How to assemble a shower tray: mounting options for typical options

The modern module for comfortable reception of water procedures at home is often called a hydromassage box. A simplified popular name is a shower cabin.

The interest to install and assemble a shower tray alone is haunting many potential buyers. We will try to figure out how to properly assemble and install, avoiding common mistakes.

The content of the article:

A variety of modern models of showers

People are interested in both inexpensive practical cabins, and advanced models, supplemented with special devices:

- cascading shower

- hydromassage module

- steam bath.

Obviously, domestic showers quickly gained popularity in society. In the wake of increased demand, the production of such modules has become profitable for manufacturers.

As a result, the production of products of various configurations intended for installation as part of a wide variety of bathroom projects was established.

It is clear that the possibility of installing a cabin in one place or another is directly related to the dimensions and shapes of the shower tray - one of the main elements of the whole structure.

Sizes and shapes of water collectors

The overall dimensions of the water collectors and their subsequent discharge to the sewer, as a rule, are the basic parameters that determine the total usable area of a fully assembled shower cabin. Designs for collecting and discharging water can be divided into small, medium, large - depending on their overall dimensions.

Compact products are limited to a size of 700 x 700 mm, the size of medium-sized modules is in the range of 800 x 800 mm, large collectors have a width of at least 1100 mm.

Also significant is the size that determines the depth of the shower tray. An insufficient or excessive parameter of the pallet in depth may complicate the assembly of the structure in some cases or, conversely, facilitate the work of the installer.

The functionality of the hydromassage box and the degree of convenience for the user to some extent depend on the parameter of the depth of the tank.

In relation to this parameter, there is also some kind of division according to the design of shower trays:

- small (up to 40 mm),

- medium (up to 100 mm),

- deep (from 180 mm).

The configuration of products by their shape also provides the user with a wide selection. The most common are shower trays that have a rectangular, square, angular shape.

Simple configurations of forms are usually preferred when it becomes necessary to assemble the structure in the conditions of standard bathroom facilities (city apartments, small cottages, condominiums).

In addition to the traditional options for the forms of shower trays, there are also others:

- oval;

- round;

- cocked hat;

- pentagonal;

- exclusive.

If you choose by price, products of a square, rectangular, angular shape are relatively inexpensive.

The assembly of the cabin with a shower unit is not affected in any way by the surface configuration of the bottom of the pallet. But this point is fundamental in terms of safety when using a shower.

Whirlpool pallets with a corrugated bottom surface reduce the sliding effect to a large extent. This provides a higher level of security for the user.

Cabin material for pallets

Shower trays are manufactured taking into account the possibilities for different installation. This approach pleases the consumer, but at the same time makes you think about assembling a pallet for a specific shower.

However, thoughtfulness quickly goes away if the successful owner of the device is ready to carefully read the installation instructions, including the assembly of such an element as shower tray.

Manufacturers of hydromassage boxes make pallets for collecting and draining water from various materials. Most often there are products made on the basis of plastic or acrylic. For buyers, this is an inexpensive option of all available, but not the most optimal in terms of performance.

Also for the production of shower trays use materials:

- enameled steel;

- machined cast iron;

- faience (ceramics);

- marble (artificial stone);

- kvaril (a combination of quartz with acrylic);

- glass;

- and even a tree.

Faience and marble pallets are best suited for showers, but assembling devices with such pallets requires a lot of money.The high cost here is due to the technology for the production of faience (marble) products.

These materials look beautiful, can quickly heat up and retain heat for a long time. In addition, earthenware and marble have increased wear resistance.

The disadvantage of faience and marble products is the fragility properties of these materials. Under shock loads, such structures are capable of collapsing.

Quartz pallets are listed in the list of expensive products after marble and earthenware. Quaril - a modern material, consists of a mixture of acrylic and quartz. In terms of performance, quartz pallets are only slightly inferior to ceramic ones.

When the buyer becomes interested in shower enclosures with a reinforced tray, the first option is usually considered primarily the quartz version. The properties of durability and good thermal insulation were obtained by the use of quartz in the structure of the material.

Cast iron pallets have a low coefficient of thermal conductivity, which means effective heat conservation. However, heating up the cast iron takes some time.

Structurally, cast iron trays are a reinforced version of the base of shower cabins. They are strong and reliable, but without adequate protection from the influence of the external environment there is a risk of corrosion.

Therefore, modern designs of cast-iron trays intended for assembling a shower cabin are usually coated with protective enamel. A pronounced disadvantage of such products is their significant weight, which affects the assembly process.

Steel pallet models are also relatively sturdy. But steel pallets do not have pronounced heat storage properties. With the work of such structures under increased load, too, everything is not unique.

There are examples of the operation of showers when reinforced steel trays are deformed from overload. This type of product, like cast-iron pallets, is treated with enamel, and deformation leads to damage to the enamel coating. The degree of reinforcement of the steel structure indicates the thickness of the material — the metal sheet.

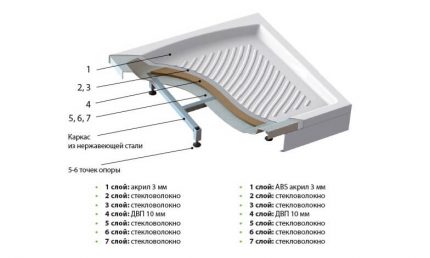

Acrylic containers for collecting and draining water - this is the most popular option used in the assembly of shower cabins. Lightness, strength, good heat storage properties, low cost have made acrylic projects the image of popular products.

For acrylic constructions, there are no restrictions on the shapes and colors. They are easier to assemble than shower trays made of other materials. They are also easily and simply repaired if necessary. To strengthen the acrylic shower trays, an additional metal frame is often mounted.

The construction of the steel frame is performed in order to smooth the load in the central region of the bottom. It is in this area that cracks or kinks usually form.

Also, supports can be made of other materials: textolite, plastic, wood, etc. Some strict schemes for manufacturing the reinforcement cage are not provided, although part of the shower cabins is equipped with ready-made solutions. You can apply any scheme. The main thing is to correctly determine the load zones and successfully select the fulcrum.

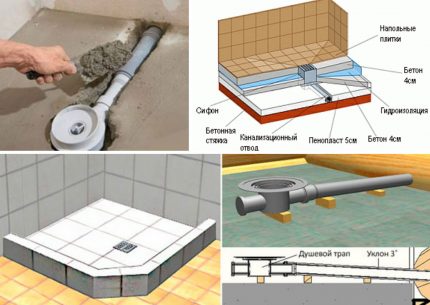

Brief photo instruction

So that you can visualize the volume and sequence of work on installing and connecting the shower tray, we suggest that you familiarize yourself with the photo selection. She demonstrates the main steps of the process:

The above steps are essentially preparation for installation and connection of a shower tray. Upon completion, proceed to the direct installation:

Installation of reinforced water collectors

Regardless of the configuration of the tank for collecting and discharging water, which is included in the package of the hydromassage box, the assembly of this design provides for the preparation of the base for installation.

Preparation includes work aimed at leveling the surface of the floor and walls in the installation area. In addition, all the necessary steps are taken to create an effective waterproofing. The sewer line for water drainage is marked and displayed. We also recommend reading about how to properly connect a shower to communications.

The drain line is connected to a point previously prepared and displayed at the installation site, or to an existing bathroom drain system through a corrugated extension cord and tee.

In the latter case, it is necessary to observe the difference in the level differences between the lines so that water can be drained unhindered. The desired differential value is achieved when assembling the shower tray by setting it to the desired height.

For the construction of a drain into the sewer, the following tools and materials will be required:

- corrugated pipe (d = 40 -50 mm);

- plumbing siphon;

- fluoroplastic sealing tape (FUM);

- building level;

- a set of locksmith tools.

The plumbing siphon and part of the corrugated pipe are mounted on the pallet body even before it is installed in the prepared place. It is necessary to observe the accuracy of the siphon installation in full accordance with the attached instructions.

The position of the gaskets, the tightening of the fixing rings should ensure reliable tightness. It is recommended to check the insulation of the joints, close the outgoing end of the corrugation and fill shower trap some water. If a leak is not detected, you can safely assemble the system.

Pallet Assembly Instructions

Consider several popular options for installing a shower tray or showers. Each of them has its own characteristics, although the procedure for performing actions is usually the same.

Option # 1 - Acrylic reinforced construction

A reinforced version of the shower tray involves the use of a frame of strength. The frame frame is usually fixed at the bottom of the pallet due to special metal studs. Such studs are screwed at one end into holes located at the edges of the pallet, and support “legs” are screwed onto the other end of the studs.

Just above the support legs, frame metal elements are placed under the bottom of the pallet. Their vertical and horizontal positions can be adjusted with nuts and fixed with locknuts.

Equipped with reinforcing elements and support legs, the shower tray is placed at the place of deployment. By rotating the support legs in one direction or another, the pallet is aligned horizontally. Horizon accuracy is controlled by the construction level.

It is also necessary to maintain the specified size of the installation height of the pallet in order to ensure the conditions of a drop in the level of discharge. According to the requirements, this difference should be at least 20 mm per 1 meter of sewer line length. All that remains is to hang decorative panels.

Such assembly technology traditionally applies to showers where an acrylic water collector is used in the kit.Some steel pallet designs may also include similar installation, but not always.

Option # 2 - mounting a steel pallet

Household models of shower cabins with a steel tray, as a rule, are available in two types: shallow in depth (less than 300 mm) with overall dimensions 800 x 800 mm or 900 x 900 mm and deep (over 440 mm) with dimensions only 800 x 800 mm.

But the requirements for joining the sewer network are the same. Thus, from the point of view of the sewerage connection, there is no global difference in the installation of steel pallets.

Another thing is the assembly of a shallow and deep steel pallet, with an eye on the supporting component. Deep structures with a high side are usually endowed with supporting parts - legs (supplied).

Option # 3 - assembly on a makeshift foundation

But the assembly of shallow shower trays is usually carried out on the foundation or on self-made supports, since the equipment is not provided with supports in this case.

The foundation for the steel shower tray is brick, stone, block, etc. In the case of supports, metal parts (channels, pipes, angles) can be used.

Masonry assembly provides an accurate definition of the boundaries of the contour of a steel pallet. On this contour, with a small indentation inward (by 5-10 mm), lay out the foundation.

As masonry is completed, consideration should be given to creating a slight slope towards the sewer inlet. Thin-walled steel tanks are not particularly strong.

Therefore, in this version of the assembly, the structure should be strengthened with an additional frame or lay supporting columns of brick directly under the points with maximum load. This approach will protect the steel pallet from its deformation.

On the surface of the brick foundation, lay a high-quality damping material, for example, a tape made of hard technical rubber half a brick wide. All additional supporting elements of the foundation are equipped with the same dampers.

Further, a steel water collector is placed on the foundation, the siphon is assembled with a drain line, after which the entire structure is finally fixed. Typically, fixing the steel water tank to the foundation is done with cement mortar. If you are interested in a homemade tile tray, we recommend that you read the detailed instructions for its construction, which is on our website.

Conclusions and useful video on the topic

Useful information from the video will help you install plumbing equipment yourself.

Acrylic Pallet Assembly:

Intentions to change the bathroom environment in an apartment of a municipal residential building are not the exclusive prerogative of the owner of the apartment. Owners of municipal housing should be aware of the existing rules related to the reconstruction of premises and communications. Only upon receipt of an appropriate permit from the authorities, it is possible to begin construction or installation work.

Have questions, notice inaccuracies or want to supplement this material with valuable information? Leave your comments in the box below. Or maybe you yourself had to collect a shower tray - share your experience with our readers.

Siphon for shower tray: design, purpose, installation features

Siphon for shower tray: design, purpose, installation features  Repair of a shower cabin: how to repair popular damage to a shower cabin with your own hands

Repair of a shower cabin: how to repair popular damage to a shower cabin with your own hands  Installing a shower tray: installation instructions

Installing a shower tray: installation instructions  Tile shower tray: detailed construction instructions

Tile shower tray: detailed construction instructions  Connection of a shower cabin to the sewerage and water supply: step-by-step instruction

Connection of a shower cabin to the sewerage and water supply: step-by-step instruction  Drain for a shower cabin: types of designs and rules for their arrangement

Drain for a shower cabin: types of designs and rules for their arrangement  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I collected the pallet myself, I can say that the work is technically uncomplicated, but very painstaking. You need to carefully prepare a place for a shower, measure everything, quite a lot needs to be drilled. Bonding must also be accurate so that not the slightest gap remains. As a result, I installed the shower room, taking it all day and cursing everything in the world. It would be better if he hired a plumber.