The device of the kitchen faucet: what they consist of and how typical faucets work

The kitchen faucet is an active appliance. He keeps the water closed, in the open - mixes a cold stream with a hot one, sets the pressure. These factors, together with improper handling, contribute to rapid wear. Therefore, when choosing, it is necessary to take into account not only the appearance, but also the reliability of the product, agree.

In order to purchase a reliable product, you need to know the device of the kitchen mixer. In addition, this information will help you understand how complicated or simple the repair will be. Can the owner independently deal with malfunctions or will you need a plumbing call?

You will learn all about the design features of kitchen faucets from our article. We have described in detail the varieties presented to the consumer by the market. For a clear perception of the information attached schemes, selections of photos and video repair instructions.

The content of the article:

Division by materials of manufacture

The name "mixer" directly indicates the main function of this plumbing equipment - mixing water. The device is connected to cold and hot water pipes, and its task is to supply water in the right proportion.

Manual adjustment by the user. In addition to temperature correction, the mixer also adjusts the pressure of the water stream.

Materials used in production

A modern kitchen faucet can be made of the following materials:

- metal alloys (bronze, brass, silumin);

- polymers;

- ceramics.

A metal faucet is the most popular option for use in the kitchen.Brass and bronze are not oxidized or corroded by regular contact with water. In addition, these materials are chemically neutral, which means that deposits of mineral salts do not occur on their surface.

Plumbing devices made of metal were widely used due to good performance and their durability.

Silumin mixers - an alloy of aluminum and silicon - are considered less reliable. As a rule, inexpensive models of Chinese or Turkish production are made from this material. Due to the low cost, this alloy has become very popular in the market of sanitary products.

Cranes made of polymers are cheaper and easier to manufacture than metal models. They also do not react with water and do not suffer from its mineral composition. In addition, the low thermal conductivity of plastic makes it possible to use it at relatively high temperatures of water.

The main disadvantage of this material is its fragility, which is why polymers are less often used for the manufacture of critical parts of the mixer, using them mainly for the production of flywheels and control levers.

Ceramics is a time-tested material that is now successfully used for the manufacture of mixers. In modern cranes use metal alloys, for example, cermets.

As for their chemical properties, you will not see any manifestations of corrosion or salt deposits, however, according to physical criteria, the devices have a number of drawbacks.

It is very difficult to make a mixer completely from ceramics, therefore it is used in combination with other materials, in particular with brass. The ceramics are fragile, and the cermet element can crack not only from mechanical stress, but also from an elementary sharp temperature drop.

Types of coating - protection and aesthetic side

The materials from which the basic structural elements of the mixer are made affect its operation, and the attractive appearance and protection of the body are provided with a coating.

Modern manufacturers cover kitchen plumbing equipment in the following ways:

- PVD;

- chromium;

- bronze;

- nickel;

- enamel;

- powder paint.

The most prestigious and expensive option is PVD - vacuum spraying. This type of coating guarantees a long service life even in the most extreme operating conditions. The strength of PVD is comparable to that of sapphire, so in a domestic environment no scratches or abrasions are scary to the mixer.

Powder coating is also a long-lasting, aesthetic and expensive option. It is used in the decoration of premium faucets. Thanks to the processing by high temperature (about 180 degrees), the paint is very firmly attached to the product.

The most common type of coating for kitchen faucets is chrome plating. Chrome is an inexpensive and very effective metal for protecting the body of the crane, which looks very attractive.

Chrome products can be glossy or matte. The only condition is sufficient coating thickness. A layer of chromium less than 6 microns will wear off very soon and does not look aesthetically pleasing.

Classification of mixers by design type

There are two main varieties of kitchen faucets:

- two-valve;

- single lever.

They radically differ in structure and principle of action. The difference can be understood by reading the name. The two-valve tap has two flywheels (valves) for adjusting the pressure and proportions of the water, and in single lever device Both functions are performed by one switch - a lever.

In addition to the above traditional options for kitchen faucets, touch taps are gaining popularity, which automatically supply water when palms are brought to them. Choosing between these options, you must initially know how they are arranged.

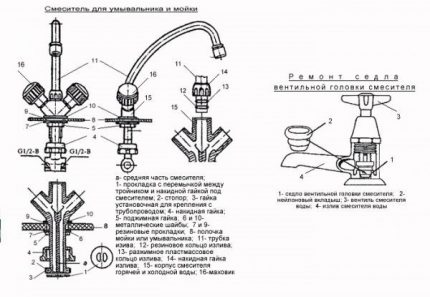

Dual valve model device

The two-valve mixer, by and large, consists of two separate taps, combined in one housing and equipped with one spout. Hot and cold water are regulated independently of each other.

The main drawback of this design is that each time you have to re-adjust the position of the flywheels to obtain water of the desired temperature.

The design of a two-valve mixer is as follows:

- valve heads (crane boxes);

- valves

- housing;

- spout;

- aerator.

The case is installed in the hole made in the kitchen sink, and at the junction place a rubber or plastic gasket for sealing. The device of a kitchen two-valve mixer depends on what type of shut-off elements (faucet-box) is used.

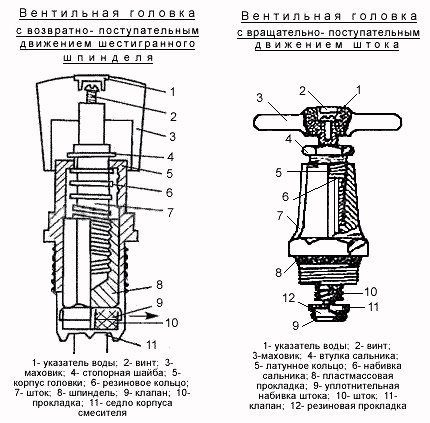

At the moment, in everyday life, two versions of the device "controls" of such a mixer are used:

- with ground ceramic discs rotating relative to each other within a limited segment;

- with valve heads making rotational-translational or reciprocating movements.

The simplicity and ease of use of the crane, as well as its service life, depends on the type and structure of the crane box.

It is possible to eliminate leakage of valve options without special difficulties with your own hands. The predominant number of such failures is due to leaky rubber gaskets, which simply need to be replaced.

In the lower part of the valve mixing device, the pin mainly drops out of the rod, due to which water flows from the hot pipe to the cold pipe and vice versa.

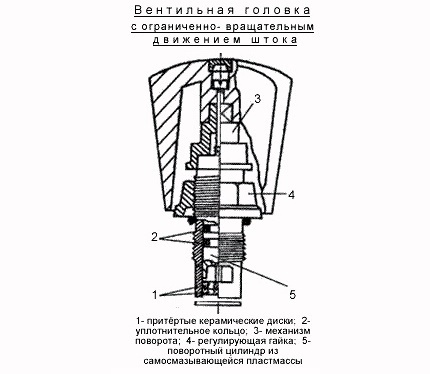

The structure of the axle boxes based on cermets

The valve head with ceramic discs as a locking mechanism feeds / blocks the flow of water depending on the position of the holes in these plates. When they are combined, water enters. The larger the area of contact, the greater the flow of water. To turn off the water, turn the valve so that the holes do not coincide with each other.

To imagine how a ceramic-axle-box axle works, look at its design.

The structure of the crane box looks like this:

- housing;

- stock;

- rod lock;

- turn signal;

- top plate;

- bottom plate;

- elastic pad.

A rod is inserted into the brass body by means of a clamp. If everything is done correctly, at the moment of fixation you will hear a characteristic click. A valve is put on the stem. The indicator is responsible for transmitting torque from the valve to the plates.

The turn signal can also be metal, but often the manufacturer saves on this part and it is made of plastic. Of course, metal models are more reliable and stronger.

A rubber or plastic gasket is located at the junction of the crane box and mixer body. If it is damaged or does not fit well, water begins to flow from under the valve. The gasket function is a reliable fit of the crane body and mixer body.

Threaded Crane Design

Threaded axle box works on a different principle. Its design is as follows:

- stock;

- fitting;

- valve;

- rubber gasket;

- body.

The principle of operation of such a valve head model is that during rotation of the valve, the gasket is pressed or squeezed, respectively, closing or opening the valve. For the progressive movement of the rod on which the gasket is located, the fitting with a thread at the end is responsible.

The main advantage of this model is the simple replacement of the rubber gasket in case of wear. But the main drawback is the need to perform this operation much more often than we would like. In addition, to use a mixer with such crane-boxes, you will have to turn the valve several turns, which complicates the process of adjusting the water temperature.

Due to the specifics of the operation of valve mixers, the most susceptible element of the system is a gasket, which ensures a tight fit of the flow-blocking device to the water supply channel.

Consider the standard option for replacing the valve seal:

You will find an overview of the best options for kitchen faucets and the rating of products on the market in another popular article our site.

Single lever mixer

Single lever mixer - a more modern and practical option for the kitchen.

The main advantages of this model:

- ease of operation - can be adjusted with one hand;

- speed of temperature and pressure adjustment - significantly affects the readings of water meters;

The mixer “remembers” the position of the handle for a comfortable temperature.

To understand the principle of operation of a mixer with one handle, you need to understand its structure.

Single lever mixer elements

The device of a single lever mixer for the kitchen:

- housing;

- shift lever;

- spout;

- cartridge;

- aerator.

Standard mixers of this type mix water by turning the rotary knob in the horizontal plane, and the pressure of the water by moving in the vertical plane. The aerator provides a uniform supply of water at the outlet, due to the mixing of the water stream with air.

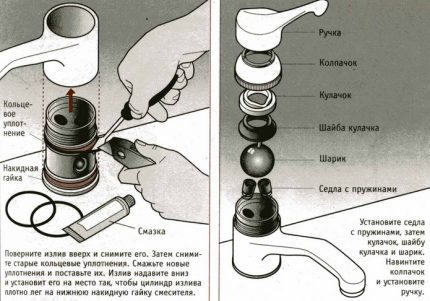

The main functional element is a cartridge, which is an analog of the crane axle box. The locking mechanism of a ball or disk type is placed in a plastic case.

Ball Valve Design

The ball-type cartridge is based on a metal hollow sphere with three holes. Two of them serve for the entrance of water (cold and hot), and the third - for the exit of water of the desired temperature. The ball connects directly to the handle and changes its position with it.

When turning the holes on the ball can to one degree or another coincide with the holes of the cartridge. In this way, both the pressure and the temperature of the water in the kitchen are regulated. Faucets of this type are now less common. This is due to the complexity of the production of such models, their high cost and frequent failure.

The principle of operation of the disk cartridge

The principle of a ceramic disk cartridge for a lever mixer is the same as that of a ceramic double-valve crane. The basis is two ceramic plates, one of which is movable and rotates with a change in the position of the lever.

If the holes on the upper and lower disks coincide, the water enters the spout; if not, it overlaps.

Such ceramic-metal cartridges are most often used in single lever mixers in kitchens.

Regardless of the design features and methods of water supply installation of kitchen faucets, connection to the water supply branches is carried out in the same manner.

Automatic Mixer - Contactless Use

If a single-lever or two-valve mixer is based on pure water mechanics, the automatic crane works thanks to the electronics.

Its device is much more complicated:

- housing;

- sensor;

- thermostat;

- membrane on the spring;

- locking solenoid;

- shielding coil;

- spring core;

- sealing material.

The solenoid is an inductor. A membrane that blocks the flow of water is located at the end of the core.

When the sensor is triggered, voltage is applied to the solenoid, the coil lifts the core, it is drawn into the cavity of the solenoid, thus raising the membrane and opening the way for water. When the power supply stops, the opposite happens: the core lowers and the membrane returns to its original position.

An automatic mixer requires a battery. You can use the connection to the eclectic network, converting the current through a transformer, but these are unnecessary difficulties during installation. More commonly used batteries or rechargeable batteries. Automation in the kitchen is a good idea.

During cooking, you often have to get your hands dirty, for example, when working with dough. Turning water on without contact with the valve will help keep the kitchen clean.

Additional functionality and features

In addition to design differences, kitchen faucets can be completely different models.

They should have a number of design features that make this faucet ideal for the kitchen, namely:

- high spout;

- the ability to turn;

- direction of the jet to the center of the sink;

- retractable hose.

A high spout will be very useful in the kitchen, as often there is a need to draw water into a high capacity, for example, a bucket or jug. Another condition is that water enters the center of the sink. It is convenient for washing dishes. The tasks in the kitchen can be very different, so it would be nice if the spout of the mixer could be rotated.

The presence of a retractable hose in the design of the kitchen faucet will make the faucet more practical and mobile. With this innovation, you can easily pick up a bucket of water that stands on the floor or wash large dishes from all sides.

Some faucets are equipped with additional functionality, for example, the ability to switch a direct jet to drip mode or the presence of an additional outlet for supplying filtered water.

Features repair faucets in the kitchen

In fact, the internal structure of the mixer is unlikely to be needed until your faucet fails. Then there is an urgent need to disassemble it and look for damage.

And if you prepare in advance and study the disassembly algorithm of the mixer even before a malfunction occurs, you can save time and nerves, being ready for unforeseen situations.

Single lever mixer disassembly

To disassemble single lever mixer and to get to his device, you need to follow this simple instruction. First turn off the water supply - turn off the water. To unwind the mixer body, you need to remove the decorative plug (often looks like a round insert of red-blue color).

Behind the plug you will see a screw connecting the lever and the stem. It must be unscrewed with a screwdriver. After that, you can remove the knob regulator. The next step is to unscrew the snap ring. To do this, use an adjustable or gas wrench.

Now you have access to the cartridge, you can get it and replace it if necessary.

After diagnosing or repairing or replacing, you need to follow all the steps in the reverse order. In plumbing, it is important not to “pull” threaded connections, but they should not “walk” either.

Repair of a mixer with two valves

The two-valve mixer is disassembled according to this scheme:

- As in the first case, turn off the water.

- Remove the plug from the valve that closes the screw. Unscrew it and remove the flywheel that needs repair, or both.

- Under the valve, you will see a nut that secures the axle box. Use a wrench to unscrew it.

- Having access to the crane box, it can be removed and inspected visually. Particular attention is paid to sealing, if damage occurs, deformation of the gasket, it must be replaced without fail.

When the inspection is completed, all parts are assembled in the same order.

Conclusions and useful video on the topic

Dismantling a crane with two valves with a detailed examination of the device:

The video shows the device and the principle of operation of the cartridge, as well as the assembly process of the mixer:

Understanding the design of the mixer is very important not only when choosing the right model for your kitchen. Plumbing equipment is used regularly and tends to fail. Knowing the design of the tap from the inside, you can detect a malfunction and repair the mixer yourself.

Do you want to share only the well-known secrets of choosing a mixer for installation on a kitchen sink? Have questions, find controversial issues? Please write comments in the block below.

Device and repair of a bathroom faucet: the main types of breakdowns + recommendations for their elimination

Device and repair of a bathroom faucet: the main types of breakdowns + recommendations for their elimination  Bathroom sink faucets: device, types, selection + popular models

Bathroom sink faucets: device, types, selection + popular models  Installing the faucet in the bathroom: device and step-by-step installation manual

Installing the faucet in the bathroom: device and step-by-step installation manual  Do-it-yourself faucet repair: popular faults and how to fix them

Do-it-yourself faucet repair: popular faults and how to fix them  Rigid eyeliner for the mixer: device, pros and cons + installation features

Rigid eyeliner for the mixer: device, pros and cons + installation features  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Kitchen faucets, if they are without any super-bells and whistles, are many times easier to install than faucets in the bathroom, because there is no discharge to the shower. And single-lever - very easy. There, in fact, you do not need to do anything, just make sure everything is tightly fitted.

Now, if all sorts of modern gadgets are added, then I already pass - I will not undertake to install contactless.

I think the simpler the mixer, the better. If only because in the event of a breakdown, any plumber could fix it. Do-it-yourself repair is out of the question. The best material is cermets and brass. Pottery looks beautiful, but does not live long. Still need to take into account our realities. For example, my water is very hard, the filters clog up instantly, and the fragile parts of the mixers quickly fail.