Water supply insulation in the ground: rules for thermal insulation of external branches

The outer part of the stationary system for supplying water to a private house is usually placed in the thickness of the soil. So it does not occupy a place on the site, it is protected from mechanical influences. However, it must be protected from low temperatures during the frosty period. What to do to prevent the formation of traffic jams in the pipeline in winter?

For uninterrupted water supply in the winter, it is necessary to carry out insulation of the water supply in the ground. We will tell you how to protect pipes laid in the ground from freezing. The article presented for acquaintance describes in detail the tested in practice options for solving this problem.

The content of the article:

Rules for the construction of underground water

Freezing of the underground water supply occurs due to the achievement of soil temperature of negative values. One way to prevent this from happening is to hold pipes at a depth where sub-zero temperatures are unattainable.

If this requirement has not been met, other measures must be taken to solve the problem of uninterrupted water supply.

The main provisions of regulatory documents

According to paragraph 11.40 of the set of rules SP 31.13330.2012, the depth of the laid pipes, counting to the bottom, should be 0.5 meters more than the estimated depth of penetration of zero temperature into the ground. This is necessary to prevent the formation of ice plugs in the pipeline and pipe rupture in places of crystallization of water, which increases with freezing in volume.

The estimated depth, according to paragraph 11.41 of the same rules, should be established by field observations of the contour of freezing ground, as well as be guided by the experience of operating pipelines in this area.

Such information may be possessed by a hydrometeorological center or water supply organizations. In the absence of field data, it is necessary to determine the depth of thermal engineering calculations.

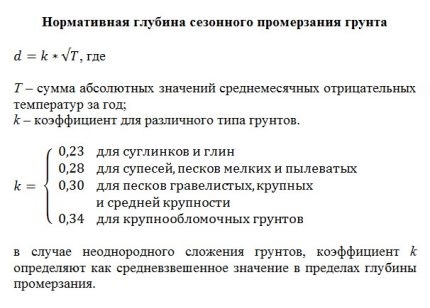

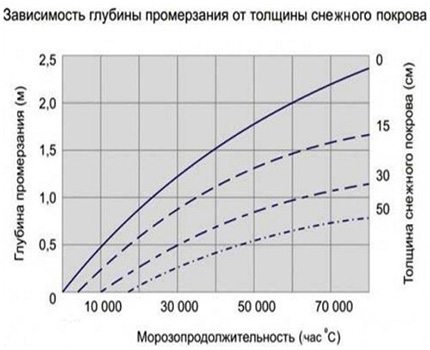

According to paragraph 5.5.3 of the set of rules SP 22.13330.2011, the normative depth of seasonal freezing of the soil in the absence of data from long-term observations must be determined on the basis of thermal engineering calculations presented in the figure below.

The values of the average monthly air temperature in the settlements of the constituent entities of the Russian Federation should be taken from table 5.1 of the code of rules SP 131.13330.2012.

In case of exceeding the obtained value of 2.5 meters, as well as for mountainous areas with a sharp change in the terrain, climatic or engineering-geological conditions, it is necessary to determine the standard depth of soil freezing according to the formulas in Appendix “G” of the code of rules SP 25.13330.2012.

The estimated freezing depth according to paragraph 5.5.4 of the set of rules of the joint venture 22.13330.2011 for areas with non-negative average annual temperature values is determined by multiplying the standard value by a factor of 1.1. For territories with negative values, this value is calculated according to SP 25.13330.2012.

Low temperature protection

It is not always possible to completely or partially lay the water supply system below the zero isotherm. Sometimes this cannot be done for technical reasons, for example, when the outlet of the water pipe from the well is above the boundary of the freezing zone of the earth.

The freezing level mark is determined in accordance with the climatic specifics of the region in which the water supply is being built.

For the middle strip, this value is 1.0 - 1.3 m depending on the type of soil, in areas with severe winters, the depth of pipe placement, according to the rules, will be more than 2.0 - 2.5 meters, which is very expensive as when laying, and in case of need of repair.

If it is impossible or expensive to place the water supply at a great depth, other measures are used for its smooth operation. They can be divided into two categories:

- Warming. Designed to reduce heat loss by an object per unit of time. It is carried out using materials having low thermal conductivity.

- Heating. Designed to increase the temperature of the object. To implement this procedure, an external source of thermal energy is required.

The choice insulation options or heating the external branch of the water supply system depends on the operating conditions, temperature conditions, system geometry, simplicity of the work performed, as well as the efficiency, cost and reliability of the way to solve the problem.

Ways of insulation of external water supply

There are many ways to warm an outdoor water supply system located in the ground. If only cold water is supplied, then, due to a small temperature difference, the thermal conductivity of the materials used is not as important as their durability, strength or price.

Application of simple techniques

In the event that the pipes are located practically on the border of the freezing zone, then to eliminate the likelihood of stopping the water supply, elementary actions can be performed that do not require large investments and skilled work.

For the southern regions, where the depth of the water supply is small, it is enough to dig pipes in the fall, fill them with environmentally friendly insulating material and again dig a trench.

For insulation, you can use leaves, straw, shavings or sawdust. They have low thermal conductivity, but by the next winter they will have time to rot in the ground, so this procedure must be repeated annually.

If, according to calculations, the pipes are located slightly above the level that allows to guarantee the system does not freeze, then instead of deepening the water supply, it is possible to solve the problem by raising the zero isotherm.

There are two ways to do this:

- increase the thickness of the layer of earth, pouring it on top;

- use snow for warming.

In both cases, the center of the land or snow dumping strip is located along the water supply, and its width should be at least twice the depth of the pipes.

The filling of the earth will change the landscape of the site area, and warming with plant and wood waste or snow must be carried out constantly. Therefore, for a long-term and reliable solution to the problem of water supply insulation, special developed materials are used.

The water supply system laid below the seasonal freezing point in the region is insulated only in the area passing through the thickness of the rocks freezing in winter. Thermal insulation is arranged from the specified level to the input of the pipe into the house.

If water supply to the house through an unheated basement arranged below the freezing depth, then insulation is carried out within the basement. Then a wooden box is arranged around the water supply section, and the space between it and the pipe is filled with sawdust or basalt wool.

Types and forms of materials

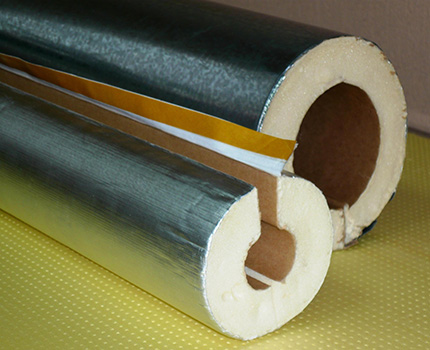

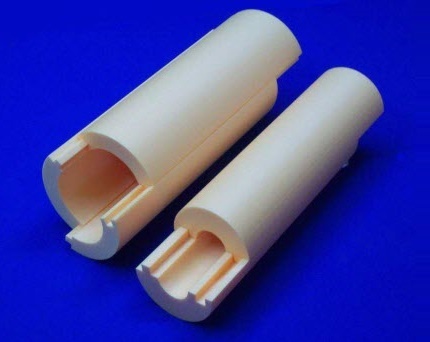

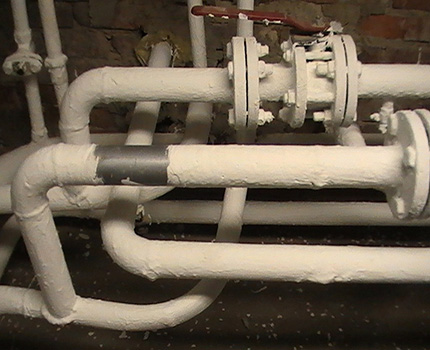

To warm the water supply, materials are used that are presented in the form of shells - forms that repeat the contours of pipes and system nodes. They are made of basalt wool, glass wool, foam, extruded polystyrene foam, polyurethane foam, foam glass.

In the case of using mineral wool and glass wool, a prerequisite for underground installation is the presence of a foil shell. It prevents the insulation from getting wet, due to which the insulation properties of the material are almost destroyed. The shell can be replaced by wrapping pipes with basalt insulation with roofing material.

Due to the ability to freely absorb moisture in the arrangement of underground networks, cotton insulation is not used in the form of mats cut into slabs or rolled into bales without waterproofing external protection.

An exception may be the laying of the pipeline in concrete trays with backfilling of the free space between the tray and the expanded clay pipe or similar material.

The heat-insulating shell is a finished workpiece of a cylindrical shape, whose inner diameter coincides with the outer diameter of the pipes. Products with a length of 60 cm to 2 meters consist of a single tube with a structural seam if the insulation material is elastic or from several (most often two) sections. The main advantage of the sectional material for insulation is the ease of installation of the product.

The halves of the relatively thin shell are joined with the edge of the element superimposed on the next element to avoid the formation of unprotected sections of the pipeline. The offset of meter sections, as a rule, is 15-20 cm.

If it is necessary to use a thickened insulation, it is better to choose a shell with a mounting chamfer along the end edge. The second option for providing tight joints is a certain displacement of the parts of the shell relative to each other.

When attaching parts of the shell, plumbing tape is used. Adjacency protection of pipe bends, turns and other system nodes occurs with the help of special shaped forms.

Thermal insulation paint and polyurethane foam spraying

One of the additional solutions to prevent freezing of the external water supply line located in the ground is liquid or spray thermal insulation. This method allows you to reliably, without seams and cold bridges, to protect areas with complex geometry, for which it is difficult to use standard materials for insulation.

Polyurethane foam has a liquid consistency and is applied to insulated objects by spraying. Having one of the best indicators of thermal conductivity, as well as a number of other positive properties, this material is characterized by a significant minus: for its application, special equipment is needed.

It is not difficult to find companies that are engaged in thermal insulation using polyurethane foam, as it is actively used at various facilities. However, all service providers have restrictions on the minimum spraying area, so it is unlikely to be able to find an affordable option solely for the sake of 10 or 20 meters of the pipeline.

Special heat-insulating paint for pipe insulation similar to polyurethane foam can be applied by spraying. It is sold in cans, so this procedure is easy to perform on your own. There is also an option in liquid form, which allows you to paint the elements of the water supply with an ordinary paint brush.

Thermal insulation paint contains additives in the form of ceramic microspheres, foam glass or perlite. The thermal conductivity of this material is quite low, but due to the thin coating layer, it alone may not be enough to solve the problem of warming a section of a water supply system crossing the thickness of freezing soils.

Due to the high cost, applying a thick layer of thermal insulation paint is expensive. Therefore, its use for warming is justified only in areas with complex geometry or in places of possible occurrence of cold bridges.

However, in the case of the use of steel pipes, the use of paint along the entire length together with other insulation can be advisable for another reason. The presence in the composition of the porous material leads to a high rate of adhesion, eliminating the possibility of the formation of external corrosion, which is important for metal structures located in the ground.

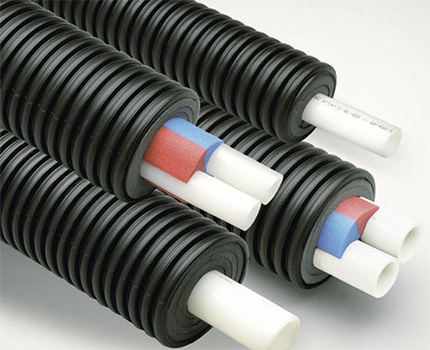

Complete solutions

The problem of freezing a street branch of a water supply system is very relevant. Demand creates supply and, therefore, there are a large number of ready-made integrated solutions on the market in the form of heat-insulated pipes and connecting elements. They are pipelines surrounded by a heater, which is enclosed in a solid or flexible shell.

There are both single-pipe and two-pipe options for a ready-made solution for insulation of the outer pipe lining. For ordinary cold water supply, structures containing plastic pipes are the best option. They are cheaper than a metal counterpart and have a high installation speed.

HDPE insulated pipes are delivered in bays up to 200 meters long. The laying of water supply systems based on them can be performed with a minimum number of joints.

If corrugated material is used as the outer shell, then it is possible to conduct a pipeline without using corner joints. This is possible due to the simplicity of making small radius bends of all parts of the kit.

Insulation protection from negative factors

Protection against freezing of a water pipe located in the ground has its own specifics. The material should not completely or partially lose its thermal insulation properties under the influence of external factors.

Re-insulating or repairing the outer layers requires expensive and time-consuming excavation work, so you must immediately take care to maintain the integrity of the protective structure.

The destructive effects of land and water

The underground water pipe is experiencing soil pressure, so the material used in the insulation can be crushed. In this case, its thermal conductivity can significantly increase. To prevent such a development of events, it is necessary to create a solid outer shell using pipes of larger diameter or special trays.

If hygroscopic materials are used as thermal insulation of pipelines, it is necessary to prevent the possibility of the influence of ground water on them, always located in the ground, regardless of the degree of soil water saturation.

To protect the mineral and glass wool, additional protective equipment is used - plastic pipes of a size larger than water pipes, which simultaneously solves the problem of crushing the insulation.

You can also use the following materials to create a waterproofing sheath:

- rolled aluminum foil;

- reinforced (plumbing) tape;

- roofing material;

- high density plastic film.

Styrofoam, extruded polystyrene foam weakly absorb moisture, but over time, too, become worthless with constant defrosting. Foam glass, polyurethane foam, as well as heat-insulating paint are not completely susceptible to crushing and moisture.

Solving the problem of insects and rodents

Another cause of damage to the insulation of the water supply can be rodents and insects. In an attractive thermal insulation, ants gnaw through numerous moves, and mice use it to build a nest. These actions expose parts of the pipes, which negatively affects the quality of insulation.

Neither insects nor mice can spoil polyurethane foam, foamglass, but they perfectly deal with basalt cotton wool. It and similar materials for external insulation of water pipes must be protected from rodents if they are located at a depth of less than 2 meters. Earth ants do not penetrate below 1 meter, while forest ants build a large anthill, the aerial part of which cannot be overlooked.

To protect against rodents, you can wrap the insulation with a metal mesh. To prevent access not only to mice, but also to ants, it is necessary to wrap the material with aluminum foil reinforced with adhesive tape or use plastic pipes or trays of any shape as the outer shell.

Heated external water supply systems

If we consider any system, then warming is just a way to increase the time to reduce its temperature to a value corresponding to the environment. Therefore, sometimes you have to resort to another option to prevent freezing of the water supply - heating.

Going on water heating due to external energy sources and there are several ways to organize this process.

Water circulation

The simplest source of additional thermal energy is water, the temperature of which is higher than in the insulated section of the water supply. If warmer water constantly replaces chilled water, then the system does not freeze. For this reason, the “ajar tap” method works when a slow but constant movement of fluid through pipes is organized.

For cold water supply of individual housing, it is possible to organize periodic replacement of water in the outer branch with a warmer one. In the case of supply from the main water supply system, it is often necessary to drain in small portions, which ensures fluid replacement.

It is rational for this to use a special container located in the house, which also functions as a sump, from which water can subsequently be taken for its own needs.

If the supply is organized from wells, in which the water temperature is usually from 7 to 10 degrees Celsius, it is necessary to turn on the pump more often. For storage of water, you can also use a conventional storage tank or tank.

Using the second pipe and a three-way valve, it is possible to organize the circulation of liquid with its discharge back to the well. At one time it is enough to pump 1.5 - 2 volumes of a section of a water supply system located in the ground between the head of the well and the entrance to the house.

When water intake from the well There is also the option of draining it by gravity back after the pump stops. This method is inappropriate to use in the case of metal elements of the water supply system. The constant change of fluid and air leads to intense corrosion of the inner surface of the pipes and deterioration of water quality.

In stand-alone well-based water supply systems, water source insulation as well as the thermal insulation of the pipeline itself. We recommend that you read the article on the methods of thermal insulation of water wells.

If there is a possibility of prolonged downtime of water and, as a consequence, its freezing, then despite the warming, it is necessary to apply other methods of heating.

Using an electric cable

Most often, as an additional source of heat for an individual water supply system located in the ground, electric cables. They can be placed both inside the water supply pipe and on its outer surface. The principle of heating is to convert electrical energy into heat.

Cables located inside the system have higher efficiency than external cables due to direct heating of the liquid.

The disadvantages of this embodiment of the cable arrangement include:

- higher price per linear meter due to environmental requirements;

- the complexity, and sometimes the impossibility of passing through curved sections of the water supply system;

- Strong recommendations by specialists to connect through an RCD, despite certificates of compliance with the increased requirements of electrical protection.

Installation of both options is approximately equal in complexity. The cable passing inside the pipe is sold complete with a special terminal sleeve. Its connection is made through a standard tee. The outer cable is fastened with aluminum tape, and an insulating shell must be laid on top so that the energy does not go into the ground.

Complete with a resistive cable that emits a constant amount of heat, it is better to use a thermostat to automatically turn the heating on and off to save energy. When using a self-regulating version of the cable, it is necessary to choose its parameters correctly, then there is no need to use a temperature regulating device.

There are ready-made integrated solutions which, in addition to a water pipe, insulation and a rigid waterproof shell, have an integrated heating cable. Such kits significantly reduce the installation time of the system, however, the purchase of all the elements separately will be much cheaper.

A heating cable can be used to heat both a part of the system and a completely external section of the pipeline, which makes it unnecessary to lay the line below the seasonal freezing mark.

The use of warm air

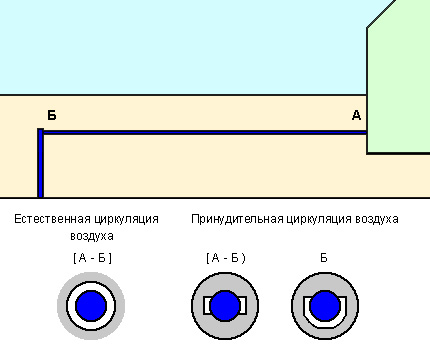

Another effective way to protect the water pipe laid in the ground from freezing is to heat it with warm air from the house. There are two options - with natural and forced air circulation, and both require the installation of an additional closed tray or pipe of a larger diameter.

In the case of natural air circulation, they put a pipe on the water supply and insulate it from the outside. It has access to a warm room and, therefore, there is a slow circulation of the air enveloping the water supply system with the transfer of heat to it from the basement or first floor of the house.

In the second case, two channels (p-shaped profiles) are fastened along the entire length of the water supply system through which air passes. They are wrapped with insulation and covered with an outer pipe to prevent the ground and insulation from being crushed by the ground.

At the end of the heated segment, these profiles are connected, thus obtaining a closed system with indoor input and output. Air supply is forced by means of a hairdryer.

Conclusions and useful video on the topic

Video # 1. Laying a pipeline in the ground from the well to the house with its insulation and the nuance of freezing around the foundation:

Video # 2. Warming of a water supply system based on a plastic pipe and a method of warming a knee with a larger diameter cylinder:

Video # 3. Detailed instructions for attaching an external heating cable, taking into account the correct bypass of fasteners and taps:

High-quality insulation or heating of the water supply system located underground, will ensure its uninterrupted flow in the winter. In case of neglecting the rules of installation and protection from the cold, a complicated defrosting procedure and expensive repair of the water supply system can follow.

Want to talk about your own experience in installing thermal insulation for water pipes in a suburban area? Would you like to share useful information with us and site visitors? Please write comments in the block below, ask questions, post a photo on the topic.

Insulation for water pipes: the choice and methods of laying thermal insulation of water pipes

Insulation for water pipes: the choice and methods of laying thermal insulation of water pipes  Water distribution in a private house: design rules + an overview of the best schemes

Water distribution in a private house: design rules + an overview of the best schemes  Water supply heating: the best heating options + analysis of technical features

Water supply heating: the best heating options + analysis of technical features  How to organize a summer water supply in a country house: laying and arranging a water supply for irrigation

How to organize a summer water supply in a country house: laying and arranging a water supply for irrigation  Plumbing in a private country house do-it-yourself: the rules of arrangement

Plumbing in a private country house do-it-yourself: the rules of arrangement  How to make a water pipe in the country with your own hands: the rules for laying, installing and arranging

How to make a water pipe in the country with your own hands: the rules for laying, installing and arranging  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

This is currently a large selection of building materials. And before it was only glass wool. By the way, even in the regions of Kolyma no one dug a pipeline to a depth of two meters. They simply built either external or slightly recessed heating mains, which consisted of a concrete or wooden box with pipes wrapped in glass wool and roofing material.

Strange, I did not know at all that there were such cases with freezing of pipes. I thought that if the pipes are underground, then they are completely safe from the cold. Although I have never had such a problem, but if this happens, I will already know what and how to do it. I’m not going to dig pipes and insulate them now, we’ll see what happens in the winter, I hope that it will carry through. And so the information is quite interesting and useful, I will take into account.

Our water supply lies at a depth of 2.7 meters. And from the underground comes into the house (cold water only). And the supply hangs in the air underground, the first year did not freeze, and in the remaining years you have to turn it on so that the water runs a little, otherwise the supply and discharge to the septic tank freezes. How to insulate these half a meter from the ground to the house? and how to heat the drain into the septic tank and it is at an angle of 15 degrees. And in the drain pipe there are three meters, and the slope is scanty, because it didn’t work in any other way.

I read about Energoflex heaters, they all praise them. Advertising or a really worthwhile thing? Has anyone come across them?

Hello. Does it make sense to look for real reviews if the official representative issued such a message on the Energoflex website:

“An important indicator for making the right decision is the depth of soil freezing in your area. It should be borne in mind that this value is not a constant, that is, it can vary from winter to winter in a fairly wide range. On average, the depth of soil freezing in the Moscow Region is from 60 cm to 180 cm and depends on both the geographical location and the terrain. First you need to understand that if you lay pipes at a depth above the freezing point of the soil, then there is a risk of freezing the utilities and breaking them down. To prevent this situation, we recommend using an electric heating self-regulating cable in combination with Thermoflex insulation“.

Tell me what insulation can be combined? for example, I would like to lay a heating cable along the PND pipe 25 mm longitudinally and insulate with synthetic foam rubber from K-Flex, and on top of another layer of cheaper stenoflex, but after reading your article, in particular, the moment about rodents and insects decided that it is better for the outer layer use something from PPU.

Tell me, is this design expedient, or you can not bother and just use one layer of PPU on top of the heating cable?

I’m going to dig up no more than a meter, because close Groundwater level. In winter, sprinkle abundantly with snow. The heating cable took a self-regulating one, but I want to take a temperature regulator to it and bring the temperature sensor to the pipe in order to regulate the heating temperature of the heating cable depending on atmospheric temperature fluctuations.In this way I want to achieve maximum energy savings.

I do not see any problems in rodents, if you use a heater with foil sheathing, for example. In this case, rodents will not be scary, you can use various materials:

- basalt fiber;

- Merilon;

- polyisol;

- Styrofoam;

- mineral wool;

- polyurethane foam;

- foam rubber.

It all depends on your budget. The cheapest option is polyisol. I would also recommend considering a material such as laminated “Thermal insulation”. Cheap, practical and rodents will not damage the insulation.