Warm water floor in a private house: diagrams, device rules + installation instruction

A well-functioning heating system is the key to a comfortable stay in the house without regard to weather conditions. Along with traditional radiator technology, heating circuit devices actively use a warm water floor system. Its installation is laborious and financially expensive, but this option of heating fully pays off in 5 years.

To save money, many equip a warm water floor in a private house on their own. Agree, the idea of obtaining efficient heating with minimal investment is very attractive, isn't it? However, its implementation requires the contractor certain knowledge and skills.

We offer for consideration a detailed material on the arrangement of water heated floors. The article outlines the design rules, provides tips on choosing the components of the system, and also describes the step-by-step progress on the installation, connection and start-up of the water circuit.

The content of the article:

Installation conditions for the water floor

The device of an additional heating circuit is recommended to be included in the project before the start of construction - it is easier to make calculations.

In a finished new house or building where the radiator system has been operating for a long time, installation of a water floor is also possible, but under certain conditions.

If the desire to insulate the floor arose after the construction of the house, it should be determined whether the building is suitable for this.One of the main conditions is pre-made insulation of the house, since heat loss above 100 W / m² will make floor installation useless.

Pay attention to the height of the ceilings: the mounting “cake” with pipes takes about 15 cm, or even more, of the total height of the room. After the introduction of the system, the dimensions of the doorways must be preserved, the height of 210 cm or more.

If the house is new, then before the start of installation it is necessary to completely complete the construction - to erect walls and a ceiling, insert windows, and plaster.

Design and assembly rules

The decision to choose a water floor, and not requiring a rigorous installation of an electrical analogue, is optimal for heating systems on gas boilers.

Such schemes are recognized as the least energy-consuming, most efficient and inexpensive to operate. Solid fuel boiler options are also acceptable.

Flawless operation of the system is possible only under two conditions: professionally executed design calculations and properly completed installation.

Therefore, the first steps on the way to the installation of a water heated floor in the country or in a private house are the analysis of the structure, the choice of materials, the preparation of the project.

The nuances of the device underfloor heating

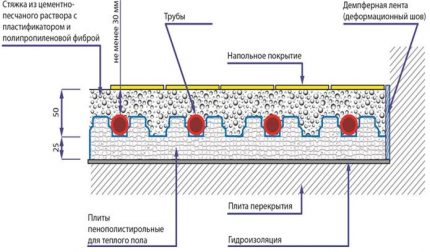

The construction of a water floor is complex and simple at the same time. It is multicomponent in composition, so the main thing is to observe the stacking order of all layers.

Each element of the "pie" has a special function. The basis for the construction is soil or concrete slab. A thin film (but not less than 0.1 mm thick) is laid on it - ordinary polyethylene or a more expensive analogue.

Then cover the floor with insulating material. One of the best options is extruded polystyrene foam - durable, relatively inexpensive, with low thermal conductivity.

Minimum Requirements:

- density - from 40 kg / m³;

- thickness - from 300 mm.

The main layer is cement castinginside of which pipes with coolant will be located. Plasticizers are added to the solution to make it more mobile and convenient for styling.

For strength, the screed is reinforced with a reinforcing mesh with a cell of 50 * 50 mm or larger 100 * 100 mm and a core thickness of 3-5 mm.

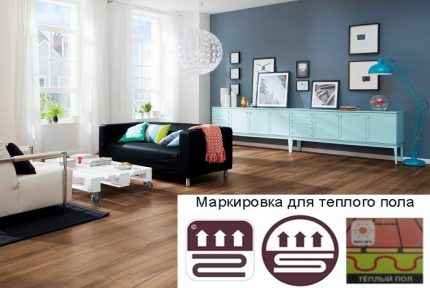

The thermal regime will depend on the choice of finish coating, which can be adjusted automatically or manually by means of mixing units - collectors.

What laying principles to adhere to?

First required make calculations. This is a separate and complex topic, however, for independent quick calculations, you can use the online calculator, scoring individual parameters in the necessary columns.

If a construction company is engaged in underfloor heating, then the settlement operations are carried out by its specialists.

As a calculation basis, standard verified numbers are taken, which must be adhered to regardless of the installation method and specific installation conditions.

Typically, PEX pipes are used for installation, which cannot be laid closer than 10-15 cm from each other, since there is a high risk of creases. If the thermal load on the floor is small, for example, many people like to relax in cool bedrooms, then a layout step of up to 60 cm is allowed.

Some more useful tips:

- one circuit is not divided into two rooms;

- for a room of 35-40 m², 1 circuit is not enough, at least 2;

- one side of the circuit - no more than 8 m;

- Damper tape compensates for deformation during thermal expansion.

There are exceptions. For example, if the toilet and the bathroom are small in size and are located next door, then only one water circuit is enough to heat them.

Installation methods for water circuits

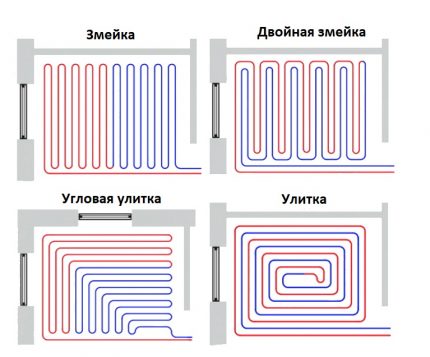

The most effective types of pipe installation — the “snail” and the “snake” —were invented long ago, so there is no need to experiment with the arrangement of circuits.

«Snake"- the easiest option to implement. Its minus is a large difference in the temperature of the coolant at the inlet / outlet. Keep in mind that the second half of the circuit will give off less heat.

«Snail»Evenly distributes heat throughout the room, but it is more difficult to perform. If the owners do not want to divide the room into warm and cool zones, then it is better to use this method.

To save pipes and improve energy efficiency, a combination of two options is often used: a “snail” is placed in the center, and a “snake” is placed along the walls. If you correctly position the hinges and calculate the installation step, then the floor temperature will be as comfortable as possible for residents.

Properly choose materials

Warm water floors are poured with screed, which means that they are planned to be used not for years, but for decades.

Given the long period of use, the choice of materials should be approached responsibly: eliminate cheap and illiquid products, select high-quality pipes, insulation, fasteners with a maximum service life.

No. 1 - we select the best option for pipes

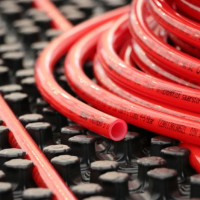

Now two types of pipes are used - PE-X and PERT, both made of cross-linked polyethylene. The advantage of PE-Xa products is that they have a memory effect due to their 85% crosslink density.

A useful effect is that the pipes stretched by a heat carrier with a high temperature or deformed pipes always return to their original position.

The use of PERT pipes is justified if there are integral sections in the screed and the fittings are installed only for fastening to the collector.

Experienced builders do not recommend the use of composite pipes with aluminum foil - there is always a risk of peeling of the metallized layer. If maximum reliability and isolation are needed, then it is better to use products with reinforcement made of polyvinylethylene located inside the products.

Construction companies usually work with trusted manufacturers who are responsible for the performance of their products. Well-established products of promoted brands Rehau and Valtecas well as lesser known Tece, Kan, Uponor.

Read more about the choice of pipes for laying a water floor heating in this article.

No. 2 - determined with a heater

The main purpose of the insulation is to separate the screed with pipes from the base, so that the heat transfer is carried up, and not go to the ground in vain. A heat-insulating layer is required, without it, installing a warm floor loses its meaning.

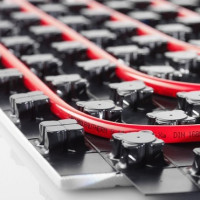

Now apply two kind of substrate, since the rest are losing to them in all respects. These are extruded polystyrene foam in the form of plates and profile mats made of polystyrene foam with mounting protrusions.

EPPS plates are convenient for installation and have standard sizes: 600 * 1250 mm, 500 * 1000 mm. Thickness - from 20 to 100 mm, its choice depends on the required degree of insulation. Thanks to the fixing side grooves, there are no gaps at the joints of adjacent plates.

How to determine the required thickness of the insulation? It all depends on the installation conditions in a particular private house: 10 cm slabs are laid on the ground, 5 cm is enough above the basement or basement, and if there is a heated room below, then 3 cm heat insulation is enough.

For fixing plates to the floor, dish-shaped dowels are used, and for fixing pipes - harpoon-clips. The distance between adjacent brackets is from 30 cm to half a meter, in places of pipe turns - 10 cm.

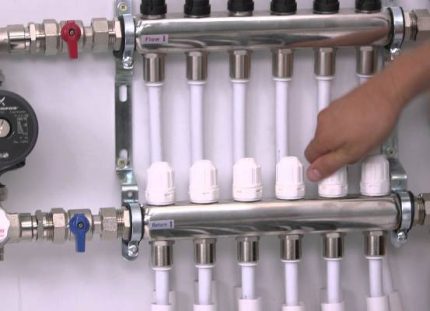

No. 3 - we buy accessories for a collector

The center of distribution of the heat carrier and the control point for the functioning of the warm floor collector-mixing unit. With its help, hot water is sent from the highway to separate circuits, they monitor the flow of coolant, regulate the temperature.

Assembled collectors are not sold, as each system has its own characteristics. It is better to entrust the purchase of components to specialists, and for independent purchase you should remember about all the necessary elements:

The installation location often depends on the nuances of service: one is more convenient to adjust the ECP in the boiler room, together with the boiler, the other from the corridor. Theoretically, a manifold cabinet can be installed in any room of the house, but it is desirable that the length of all the circuits is approximately the same.

TVP Installation Guide

Before laying the construction of the warm floor, preparatory work should be done: purchase components, designate the installation location of the cabinet, and hollow holes in the walls for communications. Then you can proceed to the first stage.

Step # 1 - Subfloor Installation

If it is planned to equip a heated floor directly on the ground, it is recommended to choose one option from two:

- make a “rough” screed from cement pouring;

- instead of screed, pour, compact and level the sand layer.

A layer of sand is required in any case, since it serves as the basis for the screed. They put a layer of waterproofing on it, the most elementary option is a thick plastic film.

In the calculations, it should be remembered that the heat loss during the installation of the system on the ground is higher, therefore, the temperature of the coolant in the pipes should be higher than normal.

Step # 2 - laying the insulating layer

The insulation is laid on a clean, even floor. Before starting work on the walls beat off a strip - the level of a clean floor, small cavities, if they were formed in the process of construction work, covered with clean, dry sand.

Assembly instruction:

- Spread waterproofing - lay sheets of film with a density of 150-200 microns with an overlap of at least 10 cm and wrap on the walls.

- Lay the plates of extruded polystyrene foam with the marking up, joining the grooves with each other. Better to start from the far corner.

- If necessary, cut fragments with a construction knife.

- Fasten the plates with dish-shaped dowels at the corners, in the middle of the joints and in the center of the plates.

- Seal the seams with construction tape.

If you need to lay the second layer, then the direction of the upper plates is better to change, that is, put them perpendicular to the bottom.

To move around the plates during installation, it is recommended to lay thin boards or pieces of plywood - the structure of the plates, despite the density, can be deformed.

Step # 3 - marking and placing pipes

Markings are applied to the surface of the plates using a marker or masking cord. If profile mats are used instead of EPPS, marking is not required.

Before the beginning pipe installation It is also advised to install collectors and prepare places for connections.

Assembly instruction:

- Unwind from the pipe 15-20 m, put on the end of the insulating sleeve and fitting for connection.

- Connect to the collector.

- Carefully lay the pipe according to the marking.

- Secure the contour with harpoon brackets.

- Bring the pipe to the manifold, attach the second end.

The length of each loop must be fixed, and not just memorized, but written down near the fitting on the wall.

Transit pipes passing through walls or transition zones are insulated as much as possible with sleeves. Instead of expensive imported products, you can use ordinary insulation - foamed polyethylene.

Step # 4 - mounting the reinforcing mesh

Correctly laid fittings should be above the pipes, not under them and not between them. An acceptable option is a metal mesh with a cell 10 * 10 cm from a 3 mm wire.

Now many people use plastic instead of wire mesh. This option is also suitable, since the polymer creates the necessary rigidity.

Step # 5 - system testing

Until hydraulic tests are carried out to check the tightness of the system, the screed must not be filled. Typically, circuits are checked in turn.

First, the line and pump are connected to the pipe, water is supplied. For drainage use a hose connected to the drain pipe of the manifold.

During inspection, staples may fly off, as the pipe tends to straighten under pressure. The flying off harpoons are fastened 5 cm from the previous place, after pouring the screed it will not fly off.

Step # 6 - laying the cement screed

The pipes are left at a pressure of 5 bar and begin to lay the screed. Usually use the traditional beacon method. As beacons, you can use a metal profile for drywall.

Laying is carried out in parts, starting from the far corner. Each fragment immediately after pouring must be aligned, eliminate dips and flows.

After 2 days, the surface is cleaned, the damper tape is cut, the screed is sprayed with water and covered with a film (the last two steps are repeated for 10 days).

Commissioning

Full maturing of the cement screed occurs in a month, it is then that it is necessary to balance with the help of manifold flow meters.

After handling cold water, if the system works correctly, it is possible to carry out tests with a heated coolant. On this installation of the underfloor heating is considered complete.

Conclusions and useful video on the topic

General installation rules for thrifty owners:

Practical recommendations of experienced builders:

What mistakes should be avoided:

When installing a warm floor, there are dozens of solutions, thanks to which you can save on accessories or choose the most suitable scheme.

If you devote more time to designing and selecting materials, then the finished heating system will fulfill its functions 100% and will not need to be repaired for many years.

Do you have personal experience in designing and arranging a warm water floor? Want to share your knowledge or ask questions about the topic? Please leave comments and participate in discussions - the feedback form is located below.

Warm floor under the laminate on the concrete floor: design nuances + detailed installation instruction

Warm floor under the laminate on the concrete floor: design nuances + detailed installation instruction  Heated floor under linoleum on a wooden floor: step-by-step installation instruction

Heated floor under linoleum on a wooden floor: step-by-step installation instruction  Underfloor underfloor underfloor heating: types, features of choice, laying rules

Underfloor underfloor underfloor heating: types, features of choice, laying rules  Screed on a warm water floor: a choice of thickness and popular methods of installation

Screed on a warm water floor: a choice of thickness and popular methods of installation  How to make a water heated floor under linoleum: design rules and an overview of installation technology

How to make a water heated floor under linoleum: design rules and an overview of installation technology  How to make a water-heated floor with your own hands: a step-by-step guide from design to assembly

How to make a water-heated floor with your own hands: a step-by-step guide from design to assembly  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

He made a warm floor at home with a total area of 100 sq.m., he installed the heat pipe with a double snake. He connected to an autonomous double-circuit boiler, but since it was of less power, he installed an additional pump. However, I used polypropylene pipes, as it turned out, the heat transfer is pretty good. The question arises: what type of pipes should you choose when installing a warm floor?

The warm floor is a real find for our family. The idea of installation was proposed by builders during the repair. Since we have small children, this option seemed very interesting. True worried, suddenly the technology of work will be violated. Fortunately, we were lucky with the brigade. They did everything qualitatively. The house has become much more comfortable, especially since the fall. And the children became less sick.