Pipes for underfloor heating: a comparative overview of all options + design tips

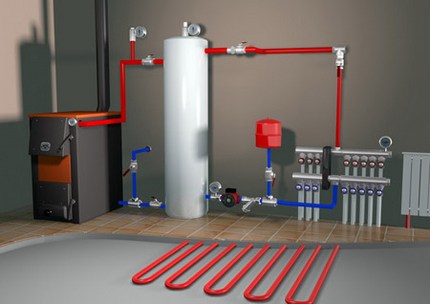

When planning the arrangement of a heating system, owners of private houses are increasingly deciding to install a heating water circuit. The option is economical and universal - it can be used to heat the entire housing or as a secondary source of heat.

It is used as the main, backup or additional source of heating. It is convenient to operate, efficient, does not occupy usable space in the interior.

To achieve maximum reliability and efficiency, it is necessary to correctly select pipes for a water floor heating, comparing the characteristics of each option.

In our material, we will consider in detail the requirements for the arrangement of a warm floor, and also talk about how to choose pipes and calculate their required number.

The content of the article:

Water circuit requirements

Heating floors are a type of heating system. Therefore, design, calculation and installation is carried out in accordance with standard regulatory documents. There is no single regulation for water floors - they are guided by the rules that apply to a specific technological process.

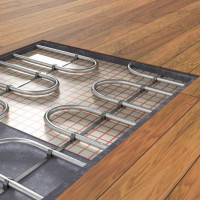

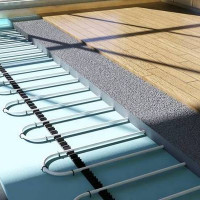

The heating circuit is operated in rather harsh conditions. The circulating coolant constantly presses the pipes from the inside, and outside the coil undergoes impressive loads: the weight of the screed, flooring, furniture and the residents themselves. Do not forget about the thermal effect.

Not all materials are suitable for such specific service conditions.

Most water systems involve pouring cement or concrete mortar, which eliminates the possibility of revising the heating branch and carrying out repairs. Any leakage is an occasion for the complete dismantling of the floor and its replacement.

The quality of the laid pipes should not be in doubt, because the system is equipped with the expectation of long-term operation. Suitable products are those that meet the set of basic requirements.

Material stability

The material should be painlessly responsive to constant contact with the liquid coolant - the development of corrosive processes and the deposition of growths on the inner walls of the pipeline are unacceptable.

The life of the circuit depends on this nuance. Quality materials easily tolerate high temperatures and have a smooth inner coating that does not accumulate lime deposits.

Also, this requirement requires the following characteristics:

- Resistance to regular temperature differences. Optimally, if the material is designed for thermal effects of + 90 ° C and above.

- Chemical inertness. The quality of the coolant cannot be foreseen for several years in advance, therefore it is better to use pipes that are not afraid of impurities, suspensions and interact minimally with different reagents.

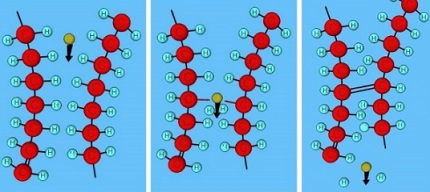

- Oxygen protection. The most durable is pipe fittings with a “gas mask”.

The separation layer prevents the flow of oxygen into the mains, slowing down the diffusion destructive processes in the heating circuit.

High strength

The circuit must maintain integrity even in the event of unforeseen water hammer and horse racing in the system.

High pressure acts on the pipes: the coolant presses from the inside, the screed from the outside. In case of possible critical changes, they should be designed for 10 bar.

The “pie” of the warm floor, taking into account the concrete screed, has a significant load on the structural overlap of the room. In order not to aggravate the situation, it is better to refuse heavy metal rolling.

Low expansion coefficient and good thermal conductivity

With increasing temperature, materials tend to increase in volume, which is fraught with damage to the screed and decorative coating. The permissible value of the thermal expansion of the pipes is up to 0.25 mm / mK.

High heat transfer ability is appreciated. The higher the coefficient of thermal conductivity, the higher the efficiency of the heating floor.

Ideally, the heating loop should be solid - without spliced sections. Welds on bends and tees are potentially hazardous areas for gusts and leaks. So, the pipe must have an appropriate length for laying an inextricable coil.

The heating line must be smooth inside, so as not to provoke a loss of pressure. In addition to maintaining hydraulic resistance, an even coating reduces the noise effect of transporting the coolant.

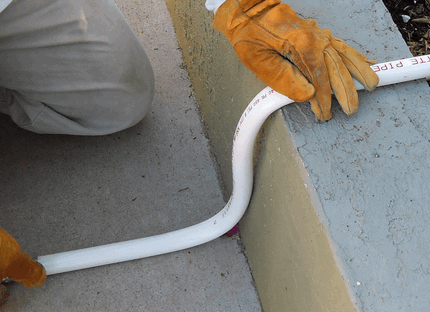

Optimum weight, length and elasticity

In addition to all of the above, you should not lose sight of a number of factors that allow you to check whether the device meets standard technical requirements:

- Optimal weight. It is forbidden to use heavy steel products in the underfloor heating installation. They overload the floors and are categorically not recommended for use in closed systems by building rules.

- Acceptable length. Any connections in the circuit made using couplings, welding, or fittings are considered a potential area for leaks and clogging. The required pipe length is determined in the course of special calculations. Usually the material is produced in bays and sold per meter.

- Flexibility and resilience. Structures that are well bent by hand will not crack and break, making it easy to achieve the desired curved shape with bends of a suitable radius.

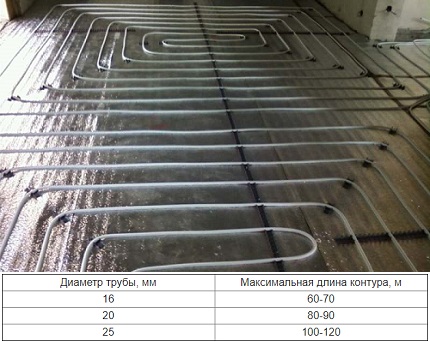

The most common diameters are 16, 18 and 20 mm. When choosing pipes for arranging a warm water floor, one thing should be taken into account: a smaller diameter will increase the resistance of the liquid and, accordingly, reduce the efficiency of heat transfer.

Increasing the indicator, you will have to increase the thickness of the screed. Such manipulation will increase the load on the floor and raise the floor level, which is not acceptable for every room.

The diameter of the product affects the limit length of the contour.

The larger the footage, the more pronounced the risk of exceeding the capacity of the circulation pump and the occurrence of fluid stagnation in place. and how to correctly calculate the number of pipes for a warm floor, read in this stuff.

Variety of pipes: performance assessment

Referring to these requirements, we will conduct a comparative analysis of the most popular products for arranging a heating water circuit.

Manufacturers make pipes from many different materials. Among them there are budget and expensive models. All of them have their own advantages, disadvantages and limitations. Depends on the selected material how often it will be necessary to open the floor for repairs.

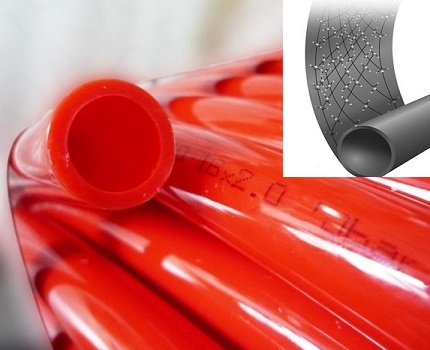

Metal-plastic - practicality and reliability

Metal-plastic floor heating is equipped in every 2-3 cases. This is due to its affordable price and good technical characteristics. Composite material is made of thin aluminum tape, butt welded butt or lap.

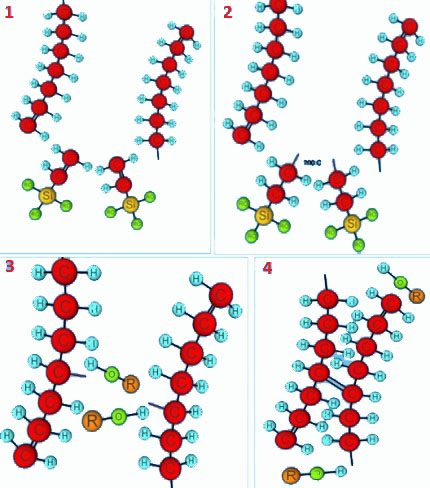

Thanks to the combination of the two materials, high technical characteristics were achieved. Composite pipes have a complex five-layer structure, where each element is responsible for a separate task.

The aluminum shell located in the middle increases the rigidity of the product, compensates for the thermal expansion of the polymer, and prevents the penetration of air from the environment. The inner polyethylene layer provides smoothness and corrosion protection.

Layers of polyethylene are fixed inside and out with special adhesive compounds. The adhesive composition is responsible for the reliable fixation of all layers, forming a single structure. It is the quality of the adhesive that largely determines the durability of the product.

Plastic products are able to withstand up to 110 degrees when heated, without changing the original appearance.

Due to the bending radius of the pipes, it is possible to lay coils more often during installation, thereby achieving greater heat transfer from the system.

The aluminum layer provides good thermal conductivity, the polymer part increases resistance to damage and overgrowth by deposits of substances contained in water, the influence of an aggressive environment. The walls of the material are qualitatively insulated, so the sound of the movement of the coolant does not reach the room.

Composite pipes are perfect for a water heated floor, as they meet a number of basic requirements.

Main advantages:

- insignificant degree of thermal expansion;

- corrosion resistance, chemical inertness;

- high temperature tolerance;

- antioxidant protection;

- good flexibility, ease of laying;

- multi-layer - provides noiseless transportation of the coolant.

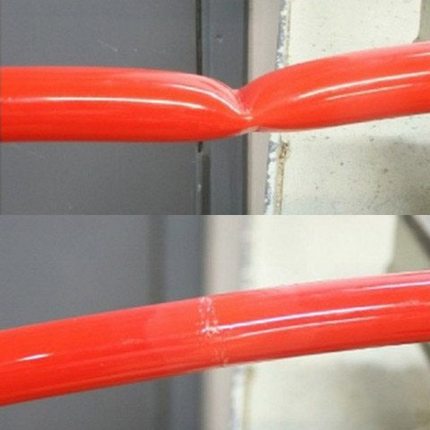

Of the shortcomings, the detrimental effects of sudden temperature changes on the inner surface of the pipes should be noted. As for bending, then special care must be taken. With repeated bends and unacceptable twisting, there is a possibility of damage to the layers of aluminum.

The metal coil will do the job perfectly. The main thing is not to try to save on the purchase of pipe fittings of dubious quality. It is better to play it safe and choose products from reliable manufacturers: Rehau, Henco, Valtec.

Products on a polyethylene basis

To organize floor heating, a water circuit is often made of polyethylene pipes.

Two categories of polymer products are used in the work:

- cross-linked polyethylene pipe products (REX or SPE);

- fittings made of heat-resistant or linear PE (PE-RT or LPE).

Both options have good physicochemical properties and are direct competitors of the metal layer in terms of price / quality ratio. We will examine in detail the distinguishing features of each material.

Crosslinked Polyethylene

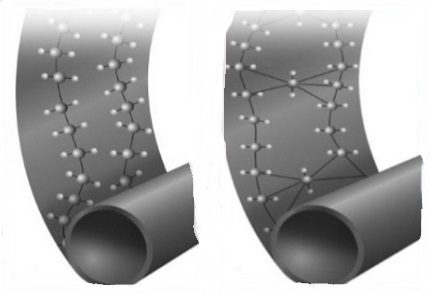

Pipes made of advanced polyethylene, pressed under high pressure, have an increased density compared to conventional material. Thanks to the innovative technologies used in production, hydrocarbon molecules are interconnected, which gives PEX products unique properties.

The material is not afraid of temperature jumps, is not damaged over time and is resistant to external influences. In many ways, its quality and durability is determined by the degree and method of crosslinking.

The optimal indicator for a warm floor is 65-80 percent of the crosslink density. The higher this value, the higher the price of the product. An insufficient degree is negatively displayed on operational characteristics.

The properties of the polymer are a consequence of its structural filling. In ordinary polyethylene, molecular filaments are in free float. The lack of connections explains the vulnerability of the material to thermal effects - it begins to melt.

Crosslinking technology has endowed the polymer with a number of distinctive characteristics:

- high compressive / tensile strength - excellent ductility and softness;

- molecular memory that returns to its original form after heating;

- immunity to acids, most organic solvents, alkalis;

- excellent dielectric performance;

- normal performance at a temperature of 0-95 degrees;

- good tolerance of pressure drops;

- lack of sensitivity to chemicals, fungi, bacteria;

- preservation of physical properties during a sharp change in environmental conditions;

- safety for health, eliminating the possibility of release of harmful compounds.

In addition, the material has high boundary marks of melting temperatures (150 degrees) and combustion (400 degrees). Despite the recommended operating range of 0-95, cross-linked polyethylene pipes can retain strength from -50 to +150 degrees. However, it should be borne in mind that with regular increased loads, the service life of the products is reduced.

PEX-polyethylene has good flexibility - the smallest radius of the loop is 5 diameters. This is enough for any circuit laying scheme.

Suppliers produce pipes in volumetric bays containing up to 600 meters. This is very convenient for installation: they can be easily laid in a single circuit without using adhesions.

Due to the special elasticity of the device should be fixed with additional fasteners, which will help to avoid unwinding.

Weaknesses of PEX polymers: instability to UV rays and the destructive effect of oxygen that has penetrated into the structure of polyethylene. To solve the latter problem, some manufacturers produce multilayer pipes with an anti-diffusion barrier.

The technique of creating a molecular network determines the density of side bonds, and hence the strength of the finished product.

Depending on the crosslinking technology, four groups of pipe fittings are distinguished, which are divided according to the method of connecting the molecules:

- peroxide - PEX-a;

- silane - PEX-b;

- radiation - PEX-c;

- nitrogen - PEX-d.

The most reliable, but also the most expensive option - models marked PEX-a. PEX-b products will be slightly simpler and more affordable. But let's look at all these 4 species separately.

Pex-a. The chemical method of forming bonds is fixation due to organic peroxides. The reaction occurs at high temperature in molten polyethylene.

Distinctive features of PEX-a:

- crosslinking uniformity;

- rigidity and strength of pipe fittings;

- high price.

Pex-b. A more affordable alternative technique for the production of modified polyethylene using organosilanides. The technology provides a degree of crosslinking up to 65%. An interesting feature - in the PEX-b polymer is a constant sluggish process. Over time, the material "shrinks" and becomes tougher. In the metal structure, the b-polymer in tandem with poor-quality glue can lead to delamination.

For household use only organosilane polyethylene pipes PEX-b with a hygienic certificate are suitable. Products based on silicas are prohibited for use in the heating and water supply systems.

Pex-c. The technology consists in passing a mass of polyethylene through an electron accelerator, where gamma radiation acts on the polymer. Unscrupulous manufacturers to reduce the cost of the process conduct radiation with radioactive cobalt, which casts doubt on the safety of the use of such pipes.

The percentage of crosslinking of PEX-c polyethylene reaches - 60%. The material is used as the outer / inner shell of metal-plastic pipes. However, even taking into account reinforcement, such products are not recommended for laying a water circuit.

Pex-d. Nitriding crosslinking is a chemical method using nitrogen radicals; the bond density reaches 70%. Rarely used due to limited release - the technology requires certain reaction conditions.

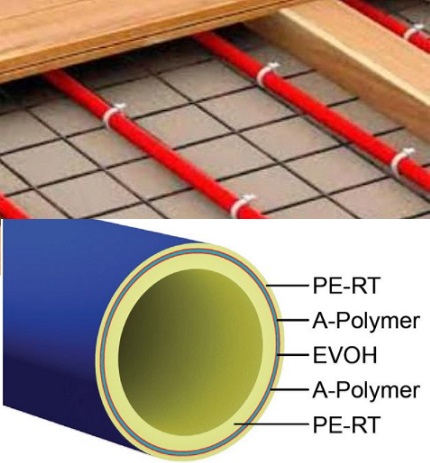

Heat Resistant Polyethylene

The material was created as an alternative to a cross-linked polymer, which, along with high technical qualities, is labor-intensive in production and has some limitations in use - it cannot be welded and recycled.

Customers often take PEX pipes for heat-resistant polyethylene. It should be understood that these are different materials. Cross-linked polyethylene is ahead of the analogue in terms of service life, degree of strength and resistance to aggressive operating conditions.

Distinctive features of the heating circuit made of heat-resistant polymer in comparison with PEX-polyethylene:

- the material is not afraid of subzero temperatures - pipes maintain integrity when freezing water in the system;

- maintainability of the coil;

- silent operation of warm floors, lack of creaks when walking;

- the maximum allowable peak temperature is 125 ° C;

- the ability to connect pipes with fittings and welding.

PE-RT pipes are mainly manufactured with reinforcement or anti-diffusion barrier. Both options are great for a water floor. To determine which pipe is best used for a warm water floor in a particular case, it is necessary to evaluate the estimated load on the system.

If wet pouring and heavy finish (tile) is used, then the contour of metal-plastic rolled - PERT / Al / PERT is suitable.

Polypropylene - saving money

Polypropylene is not suitable for creating a warm floor for several reasons:

- High rate of linear expansion. At high temperatures, the fittings poured into the screed will constantly be subjected to internal stress, which over time will negatively affect the pipes themselves and the flooring. The situation is not particularly improved by reinforcement with fiberglass or metallized layer.

- Lack of flexibility. Polypropylene is a rigid material, the allowable bending radius is about 9 diameters of the reinforcement. This requires an increase in the step between branches, which is not always permissible. Some masters resort to welding the joints of the circuit, repeatedly increasing the risks of leaks. For example, if the diameter of the polypropylene tube is 16 mm, then the minimum pitch for laying segments for it is 128 mm. Such a distance does not always fully provide the required thermal power.

- Low thermal conductivity. Polypropylene will not ensure proper heat transfer from the coolant to the floor, which means that the heating system will be ineffective.

The main argument for the PP pipeline is low cost. However, in this case, cost savings are impractical.

However, polypropylene has very attractive characteristics: low specific gravity, ease of installation, environmental friendliness, corrosion resistance, ductility and sound insulation.

These properties are quite enough to equip a plumbing system or a classic heating branch with radiators. After heat welding with a soldering iron, the products become heavy-duty almost monolithic. They should be taken only for small rooms.

Copper pipe - durability and efficiency

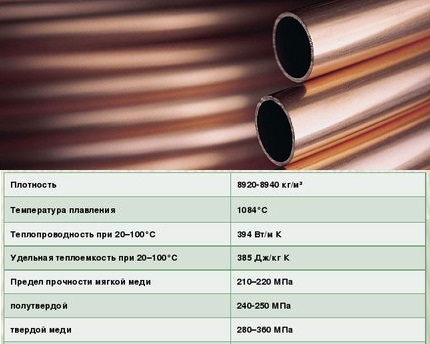

Copper heating pipes are characterized by maximum durability and excellent thermal conductivity. Today, many new technologies are developing, but copper retains its position and does not lose relevance.

Bacteria do not multiply on its surface, it is not afraid of the corrosion processes inherent in a humid environment, which is created by a liquid coolant, and withstands virtually any mechanical stress.

In the arsenal of characteristics of copper piping, positive qualities prevail:

- resistance to liming, corrosion resistance;

- complete impermeability to gases;

- stability and durability of matter;

- mechanical strength - pipes without any problems tolerate water hammer, temperature surges and pressure within 400 Atm;

- high thermal conductivity, ensuring the efficiency of the heating system.

The copper circuit can be bent over a small radius. Such pipes are suitable for any method of laying a warm floor, regardless of the given shape of the coil.

Copper has several drawbacks. The most tangible of them is the high capital investment at the stage of flooring. For the installation of the coil you will need special equipment and connecting elements made of brass.

In addition, the material is sensitive to water quality. If it is too hard or acidic, the triggering of negative electrochemical processes that reduce the operating time by several times is provoked.

The last limitation is the complexity of installation. To perform it, you need a machine or pipe bender. Since this equipment is expensive, a team of specialists will have to be invited to install a warm floor.

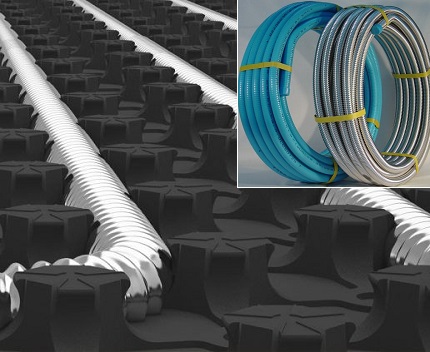

Combination of stainless steel and corrugation

Relatively recently, stainless steel corrugated pipes began to be installed in warm floors. Thanks to the symbiosis of the corrugation manufacturability and metal stiffness, it was possible to obtain an easily bending, durable channel for the circulation of the coolant.

The design features of the metal pipe-hose give the thermal circuit a number of advantages:

- variability of the bending radius - set any coil configuration manually;

- maintaining bandwidth at the bend;

- stainless steel resistance to corrosion;

- high thermal conductivity;

- low system weight and low noise floor;

- temperature range - from -50 ° C to +110 ° C;

- burst pressure at +20 ° C - 210 bar.

In fact, stainless corrugation has the full range of required qualities along with a more affordable cost relative to copper products.

Optimum diameter of pipe fittings

When choosing the cross-section of the circuit, it is necessary to take into account the length of the heating branch and the heat transfer rate of the material. Most often, rolled products with a diameter of 16, 20, 25 mm are used.

The nuances of determining the optimal size:

- with decreasing diameter, the hydraulic resistance increases, and the heat transfer intensity decreases;

- increasing the cross-section of the pipeline should be accompanied by an increase in the thickness of the screed - this leads to an increase in the floor level and an increase in the load on the ceiling.

If the parameters of the length and diameter of the heating circuit do not match, the hydraulic resistance can exceed the technical capabilities of the pumping equipment.

The thermal conductivity of materials should also be taken into account. When laying a coil of copper or metal plastic, it is permissible to use pipe fittings of small diameter - 14, 16 mm. Installation of polymer products - 20, 25 mm.

We also recommend that you read our other article, where we examined in detail the options for pipes for underfloor heating. Read more - read Further.

How to calculate the required number of pipes?

After choosing the optimal type of pipeline, do not rush to purchase. First of all, you need to calculate how much material is required in order to equip a high-quality warm floor.

Accurate layouts drawn on graph paper will help you make accurate calculations. The plan of the room is transferred to it on a scale where the existing household appliances and large furniture are displayed. The heating circuit is drawn in a piece of free space.

There are two main gasket schemes:

- Spiral. The pipe is laid in double-spaced turns, which gradually go to the middle of the room, constantly repeating the contour of the perimeter. Having reached the center point, they return to the collector.

- Snake. The pipeline is laid along the entire perimeter, and then parallel to the wall. Segments are found at the starting point. In this scheme, the zone close to the inset can warm up more strongly than the remote area.

- Double helix It is most often used in premises of complex shape, when it is required to allocate a site by the intensity of heating.

The recommended length of the pipeline in one circuit is not more than 80 meters. Otherwise, the coolant will cool, reducing the heating efficiency.

If the room is too large, it is advisable to divide it into separate sectors. The boundary gap between adjacent lines for uniform heating is not more than 35 centimeters - the interval should be reduced in places of large heat loss. You should also take into account the 15-20 cm indent from the walls.

When the drawing is ready, you can proceed with the calculations. Everything is extremely simple: to begin with, the total length of the contours is measured, then the resulting value is multiplied by the scale. It is better to add a few spare meters to the final figure.

Which brand should I prefer?

In order not to make a mistake in choosing and understanding which pipe for a thermal water floor is better, in addition to assessing the physical properties of materials, you should pay attention to the name of the manufacturer.

Many companies offer a complete set for the organization of underfloor heating, including a pump and mixing unit, pipe fittings and auxiliary elements - power supply, temperature sensors, thermostat, etc.

It is better to dwell on brands that have already managed to positively establish themselves in the construction market.The purchase of proven products will guarantee the good and effective operation of the equipment.

Today, buyers highlight the following pipe manufacturers:

- Rehau (Germany). The priority is warm PEX polyethylene systems with sound absorption and an oxygen barrier. Product Warranty - 10 years. Under normal operating conditions (coolant temperature 60 ° C), the service life is over half a century. The pipes are equipped with a noiseless design, have high heat resistance and thermal insulation. They are durable, elastic, do not burst under stress, withstand a load of up to 100 degrees in emergency situations. Rehau brand products connected by sliding sleeves are extremely popular among customers - with their participation they install underfloor heating systems of various configurations.

- Sanext (Italy). Pipes made of PEX-polymer multilayer structure - include protection against noise and gas penetration. Warranty - 10 years. The company equips pipes for underfloor heating with a reinforced anti-oxygen barrier, applies a three-layer coating on them, which reduces the noise level. The minimum bending diameter of the products is 10 cm. The company claims that its product is designed for 50 years of uninterrupted service.

- Uponor (Finland). Integrated solutions for the organization of floor heating. The assortment includes polyethylene and metal-plastic reinforcement of various fillings and any standard sizes. Pipes of this brand do not reduce the inner diameter due to corrosion and overgrowing, they are resistant to chemical additives contained in water. Products do not lose their characteristics in contact with building materials - concrete, lime, gypsum mortar. Additional layers of protection protect against mechanical stress and oxygen penetration into the system.

- Emmeti (Italy). The manufacturer strictly controls all stages of the process, the manufacturing procedure is certified according to the ISO standard. In the presence of pipes from PEX-polyethylene, metal.

- Valtec (Italy / Russia). Fittings adapted to non-standard conditions. The company has developed standard kits for specific room parameters and integrated solutions. Ready-made kits are convenient for self-installation. Pipes of this brand conduct heat well, are lightweight and easy to install, they allow to realize different sizes of the circuit without unnecessary elements. Products work well in an aggressive environment and are resistant to the damaging effects of chemicals.

- Aquatherm (Germany). German factory producing polyethylene pipes made by extrusion method. Finished products are characterized by increased elasticity and a small bending radius. Products are not prone to temperature aging, corrosion, oxidation. They operate at pressures up to 10 bar and provide good sound insulation. Components for heating systems of the Aquatherm trademark occupy a ranking position in terms of technical characteristics and quality. Even with a small thickness, the products withstand maximum temperature and pressure.

The leaders in the production of polymer and composite pipes rightfully include: Henco induetries (Belgium), Oventrop (Germany), Kermi (Germany), Purmo (Finland), Termotech (Sweden), Neptun (Russia).

Among the manufacturers of rolled copper it should be noted Hydrosta (South Korea) and Kme (Germany), corrugated stainless pipes - Kofulso (South Korea), Neptun (Russia).

We also recommend that you familiarize yourself with the articles where we tell you which floor to choose for a particular coating:

Conclusions and useful video on the topic

The video review examined in detail the structural features, physical and operational properties of various types of pipe fittings. Attention is paid to the assessment of the quality of metal-plastic products and PEX polymers:

What parameters should be considered when choosing pipe products for the heating circuit:

Tips for choosing floor heating equipment:

Video on how to choose the diameter of the product:

Strength test for different types of pipes:

If the budget allows, then the ideal solution is the arrangement of the floor from copper pipes. However, it is not necessary to overpay for the excess strength of the metal. To make a reliable, durable and efficient heating system is obtained from metal-plastic fittings based on heat-resistant polyethylene. A worthy, more affordable alternative is PEX pipes.

From the quality of materials and components will depend on the effectiveness of the service of water floor heating. The right choice will allow you to equip the most economical, comfortable and aesthetic heating system in the house.

We hope our material helped you decide on the choice of pipes for a warm floor. If you have any questions, you can ask them in the box below.

Laying schemes for a warm water floor: analysis of the most effective installation options

Laying schemes for a warm water floor: analysis of the most effective installation options  Mats for underfloor heating: selection tips + styling guide

Mats for underfloor heating: selection tips + styling guide  Water underfloor wiring diagram: versions and device manual

Water underfloor wiring diagram: versions and device manual  Insulation for warm water floors: rules for selection and installation

Insulation for warm water floors: rules for selection and installation  How to choose a warm floor under the laminate: a comparative analysis of the best options

How to choose a warm floor under the laminate: a comparative analysis of the best options  Thermostat for underfloor heating: principle of operation + analysis of types + installation tips

Thermostat for underfloor heating: principle of operation + analysis of types + installation tips  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

We live in a private house. They didn’t build it themselves, but purchased the finished version in which the previous owners had lived since 2008. There is a warm floor. The liner to the collector is made with metal plastic. Over the three years of our residence, a pipe made of this material has already cracked twice, fortunately, this happened within the collector cabinet. The master says that the structure of metal-plastic is very loose. What will happen next can only be expected, since all the main communications are under the screed. I would definitely not recommend metal-plastic material for this kind of communication.

As an option for a warm floor, a water circuit is the most economical and efficient. So not only the entire room but also the floor will be heated. When designing, do not forget that you do this for more than one year and therefore the material must be durable and not susceptible to corrosion and, in addition, conduct heat well. Of course, not everyone can afford copper pipes, but metal-plastic is quite suitable.