How to choose a pump for a well: recommendations for choosing pumping equipment

Well operation is impossible without the use of the obligatory component of its arrangement - a pump. After all, a bucket is absolutely not suitable for taking water from a narrow trunk. In addition, lifting up from the depths and transporting water manually would take too much time and energy. I don’t want to waste either one or the other, do you agree?

Properly selected pumping equipment in a matter of minutes will fill the tanks in the bathhouse, house, garden. Now it is possible to purchase equipment for servicing an object of any scale. On its base, you can easily build an automatic water supply system that does not depend on centralized supplies and the participation of owners in the pumping process.

We will tell you in great detail how to choose a pump for the well, what you need to consider and provide for the future owner of the device. A thorough explanation of important points for the user is supplemented by photos and video guides.

The content of the article:

Well Characterization

Before acquiring a suitable pump for a well, it is necessary to clarify a number of indicators of its structure:

- static level;

- dynamic level;

- flow rate;

- bottom bottom mark;

- pipe diameter.

If well drilling If a specialized drilling company was engaged, then in accordance with the contract the owner had to provide its technical passport. All the characteristics mentioned above must be indicated therein. However, in cases where the well has been used (or not used) for a long time, it will not hurt to clarify this information.

Owners of wells that were created on their own or with the help of hired “co-workers”, of course, do not have such a document. They have to study their well on their own and establish its characteristics using simple measurements.

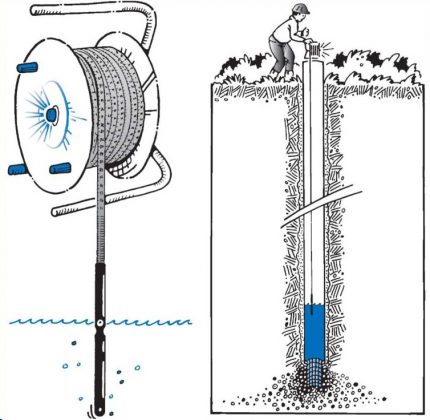

The static level is the distance that separates the constant mirror of water and the surface of the earth.To set this distance, you need a twine with a weight attached to it in the form of a cylinder or cone without a bottom.

Instead, you can use a plastic tube. You will also need a tape measure or ruler. The length of the string should be comparable with the depth of the well.

Before starting measurements, you must refrain from taking water from the well for at least an hour. During this time, the water level should become maximum. Now the cord with the load is lowered into the well until the load “slams” on the surface of the water. The characteristic sound is usually clearly audible.

It remains to make a mark on the twine, remove it from the shaft and measure with a suitable tool. The first indicator of the characteristics of the well is determined. The dynamic level is the distance from the surface of the earth to the minimum water level in the well shaft.

To determine the dynamic level, first the well needs to be prepared. Water is pumped out with a high-performance submersible pump (it can be bought or borrowed), lowering it down as the water decreases.

When the water stops falling, we can assume that the minimum level of water in the mine is reached. Now you need to do operations with twine, cargo and tape measure again. Measurements will give a new indicator of the well - its dynamic level.

Comparison of these data - static and dynamic levels - allows you to make a preliminary conclusion about the productivity of the well. The smaller the difference between these indicators, the faster the water column is filled, and the more powerful the pump can be used with such a structure.

It should be noted that for a good artesian well, the dynamic and static level indicators may well coincide, which indicates the extremely high productivity of such a structure. This happens because water arrives as fast as it is pumped out.

The difference in levels for a high-productivity well usually does not exceed one meter. Dynamic level information is useful when installing a submersible pump selected for the well. The depth of its immersion should be two meters above the dynamic level so that the device is always in the water.

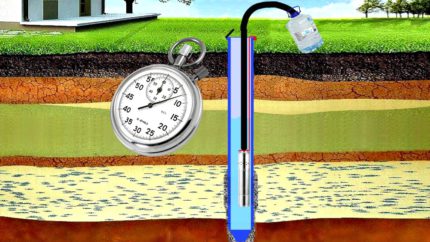

The flow rate of a well is the amount of water that can be obtained from it within a unit of time. It is measured in the following units: l / min, cu. m / h, cubic m / day, etc. If, when pumping water with a high-power pump, the change in the water level is insignificant, then the water arrives quickly.

We can assume that the flow rate of the well is large and choose a pump with high productivity for it. When calculating the flow rate of a well, it should be remembered that this is not a constant value. In the spring, water arrives at the well faster than in summer, and in winter this process is slower.

To understand that the well was filled with water and the flow stopped, you just need to measure the depth of the water level. If it coincided with the previously obtained static level, then the well is filled. Those. after pumping water, such measurements will have to be performed several times.

If the water quickly decreases, but arrives slowly, it will be necessary to establish the exact volumes of water that can be obtained from this well. It is necessary to take the capacity of a significant and yet known volume.Most often they use a barrel, but it can be some kind of tank, bathtub, etc. The main thing is to know the volume of liquid that is placed in this container.

First you need to lower the pump closer to the bottom of the well and completely pump water out of it. This will be reported by the characteristic “sobbing” sound of a running pump.

Then, time is noted and they wait until the static level in the well is restored. After that, the water is again pumped out, measuring its volume. By simply dividing cubic meters into hours or liters per minute, you can determine the debit of your well.

This indicator will allow you to choose a pump, the performance of which will correspond to the volume of water arriving in the well. If the equipment is too powerful, the well will be empty, which may cause the pump to run dry, i.e. without water. And this leads to rapid damage to equipment.

To determine the mark of the bottom of the well, i.e. its depths, again use twine with a weighty load without cavities inside. Now it is lowered to the bottom until the twine wears out. After that, it is taken out and measured.

Usually only the wet part of the twine is measured. Its dry part corresponds to the statistical water level in the well. The total depth of the well is equal to the sum of two values: the static level and the depth to the water mirror.

The diameter of the well is the diameter of its casing. To select a submersible pump, the internal diameter should be taken into account, since the dimensions of the pump should allow it to be freely lowered down, and if necessary, removed again.

Analysis of small nuances

The quality of drilling is another point to consider when choosing a pump for a well. If the drilling was carried out with the help of professional equipment and the efforts of a specialized team, such a well is considered more reliable.

If drilling was done by co-workers or site owners with the help of amateur friends, the quality of the well is unlikely to be ideal.

"Amateur" wells, as practice has shown, are more susceptible to the processes of flooding and sanding. Therefore, for such wells, it is recommended to use special pumps designed to operate in difficult conditions. Equipment of this type is more expensive.

But it better tolerates situations when they receive water with a lot of pollution. Under the same loads, conventional pumps break more frequently. Owners of “professional” wells have more options when choosing equipment, since they can choose both a universal and a special pump.

It is not always convenient to use a rubber hose to lift water from the depth of the well to a height. During the operation of the pumping equipment, air inside the hose becomes rare, from this the walls of the hose collapse, and the flow of water stops. To prevent this phenomenon is simple: instead of a rubber hose, plastic structures of suitable diameter should be used.

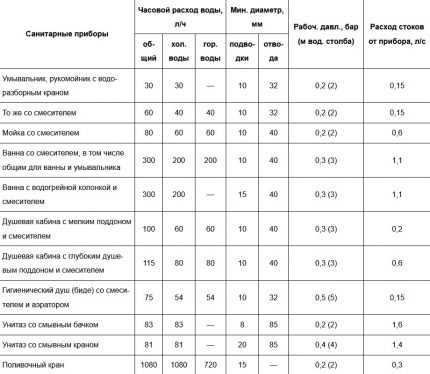

An important indicator when choosing a pump is the approximate water consumption for one day. This is an average value, since in summer the water consumption usually increases, and in winter, on the contrary, it decreases. It is estimated that the daily intake rate for a family of three to four people is approximately 60-70 liters.

These figures do not take into account water consumption for irrigation and other household needs.The daily rate should be increased depending on the number of plants on the site, the presence of pets, etc.

Prudent owners most often choose four-inch casing pipes for a well, although designs with a diameter of three inches are also used as such. The fact is that a significant part of the pumping equipment is designed specifically for a more spacious four-inch pipe.

To convert centimeters to inches, you should divide the measurement result with a tape measure by 2.54, since it is precisely this number of centimeters that is equal to one inch.

Differences between surface and immersion units

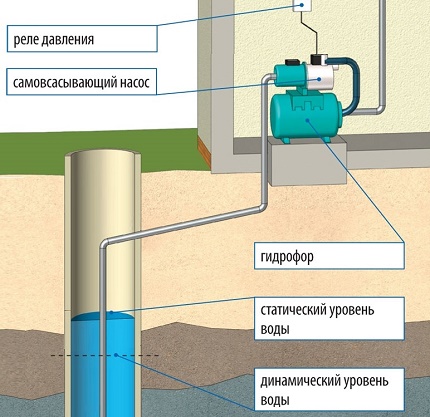

All domestic pumps at the installation site are divided into two types: submersible and surface. The first is lowered down almost to the bottom of the well. The second work on the surface. They are usually installed next to a water source or directly on the surface of the water using a special float.

Surface models use the principle of suction. The efficiency of such a pump is significantly affected by the distance that water has to be lifted. Usually they are used only if the depth to the water mirror is eight meters or less.

If we are talking about the Abyssinian well, of course, the surface pump will be just the perfect choice, since we are talking about a very specific well - narrow and shallow.

But when operating a filtration or artesian well, a surface pump may simply not be able to cope with the load. In this case, it is necessary to choose a submersible model.

Choosing between submersible and surface pump, it is necessary to take into account a much higher level of noise when operating the latter. To eliminate this trouble, just close the pump with a wooden box or install it in a separate room.

If surface pumps draw in water, then submersible pumps push it up. When choosing such a pump, the height at which water will have to be supplied, or rather, the distance from the surface to the pump, is primarily taken into account.

Therefore, a couple more meters should be added to the data on the dynamic water level. The boundary is considered to be a height of 40 meters. If the data exceeds this figure, you will have to pick up a high-power pump. The technical passport of each product indicates the maximum height to which it can supply water.

Visually, pumping equipment of high and low power varies significantly. More productive submersible pumps They have a large body and weigh significantly more models that cope with an immersion depth of up to 40 meters.

Focusing on the depth of immersion, it is better to give preference to units with a certain margin of performance. If the pump is designed to operate at a depth of 60 meters, it is more suitable for a 50-meter well.

If it is lowered to the maximum depth, the unit will have to constantly work at maximum load, which will increase its wear rate and shorten its useful life. For a well with an immersion depth of 60 meters, it is better to take a pump designed for operation at a depth of 70 meters. The presence of automatic protection against “dry running” is an important point when choosing a pump.

For various reasons, water may stop flowing into the device. If at the same time the pump continues to work, it may overheat, break, burn out, etc. If there is appropriate automation, the device will be disconnected from the power supply as soon as it starts to idle, which will prevent malfunctions.

The specifics of submersible pumping equipment

By the type of device, centrifugal and vibration pumps are distinguished. Firstly, a rotating disk with blades is used to supply water, and secondly, a special membrane that transmits water through numerous vibrations. These design features are important because they affect well integrity in different ways.

Vibration pump + well: yes or no?

Can a vibration pump be installed in the well? These models are relatively inexpensive, easy to operate and have a productivity that is suitable for a significant number of wells.

Many experts strongly object to the use of any vibration technology in the well shaft. However, owner reviews indicate that this type of pump is used quite successfully without any damage to the structure. So which pump - vibrating or centrifugal - is better for a well?

The objections of the experts are well-founded. Prolonged vibration exposure almost always negatively affects the state of surrounding objects. A well is no exception.

Vibrations from a pump located next to the filter affect the condition of the casing and surrounding soil, which are gradually destroyed. Vibration can cause a significant acceleration in the processes of siltation and sanding.

But this does not happen right away. Typically, wells successfully resist vibration for some time. Therefore, with the help of such a pump it is possible to swing the well, and clean it, and successfully operate without visible damage.

But destruction by vibration does occur, although not too quickly. Continuous use of the vibration pump can significantly reduce the life of the structure.

If necessary, the use of vibrational models is quite acceptable, but only as a temporary option. But as soon as possible, such a pump should be replaced with a safer centrifugal device.

Centrifugal Pump Selection Guide

To do this, carefully study the technical passport centrifugal device and find out a few important points:

- what is the performance of the pump;

- whether its dimensions are suitable for the well;

- how deep can he raise water;

- what are the features of its installation and operation;

- how and on what conditions warranty service, etc.

Usually consultants give quite professional recommendations when choosing such equipment. It should be remembered that many manufacturers indicate the limiting rather than average characteristics for pumps, so you need to take into account a certain margin of service life.

A few words about popular models

If a decision is made to use a vibration pump, it is likely to be purchased “Kid" or "Brook" These models are distinguished by good performance, resistance to breakdowns and quite affordable price.

They are easy to clean or repair with your own hands. But for continuous use, the vibration technique is not suitable, it must be replaced as soon as possible.

Among the popular brands of submersible centrifugal pumps it is worth noting “Aquarius”And“Water cannon" They are very similar, but according to user reviews, Aquarius significantly wins in quality and durability, although it costs more.

However, the "Water Jet" has its followers. If you are lucky to get a well-assembled model, he will demonstrate quite decent results.

Special borehole pumps will cost a substantial amount, but such costs over time fully justify themselves. As an example of such a technique, it is worth noting the 3STM2 and 4STM2 models manufactured by TAIFU.

Conclusions and useful video on the topic

Clip # 1. Visual information on calculating the flow rate of a well and choosing a suitable pump is contained in the following video:

Clip # 2. Studying the recommendations of well construction specialists before choosing a submersible pump:

Clip # 3. An example of calculations when selecting an Aquarius submersible pump for water intake:

So, in order to choose a suitable pump, it is necessary to accurately study the characteristics of a particular well. You should also take into account the general need of the family for clean water and deal with the features of the functioning of various types of equipment.

Do you want to talk about how you yourself chose a submersible pump for a well? Would you like to share information useful for us and site visitors, have found flaws in the text? Leave comments in the block under the text of the article.

TOP-12 centrifugal pumps for a well: rating of the best + recommendations for choosing equipment

TOP-12 centrifugal pumps for a well: rating of the best + recommendations for choosing equipment  Well pumps: the best models + tips for choosing equipment

Well pumps: the best models + tips for choosing equipment  Hand pump for a well: types of equipment, characteristics, their pros and cons

Hand pump for a well: types of equipment, characteristics, their pros and cons  How to choose a drainage pump: review of options + rating of the best equipment on the market

How to choose a drainage pump: review of options + rating of the best equipment on the market  Rating of pumps for drip irrigation: TOP-12 of the best offers + recommendations to customers

Rating of pumps for drip irrigation: TOP-12 of the best offers + recommendations to customers  Submersible pumps for the well: 15 best models + tips for customers

Submersible pumps for the well: 15 best models + tips for customers  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

From my own experience, I would recommend a suction sediment. For power, of course, see for yourself, and the price depends on it in many ways. If water is required to drink and wash, this is one thing, but very powerful equipment is needed for watering. A well is an ideal option since the time of the wells has already passed. It's time to get into this business with technology, but on the other hand there are also disadvantages: there will be no light, there will be no water, which is not very good.

There will be no light - there will be no Internet - there will be no life)) if it is time to enter the technology, there are solar stations.

When buying a pump, first of all, check for spare parts for this equipment. This is especially true for pumps with interchangeable vanes. Even if you are assured that spare parts are available, do not be too lazy to call the warehouse. You will be surprised, but in 90% of cases they will tell you that such parts have long been gone and are not expected. The pump that has worked out the prescribed time without the ability to replace parts or assemblies will turn into a useless piece of iron. If you buy a pump with a float sensor designed to turn off the pump to control the water level in the output, be sure to use it, otherwise you risk burning the pump ahead of time.

Correct the pump, if not right. As I understand it, it is selected in just two ways - pressure and performance. Productivity for a house of 3-4 people seems to me 3 m3 is more than enough. The head is formed from depth to a static water level + height to the top of the draw-off point and 10% of the horizontal length + 20% for losses. Then we go to almost any website of a store selling borehole pumps, drive the resulting parameters into the selection filter and see pumps suitable for us that are different in price. Correctly?

legionerix, you did not take into account the debit of the well. If you take a pump with a higher productivity, you simply drain the well.

These are the main indicators that are immediately oriented, but they are far from the only ones. We have already written about the debit of the well, but I also want to focus on such details as the chemical composition of the water in the well.

In fact, the pump is taken based on the chemical composition of the water. For example, for water with a high iron content, one type of pumping equipment is suitable, while with a high sand content in water, a completely different one will be needed. This is very important, because if you use the pump in an environment for which it is not intended, then there is a high probability of failure.

They described everything correctly. I prefer a vibration pump - it's inexpensive and safe. No damage to the structure.