equipment is not able to provide a sufficiently high circulation rate of the coolant, as a result of which the radiator heating will be uneven and insufficient.

The option is considered optimal when the TENA rod does not reach 60-100 mm to the inner wall of the opposite edge of the radiator. It is also important to choose the right shape of the case and the diameter of the device.

Different models may vary stub material. For the right choice, you should study the manufacturer's recommendations, where he describes the types of heating appliances suitable for use with a particular heater.

Automatic control

Devices with built-in automatic control or without it go on sale. The first variation is as convenient as possible and does not require the cost of acquiring additional equipment. In this case, a temperature regulator with a sensor that measures the temperature of the coolant is built into the lower part of the heater.

If there is no built-in automation, the appliance does not have a thermostat. In this case, it is advisable to connect using a detector that measures the temperature of the air in the room.

I must admit that this equipment is not so popular and in demand that large European companies are engaged in its production.

In stores you can find radiator heating elements made by Turkish, Polish and Ukrainian brands. In terms of quality and functionality, they are approximately similar.

It’s hard to say which company’s products should be preferred. But you need to be wary of Chinese TENs, since it is often possible to get a low-quality product.

Additional information on the choice of heating elements for heating is given in this article.

Features of the installation of radiator heating elements

Installing the device is quite simple. In order for the operation to proceed without any difficulties, you should also familiarize yourself with its configuration in the store. Ideally, along with the heater, all the elements and fasteners necessary for safe connection will be laid in a box.If any parts are missing, you need to immediately buy them.

Another important point: before starting installation, make sure that the system is free of water. For this reason, in multi-apartment buildings, it is optimal to carry out work in the summer, when the central heating is turned off.

Actually installation consists in dismantling the plug located at the bottom of the radiator, and then installing a heating device in its place. To make the joint airtight, a rubber gasket must be installed. It will not be superfluous to pre-treat the joint section with sealant.

The heater can be installed only in the lower part of the radiator, so that the fluid circulation can be carried out unhindered. The part is inserted horizontally into the battery, otherwise operation problems may occur.

To connect the heater is allowed to use ground outlet. It is advisable to install a voltage stabilizer in order to protect the device from power surges.

You can only turn on the device into the network after filling the radiator with liquid, otherwise the device will fail. The design with the heater is maintainable. If necessary, the device is easily removed and repaired, and often replaced with a new one.

Given the hardness of process water, experts recommend that the heater be cleaned of limescale regularly. To do this, the device is removed from the battery, and then cleaned.

You can use the mechanical method when the scum is carefully removed with sandpaper or a hard metal brush. This should be done very carefully, since the heating elements are very sensitive to mechanical damage and can fail.

In addition, you can use the chemical method. In this case, the device is treated with special substances. It is very important not to damage the rubber gasket.

Conclusions and useful video on the topic

The videos provide rational advice on the use and connection of radiators.

How to install a heater in a radiator yourself:

We offer an overview of the heater for a cast-iron radiator:

Heating element for aluminum radiator:

Radiator electric heaters are a good way to arrange additional heating for rooms of various purposes. They are relevant for cottages, garages and buildings that are used from time to time.

Such heating elements are rarely recommended as the main heating. Still, they consume a lot of electricity, so you can find another, less costly way to heat your home.

Are you looking for an effective appliance for organizing additional heating? Or is there experience using radiator heating elements? Please leave comments and ask questions about the topic. The communication unit is located below.

Thermostatic valve for a radiator: purpose, types, principle of operation + installation

Thermostatic valve for a radiator: purpose, types, principle of operation + installation  What heating batteries are best for an apartment: classification of radiators and their features

What heating batteries are best for an apartment: classification of radiators and their features  Wiring diagrams for radiators: an overview of the best ways

Wiring diagrams for radiators: an overview of the best ways  Water floor heating convectors: types, features of installation and arrangement

Water floor heating convectors: types, features of installation and arrangement  Heating registers: types of structures, calculation of parameters, installation features

Heating registers: types of structures, calculation of parameters, installation features  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I made such heating in the country, since there is no gas in the village and is not expected in the coming years, and it is troublesome to heat wood. In aluminum radiators I put TENy with temperature regulators. And, by and large, that's all, there are no problems.

He took aluminum radiators because they have better heat dissipation than cast-iron ones, and they look more modern. You do not need to paint them, just wipe them off with a damp cloth. During installation, you only need to select the heating elements correctly in terms of power and length, and install them carefully, electricity is all the same.

I took power with a margin so as not to freeze. I’ve been using it for the third year, I haven’t identified any problems yet, haven’t pulled out the heating elements and haven’t cleaned it, I think it’s done in two years. The only negative is electricity bills, more expensive than gas, but cheaper than wood. The plus is that you yourself can regulate the temperature, but with firewood this will not work.

Sergey, how much more expensive is gas heating and how much cheaper is firewood?

To be honest, the use of heating elements in a central heating system is an unreasonable waste of money. For a private house, I can still approve such a decision, but not for apartment buildings.

As for your question: it’s difficult to give exact numbers, since there is no data on the area of the house, local tariffs for electricity and so on. But I can immediately say that heating a private house with electricity will be more expensive than other options: gas, firewood, coal. But you can significantly reduce heating costs by means of electricity, if you coordinate the project of heating a house exclusively on this energy source. In addition, the use of a dual-zone day / night meter will further reduce heating costs.

Combined heating systems gas + heating elements in radiators or a solid fuel boiler + heating elements are unprofitable. In apartment buildings and even more so, since the water is heated from the entire heating system, moreover, its rigidity and impurities will not give a chance to the heater to work for more than one season.

If you connect to the solar battery, then another option. And steam-drop heating is better, either from solar collectors, or from a central power grid.

If this does not work, then in a pinch, collect a lithium battery and charge it at night at night, and switch to it during the day. Of course, there are plenty of energy carriers in Russia, but people want to enrich themselves on the sale. Therefore, it is necessary to switch to alternative sources.

Plus to build bunkers, it is warmer and cheaper in the land, at the dacha there is a foundation pit for the whole territory and 4 underground houses on 6 hundred parts, and so on. safety on the surface do not close build. Still closer to drill water from the hopper. Sow potatoes on top, build a house from a light steel profile. So a summer cottage next to Moscow or London for 4 owners can be cheaper.