Do-it-yourself water-boring for water wells: a review of technology

A well in a summer cottage will provide the owners with water. However, not everyone can afford to order mining at a drilling organization. Owners of suburban estates who want to reduce the cost of arranging their own source to the utmost have a choice - hydraulic drilling. Not everyone is familiar with this technology, agree? Those who are interested in it should first understand the technique.

We will tell in detail to interested home masters how to do hydraulic drilling of wells with your own hands. We have thoroughly set out the technological subtleties, listed the nuances of the preparation and conduct of work. Using the information carefully checked and presented by us, you can cope with a difficult drilling process without the slightest difficulty.

In addition to a thorough presentation of the technology of hydraulic drilling, the author of the article describes the specifics of equipping the site for independent drilling. Represents data on the required drilling rig, tool and improvised devices. Informative photos and video guides will provide significant assistance in mastering a difficult issue.

The content of the article:

Distinctive features of the method

Using wells as an autonomous source of drinking water is a rather old and proven method. Along with traditional, sometimes expensive technologies, the hydrodrilling method can be deservedly called economical and universal.

Popular methods for drilling wells are discussed in our other article.

This simple enough way punch a well has some nuances, ignoring which can nullify all your efforts. Its essence lies in an integrated approach.

Two main processes are combined here - the direct destruction of rocks drilling tool and washing out drilled soil fragments with a working fluid. That is, the drill is exposed to the rock and water pressure.

The load required for immersion in the soil is provided by the weight of the drill string and special drilling equipment that injects flushing fluid into the body of the well being formed.

The wash solution is a mixture of the smallest particles of clay and water. They shut it in a consistency slightly thicker than pure water. From the pit, the mud takes the motor pump and directs it to the borehole under pressure.

Water in the hydraulic drilling circuit performs several functions simultaneously:

- washing out drilled particles of destroyed soil;

- carries with the course of the blade to the surface;

- cools working surfaces of the boring tool;

- when moving, polishes the inner surface of the well;

- strengthens the walls of the well that are not fixed by the casing, reducing the risk of collapse and filling with the shaft blade.

As the deepening takes place, the drill string is expanded with rods - pipes of VGP with a length of 1.2 - 1.5 m, Ø 50 - 80 mm. The number of extended rods depends on the depth of the water carrier. It can be pre-determined during farrowing of neighbors for the mark of water mirrors in their wells or wells.

The estimated depth of the future well is divided by the length of one rod in order to calculate how many pieces need to be prepared for work. At both ends of each rod, threads must be made to make up the work string.

One side must be equipped with a coupling, which is desirable to be welded to the bar so that it does not loosen in the barrel.

In practice, pure drilling is rarely used, because a large head of water is needed. It is also difficult to drill dense clay layers. Often produce drilling with a bored hole.

This method is somewhat similar to rotary drilling, but without a rotor. For better centering of the well and easy overcoming of dense sections, a petal or cone-shaped drill shape is used.

Hydro-drilling is not suitable for driving on rocky and semi-rocky soils. If sedimentary rocks in the drilling region are represented by rubble, pebble, sand with a large inclusion of boulders, this method will also have to be abandoned.

It is technically impossible to wash and lift heavy stones and debris of heavy rocks from the well with water.

Benefits of Well Drilling

The technology of hydraulic drilling for water has become popular among people relatively recently, therefore, it has many misinterpretations. Firstly, the idea that the method is suitable only for small wells is erroneous. This is not true.

If desired, and appropriate technical support for hydrodrilling, wells can be drilled more than 250 meters. But the most common depth of domestic wells is 15-35 meters.

The opinion about the high cost of the method is also not supported by calculations. Good speed reduces financial costs.

The obvious advantages of the method can also include:

- compact equipment;

- the possibility of drilling on an extremely limited site;

- minimum technological operations;

- high speed of work, up to 10 m per day;

- safety for the landscape and environmental balance;

- opportunity hand drilling;

- minimum cost.

Perhaps the most significant plus of hydro-drilling is still the ability to drill in landscaped areas without significant aesthetic troubles.

The advantages of hydrodrilling are also very obvious when compared with dry drilling technology, where it is necessary to constantly remove the working tool from the barrel for cleaning and load it again.

Most of all, this technology is adapted to work with small-fragment sedimentary soils, which are most easily removed from the well. using the bailer. A drilling fluid allows you to do without gelation.

Of course, for a good result of the enterprise it is necessary to purchase the appropriate means of mechanization, because you can’t do with one homemade drill, even at shallow depths.

Necessary equipment for work

The standard type of hydraulic drilling is carried out by means of small-sized installations. For your own site - this is a great solution and the best way to get water on your own.

It is necessary to supply the working fluid to the borehole with a significant pressure, and for this a pump or motor pump is required for contaminated liquids.

Sometimes, to increase the breakdown force, a fraction or coarse sand is added to the working solution. For crushing large pebbles, which can be found in sandy layers, cone and cutter bits are useful.

Special small-sized MBU installations are most demanded by the consumer for the purposes of hydraulic drilling. This is an aggregate with a height of 3 m and a diameter of 1 m.

The structure of this prefabricated structure includes:

- collapsible metal frame;

- drilling tool;

- winch;

- engine transmitting force to the drill;

- swivel, part of the contour for the sliding fastening of parts;

- water motor pump to provide pressure in the system;

- exploratory or petal drill;

- drill rods for column formation;

- hoses for water supply to the swivel from the motor pump;

- Control block.

Among the necessary equipment, it is also desirable to have a current converter. It is needed so that the energy supply of the process is stable. Still definitely need a winch to raise / lower the casing and stacked pipes.

When choosing a motor pump, it is better to stop at a more powerful device, since large loads are assumed.For hydraulic drilling, you also need such a plumbing tool as a pipe wrench, a hand clamp, a transfer plug.

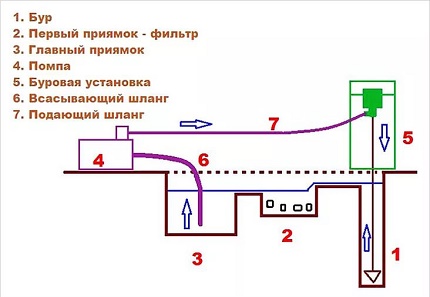

The process of hydraulic drilling from the very beginning to the end of the work includes a constant circulation of the working fluid. Using a pump, an aqueous suspension with washed out soil leaves the well, goes directly to the pit, and after sedimentation, the suspension is again fed into the well.

In addition to this order, it is possible to carry out shallow drilling of water wells without using a pit. This method does not require a recess for settling the working solution, saves time and makes it possible to drill a well even in garages and basements.

For hydraulic drilling, a motor pump is selected that can pump heavily contaminated water. It is advisable to buy a unit with a pressure of 26 m, a pressure of 2.6 atm and a capacity of 20 m3/ h

A more powerful pump ensures quick, trouble-free drilling and better flushing of the well. For quality drilling, it is important that a good flow of water always flows from the well.

Step-by-step analysis of work

The technology of hydraulic drilling is very specific, therefore, it requires the correct observance of the stages of work. It is necessary to prepare the drilling equipment, prepare the flushing solution, and prepare the casing. Then follows the assembly of the installation and the start of drilling.

The casing is growing as the well progresses to strengthen the walls. The casing is necessary so that loose sand does not crumble into the trunk, pebbles lying next to the trunk do not fall, and clay loam or sandy loam swollen from the water does not “stick out”.

Drilling ceases when an aquifer appears. All hydraulic drilling processes have some nuances, the knowledge of which comes only with practical experience.

Step # 1 - determining the occurrence of aquifers

For the success of the whole event is of great importance water search and at least an approximate determination of the depth of the aquifer in the area.

If as a result of a survey of neighbors it was not possible to obtain this information, you can find it out at a local drilling or construction organization that carried out work near the site planned for drilling.

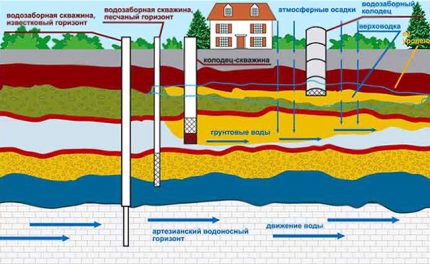

As a rule, the first water-saturated layers are located on the first 1.5 - 6 m of the well. Popularly, such water-saturated strata are called the high water.

The Verkhovodka does not belong to the horizons of the drinking category, it provides water with technical characteristics due to the traditional pollution by household wastewater and oils spilled on the ground, liquids containing oil refined products.

If cleaner water is of interest, they will have to drill up to 15 - 25 m. At this depth, the chances of getting life-giving moisture with a drinking status are approximately 70% if they are covered by a waterproof loamy or sandy horizon on top.

The underlying aquifers with a depth of 25-50 m or more 90% guarantee the availability of high-quality drinking water.

It is easy to get a well of 10-30 m or more by hydraulic drilling. In this case, we have a simple drilling process and easy installation of casing pipes. Experts recommend doing exploratory drilling with a 100 mm drill.

With positive results at 10 m, you can simply leave the drill string with a perforated launch rod as a filter in the barrel. If the water is deeper, the well is drilled with a 200 mm drill and a 116-125 casing with a submersible pump is put into it.

As a rule, aquifers consist of sand of medium size and coarse, gravel or crushed stone sediments.These are sedimentary rocks, parts of which are not connected in any way.

Non-cohesive rocks have the highest filtration qualities. Within them, water freely moves and seeps into the underlying layers.

In the natural occurrence, incoherent detrital soils usually alternate with clay deposits: sandy loam and loam. Fine-dispersed particles of clay rocks are cemented, which prevents the free passage of water through them.

They do not pass and do not absorb water, form a kind of platform - water storage for the accumulation of water.

Passing dense clay layers, the drill goes slower, quickly passes sands and other clastic rocks. Resting against a water-repellent clay layer, the underlying aquifer, drilling somewhat slows down.

If the injected water seems to be squeezed out of the working hole in an amount greater than the pump distilled, then the aquifer is opened. Drilling should be discontinued and time allowed to allow the suspension to soak into the ground.

You can focus on the lighthouse pit. As long as the aquifer is not opened during drilling, the water in the pit will be kept at the same level. If the output deepened into the underground water layer, the volume of water in the pit will increase.

Step # 2 - preparing the workplace

Proper preparation of the drilling site will relieve hitch during operation and will contribute to a good result, since interruptions in the method with the supply of the solution are extremely undesirable.

Equally important is the availability of a sufficient amount of water. In order to guarantee the required amount of water during hydrodrilling, it is necessary to count on 15 m3 and accordingly prepare the desired tank.

You can prepare additional containers of about 2 cubic meters or dig a hole for 5 or more cubic meters by treating the walls with clay mortar.

When the water supply is prepared, the small-sized drilling rig MBU is installed. The unit is installed according to the instructions. Assembly takes about an hour and does not present technical difficulties.

The main condition for competent installation is strictly horizontal placement of the device. If there is even minimal skew drill rig you cannot subsequently install the casing.

At a distance of 1.5-2 m from the structure, technological pits are excavated for filling and storing the drilling fluid.

Pits are recesses in the soil of the type of baths. They are connected by an overflow channel - a trench in the form of a tray or gutter. In these baths there is a washing solution before the barrel is injected, it is drained there along with the dump.

The optimal size of the pits is considered to be 1x1x1 m. In one pit, liquid will be collected from the well for sedimentation of solid particles. The settled water that has poured through the chute into the second pit is pumped again to the unit via a pump.

The first pit functions as a sump and may be smaller. In the process, it must be periodically cleaned of drill cuttings deposited at the bottom. The second pit is considered the main one.

Near it is a motor pump (pump). The hose from the inlet of the motor pump drops into the main pit. The hose from the outlet goes to the rig.

The water injected into the drill string cools the drill, which significantly increases the operational life of the tool.In the process of drilling, the water without heating circulates in a circle. After drilling is completed, the water is simply pumped into the recesses made for it.

If you still need to leave the unit inactive for the night, the carriage with the working body is lifted by a winch to the upper level of the MBU and is fixed.

The next day, the pump starts, runs for half an hour / hour and the drive starts. Then the column of rods lowers and rises with a winch. When the carriage begins to move easily, drilling can begin again.

Step # 3 - MBU well drilling

After technological preparations and collection of the MBU drilling rig, the pits are filled with a working solution and drilling begins.

After the launch rod is immersed in soil at 95% of its length, it is connected to the next link in the drill string by screwing it on. The process takes place until the water in the pit begins to increase sharply.

The whole process of hydrodrilling can sometimes last from 1 to 7 days, depending on the skill of the performer and the type of rock that is present in the area.

For drilling on low-moisture loose sands, a certain supply of drilling fluid is required, because these deposits absorb water quickly.

The clay component of the suspension prevents the leakage of water. It clogs the pores in the walls of the borehole, thereby reducing the absorption of liquid by sand.

It is best to make a solution by mixing clay with a mixer in a pit with water. Before starting work, be sure to check the serviceability of the winch and pump, since stops are not made when sinking sandy soil.

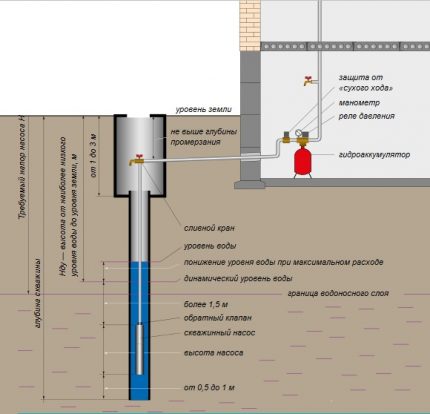

To prevent collapse of a wide borehole, the casing is lowered almost simultaneously with the deepening of the drill string. It is advisable that the casing is slightly ahead of the drill on the sand. So it is necessary to block the constant flow of collapsed loose rock into the trunk from the side.

For a casing device, steel alloy or plastic pipes are used. Today, plastic pipes have gained great popularity in view of durability, resistance to deformation and corrosion.

However, with this method of drilling, casing pipes most often have to be forced into the barrel. Therefore, it is better to prefer a steel version with a thread for screwing the next link.

In order to reliably fix the casing in the well, it is better to immediately install a collar during the buildup. They are also used for partial pulling out of the casing from the well, which is carried out to expose the filter in the barrel.

In the absence of clamps, you can use a strong cable placed on the storm in the form of a loop. The other edge of the cable before unscrewing the top of the drill is attached to a tree, log or other massive object.

It is difficult not to understand the simplest hydraulic drilling scheme, let alone cope with its implementation. The motor-pump solution is fed into the hose connected to the drill string. In the cavity inside the rods, the fluid moves to the drill and further contributes to the destruction of the rock being drilled.

The liquid that has captured the blade is sent to the first pit (filter). After shrinkage of the suspensions to the bottom of the pit, the liquid flows into the adjacent recess and is used in a new circle.

The composition of the drilling fluid must be adjusted depending on the rocks passed. A thick clay solution is used for sands - it will strengthen the walls, preventing them from collapsing.

Clay soil, sandy loam with loam, can be drilled with clean water, and for passing through dense rocks in the solution you can add abrasive, shot or coarse sand.

The MBU works well at a depth of 10-50 m. In practice, this installation even arranges wells up to 120 m.

Step # 4 - installing the filter and arranging the well

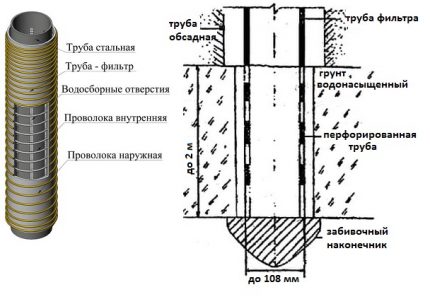

After opening the aquifer, drilling is carried out all the way into the underlying water-resistant layer. It can be determined by the deceleration and difficulty of immersion of the drill string. Drill rods are removed after thoroughly flushing the well with clean water.

If a wide well was drilled for the subsequent installation of a submersible pump, then care must be taken filter device. For this, another, but smaller diameter is inserted into the casing.

The first link of the inner casing should be with longitudinal slots or holes staggered according to a checkerboard principle.

To improve the quality of water treatment, the filter unit is complemented by a thin steel mesh or polypropylene spraying.

When the filter sinks to the bottom, the casing is slightly pulled out of the barrel so as to expose the filter holes. Excess pipes are cut and equipped with a head.

And if a gap is formed around the trunk, it is filled with crushed stone and poured with cement mortar in order to fix the wellhead and to prevent flood waters from seeping into the aquifer.

It is set in such a way that a water level above 3 m is above it, but in no case should it touch the bottom. After proper placement of the pump, the well is ready for use.

Step # 5 - the final stages of drilling

When the well is ready, it is necessary to dismantle the drilling rig and put it into operation.

In narrow workings, the drill string together with the drill performs the function of a casing with a filter. They do not need to be removed from the barrel, because water will be pumped out from the water intake point along the same channels through which the drilling suspension circulated.

The hydrodrilling process is distinguished by accessible technology that does not require special theoretical knowledge. Compliance with the main stages of the process, together with high-quality equipment, will certainly give good results and will please you with clean underground water.

You may also find the information on how to swing a well after drilling, discussed in this article.

Conclusions and useful video on the topic

Using MBU for drilling a well for water in sandy loamy soils:

Do-it-yourself well drilling:

You can avoid mistakes and small miscalculations in hydraulic drilling without departing from technological principles..

To further reduce financial costs with a single hydrodrilling of a private well, you can not purchase MBU, but rent a unit. Thus, with your own hands in a very short time you will receive your own, free source of water supply for many years.

Are you familiar with the hydraulic drilling method? Or prefer an easier way to drill a well? Perhaps you found an inaccuracy in the hydrodrilling algorithm described by us? Write to us about it - leave your comments under the article.

Core Well Drilling: Technology and Work Nuances

Core Well Drilling: Technology and Work Nuances  Rotary Well Drilling: An Overview of Drilling Technology and Essential Equipment

Rotary Well Drilling: An Overview of Drilling Technology and Essential Equipment  How to punch a well into water: options and drilling technologies that are in demand in practice

How to punch a well into water: options and drilling technologies that are in demand in practice  Do-it-yourself well repair: routine and emergency repairs

Do-it-yourself well repair: routine and emergency repairs  DIY drilling rig: making a homemade drill for drilling wells

DIY drilling rig: making a homemade drill for drilling wells  DIY water well: arrangement rules + analysis of 4 popular drilling methods

DIY water well: arrangement rules + analysis of 4 popular drilling methods  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Own well is very important, and given the price of water, so in general, it is necessary. I have a small greenhouse: if you pay for watering, it’s cheaper to buy vegetables in the market. A neighbor helped me to drill the well, without it I would not have been able to, and the equipment is needed anyway. Everything was done as usual and intuitively. We were lucky, the aquifer passes high enough, so we managed quickly. But this is, of course, not an easy one.

If you drill a well yourself, you can provide a suburban area with water everywhere. A friend of mine drilled water intakes with an auger, and immediately formed a casing pipe as it sank. You can drill almost any breed with a screw, if only you would not come across a boulder that will have to be crushed with a chisel. To make things go faster, a friend did not rotate the screw manually, but attached a motor to it. The soil is captured by the auger blades and pushed up from the well. To increase the depth, additional links are attached to the starting screw.

My neighbors were farmed on a campaign)))

I want to take a chance and try to independently make a well at the summer cottage using the method of hydraulic drilling. The situation is complicated by the lack of electricity in the plot (during the wiring) and the complete lack of experience in drilling. The first difficulty was solved by taking an inverter generator from a relative for a while, and the second by studying a bunch of materials and videos on the Internet. I really hope that the stones will not come across to me, and without them everything looks pretty simple. I think I can handle it during the holidays.