Natural circulation heating system: common water circuit designs

The construction of an autonomous gravity-type heating network is chosen if it is impractical, and sometimes impossible, to install a circulation pump or to connect to a centralized power supply.

Such a system is cheaper to install and completely independent of electricity. However, its performance largely depends on the accuracy of the design.

In order for the heating system with natural circulation to function smoothly, it is necessary to calculate its parameters, correctly install the components and reasonably choose the water circuit. We will help in resolving these issues.

We described the main principles of the gravitational system, gave advice on choosing a pipeline, outlined the rules for assembling the circuit and placing work nodes. We paid special attention to the design and functioning of one- and two-pipe heating circuits.

The content of the article:

Principles of the Natural Circulation Process

The process of water movement in the heating circuit without the use of a circulation pump occurs due to natural physical laws.

Understanding the nature of these processes will allow you to competently to design a heating system for typical and non-standard cases.

The maximum difference in hydrostatic pressure

The main physical property of any coolant (water or antifreeze), which contributes to its movement along the circuit during natural circulation, is a decrease in density with increasing temperature.

The density of hot water is less than cold and therefore there is a difference in the hydrostatic pressure of the warm and cold liquid column. Cold water flowing down to the heat exchanger displaces hot water up the pipe.

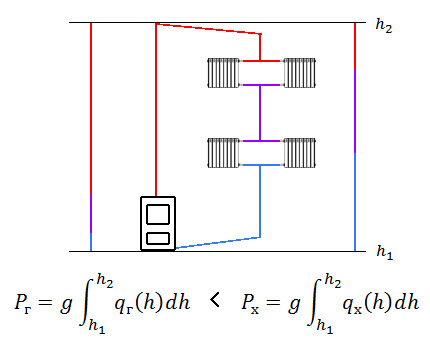

The heating circuit of the house can be divided into several fragments. Water is directed upward along “hot” fragments, and downward along “cold” fragments. The boundaries of the fragments are the upper and lower points of the heating system.

The main challenge in modeling natural circulation systemswater is to achieve the maximum possible difference between the pressure of the liquid column in the “hot” and “cold” fragments.

The element of the water circuit, which is classic for natural circulation, is the acceleration collector (main riser) - a vertical pipe directed upward from the heat exchanger.

The acceleration collector must have a maximum temperature, so it is insulated over its entire length. Although, if the height of the collector is not large (as for single-story houses), then you can not conduct insulation, since the water in it will not have time to cool.

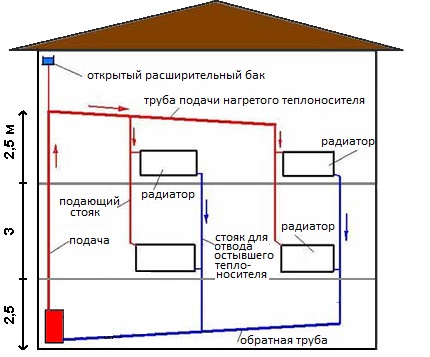

Typically, the system is designed so that the top point of the acceleration collector coincides with the top point of the entire circuit. They set the exit to open tank expander or a vent valve if a membrane tank is used.

Then the length of the “hot” fragment of the circuit is the minimum possible, which leads to a decrease in heat loss in this area.

It is also desirable that the “hot” fragment of the circuit is not combined with a long section transporting the cooled coolant. Ideally, the lower point of the water circuit coincides with the lower point of the heat exchanger placed in the heating device.

For the “cold” segment of the water circuit also has its own rules that increase the pressure of the liquid:

- the more heat loss in the “cold” section of the heating network, the lower the temperature of the water and the greater its density, therefore the functioning of systems with natural circulation is possible only with significant heat transfer;

- the greater the distance from the bottom of the circuit to the radiator connection, the larger the section of water column with a minimum temperature and maximum density.

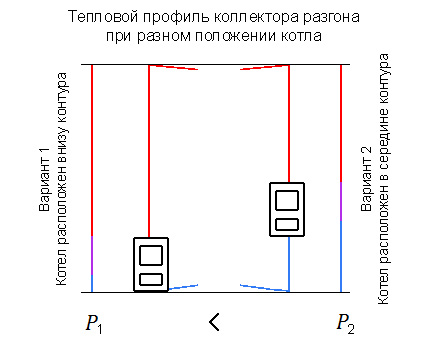

To ensure compliance with the latter rule, often a stove or boiler is installed at the lowest point of the house, for example, in the basement. This arrangement of the boiler provides the maximum possible distance between the lower level of the radiators and the point of entry of water into the heat exchanger.

However, the height between the lower and upper points of the water circuit during natural circulation should not be too large (in practice, no more than 10 meters). An oven or boiler, only the heat exchanger and the lower part of the acceleration collector are heated.

If this fragment is insignificant relative to the entire height of the water circuit, then the pressure drop in the “hot” fragment of the circuit will be insignificant and the circulation process will not start.

Minimization of resistance to movement of water

When designing a system with natural circulation, it is necessary to take into account the velocity of the coolant along the circuit.

Firstlythe faster the speed, the faster the heat transfer through the system “boiler - heat exchanger - water circuit - heating radiators - room".

Secondlythe faster the fluid’s speed through the heat exchanger, the less likely it will boil, which is especially important when heating stoves.

In systems forced circulation heating water speed mainly depends on the parameters circulation pump.

With water heating with natural circulation, the speed depends on the following factors:

- pressure differences between fragments of the contour at its lower point;

- hydrodynamic resistance heating system.

Ways to ensure maximum pressure differences have been discussed above. The hydrodynamic resistance of a real system cannot be accurately calculated due to a complex mathematical model and a large number of input data, the accuracy of which is difficult to guarantee.

Nevertheless, there are general rules, compliance with which will reduce the resistance of the heating circuit.

The main reasons for reducing the speed of water movement are the resistance of the pipe walls and the presence of narrowing due to the presence of fittings or valves. At a low flow rate, the wall resistance is practically absent.

The exception is long and thin pipes, characteristic for heating with warm floor. As a rule, separate circuits with forced circulation are distinguished for it.

When choosing the types of pipes for a circuit with natural circulation, it is necessary to take into account the presence of technical restrictions when installing the system. therefore plastic pipes it is undesirable to use during natural circulation of water due to the connection of their fittings with a significantly smaller inner diameter.

Rules for the selection and installation of pipes

The choice between steel or polypropylene pipes with any circulation, it takes place according to the criterion of the possibility of their use for hot water, as well as from the standpoint of price, ease of installation and lifetime.

The riser is mounted from a metal pipe, since the highest temperature water passes through it, and in the case of furnace heating or a heat exchanger malfunction, the option of passing steam is possible.

With natural circulation, it is necessary to use a slightly larger pipe diameter than in the case of a circulation pump. Usually, for heating rooms up to 200 square meters. m, the diameter of the acceleration collector and the pipe at the inlet of the return to the heat exchanger is 2 inches.

This is caused by a lower water speed compared to the forced circulation option, which leads to the following problems:

- reduced heat transfer per unit of time from the source to the heated room;

- clogging or air congestion, which can not cope with a small pressure.

Particular attention when using natural circulation with a lower supply circuit must be given to the problem of removing air from the system. It cannot be completely removed from the coolant through an expansion tank, as boiling water first enters the devices on a highway located lower than themselves.

When forced circulation, the water pressure drives the air to the air collector installed at the highest point of the system - a device with automatic, manual or semi-automatic control. Via Mayevsky cranes Basically, heat transfer is adjusted.

In gravity heating networks with a feed located below the appliances, Mayevsky taps are used directly for bleeding air.

Air can also be vented using air vents installed on each riser or on an overhead line running parallel to the system highways. Due to the impressive number of air exhaust devices, gravity circuits with lower wiring are extremely rare.

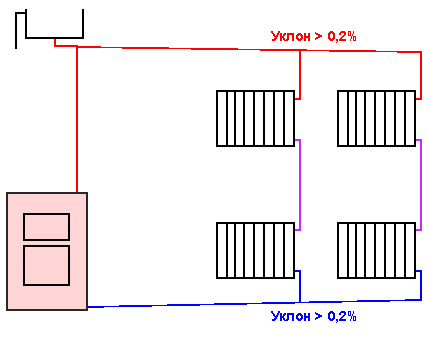

With low pressure, a small air plug can completely stop the heating system. So, according to SNiP 41-01-2003, it is not allowed to lay heating system pipelines without slope at a water velocity of less than 0.25 m / s.

With natural circulation, such speeds are unattainable. Therefore, in addition to increasing the diameter of the pipes, constant slopes must be observed to remove air from the heating system. The slope is designed at the rate of 2–3 mm per 1 meter, in apartment networks the slope reaches 5 mm per linear meter of the horizontal line.

The feed slope is made in the direction of movement of the water so that the air moves to the expander tank or the air bleeding system located at the top point of the circuit. Although you can make a counter-bias, but in this case, you must additionally set vent valve.

The slope of the return line is made, as a rule, in the direction of the movement of chilled water. Then the bottom point of the circuit will coincide with the inlet of the return pipe to the heat generator.

At installing a warm floor a small area in the circuit with natural circulation, it is necessary to prevent air from entering the narrow and horizontal pipes of this heating system. It is necessary to place the air removal device in front of the warm floor.

One-pipe and two-pipe heating schemes

When developing a heating scheme for a house with natural water circulation, it is possible to design both one or several separate circuits. They can differ significantly from each other. Regardless of the length, number of radiators and other parameters, they are performed according to a one-pipe or two-pipe scheme.

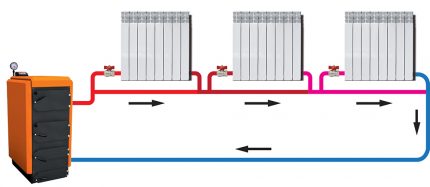

Single line circuit

A heating system using the same pipe for a sequential supply of water to radiators is called a single pipe. The simplest single-tube option is heating with metal pipes without the use of radiators.

This is the cheapest and least problematic way to solve home heating when choosing in favor of the natural circulation of the coolant. The only significant minus is the appearance of bulky pipes.

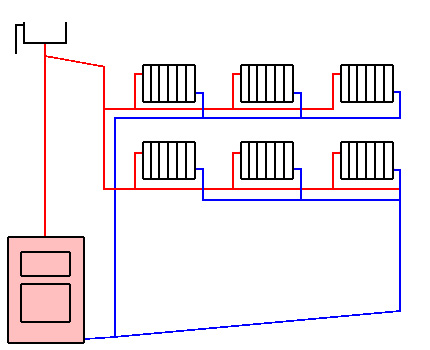

At the most economical single tube version with heating radiators, hot water flows sequentially through each device. Here you need a minimum number of pipes and valves.

As you progress coolant cools down, so subsequent radiators get colder water, which must be taken into account when calculating the number of sections.

The most effective way to connect heating appliances to a one-pipe network is the diagonal option.

According to this scheme of heating circuits with a natural type of circulation, hot water enters the radiator from above, after cooling it is discharged through the pipe located below. When passing in this way, heated water gives off the maximum amount of heat.

With a lower connection to the battery, both the input pipe and the output pipe, the heat transfer is significantly reduced, because the heated coolant must go as long as possible. Due to significant cooling, batteries with a large number of sections are not used in such schemes.

Heating circuits with a similar connection of radiators are called “Leningradka“. Despite the noted heat losses, they are preferred in the arrangement of apartment heating systems, which is due to the more aesthetic appearance of the pipeline.

A significant drawback of single-pipe networks is the inability to turn off one of the heating sections without stopping the circulation of water throughout the circuit.

Therefore, usually apply the modernization of the classical scheme with the installation of “bypass”To bypass the radiator using a branch with two ball valves or a three-way valve. This allows you to adjust the water supply to the radiator, up to its complete shutdown.

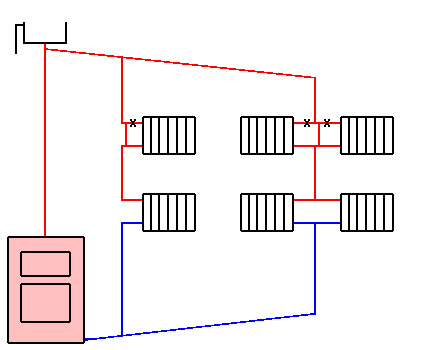

For two or more storey buildings, versions of the one-pipe scheme with vertical risers are used. In this case, the distribution of hot water is more uniform than with horizontal risers. In addition, the vertical risers are less extended and fit better into the interior of the house.

Return pipe option

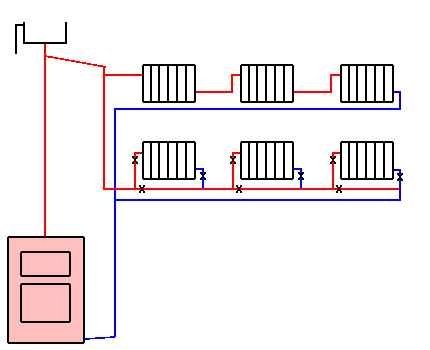

When one pipe is used to supply hot water to radiators, and the second to drain chilled to a boiler or furnace, this heating scheme is called a two-pipe. A similar system in the presence of heating radiators is used more often than a one-pipe one.

It is more expensive, since it requires the installation of an additional pipe, but has a number of significant advantages:

- more uniform temperature distribution heat carrier supplied to radiators;

- easier to do the calculation the dependence of the parameters of radiators on the area of the heated room and the required temperature values;

- more efficient heat control to each radiator.

Depending on the direction of movement of the chilled water, relatively hot, double pipe systems subdivided into passing and deadlocks. In associated circuits, the movement of chilled water occurs in the same direction as hot, therefore the cycle length for the entire circuit coincides.

In dead-end schemes, chilled water moves towards hot, therefore, for different radiators, the lengths of the coolant revolution cycles are different. Since the speed in the system is small, the heating time can differ significantly. Those radiators in which the cycle length of the water cycle is shorter will be heated faster.

There are two types of location of the eyeliner relative to the heating radiators: upper and lower. With the upper connection, the hot water supply pipe is located above the radiators, and with the lower connection it is lower.

With the bottom connection, air can be removed through radiators and there is no need to hold pipes on top, which is good from the perspective of the design of the room.

However, without an acceleration collector, the pressure drop will be much less than when using the upper supply. Therefore, the bottom eyeliner is practically not used when heating the premises by the principle of natural circulation.

Conclusions and useful video on the topic

Organization of a single-tube scheme based on an electric boiler for a small house:

The work of a two-pipe system for a one-story wooden house based on a solid fuel boiler of long burning:

The use of natural circulation during the movement of water in the heating circuit requires accurate calculations and technically competent installation work. Under these conditions, the heating system will heat the rooms of a private house and relieve the owners of the noise of the pump and dependence on electricity.

If you have any questions on the topic or have a desire to share personal experience in organizing and operating a gravity-type heating system, please leave comments on this article. The feedback box is located below.

Compulsory circulation water heating system: schemes, implementation options, technical details

Compulsory circulation water heating system: schemes, implementation options, technical details  How are heating systems with pump circulation arranged: organization schemes

How are heating systems with pump circulation arranged: organization schemes  Open heating system: schematic diagrams and features of the arrangement

Open heating system: schematic diagrams and features of the arrangement  One-pipe heating system Leningradka: schemes and organization principle

One-pipe heating system Leningradka: schemes and organization principle  One-pipe heating system of a private house: schemes + an overview of the advantages and disadvantages

One-pipe heating system of a private house: schemes + an overview of the advantages and disadvantages  How the radial heating system works: schemes and wiring options

How the radial heating system works: schemes and wiring options  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Heating systems with natural circulation are used, as a rule, in private houses, so which type to choose, single-pipe or with a return (two-pipe), is determined by the project budget. Moreover, with a small area and rational arrangement of rooms, you can calculate the layout of the batteries in such a way that the effect of cooling the coolant in each will be insignificant. In terms of the complexity of the construction, a one-pipe system is preferable, plus it is also cheaper.

I decide on the heating project in my private house. I can’t decide which type is still better to choose: one-pipe or two-pipe? On the one hand, the first method is less expensive. You can save money on materials, but on the other hand, it has its drawbacks. For example, it is impossible to regulate the heating temperature; the coolant is colder in rooms farthest from the boiler. For example, with a two-pipe system, if it became hot in the bedroom, a valve was screwed to lower the temperature. And in a house with one-pipe heating, after that, the other rooms will also cool down.

Hello. There will be nothing to cool if you install bypasses with thermostats. AT this article details about the bypass in the heating system. However, a two-pipe heating system is still more preferable, albeit financially expensive.

Hello. Tell me please. A wood-burning stove, a battery with a small heat exchanger (1.3 l), next to a 200 l barrel for watering the greenhouse. At what height should it be set so that the water circulates?

I express my gratitude to the authors for the accessible presentation of technical information. Accessible to people without special technical education. Without a lot of formulas and terms.

Thank you for the competent presentation.

Thank you very much for the information. I got acquainted for my own reassurance, if there are any errors I will correct. But so, in principle, a diagram was drawn in my head, I hope it will work as it should.

Good afternoon. With a two-pipe system with the accompanying movement of the coolant, all the same, on the first floor, I would like to carry out the lower connection to the radiators, by conducting a supply pipe in the basement of the house. Can you tell me the features of the connection. What is the maximum allowable height for the radiator from the basement? At what point (in the basement or higher) is it best to connect the mains to the riser? The boiler is located in the basement at the lowest point. And is it permissible on a hot riser not vertical sections? Thank.

Let's try to help in solving your question, as far as I can imagine visually everything that you described. For an illustrative example, I’ll immediately attach a general scheme according to which you can navigate how the future wiring will go. In this case, with the installation of an expansion tank in the attic.

I would recommend doing it through the upper eyeliner to the radiators, so it will be more practical, the diagram shows everything quite clearly. I don’t think you have a very high basement so that you can talk about any restrictions on the height of the eyeliner.

It is best to connect the trunk to the riser in the basement for a number of reasons. Firstly, in the house such a unit will be striking, and in which case repairs are difficult to do. In the basement is a technical room where you can carry out any repair work.

From the expansion tank, it is necessary to throw the pipe into the return so that it warms up, otherwise it will always be cold.