Return draft in ventilation of a private house: why ventilation works in the opposite direction and how to eliminate it

A sufficient supply of fresh air is required to create a comfortable environment. With improper functioning of the air exchange system, back draft may occur in the ventilation of a private house, which affects its microclimate badly.

In this case, it is necessary to understand and eliminate the causes of the change in flow direction. Let's look at the causes of back draft in the ventilation system of the house and how to eliminate them.

The content of the article:

Causes of Backdraft

Reverse thrust occurs when there are miscalculations in the design of the ventilation system or its insufficiently qualified design. But since air has well-studied physical properties, it is easy to identify the causes of the origin of the problem and find ways to eliminate it.

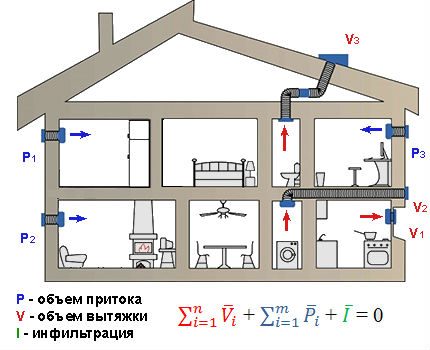

The law of conservation of volume during ventilation

When modeling air exchange for small volumes, which are characteristic of private houses, one can neglect such parameters of the air environment as the degree of compression and uneven density.

In this case, the basic physical law of supply and exhaust ventilation can be formulated as follows: the difference in the volume of incoming and outgoing air for any period of time is zero.

Exhaust ventilation is installed in places of the greatest concentration of polluting aerosols. It has a bathroom, kitchen and office space. Some hoods are equipped with fans to force increase the volume of exhaust air.

Supply ventilation is installed in the living rooms for fresh air to the places of permanent residence of people. As a rule, it is of a forced type with predetermined volumes of the incoming stream.

This is necessary to accurately maintain microclimate parameters such as temperature, humidity and oxygen conditions.

Thus, most often the volumes of air intake in different places of the house are fixed, and the distribution of exhaust air through the holes is variable.

If at a certain point in time a part of the exhaust system passes a stream greater than the supply ventilation provides, the missing volume is compensated through openings for air exhaust.

To prevent such a scenario, it is necessary when developing a ventilation system to perform the following set of actions:

- install a check valve on each exhaust opening to prevent air flow through it;

- organize one or more backup inlets of a natural type to compensate for the missing volume.

The cross-section of the openings of the backup air supply devices must be calculated so that they can fully compensate for the maximum amount of missing air. Each must be equipped check valveto prevent air outflow. This is fraught with icing and clogging of the inflows in the winter.

Unaccounted air exchange with the street

Filtration makes its role in the air balance of a house - uncontrolled passage of air through slots and leaks. If this phenomenon is intense, it is impossible to carry out accurate parameter calculations ventilation system.

In addition, infiltration (inward filtration) allows air to enter the room without being treated with dust filters and without heating to the desired temperature in winter. Therefore, this phenomenon must be completely eliminated or its effect on the total air circulation insignificant.

Open windows, balconies and attic doors create additional air exchange. It is impossible to calculate it in advance, since the speed and even the flow vector depends on many factors, especially the external and internal temperature, as well as the direction and intensity of the wind.

The only solution when detecting the occurrence of backdraft in ducts may be to install check valves.

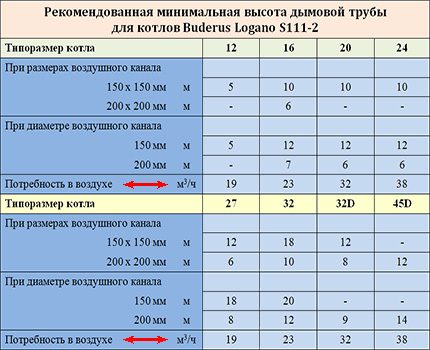

In cold weather, a chimney serves as an additional exhaust device of variable power. On it, hot air with combustion products comes out, making a significant contribution to the total value of the volume of the exhaust stream.

The volume of air leaving the chimney depends on the capacity of the boiler. For factory products, it is easy to calculate, since the instructions have tables that indicate the minimum cross section of the chimney and the rate of emission of combustion products for a particular model.

If the furnace or boiler is manufactured independently, then the approximate value of the volume of exhaust air must be taken from the technical documentation of a device similar in parameters.

If we consider the chimney as an exhaust channel, then its specificity is the impossibility of installing a check valve on it. An alternative may be an integrated smoke exhaust, but only if its installation is technically possible. Then heating can be included in the model as a hood with a fan.

The calculation of the air balance in the presence of the chimney must be approached responsibly.Even a single reverse flow can completely ruin the interior of the room. In addition, with a large flame, there is a risk of fire, as well as the possibility of poisoning people with combustion products.

Typical problems with the organization of air exchange

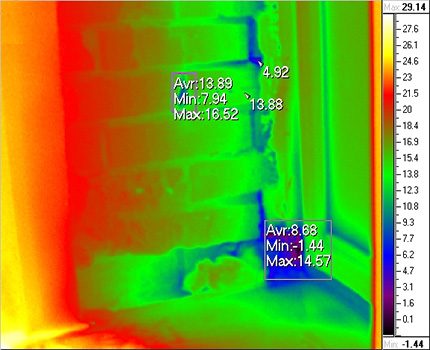

A decrease in the flow rate relative to the calculated one, even in one inflow or exhaust, leads to an imbalance of air circulation in the house. This affects the operation of other devices in which there is a compensation change in the flow parameters, including a reverse may occur.

Therefore, it is necessary to examine all the places of intake and outflow of air and then it will be possible to find out why the general house ventilation works by directing the flow in the opposite direction.

Reduced air volume

The decrease in air speed in the air handling unit with a fan can be caused by the following reasons:

- Engine power lossfan vibration and other signs of equipment wear. It is necessary to carry out repairs and eliminate the identified malfunctions.

- Failure to configure system settings. It is necessary to reconfigure the system or repair the control unit.

- Filters are dirty. The most common reason for reducing the supply ventilation power. Clean or replace the liner.

- Fan pollution. As a result of the buildup of contaminants, the geometry of the blades changes. Then, with the same number of revolutions, the pressure characteristic of the device decreases.

- Reduced live section of the channel. It can occur in any node of the supply system through which air passes: a pipe, a recuperator, a heater, etc. It is necessary to carry out their regular service cleaning.

- Partial or complete closure of the external grille. The filter grill may be clogged with insects, foliage and other debris. In winter, it is possible to sweep it with snow. Therefore, you need to periodically check its throughput.

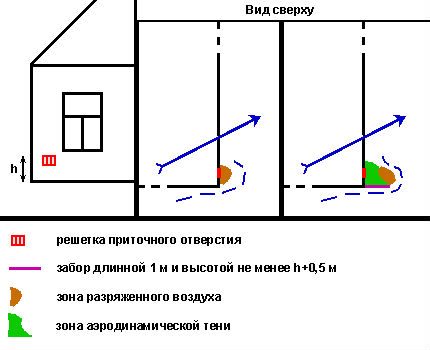

With natural ventilation, a common cause leading to inadequate inflow, and sometimes even back draft, is the effect of discharged air from the street.

This phenomenon may occur on the leeward side of the building. It can be eliminated using special fences near the air intake.

Hood malfunctions and their elimination

The reasons for the poor performance of the forced draft hood are the same as those of the air intake device. But most often the problem arises not due to contamination of the filters (which are not always installed on the hood), but due to the narrowing of the living section of the ventilation duct.

Unlike fresh air, the removed stream carries moisture, vapors, small drops of fat that adhere to the walls of the ventilation duct.

Over time, growths form on the inner side, creating aerodynamic drag, which leads to a decrease in the volume of outgoing air. In this case, the exhaust device itself can work properly.

In private homes ventilation duct design so that you can effortlessly conduct a visual inspection of it. It is necessary to do this 2-3 times a year, and if any narrowing is found, clean them yourself or with the help of employees of organizations providing such services.

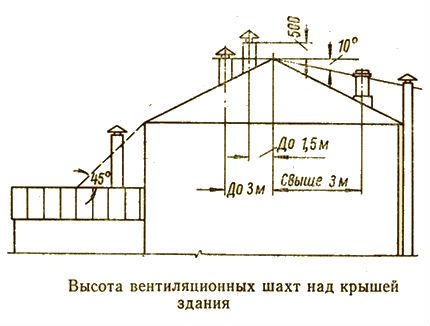

There are rules for the location of the pipes of the exhaust system on the roof. If they are ignored, depending on weather conditions, a wind back up may occur, which will slow down the ventilation speed or even tip the traction.

The indicator pointing precisely to this reason is the variables, not the constant problems with air circulation.

The position of the chimneys relative to the roof elements is regulated Clause 6.6.12 of SNiP 41-01-2003 “Heating, ventilation and air conditioning”. It is spelled out in this document on the basis of calculations of wind backwater, so it can be used for ventilation pipes.

Often there is a situation when during the construction of the house all the rules for the placement of ventilation outlets were met, but later on the landscape changed, which led to the formation of zones of wind backwater:

- modification of the geometry of the roof (including the installation of a satellite dish);

- construction in the immediate vicinity of a tall building;

- grown near a tree.

In this case, you can move the outlet of the ventilation duct to another place, increase the height of the pipe, or try to remove the cause that creates the zone of wind backwater.

You also need to check the quality of work deflector. If it has mechanical damage or as a result of poor fastening has changed its position relative to the pipe, then this can also cause problems. Traction can be significantly increased by replacing an ordinary deflector with a rotary one.

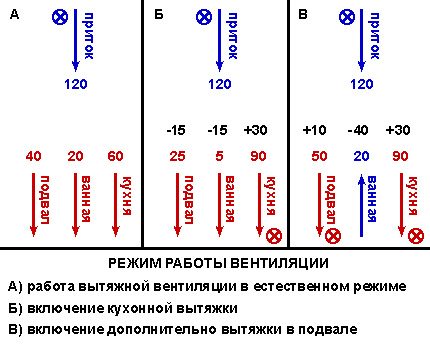

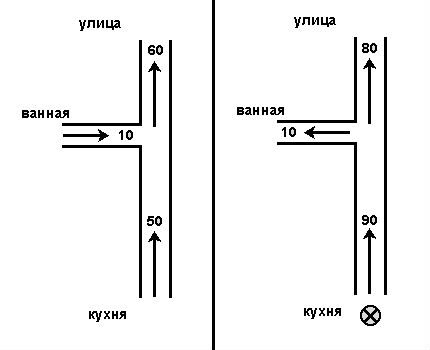

Reverse in the duct system

In private homes, a duct system has been established that connects several exhaust openings to one ventilation shaft. Some points may be equipped with forced air intake devices such as a cooker hood or duct fan.

The occurrence of reverse thrust in one of the branches of the duct can be caused not only by the problems described above with a common exhaust, but also by the redistribution of the flow vector inside the system of ventilation ducts.

To prevent this scenario, the installation of check valves for each of the branches of the duct is used. These devices pass the flow in one direction and close the channel cross section when it is reversed.

As a rule, when installing the duct, specialists install check valves. It may not be in the case of an additional tie-in of branches, if the installation was made later. In this case, you must install such a device. You can do this yourself without restructuring the entire duct system.

To do this, you must:

- Purchase a valve of suitable size.

- Disassemble the duct system in the place where it will be installed.

- Cut off part of a rectangular channel or flexible pipe the size of a valve.

- Assemble the system with valve.

- Check for leaks.

If a non-return valve is installed, but back draft occurs, it means that the device is malfunctioning.

There may be several reasons:

- the appearance of a gap in the membrane, cusp or shell of the valve;

- wear of moving parts, as a result of which the sash or membrane does not close;

- solid debris (such as a piece of paper or a large bug) that interferes with the complete closure of the device.

In any case, it is necessary to disassemble part of the duct and remove the valve. If it is impossible to repair it, you should purchase a device of the same size and reassemble the duct.

Conclusions and useful video on the topic

How to make fresh air ventilation to prevent back draft in hoods:

Proper operation of the exhaust and, especially, the supply ventilation is the key to the absence of back draft. To do this, it is necessary to periodically inspect devices and measure flow rates for them.

If after reading the material you have questions or find inaccuracies, please leave comments in the block below. Perhaps you also had a problem in the ventilation system? Describe it and together we will try to cope with it.

Ventilation on the roof of a private house: the construction of the passage of the duct through the roof

Ventilation on the roof of a private house: the construction of the passage of the duct through the roof  Window sill ventilation: methods and detailed instructions for arranging window sill ventilation

Window sill ventilation: methods and detailed instructions for arranging window sill ventilation  Is forced ventilation in the bathroom necessary: norms and stages of arranging efficient air exchange

Is forced ventilation in the bathroom necessary: norms and stages of arranging efficient air exchange  Ventilation of a septic tank in a private house: is it needed + tips for arranging

Ventilation of a septic tank in a private house: is it needed + tips for arranging  Heated ventilation in the apartment: types of heaters, especially their selection and installation

Heated ventilation in the apartment: types of heaters, especially their selection and installation  Ventilation in the steam room: examples of proven schemes and analysis of the rules of arrangement

Ventilation in the steam room: examples of proven schemes and analysis of the rules of arrangement  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

My neighbor had a similar problem, for a long time we could not figure out what was wrong? From the hole, which is designed to remove the processed air from the room, on the contrary, it entered this very room. Until the son came to visit and “googled” what was the matter. Google brought us here, but here everything is painted to the smallest detail, and so detailed and abstruse as if the author concurrently teaches physics at the institute. As a result, the problem with reverse thrust was solved, and the grateful neighbor was happy as an elephant.

I somehow had such a problem. The pull went back. For a long time I was looking for a problem, I did not understand what it was. And then everything somehow passed by itself. It will be necessary to call the masters to check the ventilation.

This is the “first bell” about problems with ventilation when back draft appears periodically. I can give several reasons that lead to this problem:

1. The ventilation ducts were “clogged” with a large amount of steam or cold air, which disrupted normal circulation;

2. It is possible that the channels are clogged with garbage or bird nests (in such cases, you can solve the problem yourself);

3. In winter, ventilation ducts can become clogged with ice or snow;

4. In large rooms without partitions, drafts appear and interfere with normal air circulation;

5. Hoods, compressors, fans - all of these devices can affect normal circulation and create reverse traction.

As you can see, it is not always necessary to call the wizard, with points 2,3 and 5 the problem is easy to solve on your own.