Stinol Refrigerator Repair: Frequent Problems and Solutions

The Stinol brand is popular among lovers of high quality and reasonable price. Reliability, high-quality assembly, functionality and durability of these devices are not in doubt among consumers. But technology remains technology and, despite careful operation, sometimes it breaks.

Stinol refrigerator repair is not a problem, since service centers are almost everywhere. You can repair the equipment yourself. In our article, we describe in detail the causes of characteristic breakdowns and methods for restoring the performance of refrigeration machines.

The content of the article:

The principle of operation of a typical Stinol unit

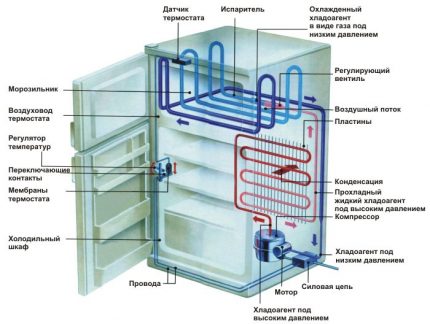

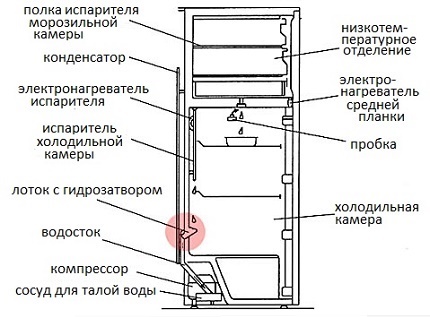

Range refrigeration units Stinol It is represented by a wide range of models with various operational characteristics. All of them belong to evaporative or compression type devices. This means that a compressor and an evaporator are necessarily present in their design. Let's see how they work.

To cool the working chambers of the equipment, the so-called refrigerant is used. The composition is a liquid capable of evaporating at a certain pressure at room temperature.

Most often, refrigerant R22 is used as the refrigerant, but there may be other compounds. All types of refrigerants are called freons.

The duty cycle is as follows. Liquid freon is fed into the die. This is a narrow nozzle in the form of a fragment of a capillary tube through which the refrigerant is injected into the evaporator.

The latter is made in the form of a coil, which allows heat exchange to proceed with maximum efficiency.Inside the evaporator, freon rapidly expands and transforms into gas, while absorbing a large amount of heat.

As a result, the temperature inside the refrigerator or freezer compartment drops. If the refrigerant is constantly pumped into the evaporator, the pressure in it will increase sharply and the evaporation process will stop.

Therefore, the freon vapor is continuously pumped out by the compressor and fed into the radiator. This is another coil located on the back of the refrigeration unit. Here the refrigerant vapor condenses and gives off heat.

Next, the liquid freon is fed into the die and the cycle repeats. The main feature of such a system is the presence of moving parts and mechanisms that may sooner or later fail.

Under the Stinol brand, refrigeration units are manufactured with one or two compressors. In the latter case, it becomes possible to separately control the freezer and refrigerator compartments, each of which is serviced by its own compressor.

It is convenient, but significantly complicates the system, as well as its maintenance and repair. In addition, the brand produces No Frost equipment and models with drip thawing system.

Electrical system device

Normal operation of any compressor refrigerator provides an electrical circuit.

In its simplest form, it includes several elements:

- Thermostat, responsible for maintaining a certain temperature.

- Thermal protection relay to prevent compressor overheating.

- Electric motor

- Start relay, responsible for starting the motor.

The duty cycle is as follows. When voltage is applied to the device, current flows through temperature controller with closed contacts, the forced defrost button, then through the thermal protection relay to the start relay and to the working winding of the motor.

Since the motor shaft is standing, the current flowing through its working winding is much higher than the nominal value. This is necessary because the design starting relay provides for the closure of contacts on the starting winding only when the rated current is exceeded. Thus, the relay transfers the current to the starting winding, the motor starts its rotation, the voltage in the working winding disappears.

The motor continues to operate in normal mode, the refrigeration unit begins to freeze. When the previously set temperature is reached, the thermostat is triggered.

It opens its contacts, and the current ceases to flow to the motor. Refrigerator compressor stops. When the temperature changes, the thermostat contacts again close and the cycle repeats.

To protect against overheating hazardous to the motor, a thermal protection relay is provided. Its main element is a flexible bimetallic plate. Upon reaching a dangerous temperature, it bends and opens the contacts, the cooled element "rises" into place and closes them.

Overview of typical failures

It is clear that if the equipment stopped working, it needs repair, and sometimes replacement. However, there are signs indicating that the owner needs to pay attention to his unit and, perhaps, invite the master.

Normally, the compressor should operate without excessive noise, periodically turn on / off. Continuous compressor operation is a direct signal of a malfunction.

The temperature inside the refrigerator and in the freezer compartment must correspond to the set. There should not be excessive frost inside the freezer, and water should not accumulate in the refrigerator compartment. A variety of factors provoke breakdowns.

Most often this is improper operation or installation of the device, mechanical damage, environmental influences, for example, too high temperature in the room. Power surges are also very dangerous.

If the engine runs without interruption, and the temperature drops extremely low, the temperature controller is most likely to blame. With its breakdown, a different picture is also possible. The unit refuses to start and defrosts, the compressor does not work.

The compressor will work without shutting down, and ice may appear in the evaporator. Refrigerant may leak through the cooling circuit. This problem is more common with equipment with a lower freezer arrangement.

A metal tube runs along its perimeter, which can corrode in about 6-7 years. In this case, it becomes a source of evaporation of freon.

If there is a leak, the freezer will continue to work, but the refrigerator compartment will not. Corrosion can occur both in the evaporator and in the condenser. Repair in such cases is not possible, only the replacement of damaged elements.

Quite often, Stinol owners turn to masters with compressor problems. It can be jamming of the motor mechanism. The engine will turn on, but not spin, but only buzz. After a short time it will work thermal protection relay.

Frequent and short circuits in the working or in the starting winding of the motor. Less commonly, the capillary conduit fails. This can be seen by the increase in temperature inside the refrigerator and freezer compartment, the appearance of ice on the evaporator.

The engine will work, almost without stopping. All these are typical breakdowns, which the master will most likely have to cope with.

Self Repair Guide

The user, even a little familiar with the technique, understands that it is impossible to give detailed instructions for repairing equipment of a particular brand. Models are too different in their technical characteristics. You can only give general recommendations for the repair of individual components.

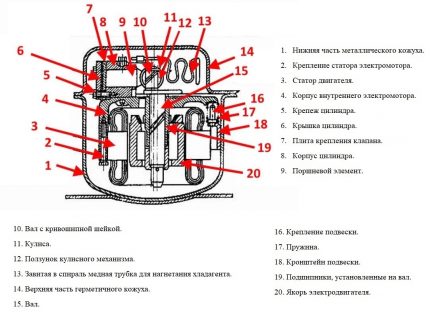

#1. The compressor of the device and its suspension

The compressor unit of the refrigeration unit is quite simple. But at the same time, its independent repair is practically excluded. Frequent inter-turn winding closures involve compressor replacement.

Amateur craftsmen trying to rewind them usually spend time and energy for nothing. The reason for this is moisture and dust mixed with air that get into the compressor during operation.

As a result, the node still has to be changed. Masters do not advise doing this. Another thing is the suspension of the compressor. Due to its deformation, failures in the operation of the entire node are possible.

First of all, it is worth checking the elasticity of the stroke of all its mounting legs. It should be about 8-10 mm or even more. If this is not the case, you will have to replace the shock absorbers, which is neither expensive nor difficult.

The main difficulty will be that the compressor is massive and capable of breaking the cooling circuit tube by weight. Therefore, in the process of replacing shock absorbers, the assembly should be firmly fixed in the working position and handle it as carefully as possible.

In the latter case, it is worth wrapping it with cloth or felt and securing this bandage with a woolen or cotton thread. Synthetics or foam rubber is strictly not recommended.

When the temperature changes, they will become brittle or stick together. In any case, there will be no benefit from them. Such a “bandage” will not only solve the noise problem, but also protect the tube from premature wear.

Another common problem is a decrease in the amount of freon. After watching the videos on the Internet, some craftsmen try to refuel on their own. Masters persistently do not recommend this.

It will be possible to fill in Freon, but whether the unit can work after this is a big question. Water vapor and dust will inevitably fall into the cooling circuit during the charging process, which will subsequently lead to breakage.

Besides, refrigerant charge A full-time compressor assumes its wet operation by force. And this is extremely dangerous. In this case, the best thing you can do for your compressor is to invite a qualified specialist with a license, who will perform the necessary work.

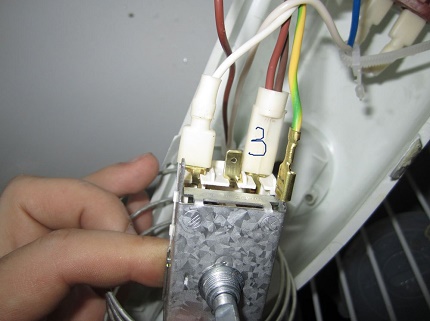

# 2 Protection and start system

The starting and thermal protection relays are usually combined by designers in a common unit. In order to get to it you will have to drill the rivets holding the cover.

After carrying out repairs, it is best to put it on plastic glue and “grab” it with screws. The most “weak” places of the node can be considered contacts. They are often fouled or fused. Elementary cleaning will help here.

Another “dangerous” area is the starter core. It can be filled with dust, which leads to sticking of the contacts of the starter. The problem may be in the bimetallic plate. Over time, it is able to lose some elasticity. If the part is slightly curved in cold form, it is enough to give it the desired shape.

Loose adjusting screws may converge, and then the compressor starts to work as if there are inter-turn faults on both of its windings. To solve the problem, it is enough to unscrew the screws to the required clearance. It is about 0.15-0.25 cm. And clean the contacts of the current protection.

# 3 Thermostat of the refrigeration unit

The design of thermostats used in refrigerators may be different. In general, two types of such elements are distinguished: electronic and thermomechanical.

The first are used in devices with electronic control and are a group of detectors and thermistors connected in a single unit with the control board. Only a certified electronics engineer can try to repair anything in such a system.

The thermomechanical thermostat is designed as a single unit, but it is considered completely non-repairable. This is because the thermotube is glued to the evaporator, the seam is filled with sealant, and the entire system is covered with a casing.

It is extremely difficult to separate the unit from the evaporator without special tools and skills. In addition, you can not violate the correct position of the thermotube, which is fraught with serious damage.

The only thing you can try to do with the thermostat is to work with it without removing it from the unit. So to say "on weight." In this position, the transfer spring can be inspected and replaced if necessary.

You can check the operability of the chipper screw, as well as inspect and thoroughly clean the contacts. Reassembly should be carried out very carefully.

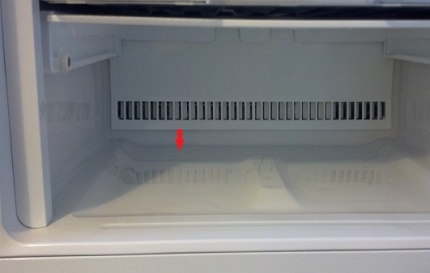

#4. Weeping device drainage system

In units with a drip system, water may appear and accumulate inside the refrigerator compartment. The main reason for this unpleasant phenomenon is a blockage in the drainage system. The design is designed to drain water from the chamber and passes inside the refrigerator.

Another sign of clogging is the appearance of a snow coat in the freezer. Since the drainage begins in the food storage compartment, in order to protect against organic matter getting inside the tube, it is necessarily made with a water seal.

In practice, it looks like a slight bend in which all unnecessary contaminants can linger. To clean the hydraulic seal, the manufacturer offers special tools that need to occasionally clear the hole from accumulated contaminants.

In this case, the outflow of water is improving. If the drainage is clogged, such a cleaning will not help. The blockage will need to be pierced.

This must be done very carefully, since the drainage system itself is a tube made of thin-walled plastic. It is best to take fishing line with a diameter of 1 mm and smoothly melt its end.

The resulting impromptu cable is lowered into the drainage hole and the system is cleaned. Then, one and a half to two liters of warm washing solution is poured into it and finally washed with clean water.

#5. Fuser, timer and fan in No Frost appliances

Refrigerators “Without hoarfrost” are structurally more complex than “crying” ones. Accordingly, there are more problems with them. Their main difference is the presence of blowing, which drains excess moisture, which prevents the appearance of frost.

The masters consider the fan, fuser and timer to be the “weakest” places of such devices. Inspect the fan from the freezer. Depending on the model of the refrigerator, the element can be open or closed.

In the latter case, the assembly is covered with a cover with holes. Electronic devices typically use open nodes. The timer in this case is also electronic.

Such a tandem cannot be independently repaired; a master is needed here. For simpler models with a removable cover and an electromechanical timer, repair is quite possible. First you need to carefully remove the cover.

When reaching the fan, it should be carefully inspected and try to turn the impeller with your finger. If it does not give in or is tight, you need to disassemble the node. For this, a fixing plug is found.

It should be on the axis of the device, it can be covered with a company sticker.There is a washer under the cork, it may be made of plastic or metal. The first is bred and removed using conventional needles.

Steel is removed with pliers or a special tool. Under this washer are a few more Teflon, which are carefully removed and stored. Further, the impeller along with the rotor is removed, cleaned and lubricated.

Wizards warn that the lubricant must be selected correctly. Only low-temperature compositions are used, otherwise they will thicken. After that, reassembly and performance testing are carried out. Maybe, refrigerator repair went quite well and the problem is resolved.

If not, it remains to check the operation of the fan. To do this, the unit is opened at the back, then you need to access the device through which the fan is turned on. It can be either a mains filter or a low voltage filter.

For testing, the fan is connected to the narrow standard terminals of the filter, and the wide ones supply mains voltage. If the impeller does not start to rotate, there may be a problem in the filter.

To verify this, remove a similar filter from the compressor cooling fan and repeat the experiment. When a failure is confirmed, the filter is replaced with a similar one. If everything is in order, it is worth checking the fuser and the timer start timer. They are located in the evaporator area.

First you need to remove the fuser from the connectors and ring it with a tester. Resistance should be zero. If not, change the part, it is disposable. Pre-check for breakdown of the heater TEN of the evaporator.

After that, you need to put in place all the disassembled parts and close the control sockets of the thermic jumper. You only need to do this on an off-line unit. Then it is turned on. It should work on a short cycle, abnormally. If so - the problem is in the termichka, it needs to be replaced.

An important nuance. Such a check should be very short in time, literally 3-4 seconds, otherwise the timer will fail. If the timer does not work, most likely the cause of the problem is in it. Do not try to repair it, it is within the power of experienced craftsmen. It will be easier to replace the entire defective assembly.

Conclusions and useful video on the topic

The algorithm for restoring the operating parameters of the thermostat of the Stinol refrigerator:

Video about compressor replacement procedure:

A briefing for those wishing to repair the Antinei system in the Stinol refrigerator:

Stinol refrigerators are of good quality and reliability. However, they also fail. If you have the desire and skills, of course, you can try to "revive" the unit on their own. You need to understand that this event can not always end successfully.

Unskilled repairs can only aggravate the situation and then you have to fork out for more complex repairs or, which I would not want at all, to purchase a new refrigerator.

Want to talk about how you repaired a Stinol refrigerator with your own hands? Have a desire to share useful information on the topic of the article and technological secrets? Please leave comments in the block below, ask questions, post a photo.

Repair of refrigerators "Atlant": common problems and solutions

Repair of refrigerators "Atlant": common problems and solutions  Liebherr Refrigerator Repair: An Overview of Common Problems and Their Solutions

Liebherr Refrigerator Repair: An Overview of Common Problems and Their Solutions  Samsung refrigerator repair: the specifics of repair work at home

Samsung refrigerator repair: the specifics of repair work at home  Why the refrigerator does not turn off: an overview of frequent breakdowns and how to fix them

Why the refrigerator does not turn off: an overview of frequent breakdowns and how to fix them  Why the refrigerator does not freeze: frequent malfunctions and solutions

Why the refrigerator does not freeze: frequent malfunctions and solutions  Why is the refrigerator knocking: finding the causes and methods of eliminating the knocking

Why is the refrigerator knocking: finding the causes and methods of eliminating the knocking  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

It seems to me that you shouldn’t climb to repair the refrigerator yourself if you are not a master in this area. Danger to life in any case, and even more can be broken. It is necessary to contact specialized service centers for this brand. By the way, can you tell me where such centers (addresses) are located in Moscow in the northern district, with competent specialists in the repair of this brand of refrigerators?

Hello. I’m a topographical cretin and not strong in the areas of the capital, so I can only recommend asking this question here.

I can’t get the thermotube out of the Stinol refrigerator. Acidified, it seems. It seems to pull a lot, but not amenable. Are there any ways to get her out? I'm afraid to break.