Do-it-yourself evacuation of the air conditioner: technology for work + valuable recommendations

When buying a split system and calling the installation team to install it, we all want the climate control device to get rid of the heat in the summer, and from the cold in the spring and autumn. And to still work properly for 6-7 years at least without maintenance. Is that all right?

If the manufacturer’s warranty protects you from factory defects, then from the negligence of the installers you only need to understand the installation procedure of the split system. In 70% of installation works, “air conditioning” masters simply do not vacuum the air conditioner, since it is long (about 30-60 minutes) and expensive (a good vacuum cleaner costs more than 12 thousand rubles).

Meanwhile, this “minor” installation omission seriously affects the life of the split system. We will talk about the vacuuming of air conditioning systems in detail.

The content of the article:

Split system evacuation goals

Most multi-brand split systems can easily cope with a six-year or longer uptime under two conditions. The first is the lack of factory defects in split units. The second is right air conditioning installation in place.

After placing the blocks (outdoor, indoor) in the field, connecting the flared ends of the copper tubes with the taps of the external and the fittings of the internal split modules, the work of the installers looks completed.

However, before letting in the freon refrigerant into the pipe line and turning on the air conditioning, climate control manufacturers recommend pumping air out of the connecting pipes and the circuit as a whole.

So is vacuuming a home air conditioner necessary or is it an unnecessary operation, as many installers of split systems confidently declare? We will see.

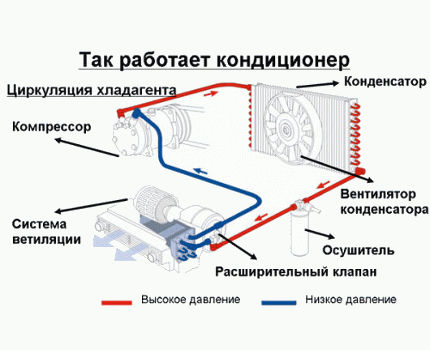

The working processes of the refrigerant circulating through the tubes and components of the air conditioning device are precisely balanced by the manufacturer. The cycles of compression, condensation and hypothermia of Freon go under strictly defined aggregate states of the refrigerant.

The following happens:

- Vapor refrigerant flows through a thick pipe from the evaporator (internal split unit) to the condenser (outdoor unit), where the compressor pumps it. There, freon is blown by a fan and cooled;

- The liquefied refrigerant is sent through a thin tube to the evaporator of the indoor unit. Its pressure is reduced by a thermostatic valve;

- In the indoor unit, Freon boils and actively evaporates, absorbing heat. A cold heat exchanger is blown by a fan that distributes chilled air throughout the room. Then the refrigerant is pumped from the indoor unit into the “outdoor” unit - the duty cycle is repeated.

But air and moisture mixed with freon change its operating parameters, seriously interfering with the air conditioner. How do these extra components get into the refrigerant?

The connecting modules of the climate system, the copper tubes contain air after they are connected to the split blocks. What is also important - the air always contains moisture, which also affects the characteristics of the air-conditioning device negatively. Let us explain how water and air affect freon refrigerant and the compressor of a split system.

Air mixed with Freon

Preserving in the tubes of the split system (that is, vacuum was not performed), atmospheric air accumulates in the condenser of the “street” unit, since the receiver blocks its further passage (like vaporous (non-condensed) freon).

The air collected in the condenser significantly increases the pressure required to condense the refrigerant. In addition, an air film appears on the condensation surface, many times worsening the selection of heat from the condensed freon.

Since heat removal is degraded, and the amount of incoming refrigerant remains the same, condensation pressure increases, requiring an increased degree of compression from the compressor. As a result, an unacceptably high pressure and temperature are observed at the outlet of the compressor, which sharply accelerates its running time for wear.

Moisture in A / C compressor oil

In addition to the main refrigerant material, the split air conditioning system circuit contains synthetic polyester oil. Like other refrigeration equipment, POE oil lubricates the moving parts of the compressor.

The oil intended for lubrication and sealing of compressor units is made on the basis of polyesters. It is contained in the capacity of the compressor. During operation, the oil enters the refrigeration circuit in a small volume - about 5-10% of the total.

Covering with a thin layer the walls of the tubes of the refrigeration circuit, the oil film in addition to heat dissipation contributes to improved circulation of freon.

However, ester oils are highly hygroscopic. If the water content of POE oil exceeds 30 ppm (30 parts per million parts of polyester oil), its performance will deteriorate dramatically. This may be followed by jamming of the compressor - the most expensive unit in the split system.

The increased water content weakens the dielectric strength of the polyester oil, which will lead to breakdown of the compressor winding.

In the presence of water in oil at a level above 30 ppm and in the presence of fluorine, chlorine and bromine atoms contained in R410 freon, hydrolysis processes develop, causing the formation of active acids - hydrochloric (HCl), hydrofluoric (HF) and hydrobromic (HBr). Even in a small volume, these acids will corrode the tubes of the refrigeration circuit due to chemical corrosion.

Finally, water not dried by vacuum and saturated with synthetic oil will cause internal icing of the thin tube of the Freon circuit near the external unit.

This is especially evident when the split system is working on heat during the off-season. As a result, the compressor works with insufficient refrigerant volume, quickly overheats and turns off (protection works). In the worst case scenario, the compressor burns out. With the rules compressor performance checks and its repair will be introduced by our recommended article.

Note that by evacuation it is impossible to remove moisture from the synthetic oil contained in the air conditioner. There is one option - to drain the moisture-saturated POE, replacing it with new oil.

How is the air conditioning system evacuated

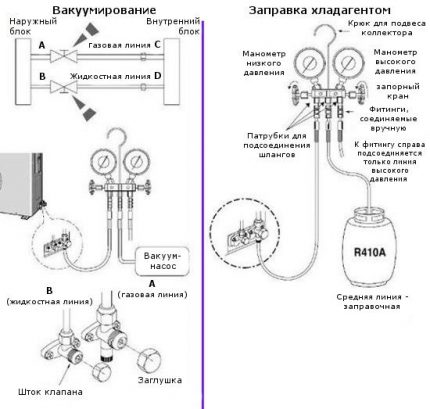

To perform the dehumidification and deaeration of the air conditioning circuit, the following equipment will be required: manometric (collector) station, which is also used to refuel split systems with freon; vacuum pump; screwdrivers and wrenches.

To let Freon into the circuit after evacuation, two hex keys (usually 4 mm) are required.

In order, we will consider how to vacuum the newly installed (new) two-block air conditioner:

- We connect the hose (blue color) of the manometer station from the fitting under the low pressure gauge to the service port on the valve of the external unit of the split system (thick tube of the "gas" phase of the refrigerant). The taps on the valves of the split block (open with a hex key) must be closed;

- We connect the filling hose (yellow) from the middle fitting of the collector station to the vacuum pump;

- Turn on the pump;

- Open the low pressure valve (blue, under the blue pressure gauge) at the manometer station. The evacuation process has begun;

- We wait from 15 minutes to half an hour (the longer the freon line, the longer) until the pressure gauge needle goes below zero;

- We turn off the pump and expect maximum purification of the atmosphere in the trunk of the split system from moisture and air gases. It will take more than 30 minutes;

- Close the blue valve at the manometer station, only after that - disconnect the vacuum pump;

- Without opening the blue valve and without removing the blue hose from the valve on the "street" split block, open two taps on the external block of the air conditioner with hex keys, let the freon into the circuit. Then you can disconnect the blue hose.

Follow the arrow of the blue pressure gauge. As the degree of rarefaction of the atmosphere of the refrigeration circuit increases, it should slide to zero. Depending on the pump capacity and the length of the freon line, the vacuum will take 15-20 minutes.

Then, turn off the pump (do not disconnect!) And follow the gauge needle for 30 minutes. Pressure is maintained - everything is fine, you can fill the circuit with refrigerant. Models of vacuum pumps of the middle price range and higher are equipped with a vacuum gauge scale; it is especially convenient to monitor the degree of rarefaction of the atmosphere on it.

Errors in the vacuum systems of split systems

In the absence of a vacuum meter, air conditioning installers are guided by the pressure on the manometer - they wait for the arrow to drop below zero, and then complete the vacuumization. This is the deepest mistake!

Continue to maintain atmospheric rarefaction in the freon circuit for at least half an hour with the pump turned off to evaporate and remove moisture from the air conditioner. This operation is called crimping.

If during the vacuum crimping the blue pressure gauge shows spontaneous pressure normalization - the arrow will go from zero to one - depressurization is observed. We check the attachment of the hoses to the manometric system, to the taps on the street split unit and the vacuum pump.

Not finding a weak fastening between these devices, we are looking for a mounting defect - tightened or loose nuts on the copper pipes of the line, or poor-quality rolling of their ends.

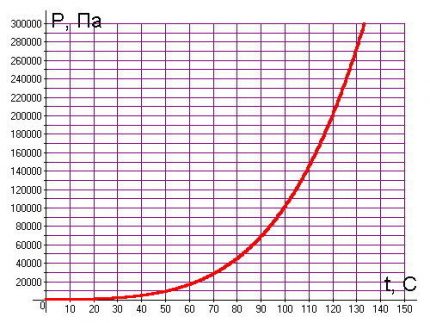

Evacuation of the refrigerant line is effective if only the temperature in the area of the external air conditioning unit exceeds +15aboutC. Water at low street temperatures in a rarefied atmosphere does not evaporate, but freezes - it is practically impossible to remove it from the pipe line.

For example, at +30aboutWith enough 40 mbar to evaporate the water available in the refrigeration circuit. And at 0aboutC you will need to reduce the pressure to a deep vacuum - below 6 mbar, otherwise there will be no evaporation and moisture removal.

Therefore, evacuation must be performed either in the warm season, or with special heating of the heat exchanger of the external split unit (for example, a heat gun) for the entire time while the vacuum is maintained in the prepared freon line.

Note that the purge of the circuit with freon, practiced by negligent installers, cannot give the proper result to eliminate air and moisture. This is only the aimless consumption of freon, by the way, not cheap.

Pumps for evacuation of split systems

To remove a larger proportion of gaseous substances from collected, but not yet filled with freon condensing unit, requires a special device - pump-vacuum. The pumping process of the air from the split system is able to perform pumps of two main types - low-vacuum and high-vacuum.

We repeat once again: vacuuming the air conditioner with your own hands is possible, but without the vacuum pump this work cannot be done.

Types of low vacuum pumps:

- Rotary vane (single stage). They are characterized by low noise during operation, the ability to adjust the residual pressure, simplicity of design. Their disadvantages are the need for periodic replacement of consumables (for example, oil);

- Two-rotor (two-stage). Equipped with two main rotors operating synchronously. Economical, effectively “push” the air to the drain pipe by increasing the pressure in the circuit of the evacuated device;

- Water ring. They can equally well remove both air and liquid. The disadvantages of such devices are significant energy consumption and water demand.

Of the above types of vacuum pumps exclusively in the low vacuum range (105-102 Pa) only water ring devices work. In other types, the vacuum range is wider and reaches 10-3 Pa, i.e. degree of high vacuum.

Types of high vacuum pumps:

- Diffusion. Highly effective, provide fast vacuumization. But they can not be used for the refrigeration circuit, because the working fluid of these pumps are synthetic oils that pollute the vacuum circuit;

- Cryogenic. Their work is accompanied by an injection of nitrogen, which freezes and removes gases and liquids while increasing the degree of rarefaction of the internal atmosphere of the circuit;

- Ionic getter. Equipped with a thin titanium film that traps the molecules of gases and liquids removed from the refrigeration circuit during vacuum. The most effective - eliminate up to 97% of impurities.

Despite the advantages of ion getter vacuators, turning off the provision of a high degree of vacuum (over 10-5 Pa), when installing split systems, they are rarely used - these devices are expensive.

Which vacuum is better to choose?

The choice of the optimal type of vacuum pump depends on the length of the freon line and the capacity of the air conditioner, which needs vacuum cleaning from atmospheric gases. It is also necessary to take into account the dimensions of the pumping device, since it will need to be set close to the external split-block for connection to the vacuum procedure.

A significant criterion is the residual (lowest) pressure reached by the vacuum pump in the no-load operation mode (inlet pipe closed). The lower the residual pressure (indicated by the manufacturer in Pa, in mbar or microns), the better the vacuum.

The next criterion is the capacity of the vacuum pump (indicated in l / h). It determines the volume of gas pumped by the device for an hour of operation at a given outlet pressure.

The last responsible criterion is the electric motor power of the vacuum installation (indicated in W). The longer the freon line, i.e. the farther apart the split units of the air conditioner are located, the longer it will take to perform vacuum cleaning of the refrigeration circuit. So, you need a vacuum with a fairly powerful engine.

Most often, split-system installers use two-stage and single-plate type vacuum pumps. The former are considered semi-professional and vacuum air conditioning systems well, and the latter are the cheapest, although they do not provide enough quality for vacuuming freon circuits longer than 3.5 m.

Homemade Vacuum Pump

A vacuum can be made on the basis of a compressor from an old refrigerator (Saratov, ZIL, etc.). It is necessary to drain the mineral oil from it, replacing with preliminary washing with kerosene more viscous machine (summer "synthetics").

In operation, the compressor will actively throw “mineral water” through the outlet pipe, quickly filling the oil trap. Replacing "synthetics" will dispense with a separate receiver with a filter. But the installation of an oil trap is required. To control the degree of evacuation, you will need a vacuum gauge or at least a pressure gauge.

However, if a good air compressor can be assembled with a refrigerator compressor, then the vacuum cleaner will turn out to be rather weak, low vacuum. Such compressors cannot give a vacuum of more than 104 Pa, i.e. they are not suitable for evacuation of split systems.

Conclusions and useful video on the topic

The order of evacuation of the freon circuit of the split system:

Overview of different types of vacuum pumps, their capabilities and applications:

Comparison of the efficiency of a vacuum pump from a compressor from a refrigerator with a two-stage compressor:

When installing a split system, it is impossible to do without a circuit vacuum, since such an air conditioner will not show reliable long-term operation.

However, it is not profitable to specifically purchase a vacuum pump with a manometer station, even for installing two or three home split systems. It is more rational to rent these appliances. Or, nevertheless, call the masters, after making sure they have the necessary equipment.

Want to share your own experience in evacuating an installed home split system? Do you have useful information on the topic of the article, which is worth sharing with site visitors? Please leave comments in the block below, ask questions and post a photo.

How to install air conditioning on the loggia and glazed balcony: instructions and valuable recommendations

How to install air conditioning on the loggia and glazed balcony: instructions and valuable recommendations  Refueling split systems: how to fill freon climate equipment with your own hands

Refueling split systems: how to fill freon climate equipment with your own hands  Maintenance of split systems: do-it-yourself cleaning, repair and refueling of HVAC equipment

Maintenance of split systems: do-it-yourself cleaning, repair and refueling of HVAC equipment  DIY split-system cleaning: routine inspection and maintenance

DIY split-system cleaning: routine inspection and maintenance  Installation of an external air conditioning unit in the attic: the possibility of solving and analysis of technical specifics

Installation of an external air conditioning unit in the attic: the possibility of solving and analysis of technical specifics  Gree air conditioner error codes: how to decipher the fault symbol and repair the unit

Gree air conditioner error codes: how to decipher the fault symbol and repair the unit  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements