Methods of drilling wells: technological principles and features of the main methods

The device of the water well is associated with the use of various drilling methods. Loose and water-saturated soils are extracted using a bailer. For drilling through clay and rock formations, well drilling methods based on the rotational and vibration principle are used.

The work involved mechanisms that allow the development of soils of various types and at different depths. We will tell you how to choose the optimal drilling technology that allows you to quickly and flawlessly go through the development for a water intake device.

For a visual presentation of the information we have proposed, the text is supplemented by useful schemes, photo collections, video guides.

The content of the article:

Types of Drilling Methods

Earlier drilling of aquifers for personal use was carried out mainly manual way. It was a time-consuming and lengthy process, so not every owner of the site or cottage could boast of having their own source of water supply.

Gradually, mechanized drilling displaced manual methods due to the significant facilitation and acceleration of the process.

Today, almost all aquifers are drilled in a mechanized way, which is based on the destruction of the soil, feeding it to the surface in one of two ways: dry, when the waste soil is removed from the well using mechanisms and hydraulic, when it is washed out by water supplied under pressure or by gravity.

There are three main methods of mechanical drilling:

- Rotational (soil is developed by rotation).

- Shock (bursnaryad destroys the ground with blows).

- Vibrating (soil is developed by high-frequency oscillations).

The rotational method is considered the most high-performance, 3-5 times higher in efficiency than the shock and 5-10 vibrational. In addition, the rotational method is the most inexpensive and affordable, it is often used as the main method of manual drilling.

In turn, the rotational drilling method, widely used for constructing water wells, is divided into four main types of drilling:

- core;

- auger;

- shock-rope;

- rotary.

Each type of rotary drilling has its own characteristics and is performed by equipment specially designed for this. Consider these types of drilling in more detail, determine what their differences are and what method must be applied in each case.

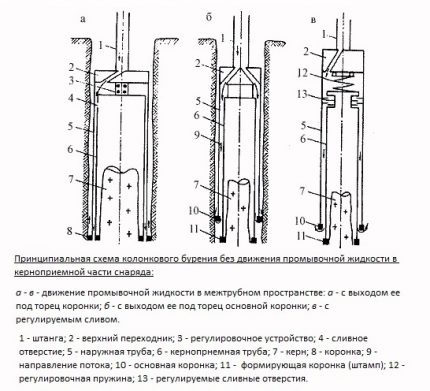

The specifics of core drilling

Core drilling is a mechanical rotational method in which clay or dense sandy soil is extracted in the form of a cylindrical core. The core drill is a thick-walled metal pipe.

At the top of the core drill is a device for attaching the rods necessary for building the drill string. Below is a crown, the type of which is selected depending on the category of soil to be drilled.

When driving through the column method, the soil is destroyed by an annular crown. At the same time, the core core remains intact. To facilitate the drilling process on hard and semi-solid loams, clays, rocks, flushing fluid is supplied to the face.

Sludge from the bottom is sometimes removed by washing - pumping a large amount of water into the barrel. Most often, flushing is replaced by blowing with compressed air supplied by the compressor into the pipe. This type of drilling allows you to drill wells up to 1000 meters deep and with a diameter of 8 to 20 cm.

Mechanical core drilling is carried out by drilling rigs of the ZIF, UGB, UKB type, mounted on KAMAZ, KRAZ-type cars, skidders, etc. In the embodiment for manual drilling the core tube is shortened, called a bell or a glass. With the last household item turned upside down, the core tube is structurally similar.

Core drilling is used in the following cases:

- mineral exploration;

- exploratory well drilling;

- arrangement of aquifers of any depth, including filterless wells in rock formations.

For device private water wells in some cases, the core method is used before starting auger or rotary drilling, performing both reconnaissance and preparatory roles.

In the construction of private wells, core drilling is used in combination with shock-rope drilling. Clay layers pass through a core pipe.Loose sands, gravel and pebble with sand aggregate that do not linger in the core tube are removed from the barrel by zheloning.

In terms of efficiency, the core method is somewhat inferior to the screw method of drilling water wells. They drill auger faster, but it does not allow to completely free the trunk from drilled rock. They are rarely used in pairs. And if it is given, then the first few meters pass with a screw.

Used equipment and tools

The following tools are used for core drilling:

- drill bits made of diamond or other carbide material (steel, tungsten, win);

- core pipe;

- pipe for removal of sludge;

- rods required to build the drill string;

- coupling joints, adapters between pipes, flushing seal.

When drilling in rocks, the drill bit wears out quickly and needs to be replaced. The material of the crown is expensive, withstanding enormous loads, the most widely used diamond drilling options.

All tools used in the drilling process must be aligned, i.e. located exactly relative to the axis of drilling.

Core drilling technology

The main feature of core drilling is the passage of the rock with its full preservation in the core pipe. Those. during the operation of drilling equipment, the crown on the ring destroys the soil, which, as it goes deeper, is pushed into the core pipe and held in it due to its own density.

When removing the filled pipe from the working shaft, it is freed from the core by tapping with a sledgehammer.

The phased core drilling process is as follows:

- the drill bit is connected to the core pipe;

- the core pipe is connected to the rods, which grow as they deepen;

- the upper bar is fixed in the drilling rig;

- the drill rotates the drill string and gradually “screw” it into the ground;

- core pipe is gradually filled with core - jammed soil in its cavity;

- after driving 50 - 70 cm, the drill string is removed to the surface, the rods are disconnected in turn until the core tube is removed;

- the pipe is freed from cuttings;

- the empty shell is again lowered to the face, increasing the drill string with rods.

Actions are carried out in the described order until the well reveals the aquifer and dives 50 cm into the underlying waterproof rock.

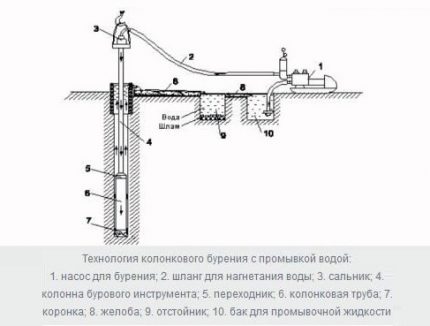

If fixing the upper aquifer is not the goal of sinking, then the upper layers can flushing. In this case, the pump sells the flushing solution through the hose into the pipes. Then the solution carries the developed soil to the surface.

Good strengths and weaknesses

Compared to the shock-rope and rotary methods of mechanical drilling, core drilling is performed quite quickly, significantly reducing the time of work. Its main drawback is the impossibility of lifting loose soils and pebbles saturated with water. Slowly moving along the rocks, a bit is required to drive the boulders.

The advantages of core drilling include:

- high productivity and the ability to drill wells with a depth of over 100 m;

- reduction of loads on drilling equipment due to the destruction of clay, comparable to its cutting;

- the possibility of using a mobile drilling rig of compact dimensions.

Core drilling is one of the fastest methods for developing water intake workings.A well on the sand with its application can be completed in one working day. Being developed manual water intake will take much more time.

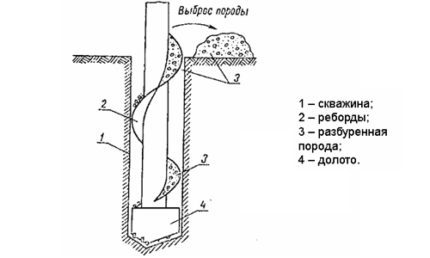

Features of auger drilling

This type of drilling is most often used today in the construction of aquifers in private farms. A feature of auger drilling is that the developed rock is completely removed from the borehole without involving additional equipment. The method resembles screwing, allows you to drill to a depth and at the same time remove unnecessary soil.

The tool used for drilling is called auger. It is a metal rod with blades. Screwing into the ground, the screw destroys the rock, which lingers on its blades. Due to the specific design of the screw, it is impossible to completely free the face from the blade. Therefore, it is mainly used for driving the upper layers.

Drilling using a screw does not require much effort and financial costs, so the scope of this method is wide enough: exploration wells, laying of communications, construction of bored wells and partially water drilling.

It is now actively used for the construction of Abyssinian wells, so as not to completely plug the needle-hole into dense soil, but to slightly facilitate the process of immersing the trunk in a previously destroyed rock.

The method is suitable for the development of aquifers with a depth of up to 30 m on soft and loose soils and up to 20 m on medium-dense. After auger penetration and installation of a casing, the wellbore must be cleaned of unexcited rock by the bailer.

The auger is categorically not suitable for work in rocks! It is used for partial penetration of wells up to 120 m, while this method is combined with others: rotary, shock-rope, core.

Equipment and tools involved

Auger drilling is performed by a drilling rig, the main element of which is a screw type drilling tool made of high strength metal. Drill string as deepening build up screws of equal size.

In the kit, sometimes used blade bits required for the passage of loose rocks, as well as bits with round or conical heads, used for the development of hard rocks.

Most modern drilling rigs are equipped with hollow shells equipped with reversible locks that prevent the tool from moving in the opposite direction.

The cutting parts of the auger during drilling are cooled due to the developed soil, and the developed rock rises up in spirals. This allows you to drill without stopping, significantly reducing the time and energy costs of creating an aquifer.

Auger drilling technology

After completion of the penetration, the depth of which is 1.5 - 2.0 m, the auger is removed and installed in the well casing. The diameter of a water well drilled with a screw is 50-200 mm and depends on the size of the tool used.

Collapse of the walls of the borehole prevent casing. This is especially important for loose, incoherent soils, so drillers have a rule: when driving sandy loam and loam, use augers with blades at an angle of 30 - 60º, and when drilling sands of dense addition, a tool with blades at an angle of 90º.

With a smaller slope of the turns of the auger spiral, a larger auger blade brings the auger to the surface.

Pros and cons of using a screw

The auger method of drilling allows the well to be constructed as quickly as possible, provided that the size of the auger and the angle of inclination of the bit were selected correctly.

The advantages of auger drilling include:

- soil rises to the surface immediately during drilling;

- high speed of deepening into the ground without technological stops;

- there is no need to flush the wellbore;

- a compact auger rig or a hand auger can be drilled inside the house (in the basement);

- there is no need to raise the first link to the surface and disassemble / assemble the drill string as in the core method.

The main disadvantage of auger drilling is the impossibility of working on loose and very hard soils, but at the same time, the auger is an ideal tool for drilling in loamy, mixed (clay and sandy loam) and soft clay soils.

Another drawback that restricts the use of a screw for the construction of aquifers is the need to use a shock-rope method to clean the trunk of dumped rock.

Similarity auger - coil widely used in manual drilling. It also destroys the rock and grabs it with blades for extraction up.

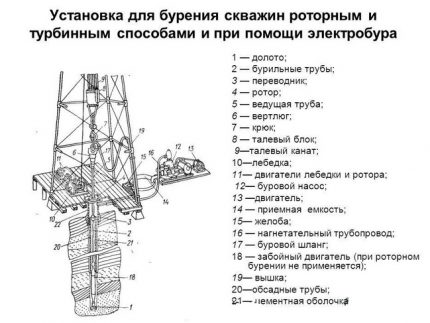

Rotary Drilling Feature

Rotary drilling is a method of rotational vibration drilling, in which the destruction of the soil is carried out using a bit driven in the bottom of the well from the rotor of the drilling rig. The rotor rotates from a car engine or a separately installed electric motor through a drive shaft.

The developed soil is washed out of the well shaft by direct or reverse flushing. Wash solution can be supplied either by gravity or by a pump station.

Rotary drilling is used to develop rocky and semi-rocky soils with the installation of deep wells up to 150 m. A rotary drilling rig with a correctly selected bit and weighted drill pipes copes with rock formations.

Drillers recommend using this drilling method under the following conditions:

- The hydrogeological section of the site has been studied quite well. It is known that rock is to be drilled. The level of occurrence of the aquifer in bedrock is known.

- Groundwater has a characteristic pressure for artesian wells

- There is the possibility of uninterrupted delivery of process water for flushing the well.

In the southern regions, rotary drilling can be carried out all year round, and in the northern climate the application of this method is limited due to the possibility of freezing of the flushing fluid.

Applied equipment and tools

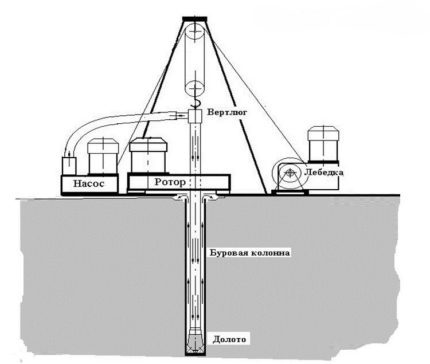

Rotary drilling of aquifers is carried out using a frame or trellis tower, on which lifting equipment and other elements of the drilling rig are located. The tower makes it possible to raise and lower drill strings into the well.

The rotary type drilling rig includes:

- frame or trellis tower;

- motor with drive;

- rotor and drill string;

- pumping equipment and flushing fluid treatment system;

- lifting equipment, pressure line, swivel, oil seals, etc.

In self-propelled units, the engine of the vehicle is used as the engine, on the basis of which the drilling complex is located. In this case, the engine speed is regulated by the speed of the drilling tool.

The rotor with the help of a gear device transmits rotation to the lead pipe, which in turn communicates it to the main drilling tool - the chisel. The bit can have a different shape and is made of high-strength materials: composites, diamond-coated steel, etc.

For each type of soil, a special size and shape of the bit is selected, thereby ensuring high efficiency and penetration rate.

The peculiarity of rotary technology

Rotary drilling of wells for water is carried out in three stages:

- Rock breaking with a chisel.

- The removal of the destroyed rock to the surface by the flow of injected water.

- Strengthening the walls of the borehole with casing pipes.

The removal of the destroyed soil is carried out by reverse or direct washing. The choice of flushing method depends on specific conditions: well depth, soil type, availability of the required volume of flushing water.

Typically, private farms use direct flushing drilling technology, which includes the following steps:

- deepening of large diameter bits into the ground;

- bit rotation under the influence of a rotor;

- installation of drill pipes and installation of weighted pipes between them and the bit;

- removal of waste soil by fluid pressure using a pump;

- casing installation to prevent soil sprinkling inside the well;

- drilling with a smaller diameter bit and repeating the entire cycle.

When backwashing, the soil is removed from the well through the drill pipe, and the flushing fluid is poured between the walls of the well and the pipes.

Water flows by gravity into a previously prepared reservoir, where it is cleaned of soil and sludge, and returns to the drill string for a new portion of the waste rock.

Advantages and disadvantages of rotary drilling

The main advantage of the rotary method is the ability to drill deep wells with water intake in fractured limestone.

In addition, this drilling method has the following advantages:

- high quality opening of a water carrier in bedrock;

- the possibility of arranging large diameter wells up to 200 cm;

- high drilling speed, low energy costs.

A significant disadvantage of rotary drilling can be called the need for flushing the well.

Which drilling method to choose?

All the considered methods of mechanical drilling are widely used for the construction of aquifers.

Summing up, we can say that:

- Core drilling is advisable to use for sinking in plastic clay soils. The column method is suitable for the device of most water intake workings; if necessary, it is used in conjunction with a shock-rope.

- Auger drilling in application is similar to the core method. It differs from it by poor-quality cleaning of the barrel, it requires the mandatory use of a bailer or long-term washing of the well before operation.

- Rotary drilling is the best option for punching wellbores in rocky soils.

The cost of developing a well using one or another drilling method largely depends on what equipment is used, as well as on the categories of rocks passed by drillability.

You can read about how to make a drilling rig with your own hands in another popular article our site.

Conclusions and useful video on the topic

Video # 1. Demonstration of the principle of classical core drilling with core extraction by water pressure:

Video # 2. Features of auger well drilling:

Video # 3. Core drilling of a well with washing the bottom and installing a double casing, the outer part of which is made of steel pipes, the inner polymer:

Drilling an aquifer is a time consuming process. Not only the speed of the device of an autonomous water source, but also the financial costs depend on the correctness of the chosen drilling method.

The first thing you should pay attention to when choosing a drilling method is the type of soil and the depth of the aquifer. Based on these parameters, you can choose the best option that will allow you to drill a well quickly and inexpensively.

Do you want to share the history of well drilling in your own area or useful information on the topic of the article? Please leave comments in the block below. Here you can ask a question or point out controversial points in the text.

Auger drilling of wells: features of technology and shell for manual drilling and installation

Auger drilling of wells: features of technology and shell for manual drilling and installation  Rotary Well Drilling: An Overview of Drilling Technology and Essential Equipment

Rotary Well Drilling: An Overview of Drilling Technology and Essential Equipment  DIY drilling rig: making a homemade drill for drilling wells

DIY drilling rig: making a homemade drill for drilling wells  How to drill a well with your own hands: ways to budget independent drilling

How to drill a well with your own hands: ways to budget independent drilling  Core Well Drilling: Technology and Work Nuances

Core Well Drilling: Technology and Work Nuances  Methods and technologies for cementing wells: how to prepare and pour grouting mortar

Methods and technologies for cementing wells: how to prepare and pour grouting mortar  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Once we decided to drill a well ourselves and regretted it very much, we lost only our time. The conclusion has ripened that it is better to turn to drillers - specialists who have been engaged in this business for many years. In addition to experience, they have equipment and tools for driving on different types of soils. But I, as they say, already got acquainted with the drilling process with my own eyes and even was supported by knowledge thanks to this site. There was an idea to try again to drill a well in the area of my mother)))

Drilling a well is quite difficult, if you do everything wisely, competently go through and equip after. At first, I also thought to take up this matter on my own, since I know how to do a lot with my hands, but I did not dare to poke myself here. As a result, he hired drillers, they did everything on their own, though I stood almost all the time and asked how it was for the future) The guys got good, they told us everything in an accessible way.

I did everything right.Self-drilling is a very time-consuming process, besides with a lot of subtleties, without knowing which you can screw up. Several years ago, I helped a relative drill, so almost every summer we went there every weekend as if to work. I decided for myself - it’s better to pay professionals to spend time and nerves, the main thing is to find normal ones.