One-pipe heating system Leningradka: schemes and organization principle

To heat a small living room or a two-story frequent house, it is not necessary to use complex expensive technologies. The Leningradka heating system, known since the times of the Soviet Union, is effectively used today to provide heat to small residential buildings.

It remains popular due to its simplicity of design and economical consumption of materials. Indeed, you must agree that it is more expensive and more complicated - it does not always mean better.

It is possible to equip a single-pipe “Leningradka” yourself. We will help you deal with the principle of the system, give the main technological schemes and describe step by step the technology for installing the heating system. Visual photo and video material will help to plan the implementation of the project.

The content of the article:

The principle of operation of the heating circuit “Leningradka”

The appearance of modern heating equipment, new technologies has allowed to improve the “Leningradka”, make it manageable and increase functionality.

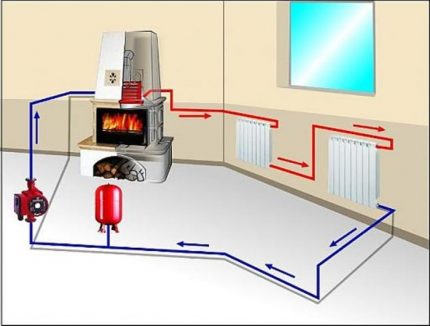

The classic “Leningradka” is a system of heating devices (radiators, converters, panels) connected by a single pipeline. The coolant circulates freely through this system - water or a mixture of antifreeze. The boiler acts as a heat source. Radiators are installed around the perimeter of the housing along the walls.

The heating system, depending on the location of the pipeline, is divided into two types:

- horizontal

- vertical.

The piping of the system can be located either below or above. The upper pipe arrangement is considered to be the most effective in terms of heat transfer, while the lower pipes are easier to install.

The lower connection of devices requires use of pump, because of which the economic priorities of the system are somewhat reduced. In the upper version, accurate calculation during the design period and the installation of the upper stage are necessary, which increases the length of the pipeline and the cost of its construction.

The circulation of the coolant can occur by force (using a circulation pump) or naturally. Also, the system can be closed or open type. We will describe the features of each type of system in the next section.

Named “Leningradka” single pipe heating system suitable for single-, two-story residential buildings of a small area, the optimal number of radiators is up to 5 pieces.

When using 6-7 batteries, it is necessary to carry out rigorous design calculations. If there are more than 8 radiators, the system may not be efficient enough, and its installation and refinement may be unreasonably expensive.

Overview of the main technological schemes

Each of the heating schemes of Leningrad has its own characteristics of practical implementation, advantages and disadvantages, which we will familiarize with below.

Features of horizontal schemes

In one-story private houses or rooms of a small area, Leningradka is usually installed according to the horizontal scheme. In the practical implementation of horizontal schemes, it should be borne in mind that all heating elements (batteries) are located on the same level, and their installation occurs along the walls around the perimeter of the premises to be equipped.

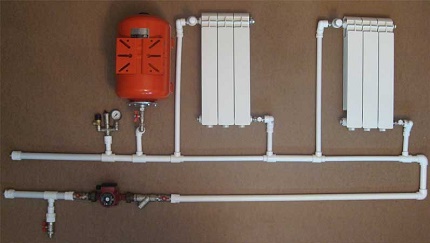

Consider the simplest classic horizontal open circuit with forced circulation.

The diagram shows that the system consists of:

- Heating boilerwhich is connected to the water supply system and to the sewer networks;

- Expansion tank with nozzle - thanks to the presence of this tank, the system is called open. A pipe is connected to it, from which excess water comes out when filling the circuit, and air, which can appear when the liquid boils in the boiler;

- Circulation pumpwhich is integrated in the return pipe. It provides water circulation along the circuit;

- Hot water piping and a coolant coolant discharge pipe;

- Radiators with installed Maevsky cranes, through which the air comes down;

- Filterthrough which water passes before entering the boiler;

- Two ball valves - when you open one of them, the system begins to fill with coolant-water up to the nozzle. The second is secret, with its help, water is drained from the system directly into the sewer.

The batteries in the diagram are connected by a pipeline from below, but you can organize a diagonal connection, which is considered more efficient in terms of heat transfer.

The above scheme has significant drawbacks. For example, if you need to repair or replace the radiator, you will have to completely turn off the heating system, drain the water, which is extremely undesirable in the heating season.

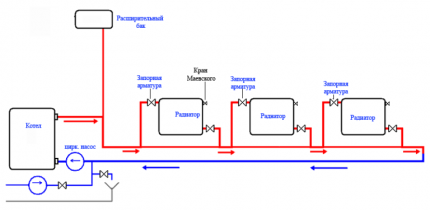

Also, the scheme does not provide the ability to regulate the heat transfer of the batteries, reduce the temperature in the premises or increase it. The advanced scheme below solves these problems.

Ball valves mounted on both sides of the battery have been introduced in order to be able to shut off the water supply to the radiator. To dismantle the battery for repair or replacement without discharging water from the system, ball valves can be shut off.

Thanks to the availability bypass Removing the battery can occur without shutting down the system - water will pass through the loop through the bottom pipe.

Bypasses also allow you to adjust the amount of coolant flow. If the needle valve is completely closed, the radiator receives and gives off the maximum amount of heat.

If you open the needle valve, part of the coolant will pass bypass, and the other part will pass through the ball valve. In this case, the volume of coolant entering the radiator will decrease.

Thus, by adjusting the level of the needle valve, you can control the temperature in a particular room.

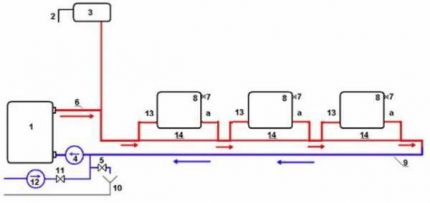

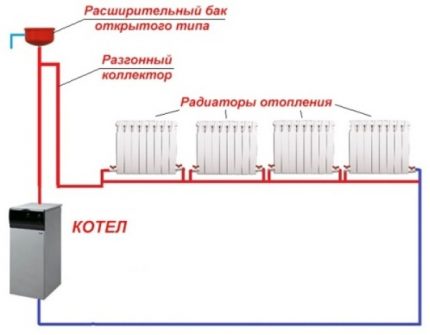

Consider a horizontal closed heating circuit with forced circulation.

Unlike an open circuit, closed system under pressure due to availability closed expansion tank. Also in the system there is a control panel.

It consists of a housing on which to install:

- Safety valve. It is selected based on the technical parameters of the boiler, namely, according to the maximum allowable pressure. If the temperature regulator breaks down, then excess water will come out through the valve, thereby reducing the pressure in the system.

- Air vent. The device removes excess air from the system. If the temperature control system fails, then when the liquid boils, excess air will appear in the boiler, which will automatically exit through the air vent;

- Pressure gauge. A device that allows you to control and change the pressure in the system. Usually the optimal pressure is 1.5 atmospheres, but the indicator may be different - usually it depends on the parameters of the boiler.

A closed system is considered the most modern solution due to the automation of some processes.

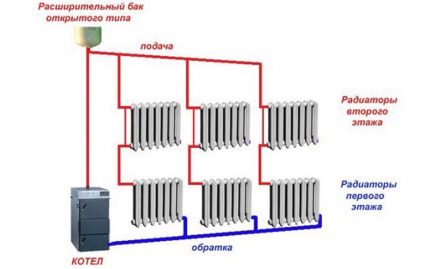

Application of vertical schemes

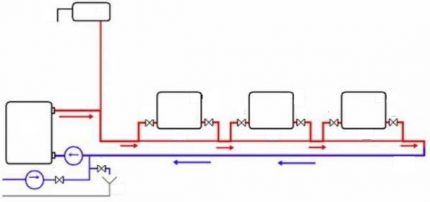

Vertical layouts of the Leningradka installation are used in two-story houses of a small area. By analogy, they can be open or closed type, represented by circuits with forced circulation and with gravity.

Systems with a circulation pump we have given above. Consider a vertical circuit with natural circulation of a closed type.

Implementing a circuit with natural circulation is quite difficult. Here the pipeline is mounted in the upper part of the wall at a certain angle in the direction of water movement. The coolant flows from the boiler to the expansion tank, from where it moves under pressure through pipes and radiators.

For efficient operation of the system, the boiler must be located below the radiator installation level.

The scheme may also provide for the possibility of removing radiator batteries without stopping the heating system by installing bypasses with needle valves and ball valves on the pipeline.

Comparison of gravity and pumping systems

It is believed that the organization of a gravity heating system allows you to save on a circulation pump.

In order to organize the natural movement of the coolant along the circuit, it is necessary to correctly calculate the inclination angles, diameter and length of the pipes, which is not easy to do. Moreover, a self-flowing system is capable of smoothly and efficiently working exclusively in small single-storey rooms; in other houses, its operation can cause a number of problems.

Another drawback of gravity flow is that its organization requires pipes with a diameter greater than when constructing forced heating circuits. They are more expensive and spoil the interior.

The basement for the boiler should be equipped in the room, since the heat source should be located below the level of radiators. Also, for the organization of gravity, you will need a well-equipped and insulated attic, on which an expansion tank will be mounted.

The problem of any gravity flow in a two-story house is that on the second floor the batteries heat more than on the first. The installation of balancing cranes and bypasses will help to partially solve this problem, but not significantly.

Moreover, the introduction of additional equipment leads to a rise in price of the system itself, and its operation may remain unstable.

The most rational solution to the problem of the difference in temperature of the coolant leaving the boiler and reaching distant appliances on the ground floor is to install radiators with an increased number of sections.

An increase in the heat transfer area in this way allows you to practically level the characteristics of heating on different tiers of the system.

The self-flowing “Leningradka” is not suitable for attic-type houses, because it is only possible to position a pipe in a house with a full roof. Also, the system should not be implemented if people live in a house unstable.

The specifics of the installation of the heating system

The one-pipe system “Leningradka” is complicated in calculations and execution. For its introduction into the house as an effective heating system, you must first make thorough professional calculations.

The main elements of the Leningradka system:

- boiler;

- pipeline metal or polypropylene (but not metal-plastic);

- sections of radiators;

- expansion tank (for a closed system) or a tank with a valve (for an open);

- tees.

May also need circulation pump (for systems with forced coolant movement).

To improve the capabilities of the system use:

- Ball Valves (2 ball valves per one radiator);

- bypass with needle valve.

It should be noted that the main line of the system can be sharpened in the plane of the wall or located on top of this plane. If the pipe is in a wall, ceiling or floor, it is important to ensure its thermal insulation with any material. Thus, the heat transfer of the pipes is improved, and a decrease in temperature in the last radiators will be minimal.

If the trunk is installed in the plane of the floor, then the installation of the flooring itself is carried out above the pipe. If the pipeline is laid over the floor, this will allow in the future to make some changes in the construction of the system.

The feed pipe and the return line of circuits with natural coolant movement are usually mounted at an angle of 2 - 3 mm per linear meter in the direction of movement of water or other coolant in the system. Heating elements are installed on the same level. In circuits with artificial circulation in the observance of the bias is not necessary.

Preliminary work of the premises

If the pipeline is hidden in building structures, then before installation of the system they make strobes around the perimeter in the places where the pipes will be located.

When gating, microcracks form in the wall, through channels appear both outside and inside. This is fraught with the ingress of cold street air and the formation of unwanted condensation on the pipe. As a result, heat losses of radiators and gas overruns increase.

Therefore, during the installation of the trunk in the wall, floor or under the ceiling, it is important to insulate the pipe with any heat-insulating material.

The choice of radiators and pipes

Polypropylene pipes are easy to install, but not suitable for homes located in the Northern regions. Polypropylene melts at a temperature of + 95 ° C, therefore, the probability of a pipe rupture increases with a maximum heat transfer from the boiler.

It is advisable to use exclusively metal pipes, although their installation is accompanied by difficulties.

When choosing a pipe diameter, the number of radiators must be considered. A trunk with a diameter of 25 mm and a bypass of 20 mm are suitable for 4-5 batteries. For a circuit consisting of 6-8 radiators, a 32 mm line and a 25 mm bypass are used.

If the system involves gravity, it is necessary to choose a highway of 40 mm and above. The more radiators are involved in the system, the larger the diameter of the pipes should be, otherwise it will later be difficult to balance.

The number of sections of radiators is also important to correctly calculate. The coolant, getting into the first radiator battery, has the highest efficiency. In it, water is cooled by at least 20 degrees. As a result, at the outlet, water with a temperature of 50 degrees is mixed with a substance with a temperature of +70 degrees.

As a result, the coolant with a lower temperature will get into the second radiator. Passing through each battery, the temperature of the medium will drop lower and lower.

To compensate for heat loss, to provide the necessary heat transfer of each battery, it is necessary to increase the number of sections of radiators. For the first radiator, 100% of the power must be taken into account, for the second - 110%, for the third - 120%, etc.

Connection of heating elements and pipes

Bypass is built into the existing highway, manufactured separately with bends. The distance between the taps is taken into account with an error of 2 mm, so that the radiator fits during the welding of angle valves with an American.

The allowable clearance for pulling up an American is usually 1-2 mm. If you exceed this distance, it will go downhill and flow. To get the exact dimensions, you need to turn the angle valves in the radiator, measure the distance between the centers of the couplings.

Tees are welded or connected to the taps, one hole is allotted for bypass. The second tee is taken by measurement - the distance between the central axes of the branches is measured, taking into account the size of the bypass fit on the tee.

Welding

When welding, if the pipes are metal, it is important to avoid internal influx. If half the diameter in the pipe is closed, then the coolant under pressure will prefer to go along a more spacious line. As a result, radiators may not receive enough heat.

When welding the bypass and the main pipe, it is necessary to determine in advance which end should be welded first, since there are situations when, by welding one edge, it is impossible to insert a soldering iron between the pipe and the tee.

After all the elements are ready, the radiators are hung using angle valves and combined couplings, laid in a bypass with taps, measure the length of the taps, cut off the excess, remove the combined couplings and weld to the taps.

Final moments of work

Before starting the system from the pipeline and radiators, it is necessary to remove the air using Maevsky cranes.

Also, after starting and checking all the nodes and connections, it is important to balance the system - equalize the temperature in all radiators by adjusting the needle valve.

In vertical schemes, water is supplied from above along risers.The expansion tank should be located above the level of the radiators, and the pipe is usually mounted in the wall. It is also important to implement a forced circulation device in the system.

Advantages and disadvantages of the system

The main advantages of Leningradka are ease of installation, high efficiency, savings on consumables, installation (a strob is formed for one pipe or not at all if an open installation type is selected).

Thanks to the introduction of bypasses, ball valves, control panels, it became possible to regulate the temperature in rooms without lowering the heat level in other rooms; to replace, repair radiators without stopping the system.

The main disadvantage of the system is the complexity of the calculations, the need for balancing, which often translates into additional costs - installation of additional equipment, repair work, etc.

Conclusions and useful video on the topic

Cognitive video about the implementation schemes of the Leningradka system:

Called the “Leningradka” heating system is a budget efficient solution for heating houses of a small area.

There is something to supplement the above material or questions have arisen on the topic - please leave comments on the publication, share your personal experience in arranging Leningradka. The contact form is located in the lower block.

One-pipe heating system of a private house: schemes + an overview of the advantages and disadvantages

One-pipe heating system of a private house: schemes + an overview of the advantages and disadvantages  How are heating systems with pump circulation arranged: organization schemes

How are heating systems with pump circulation arranged: organization schemes  Natural circulation heating system: common water circuit designs

Natural circulation heating system: common water circuit designs  How the radial heating system works: schemes and wiring options

How the radial heating system works: schemes and wiring options  Open heating system: schematic diagrams and features of the arrangement

Open heating system: schematic diagrams and features of the arrangement  Collector heating system: wiring diagrams for private houses and apartments

Collector heating system: wiring diagrams for private houses and apartments  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Due to the simplicity of installation and the relative cheapness compared to other heating systems in the country, I decided to put “Leningradka.” I have a small cottage, one-story, even in winter we come there for the whole weekend, because such a heating system suited me perfectly. The only inconvenient moment is that you can’t leave the cottage for a long time without supervision.

I would not even advise a single tube for a country house. If you delve into the question, then most of its advantages are lost during operation. And now I will tell you why. It is not possible to adjust the flow temperature to the radiator. If the extreme device enters the room from the windward side, in winter there, no matter how gray, it’s still a cudgel. Yes, I do not argue, you can additionally embed a balancing valve. You can install thermostats. But then that simplicity and cheapness is lost, because of which this system is most often chosen.

Vladislav clever, he thinks in systems!

The scheme is so-so ... done, now we are suffering - out of 5 batteries, 3 do not heat. Those near the boiler warm, but the 3 far ones do not heat. Water chases through the pipe, but does not go into the batteries. If only it would be possible to redo it before the cold, so that the pipe was one that immediately entered the battery and exited from the other end of the battery. And then the gas is burned for nothing, and the batteries are cold.

The scheme is frankly bad, to put it mildly ... Water is easier to chase in a circle - the law of conservation of energy on the face. If you knew right away, they would have done a double-circuit with the upper and lower pipes.

Why do I need a two-pipe system if I have 4 radiators. The first in the inner small room, then two radiators in the hall and the last in the corridor. Thermostatic heads control the temperature in the first and corridor radiators, that is, to heat two radiators in the same room. Do I need a two-pipe system?

So no one offers you to mount a two-pipe heating system for four radiators. In this case, there are more costs, but not so much practical benefit.

The article also deals exclusively with a single-pipe heating system. In particular, for four radiators “Leningradka” is the best option. For six radiators, it is already debatable, since at the temperature of the first radiator at 80 ° C, the extreme radiator in the system will warm up to only 45 ° C. What is the temperature ratio between the first and last radiators you have? Predictably 80 ° C / 45 ° C.

It is still very important to consider what distance between radiators, if the room is stretched, then a single-tube system may not be practical.

If without forced circulation, it is better to do a two-pipe. And it works more stable and as a result is cheaper.