Rotary Well Drilling: An Overview of Drilling Technology and Essential Equipment

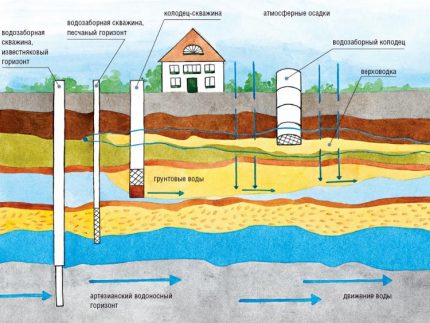

If a country house cannot be connected to the central water supply, you need to organize an autonomous system. Most owners prefer to arrange it on the basis of the well, in the development of which various methods are used. We will consider rotary well drilling - a very promising, but so far little-known option.

In our article, the intricacies of rotor technology and the tools used are described in detail. The advantages and disadvantages of this technique are examined, and methods for its implementation in practice are presented. Our tips will be useful to the prudent owners of private plots who want to monitor the work of drillers.

The content of the article:

Definition of rotary drilling

To begin with, let's analyze what rotary drilling of wells is all about and what are its alternatives? Auger drilling is still recognized as one of the most common ways to draw water.

However screw technology does not allow to pass rocky bedrock. The screw drill used in screw drilling is not able to destroy limestone. But it often happens that you need to drill in it, because the overlying layers are not stable and sufficient for operation flow rate.

Therefore, rotary technology, previously used only in the mining industry, began to be introduced into the scope of the construction of private water intake facilities. Its working element is a bit located in the bottomhole part of the well. Using a chisel, cohesive and incoherent soils are destroyed, rocky bedrock is crushed.

The excavation of the destroyed rock is carried out with the help of a liquid, which is supplied to the face through a working column or annular space.These are 2 different drilling methods, each of which will be discussed in detail below.

The diameter of the bit exceeds the diameter of the working column, which allows:

- reduce energy costs for the entire drilling process (the power here is spent directly only on turning with the force of the bit in the face, and the friction losses of the working string against the borehole wall are minimized);

- protect most of the elements of the working string from damage, as well as the walls of the drilled well from destruction;

- create impressive diameter boreholes (for example, up to 70 cm) at extremely impressive depths.

This way you can form aquifers, with a depth of 300 meters or more, i.e. to drill water intakes to supply water to summer cottages and villages.

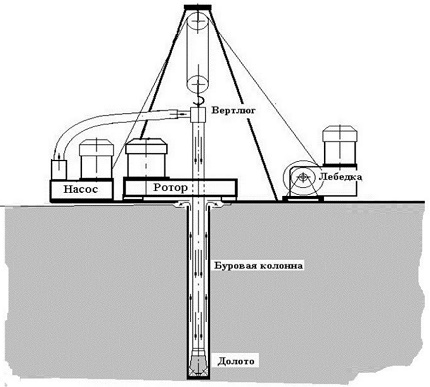

So, the definition: rotary drilling is such a way of developing a well in which the force on the bit in the face is transmitted from the rotary rotator through the working column. It is assembled from rods - narrow steel pipes that are connected sequentially to each other by changing the depths into the ground.

But in clearing the trunk of the mine and slaughter from the sludge, the water supplied under pressure is used. Thanks to this decision, it is not necessary to disassemble and assemble the drill string for core extraction as in core drilling.

The fluid injected into the mine immediately solves two important tasks: it frees up the path for the drill to carry out further work and produces flushing the wellnecessary to prepare the water intake for operation.

Benefits of Rotary Technology

What are the advantages of rotary drilling over possible alternatives? There are several of them.

FirstlyUsing a rotary bit, it is possible to create large-diameter wells that can fully satisfy the water requirements of several households at once.

It is no secret that drilling is not an expensive process: it requires specialized equipment, and experienced drillers must control and manage the process. After all, drilling activities are licensed. Hence its high price.

Combining several households at once to finance one common well for adjacent sites is a cost-effective venture. But this requires a significant debit. In most cases, aquifers of Quaternary sediments (sands) cannot provide them.

Naturally, for collective operation, the water intake should be put on limestone. Groundwater extracted from it is characterized by greater water mobility and purity. The volume of precipitation does not have the slightest effect on the flow of wells to limestone. What can not be said about the wells on the sand.

Secondly, relatively small energy costs convince. The working element for rotary drilling is a chisel. But unlike auger and core drilling, the drilling tool does not interact with the walls of the drilled well

That is, only a bit whose height is negligible relative to the height of the entire drill string is in direct contact with the soil. As a result, this method of forming wells is the fastest - up to 1000 linear meters per month!

Thirdlycollective customers are attracted by the depth of drilling. Only the rotary method can be used to drill a well buried in indigenous metamorphic and igneous rocks, from the cracks of which water can be pumped, the composition of which is most suitable for drinking purposes.

Most often, only industrial water is extracted from intakes with a depth of less than 30 m.Its composition is influenced by nearby water bodies, rivers littered with garbage, precipitation, and just technical liquids spilled onto the ground. The screw and core pipe will help to get only such an intake.

In addition, rotary drilling allows you to go through development to full depth without switching to another method of drilling. When developing a well with a screw, for example, if it is necessary to drill a boulder, they switch to a shock-rope technique.

For this, a screw shell is removed from the barrel and the bit is thrown to the face until a boulder is broken. Then slaughter cleared by a bailer. It is used if it is necessary to raise water-saturated sand to the surface, which is not corny in the core pipe.

Practice shows that wells drilled by the rotary method have a longer life. Technologically, this is due to the fact that after the installation of the casing string forming the borehole walls, the annulus is further strengthened.

Well Equipment

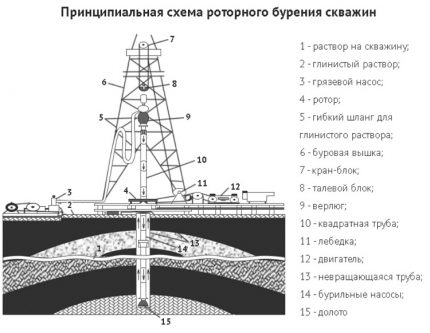

First, a vertical console is mounted on the surface above the well for further fastening of the vertical links of the working string. The first link of this drill shaft is equipped with a working element - a bit, which can have a different format, depending on the category of rock for drillability.

Drill Tool Set

When deepening the first link, the candle, the next one, called the bar, is mounted on it, and so on. The length of each such block of pipes can vary from 20 to 50 m. To simplify the formation of the working column, each rod is equipped with a tapered thread with a lock.

As a result, a drill is formed, which consists of:

- working bit;

- lead bar;

- columns of ordinary rods interconnected by couplings.

The holding of the working column is carried out using swivels, the rotation of which is carried out by the rotor. Depending on how deeply it is supposed to drill, and also what physical and mechanical properties of the soil, standard or weighted rods are used to form the leading link.

The drive rod, as a rule, is a weighted pipe, because it has an important technological mission. Through it, a flushing solution enters the face to the bit, whose task is to wash out the crushed rock. And this, in turn, puts forward requirements for coupling joints, the task of which is to seal joints between links.

Do not forget that the fluid pressure directly depends on the height of the formed column (and does not depend on the cross-section of the pipe). Moreover, even if water is used as a washing solution, then every 10 meters the pressure will increase by 1 atmosphere.

For comparison, it is worth giving an example. The working pressure in the household piping network in the house is 10 atmospheres, and the most durable pipes are designed for a pressure of 20 atmospheres.

Only if household systems are stationary and do not move, then the pressure is equal to the weight of the drill string on the drive rod. But she still has to transmit rotational momentum and force to the bit.

The following requirements are imposed on couplings as structural elements of a drill string, they are:

- must ensure the tightness of the connection of the rods and withstand fluid pressure up to 100 atmospheres (for clearing the bottom of the pressure stream);

- must be resistant to wear, so as not to become unusable when rubbing against the walls of the well;

- must be able to transmit torque from the top of the work string to the bottom and, finally, to the bit.

It is imperative that the couplings are of the proper quality. If at least one of them cannot withstand the load and the working string is broken, it will be extremely difficult to get its lower part together with the bit. In terms of capital expenditures, it is sometimes easier to drill a new well nearby than to get an detached lead rod.

Water use during drilling

The liquid that is supplied to the face is usually ordinary water. Sometimes, in order to stabilize the trunk passing through loose incoherent rocks (sand, gravel, gravel and pebble deposits), a solution with drilling additives is fed into the well. This is necessary, because the casing is not placed in the first stages of penetration.

Water enters the outlet either under pressure inside the drive rod (and then pumping out through annular space), or by gravity down through annular space, and removal is already taking place through the working column with a suction pump.

These are 2 different rotary drilling technologies, the features of which will be discussed below.

However, no matter what method is used, the fluid used in drilling everywhere needs to be cleaned (for further use).

To do this, use the following equipment:

- Drilling fluid storage barn. (If you plan to drill a shallow well - within a few tens can be arranged directly in the ground, and ordinary water is used as a flushing fluid). The barn acts as a battery for flushing fluid.

- Vibrosieve. The flushing solution, lifted from the well, carries particles of crushed rock that must be removed. The most effective way is a mechanical one using vibrating screens.

- Sedimentation tank. After the removal of large particles of the rock, the liquid enters the sump to get rid of suspended particles that precipitate. When using water as a washing liquid, a sump is also sometimes built directly in the ground. In addition, for the separation of liquid substances and the separation of sediment is used hydrocyclone.

- Mud pump. It is he who provides the circulation of the washing solution.

- Gutter system. They are needed for the movement of water from the point of formation of the mine to the place of its treatment.

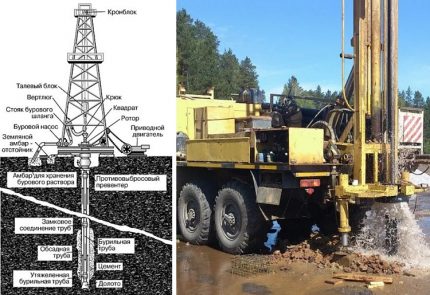

In total, the following mechanisms and equipment are needed to develop a well using rotary technology:

- Tower or console for assembling the drill string from the rods and disassembling it at the end of drilling, as well as a tackle system.

- Engineproviding rotation of a rotor.

- Fluid equipment. Mechanisms and devices for circulating washing fluid and cleaning it (pump; vibrating screen; sumps and / or hydrocyclone; a barn for storing flushing fluid; system of pipes and gutters).

For rotary drilling of shallow wells, the entire listed set of equipment is very compact (for example, the boom of the console is folding). This makes it easy to place drilling equipment in any convenient place for drilling and subsequent operation.

Two rotary drilling options

Depending on the method of supplying flushing fluid to the face, there are 2 types of rotary drilling technology:

- direct feed;

- with reverse feed.

It should be noted that the liquid supplied to the face is intended not only for flushing and removal of crushed rock. It also cools the bit, which is very hot from friction. In the case of direct fluid supply, the pump creates its overpressure.

Water enters the face through the technological holes in the bit, "picks up" the crushed rock and then by gravity through the well (that is, through annular space in relation to the leading rod) enters the surface, where it enters the cleaning complex (vibrating screen, hydrocyclone).

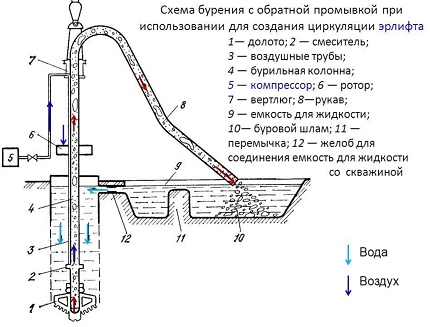

The reverse feed technology implies that the flushing fluid flows to the bottom by gravity, descending through the well, but the solution with crushed material returns to the surface already through the lead rod pipe. The mud pump in this case creates negative pressure in it.

Despite the seeming simplicity of both technologies, there are much more nuances than it might seem at first glance. Therefore, it seems appropriate to dwell on each of these drilling technologies in more detail.

Direct flushing drilling

This technology is sometimes called "direct watercourse." It is advisable to use it in sandy, gravel, gravelly soils. It is also used if the depth of the aquifer does not exceed 30 m. It is here that additives are added to the fluid that increase its density and trunk stability.

Rotary drilling is characterized by a gradual decrease in the diameter of the well being drilled. In other words, first the largest diameter well is drilled, then it craps pipe, and the annular space between the outer surface of the pipe and the wall of the well through technological holes are filled with cement mortar.

Further drilling continues with a smaller chisel. Then again casing, and the new section has an even smaller diameter, etc. The less often you need to be "distracted" by cementing the well, the greater the drilling productivity, which ultimately translates into the total cost of the process and the well as a whole.

In addition, too frequent casing leads to the fact that the effective diameter of the well (the diameter that opens the aquifer) is greatly reduced. So “direct watercourse” is characterized by the fact that the well with this method of its formation can not be cased up to 100 meters.

The main pressure of the flushing fluid is created by the pump inside the drive rod, and annular the liquid with elements of crushed rock fills the space by gravity, without destroying the borehole wall with excess pressure.

However, this method of drilling has its disadvantages. In particular, too long open The site leads to the fact that finely dispersed clay particles enter the aquifers, which can significantly reduce and slow down the flow of water into the output from the aquifer.

These particles here play the role of peculiar plugs of pores and microchannels in the rock through which water seeps. Therefore, the casing procedure performed during the drilling process is necessary to maintain the future productivity of the well as a whole.

Flushing Reverse Drilling

With this method of controlling the flow of fluid, the barrel and bottom are cleared best. The pump here does not squeeze the liquid into the bottom, but on the contrary, it sucks it back, and this leads to the fact that the speed of formation of the well with a chisel increases by an order of magnitude and several times more compared to direct flushing.

The well itself is not contaminated with clay inclusions with a flow of flowing washing fluid. After all, the pump sucks up everything that can be contained in it. By the way, there is no longer any practical sense in additional additives, therefore pure water is used as the same washing liquid.

So, to summarize the advantages of drilling with a reverse stream:

- drilling speed increases (compared with direct watercourse) up to 15 times;

- the aquifer is not clogged with clay particles and silty grains of sand from the lower open-hearted well levels;

- due to the high-quality opening of the aquifer, the well does not need to be additionally prepared for operation, you can immediately install the internal casing with a filter and start pumping out with a pump;

- simple (and, therefore, cheap) water is used as a working fluid.

However, this method has a significant drawback. It requires the involvement of expensive equipment, which ultimately leads to a significant increase in the cost of the entire drilling process as a whole.

Therefore, drilling with a “reverse watercourse” is carried out only in those cases when the well is designed for operation by several households at once. But in case the well is designed for individual operation, it is much more reasonable to use rotary drilling technology with a direct watercourse.

Conclusions and useful video on the topic

Video # 1. Visual demonstration of the rotary drilling process in steps:

Video # 2. Analysis of rotary technology and principles of well arrangement:

Video # 3. Water circulation during rotary drilling:

The situation with the presence and depth of aquifers can be very different from place to place (but somewhere there are none at all, as on the island of Madeira).

When designing a well and choosing the optimal method of rotary drilling, existing maps of proven aquifers should be used. This will save you significant time and money.

Tell us about your experience in developing a well using rotary technology. Share technological nuances that are useful to site visitors. Please leave comments in the block form below, post a photo and ask questions about the topic of the article.

Auger drilling of wells: features of technology and shell for manual drilling and installation

Auger drilling of wells: features of technology and shell for manual drilling and installation  Drilling a borehole: a complete overview of shock-rope technology

Drilling a borehole: a complete overview of shock-rope technology  Do-it-yourself water-boring for water wells: a review of technology

Do-it-yourself water-boring for water wells: a review of technology  Methods of drilling wells: technological principles and features of the main methods

Methods of drilling wells: technological principles and features of the main methods  Core Well Drilling: Technology and Work Nuances

Core Well Drilling: Technology and Work Nuances  Arrangement of a water supply system at a dacha from a well: schemes, nuances, an overview of the necessary equipment

Arrangement of a water supply system at a dacha from a well: schemes, nuances, an overview of the necessary equipment  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

You correctly write that the rotary method of drilling a well is quite expensive. This begs the question - is it possible to pass soft layers with something cheaper, for example, with a screw, and use a rotor only starting with limestone? Do such manipulations make sense or will it not be possible to save?

If you are looking for an inexpensive way, I advise you to consider water boring. Proven method, almost every homeowner will be able to get the necessary equipment. Actually, here's what you need for this:

- collapsible metal frame;

- water pump (provides pressure in the system);

- hoses for water supply;

- drill (exploratory or petal);

- engine for transmitting force to the drill;

- winch;

- related tools for drilling;

- drill rods forming columns;

- Control block;

- swivel for sliding fastening of parts.

In this way, you can drill wells up to 30 meters without much experience. For depth below this mark, appropriate practical knowledge is already needed.

Drilling on limestone is best done by shock-rope method.