Installing a shower tray: installation instructions

Want to save space in the bathroom by installing a shower? The bathroom is a place of relaxation, which should be practical and have a nice aesthetic design, right? Do you plan to do all the installation work yourself, but are you confused about installing a shower tray and connecting plumbing?

We will tell you how to cope with this task - the article discusses the important points that you will encounter during installation. And also we paid attention to the features of pallets of various materials, describing in detail the installation process of each of the options.

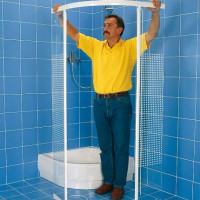

To help the novice plumber, we picked up photo materials demonstrating important nuances, and a video detailing the assembly and installation of a compact cabin for receiving shower procedures.

The content of the article:

Types of shower trays

Manufacturers are ready to surprise the most sophisticated owner, offering a variety of shapes, sizes and options shower trays.

One of the first classifications is the separation of models by shape. It can be square, oval, round, triangular, rectangular products.

It is worth choosing the shape and size of the pallet, which will distribute the space in the bathroom as ergonomically as possible with the appropriate level of convenience.

Another classification is related to performance material. Today you can purchase a pallet from:

- cast iron;

- acrylic;

- marble;

- ceramics;

- steel.

In this case, the pallet can be installed in different ways: using a metal frame, pedestal or flat surface (for ceramic models).

It is worth noting that marble products are very fragile and can be damaged from a blow at the installation stage, so all work must be done as carefully as possible. A ceramic pallet can also crack from impact.

Each manufacturing material has its own characteristics:

- cast iron and steel models May be unpleasantly cold in the morning;

- acrylic warm to the touch, but quite fragile;

- kvarilovye - these are the same acrylic products, but with the addition of quartz dust, due to which the cabin becomes stronger and more durable;

- marble pallets are distinguished by their spectacular appearance and quickly warm up, give a pleasant tactile sensation when in contact with the skin;

- ceramic models slowly heat up, but are practical in everyday use and durable.

Prices for ceramics and stone products are significantly higher compared to other models of shower trays.

Pallets also differ in depth. When choosing, you can use the following guideline: very flat (6-10 cm), medium (10-18 cm), deep (25-35 cm).

The choice the size of the shower or a pallet should be based on the dimensions and configuration of the bathroom.

Pallet Installation Instructions

Installation rules often depend on the material of which the pallet is made, so we will consider four popular options. Acrylic and steel modifications are more common, and cast-iron, marble and ceramic are less common.

The standard cycle of installation and connection of shower trays includes a number of traditional steps:

After completing the installation and fixing the pallet, you can safely proceed to the finishing stages of work:

No. 1 - installation of acrylic models

Acrylic solutions have the smallest weight, affordable price and are sold in a variety of shapes and sizes. Such models are equipped with brackets, legs and other fittings, which helps to carry out installation and fix the pallet on the base.

The disadvantage of the design in many cheap models is the lack of reinforcing support under the bottom, so when choosing, you need to pay attention to the fact that the bottom is strengthened.

Step 1. Installation of legs. Depending on the model, the kit can go from 3 to 5 supports.

Some products use a support frame based on plastic or metal. The holes for mounting the legs will be in this frame.

When screwing the supports, it is necessary to ensure that the length of the legs is not less than the height of the siphon. Also, all the supports should be screwed to the same height (then it will be possible to adjust the horizontal position of the pallet using the level)

Step 2. Installation of the drain system. Necessary connect the pallet to the sewerby placing the product on the edge. A complete sleeve is inserted inside, which is used for connection.

A siphon nozzle is placed on the protruding end of the sleeve. To prevent leaks, the joints are smeared with glue. You can use epoxy glue or epoxy plasticine. Connect the nozzle and the sleeve, and coat the connection with sealant on top.

In some models of shower cabins, a system of connections with paronite or polymer gaskets can be used. In this case, you do not need to use glue. Place the pallet on its feet, making sure that the edge of the siphon does not touch the floor.

Step 3. Pallet adjustment. Now it's time to adjust the horizontal structure. To do this, rotate the legs, placing the level on the walls of the pallet (grooves into which the shower enclosure will be mounted).

The horizontalness must be checked on all sides of the pallet. If the product is installed against the wall or corner of the room, then it is necessary to lubricate the surfaces in contact with each other with glue and press firmly.

It is necessary to wait until the glue dries, and then tighten the seal with a sealant, applying a layer of it to the place of contact between the sides of the pallet and the wall.

Step 4. Siphon connection to the drain pipe of the sewer system, installation of a decorative casing, which comes complete with a pallet.

It is recommended to use a shower cabin 6-10 hours after the sealant and adhesive have completely dried.

No. 2 - installation of a cast-iron pallet

Installation of a cast iron product is similar to the steps taken with the installation of an acrylic pallet.

The fundamental difference is only in the design of cast-iron models:

- Cast iron is very strong and resistant to metal. In its design there are no reinforcing elements, and the legs are an integral part of the pallet and are cast simultaneously with the body.

- To align such a model horizontally, you will have to lay steel strips under the legs or other objects that will prevent the floor from being forced through, because The cast-iron pallet has considerable weight.

- The sides of the cast iron product do not stick to the room wall.

But how to fix the pallet so that it does not move off the plates installed under the supports?

This problem can be solved by cementing the bosses, which will frame each leg, preventing shifts. For formwork, a normal matchbox will come off.

It is worth noting that the complete shower stalls are not equipped with cast-iron trays. Usually they are used with simpler fences, including curtains, screens and other lightweight materials that do not require accuracy, so as not to fit them under the geometry of the pallet.

Sometimes the height of the legs of such a product is not enough to place a drain siphon under it. In this case, you have to prepare a special parapet.

The procedure is not difficult to implement. It is enough to make brick laying around the perimeter of the pallet or to erect a concrete shoulder - this will be the parapet. It should have space for installing a siphon and sewer.

Then you need to level the pallet with a level, placing plates under the legs, cementing them with cement lugs. To hide the parapet and the space above it, you can use tiles or mosaic modules.

No. 3 - features of installation of steel products

Steel models are produced using stamping, so it is quite difficult to make an integral structure from a pallet and legs.

Steel products are equipped with a stand. The factory, which produces steel pallets, also produces the appropriate supports for them.

They have a rectangular or square shape and represent a failure of the welded structure of the profiles in which the threaded bushings are located. Threaded legs are screwed into them, with which you can make the alignment (alignment) of the pallet.

Steel pallets are often included with factory shower enclosures. It is also a reliable option to replace a worn acrylic pallet.

If the pallet is installed as an independent product, then a cement substrate or pedestal is mounted on the bathroom floor. Their height should be sufficient for the location of the siphon and the piping.

The contact points of the pallet with the wall can also be glued and sealed, as when installing an acrylic product. The construction of the pedestal will be discussed in the next paragraph.

Details on the assembly and installation of steel models are written in this article.

No. 4 - installation of ceramic and marble models

Today the trend is ceramic and marble plumbing. Shower trays are no exception. Such products are durable and massive, therefore, do not require the use of legs or reinforcing elements.

The installation method is selected depending on the design of the pallet.

Two options are possible:

- Niche Design. Many ceramic models have a niche in the cavity of the pallet for mounting the siphon and draining the sewer system. It is enough to connect such a pallet to the sewer and install it directly on the bathroom floor without any additional actions. It remains only to attach the walls of the shower.

- Monolithic option. In this case, to connect the drain hole to the siphon, you will need to erect a pedestal. Inside it will be a space for connecting to the sewer.

The construction of the pedestal is as follows. Apply a layer of waterproofing to the area where the pedestal will be built.

To do this, you can use liquid rubber, roofing material, polyurea, or other composition. It is necessary to wait for the complete polymerization if you have used a liquid product.

Next, create a layer of cement screed with a horizontal surface (use a level). We are waiting for complete drying.

Inside the contour of the pallet, we make brickwork with a height that would be enough for the normal location of the siphon. It is necessary to provide a cavity for drainage.

Connect the drain hole siphon tray, the reverse end of which is connected to the branch pipe. Apply a layer of cement mortar over the masonry.

Next, we install the pallet on the pedestal so that the siphon and outlet are in the places reserved for them. In the end, you need to make the lining of the pallet using tiles.

DIY pallet construction

The process begins with preparing a future place for a shower.

Step 1. To begin with, the installation area is waterproofed, as in the previous paragraph. This will help protect the walls and floor from mold, mildew and dampness.

The process of a pallet device includes the following steps:

Step 2. Plum preparation. Ready-made drain assembly can be purchased at a construction or plumbing store. It is also called a shower ladder. It must be of high quality.

The drain hole is immediately connected to the sewer system. The installation must be very tight, so you can use glue and sealants on all threaded connections.

Step 3. Now you need to lay out the base (use brickwork or rough screed) after drying the waterproofing composition.

We make the laying of walls using silicate or ordinary brick. Before this, it is necessary to put a metal mesh on the base for solid construction.

Experts recommend laying out the sides with a square, and making the protruding corner beveled. This will prevent injury to the corner and visually expand the space. After 3-4 days, you can proceed to the next stage.

We process the entire base of the pallet with a waterproofing material. After drying, we make a layer of screed over the entire surface of the pallet to hide behind it all the brickwork.

It is important that the screed has a minimum slope towards the drain, so that water does not accumulate after using the shower. After drying, apply the penultimate layer of waterproofing.

Step 4. Leveling the surface of the pallet. To do this, you can use a self-leveling mixture. We apply the final layer of waterproofing and tile the pallet. It can be a mosaic or any other tile.

Tiling or mosaic

In many cases, sidewall cladding is required to hide the mounting bases.One of the most convenient options for solving the problem is the use of mosaic tiles on a plastic or glass basis.

A glue layer is applied to the base with a notched trowel. After pressing the tiles, excess glue must be removed immediately.

Using the mosaic, you can veneer any uneven surfaces, as it is easily cut with construction scissors or a knife thanks to the paper base.

It doesn’t matter if you use tiles or mosaics, all seams must be sealed. This especially makes sense when you decide build a pallet yourself.

When forming seams, use crosses. After facing, grind the joints with a waterproof grout and a rubber spatula. Then the remnants of the grout are removed and everything is wiped with a piece of cloth. After everything dries, you need to wash the tile.

Reinforcing a steel or acrylic product

These solutions, especially acrylic, are not strong enough. Measures to increase strength are reduced to the installation of supporting elements, which may be bricks.

At the same time, all the supports in the places of contact with the bottom should repeat its shape. You can also use gaskets made of paronite or rubber.

Some complete models of showers have a high height of the fence and the pallet, for the installation of which there may not be enough ceiling height. In this case, you need to make a recess of the floor in order to install the pallet and connect to the drain.

Conclusions and useful video on the topic

Use the pallet installation recommendations by watching the video.

How to install a shower cabin:

Installing a shower tray with the right approach does not take much effort and does not require special training. If you follow the instructions, you will get first-class installation of a monolithic pallet with the highest reliability.

Have something to supplement or have questions about installing a shower tray? Share your opinion and leave comments on the publication. The contact form is located in the lower block.

Siphon for shower tray: design, purpose, installation features

Siphon for shower tray: design, purpose, installation features  The device of a shower cabin without a pallet: detailed assembly instructions

The device of a shower cabin without a pallet: detailed assembly instructions  Repair of a shower cabin: how to repair popular damage to a shower cabin with your own hands

Repair of a shower cabin: how to repair popular damage to a shower cabin with your own hands  Siphon for a shower cabin with a low pallet: types, selection rules, assembly and installation

Siphon for a shower cabin with a low pallet: types, selection rules, assembly and installation  How to assemble a shower tray: mounting options for typical options

How to assemble a shower tray: mounting options for typical options  Drain for a shower cabin: types of designs and rules for their arrangement

Drain for a shower cabin: types of designs and rules for their arrangement  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

When for the first time I got a shower cabin, then I went down with just an acrylic tray. The first six months after installation, no stocks occurred, but then the design became unstable. I tried to additionally fix it, however, since the pallet without normal stiffening ribs, nothing really changed, in the end I decided to replace it. Ceramic has been standing for a year now, no questions - everything is like the first day.

The acrylic pallet has many of its advantages, the main of which is the price. You just need to fix it right away, without waiting until it loosens up.

I used to have an enameled tray. Well, he stood and stood until his wife dropped a shower head on him and broke off a piece of enamel. There was a question about replacement, I thought to buy from stainless steel, but I did not find anything sensible in size and shape, there is a very limited choice of such options.I didn’t put ceramics or stone, I can’t afford it. He stopped at the choice of cast iron. Yes, it warms up slowly of course, but it keeps the temperature well, it feels good for the feet.