Floor insulation by logs: materials for thermal insulation + insulation schemes

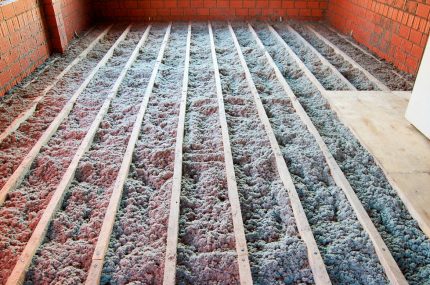

Regardless of whether there will be a screed under the floor or just filling with expanded clay, or maybe there will be damp earth under the floor, so that the wooden floorboards are warm, the space under the upper deck will need to be insulated.

For this, the well-known and most common method is used: floor insulation by logs. About what lags are and what kind of insulation is best suited for thermal insulation of wooden floors, as well as what schemes it is best to implement and will be discussed in our material.

The content of the article:

Types of insulation for the floor

Logs are wide bars mounted on an edge and running from wall to wall parallel to each other. Plastic or metal beams can also play their role. Further, the final floor boards are attached to them, so it is very important to lay them correctly so that over time the floor does not creak or deform.

The selected version of the insulation fits between, and sometimes under the lags. Let's try to figure out which material for thermal insulation of the floor is better to give preference to, and which ones are even better to refuse.

We will consider the most popular varieties of materials for insulation, which are distinguished by fairly high rates of heat saving.

These included:

- sawdust or sawdust mixture;

- expanded clay;

- glass wool;

- mineral wool;

- ecowool;

- penoplex;

- polystyrene foam.

All of the listed heaters are quite airy, which means they will miss the cold with great reluctance.In addition, a qualitatively laid insulation layer is able to prevent the appearance of high humidity in the house, which is also important.

Option number 1 - budget sawdust

This material has the most unstable performance. Often, it is saturated with moisture, which at times worsens its heat-shielding performance.

In this case, it is better for the owner to take care of the lower layer of waterproofing, since wet wood begins to churn, rot, and this can cause not only damage to the coating, but also a number of serious diseases.

Often, as a relatively budget option, pellets or sawdust granules similar to pellets are used to warm the floor. In them, sawdust is pressed and held by means of an adhesive base.

Such a heater has indicators thermal conductivity will be a little better, but experts do not recommend insulating the floors of your home with such material. Its moisture resistance leaves much to be desired.

Of course, if you plan to insulate the floor in the country house or in the outbuilding, then you can use sawdust, but they are completely unsuitable as floor insulation in the house. It is better not to save, but to purchase a more expensive and high-quality insulation.

Option number 2 - eco-friendly expanded clay

This material is quite popular, because of its affordable cost, insulation. Therefore, it is not surprising that he has the most mediocre indicators.

At a relative and relatively low thermal conductivity for thermal insulation materials (within 0.1 W / m * K), it also has a number of unconditional advantages:

- it is the most environmentally friendly material of all presented in our list of heaters;

- it is loose, and therefore easy to install;

- completely fireproof, since it does not burn at all;

- does not decay;

- its granules have a high degree of strength.

But residents of the northern regions, in which expanded clay is covered with expanded clay under the floorboards, often complain about the fact that it draws cold from below. And this is no wonder. Even with the fact that the expanded clay material is porous, its foundation itself is solid, and therefore it is also inclined to absorb the cold, as well as give it away.

And, of course, its thermal conductivity varies greatly according to the size of the granules. The larger the granules, the higher the level of thermal protection will be, and vice versa.

Option number 3 - affordable glass wool

Despite the fact that glass wool is a subspecies of mineral wool, it is considered to be unsafe material, so we will consider it separately. Her villi are nothing more than real glass fibers. They can not only cause irritation on the skin and damage the eyes, but also cause serious lung problems. That is why it is universally preferred to replace it with mineral and ecowool.

The main advantages of glass wool are:

- chemical inertness, the material is dangerous only in its physical characteristics;

- high vapor permeability;

- ease of installation. This material is perfectly cut with scissors.

But some still have not refused to use it. After all, the thermal conductivity parameters of it are more than two times lower than that of the same expanded clay (within 0.04 W / m * K).

And if a protective layer of vapor barrier and the threat of fiberglass fiber damage are laid on top of it, thereby being reduced to 100% to zero, why not use this material?

Option number 4 - popular mineral wool

This is a more expensive analogue of glass wool. It has all its advantages, but at the same time, it is completely safe for health.

This is due to the fact that the mineral wool fibers are smaller, softer and not made from glass solidified fibers, but from natural natural minerals - carbonates, that is, rock formations that are mixed with various additives.

Such cotton wool is even more convenient, since it can even be taken with bare hands without fear. For convenience, it is available both in rolls and sliced to specific sizes.

Option number 5 - quality ecowool

Ecowool is an even more expensive analogue of glass and mineral wool. Its advantages are mainly 100%, as in the case of expanded clay and sawdust, environmental friendliness. It, like the previous materials, has a low degree of thermal conductivity, but, at the same time, remains the only material from all that are not affected by rodents.

Its important advantage is that if in the glass wool, mineral wool and polystyrene, mice and rats arrange not only moves, but also whole nests, they do not touch ecowool, because it causes a strong allergic reaction and dehydration in them.

Option number 6 - high strength foam

Penoplex is a foamed polystyrene foam. In other words, it is a frozen foam mass of molten polyethylene granules. Something remotely it resembles foam rubber, only hardened and hardened.

In terms of its thermal conductivity, it is ahead of all of the above varieties of wat. The coefficient of thermal conductivity of a penoplex varies in the range of 0.03 W / m * K.

He has:

- low rates of water absorption;

- high strength indicators;

- low density.

The only drawback of it, and even then not in all cases, is poor vapor permeability. But in case the room is equipped with good ventilation, this is not critical.

You can read more about thermal insulation foam foam here.

Option number 7 - popular polystyrene foam

Its performance is not worse than that of penoplex. It differs from the previous material only in that it is not a foamed layer of hardened plastic, but a layer made of compressed granules of air polystyrene.

If you look closely, you will see that the material consists of small balls. In a piece of regular polystyrene, they will be larger - up to 5 mm in diameter, in extruded polystyrene - on the contrary, less - up to 0.1 mm.

But this does not affect the merits of the material, which are one-on-one similar to those described for penoplex. The only difference is that the foam will be more difficult to cut, and after the laying work is done, between the lags there always remain mountains of garbage that are electrified, which makes it not so easy to remove.

It is also worth noting that the expanded polystyrene will have to be cut strictly in size between the logs with a small overlap of 1-2 mm, otherwise the gaps remaining between the board and the insulation will negate all thermal insulation. That is why cotton insulation is most often used for floor insulation.

Popular floor insulation schemes

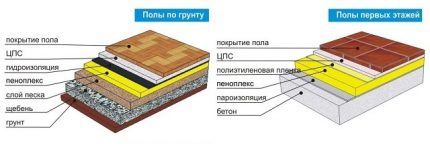

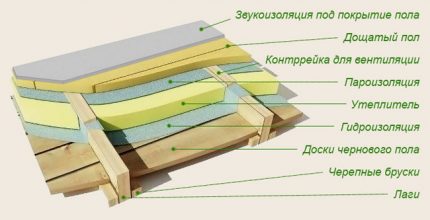

In practice, most often, two schemes are used to warm the floor of the basement / lower floor. The first is the most enhanced when the insulation is present both under the lags and between them. Such thermal insulation, as described in the first case, is used only in the northern latitudes, where the ground freezes in winter quite noticeably.

But most often, on the ground floor of the building, the logs are mounted over the screed, and in some cases over well-planned soil.

Consider both examples suitable for the basement, and then we will talk about floor insulation of the upper rooms.

Reinforced thermal insulation

According to this scheme, first, even before the installation of the lag, it is necessary to plan the soil and insulate it with a lower layer.

As a heater for the first layer, builders can choose:

- expanded clay concrete;

- expanded claydite layer;

- extruded polystyrene foam;

- harder and denser variety of penoplex.

On top of it, logs are already mounted, after which the space between them is also carefully filled with insulation. This time, the same penoplex or one of the varieties of wat can act as it.

In this case, people often resort to double waterproofing - one is laid between the upper and lower layers of insulation, the other - on top of the top, on which counterrails for ventilation and, directly, floorboards will be mounted.

The usual insulation scheme

Everything is clear here. Logs are mounted directly on top of the planned ground surface or, in the case of screed, on it.

Next, a layer of insulation is laid on them. On the insulation there is a vapor barrier layer, the role of which, as a rule, is an ordinary thick polyethylene film. Then, thin counter-rails are beaten on top of the lags (some of them can be neglected), after which a fine floor covering is laid.

If you want to insulate the floor on the upper floors, then you have to act a little differently. Here, a vapor barrier layer is first laid on the flooring material - the same film, then only the logs are mounted.

When insulating the floor with mineral wool or ecowool, the lower layer of vapor barrier must be present. This is especially true for the second and all subsequent floors.

The space between the lag is covered with a heater, after which everything is covered again with a film. Counterracks are screwed onto the logs with a screwdriver, on which the final floor spreads.

We also recommend reading an article where we described in detail how to put into practice wooden floor insulation.

Conclusions and useful video on the topic

You can visually familiarize yourself with the process of floor insulation by logs from this video:

It can be seen from all that the process of floor insulation on logs is not so costly and time-consuming as it seems at first glance. The choice of insulation is always at the discretion of the owner. In addition to sawdust and expanded clay, any of the listed materials will be optimal. Except, perhaps, polystyrene, with the cutting of which you will have to very much tinker.

Do you have a different opinion about floor insulation? Please share it with people who first encountered this issue. Leave your comments in the communication block, which is located under the article.

Insulation for the floor in a wooden house: materials for thermal insulation + advice on choosing insulation

Insulation for the floor in a wooden house: materials for thermal insulation + advice on choosing insulation  Warming of a wooden floor: popular insulation technologies + expert advice

Warming of a wooden floor: popular insulation technologies + expert advice  Garage floor insulation: varieties of insulation for the floor + step-by-step instructions

Garage floor insulation: varieties of insulation for the floor + step-by-step instructions  Types of insulation for the walls of the house from the inside: materials for insulation and their characteristics

Types of insulation for the walls of the house from the inside: materials for insulation and their characteristics  Attic roof insulation: a detailed instruction on the installation of thermal insulation in the attic of a low-rise building

Attic roof insulation: a detailed instruction on the installation of thermal insulation in the attic of a low-rise building  Floor insulation in a wooden house: work procedure + popular heaters

Floor insulation in a wooden house: work procedure + popular heaters  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

How many different materials should be used for insulation. Isn’t it easier to initially conduct the warm floor and not to bathe? The acquaintances have the first floor of the house under a warm floor, and the second floor is simply insulated with foam, that's all. Feel quite comfortable.

If there is a lot of extra money to pay for electricity, then you can conduct a warm floor. But for someone, after all, more cost-effective options for insulation will be interesting. For example, I immediately abandoned this idea when I found out how many kilowatts it “eats” in a month.