DIY acrylic bathtub installation: detailed step-by-step installation instructions

The advantage of acrylic bathtubs is lightness, but this point is also their drawback, since a sufficiently fragile and thin design may not withstand and burst upon impact or be damaged by the fall of a heavy object.

Agree, I would not want to spoil the new plumbing during installation. In general, installing an acrylic bathtub with your own hands is a simple task. The main thing is to understand the principle of work and adhere to technology.

Below are various ways of installing a bathtub; the procedure for connecting a siphon and a sewer supply is described. All instructions are accompanied by visual photographs and videos.

The content of the article:

Advantages and disadvantages of acrylic bathtubs

Acrylic bathtubs are very beautiful, have an original design and a variety of colors. At the same time, they have their weaknesses and vulnerabilities.

Therefore, it will not be superfluous to find out what problems you may encounter during installation and subsequent operation, and how to prevent them.

Among the advantages can be identified:

- Plastic. Acrylic lends itself well to molding and subsequent processing. This property of the material determines the presence of a huge variety of shapes of acrylic bowls.

- Lightness. The acrylic bath has a small weight (15-25 kg), so one adult man can easily cope with its installation.

- Priority heat engineering. Acrylic itself is a warm material. In addition, it has low thermal conductivity, acrylic bathtubs can retain heat for a long time, the water in them cools much more slowly than in cast-iron structures.

- Maintainability. Plumbing and generally acrylic products lend themselves well to repair and restoration.If the damage is significant, then you can restore the bath using an acrylic liner, which is made for a specific design, and then simply inserted into the old container.

As for the shortcomings, they are also present. acrylic products must not be forgotten. Following the guidelines below will help you avoid potential problems and extend the life of your acrylic bathtub.

The disadvantages of acrylic plumbing include:

- Sensitivity to high tº. Acrylic does not withstand very high temperatures. When heated above 60 degrees, it can deform, so you should not pour too hot water into the bath.

- Fragility. If you accidentally drop a heavy metal object, a step, a similar rough surface into the bathtub, you can pierce its bottom through.

- Vulnerability. Acrylic bath capricious in care - it can not be rubbed with hard brushes, washed with powders containing abrasives, since the enamel is very susceptible and can easily be scratched from the effects of solid particles.

And it should be noted, if not a drawback, then the inconvenience that one who first plunged into an acrylic bathtub encounters. Due to the fineness of the material, the bottom may bend slightly under the weight of a person. However, you get used to this feature of an acrylic bath rather quickly.

Acrylic bathtub installation methods

There are several options for installing an acrylic bath. The easiest way is to mount on the legs, which are pre-installed on the strips, and then attached to the bottom of the bathroom with three to four screws.

The installation process includes a number of standard steps:

However, this option cannot be called reliable, since the bathtub is held only on four racks, while its sides remain without support. In addition, the bottom when bathing a person of fat complexion will greatly sag, which is also not very nice.

Thin-walled acrylic bathtubs require a stronger support, which is commonly used as:

- Massive metal frame from a thick profile pipe, manufactured in the factory.

- Brickwork, built under the bottom of the bath.

- Support legs and bricks at the same time.

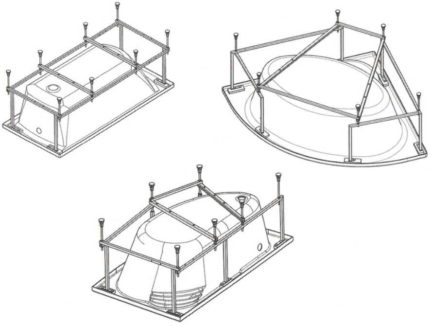

Often the choice of installation option depends on the configuration. The most optimal installation method is mounting on a factory frame, but not all manufacturers complete the bathtub with a metal frame.

As a rule, inexpensive products are sold either with legs or without any mounting kit. The frame can be purchased separately. You can install the bath on bricks, which is also a reliable type of fastening.

# 1: Installing the bowl on the legs

The installation of an acrylic bath on the legs is permissible only for standard designs of a rectangular shape. In other cases, you should choose a different installation method.

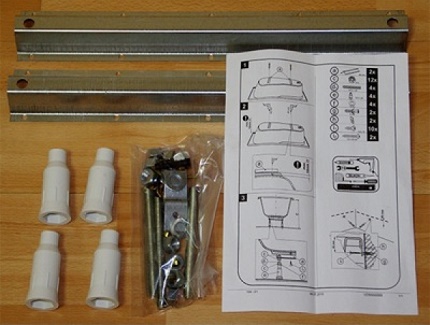

Turning the bath upside down, step back 4 cm from the edge of the reinforcing plate and mark the middle. Locate the center of the mounting rails and align it with the middle of the bath. Mark the locations of the fasteners, drill holes in the bottom and fasten the slats using self-tapping screws.

For fastening the legs, a rod with a lock nut is inserted into the hole on the bar and secured with another nut. Then adjustable plastic legs with thrust bearings are screwed onto the hairpin.

Now you need to turn the bath over, put it on the legs and adjust their height so that the structure stands exactly without distortions. We carry out this operation using the building level.

To fix the structure, the side of the bathtub is put on special mounting plates included in the delivery, which are screwed to the wall. To determine where the fixtures will be located, attach the bathtub to the wall and mark the edge of its side with a line.

The top edge of the plate should be approximately 4 mm below the mark. For standard bathtubs, four fixtures are usually made in length and two in width. Screw the plates in the places of marking.

# 2: Mounting on a metal frame

This method of installing an acrylic bathtub is somewhat more complicated and will require more time, but it is also more reliable. Frames are developed by manufacturers for a specific model and, as a rule, are sold as a set.

For standard rectangular designs, you can purchase the frame separately or make a support frame by yourself.

The main element of the frame is the frame, on which the remaining structural parts are then attached. Often, a frame welded in the factory, but not always, is included in the package. In some cases, it will have to be assembled independently according to the manual attached to the product.

The frame is placed on an inverted bathtub, and in this position they begin to assemble the entire frame, sequentially fixing the remaining parts. The package includes racks, studs, plastic legs with thrust bearings, nuts, screws and wall mounts.

The number of parts depends on the size and shape of the bath, the more complex the design, the more elements.

To fix the vertical rack, a stud with a screwed nut is threaded into the corner hole of the frame, and then inserted into the rack and screwed into it. The top of the stud is fixed with another nut. Thus, all the racks of the frame are installed.

When all the racks are screwed, it is necessary to align the frame evenly, adjusting its height and checking the accuracy of the installation with the building level. Next, the frame is screwed with screws to the bath. First, the frame is attached to a reinforced bottom plate, and then the racks are fixed in the corners of the bathtub in places where there are embedded plates.

Now it remains to screw the legs to the frame. In the places where they should be located, holes were made where the studs are screwed first and secured with nuts using the correct height. Then plastic legs with thrust bearings are screwed on them.

If you purchased an acrylic bathtub with a screen, then metal L-shaped plates for attaching the screen are additionally inserted on the legs, which will be located on the outside.

Turn the bath over, place a screen on it and adjust the height of the structure using the nuts on the legs. Put it against the wall and mark the places where the wall mounts will be located. Screw them and fix the sides of the bath on the plates, as described above.

Once again attach the screen to the bathtub, mark the places for fastening the screen along the edges and in the center of the bathtub and screw on the plates that are supplied with the screws. Fix the screen on all plates, including those that were previously screwed to the legs.

Seal the joints of the acrylic bath with the wall with silicone sealant. To do this, first clean both surfaces of dust, and then degrease with alcohol. Stick construction tape on the wall and sides of the bathtub, apply an even layer of silicone, and then wet your finger with soap and water and smooth.

# 3: Option with a brick support device

If you purchased an acrylic bathtub in which there is neither a frame, nor legs, and at the same time do not want to burden yourself with additional costs, that's okay. There is an opportunity to solve this problem, if not completely free, then very inexpensively.

To do this, you will need a few bricks, some cement, a metal (preferably aluminum) corner for attaching the bathtub to the wall and plumbing silicone to seal the seams. Your task is to create two brick supports on which the bath is then installed.

Brickwork is done on both sides of the acrylic bath so that the bottom reinforcing plate rests firmly on two brick supports. Depending on the required height of the bath and the location of the sewer inlet, two or three rows of bricks are laid out.

The solution should consist only of cement (1 part) and sand (3 parts), or you can buy an inexpensive masonry adhesive.

After two rows of bricks have been laid, wait for the cement to set and place an acrylic bathtub on them. If the height suits you, mark the level of the sides of the bath on the wall, and then attach a metal corner according to the marking and apply a silicone compound to it.

Put a layer of cement on the brick foundation and install the bath from above, lowering its sides to the corner and sliding it tightly against the wall. Do not forget to remove the protruding silicone from the sides and remove the excess solution from under it a maximum of half an hour after installing the bath.

There is another way to install an acrylic bath on bricks, which consists in creating a kind of pedestal on which the bowl will stand. At the same time, the bottom of the bathtub can be installed directly on the bricks, or the legs can be pre-fixed and a brick foundation can be built under them.

Brickwork is preliminarily done as described above with the only difference being that there is no space left between the bricks, but one solid foundation is made. Further, if a bathtub without legs will be installed on the pedestal, then it is necessary to lay two metal strips on the bricks and put a bowl on them.

This is done so that between the brickwork and the acrylic bath there is a gap of about 1 cm, where then, after the mortar has completely solidified, the mounting foam will be blown for mounting the bowl.

If the legs are pre-screwed to the bath, then in this case everything is simple: it is installed above the foundation, the legs are adjusted to the desired height, then the foam is blown.

The space between the bathroom and the bricks is blown out with construction foam. To ensure optimum pressure on the foam, it is advisable to fill the bath with water.

Sealing joints between the wall and the side of the bath

The silicone sealant with which you processed the joints between the wall and the acrylic bath is a good thing, but not enough. No matter how tight the construction is to the wall, cracks still remain. In construction stores you can buy a special tape.

It is mounted on silicone and mounted on the wall and sides of the bathtub. In addition to complete tightness, it gives the design an aesthetic and complete look.

Joints can also be sealed with plastic corners. Their edges are equipped with rubber inserts that prevent water from entering. There are many skirting boards of various shapes, colors and designs, which allows you to choose a product for any bathroom interior.

Corners are attached to the bathtub and walls using silicone, which is applied to pre-alcohol-free surfaces. It is recommended to fill the bath with water before applying it and leave it filled until the sealant has completely dried. If this is not done, then in the future microcracks may appear on it.

Siphon assembly and sewer connection

We took this item to the end of the article to describe in detail the process and the nuances of connecting siphon equipment to an acrylic bath. However, this work must be done immediately after installing the legs or frame, before installing the screen and until the bath is finally attached to the wall and brickwork.

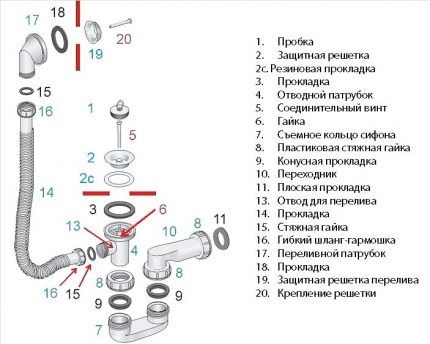

As a rule, the siphon is delivered unassembled. A large number of randomly arranged parts can even frighten a person who first encountered a bathtub connection at first glance.However, in the attached instructions, everything is described in detail and shows how the siphon is assembled, so the assembly does not cause special difficulties.

Installation siphon Starts by connecting the receiving pipe (4) and the protective grill (2) to the lower bath outlet. Before this, the joints should be treated with sealant and put inside the rubber gasket (3), on top of which a layer of sealant is also applied.

Then, without waiting for drying, the branch pipe is inserted into the lower part of the bath.

Next, an already assembled flexible hose (16) is inserted into the overflow outlet (13), and its other end with a pre-installed gasket (18) is connected to the upper hole of the bathtub and secured with a protective overflow grille (19).

Then the part of the siphon that connects to the sewer pipe is collected. All joints are sealed. When collecting the siphon, try not to overtighten the threaded connections, as this can lead to deformation and breakage of plastic parts.

At this stage, it’s worth taking care of mixer installation.

Exterior finish methods for acrylic bathtubs

If you purchased an acrylic bathtub without a decorative screen, then this part can be done by yourself.

When performing finishing work, it is necessary to observe some rules:

- use only moisture-resistant materials, resistant to temperature extremes, not susceptible to the formation of mold and fungus;

- provide quick and easy access to communications under construction.

In the event that the bath is installed on bricks, it is possible to lay a brick wall on the front part in half a brick thick, and then veneer it ceramic tiles or mosaic. The upper row of bricks is made 2-3 cm below the side of the bathroom, and then blown with foam for sealing.

It is also necessary to leave the technological hole, and then use the awnings to make the door.

Finishing an acrylic bathtub with plastic, MDF or moisture-proof drywall is very popular. The original solution is to create mirror screen. Plastic panels allow you to quickly and inexpensively make the final lining of the bath. In addition, if the panel has become unusable, it can be very simply replaced.

As for drywall, after installation, it can be finished with different materials: tiles, waterproof wallpaper, paste over with a film or apply decorative plaster.

In both cases, you must first make the frame of a metal profile or wooden beam. In this case, the metal must be treated with an anticorrosive composition, and wood - with a moisture-resistant primer.

To make a wooden frame, install boards around the entire perimeter of the bathtub, which will serve as the base, and screw them with screws to the floor. Make vertical racks in the corners, attach the upper horizontal board to them using metal corners and install additional vertical racks in increments of 50-60 cm.

Interesting options for creating a screen for the bath are proposed in this article.

Conclusions and useful video on the topic

The frame assembly and installation of the bathtub with a plastic screen are described in the following video:

Video instruction on how to properly assemble the factory metal frame for an acrylic bath:

Acrylic bathtubs of angular, round or asymmetric shape are installed only on the factory metal frame. Manufacturers attach detailed instructions according to which any man will be able to cope with this work on his own. However, it is better to entrust the installation of a bathtub with a hydromassage to specialists, since it requires the connection of complex electrical equipment.

Have something to supplement or have questions about installing a bathtub? Share your personal experience in installing plumbing and please leave comments on the publication.

How to install a steel bath with your own hands: step by step instructions

How to install a steel bath with your own hands: step by step instructions  DIY cast iron bathtub installation: a detailed step-by-step guide

DIY cast iron bathtub installation: a detailed step-by-step guide  How to install a bath yourself: a step-by-step installation guide

How to install a bath yourself: a step-by-step installation guide  DIY enamel bath: how to treat the bath with liquid acrylic at home

DIY enamel bath: how to treat the bath with liquid acrylic at home  DIY bathtub painting using epoxy enamel and liquid acrylic

DIY bathtub painting using epoxy enamel and liquid acrylic  Do-it-yourself cast iron bathtub repair: common damage and repair

Do-it-yourself cast iron bathtub repair: common damage and repair  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

There was the first experience of installing such a bath, rather sad than successful. I decided to install it myself, and in vain. Included with the bathroom were free fixtures for installation, legs and mounts. It took me half a day to do it, I did everything according to the instructions, in the end everything was ready to look, but due to inattention, or because of the rush when moving, I did not take into account one thing - the uneven floor in the bathroom, the bathtub rocked. I had to redo it. So, advice for newcomers to the future - check everything thoroughly from and to.

We also have an acrylic bathtub at home, I do not agree with the minuses that are listed above. Not so fragile, they dropped pretty heavy things. And not only did the bottom fail, but there were no scratches. Of course, it is impossible to clean with powders, but in general it is not so whimsical. They did not install it themselves, but the master who did the repair, but, in his words, the process is simple. There was a frame with legs in the kit with the bathroom, so it turned out pretty steadily. The only thing, after installation, the master filled the bath with water and forbade us to drain for three days, apparently so that the joints froze properly.

Why, when installing the bowl on the legs, you need to leave 4 mm. for subsidence, if she is already standing? Legs will not let her sag 4 mm.

If on bricks with foam, then okay. And if the legs, then why? Then the legs must be aligned after. I do not understand.

Hello. Take into account the subsidence of the bath under load with the absence of wall mounts.

Count. The weight of the bath, on average - 25 kg (acrylic), water 200-250 kg, the weight of the human body. The bath has a drawdown, the load on each leg is 25%, which is not enough.

Tell me, please, the mounting plates that are screwed to the wall, are located on the same level?